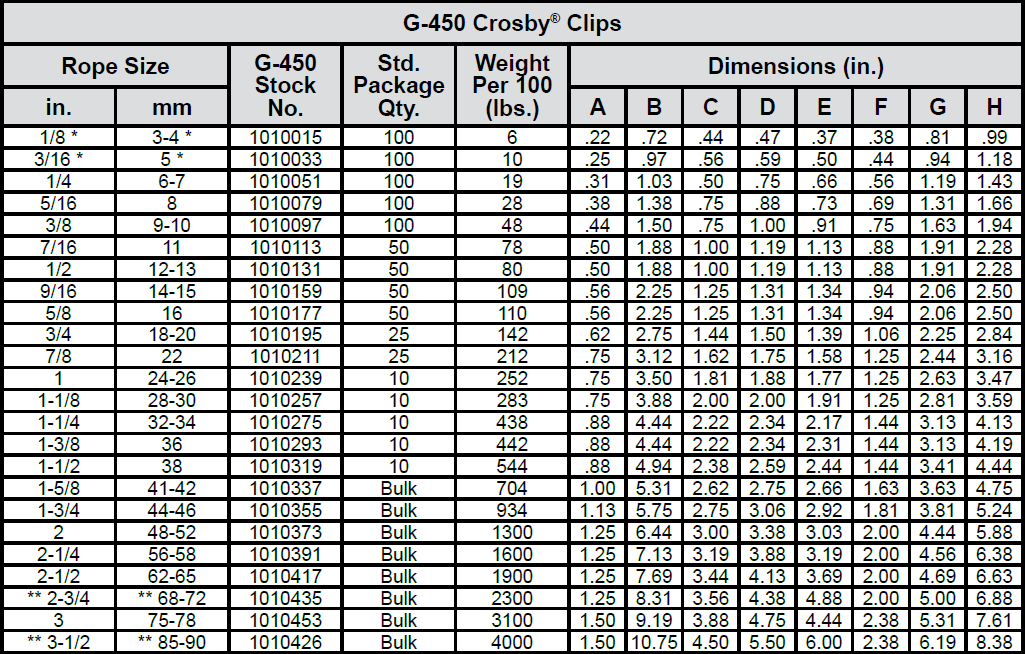

wire rope clamp specification in stock

Murphy offers many sizes of wire rope clips in 4 different fabrications: zinc plated, stainless steel malleable, galvanized drop forged, and stainless steel drop forged.

You can use wire cable clips to secure the loose ends of your wire ropes. They often have nuts, u-shaped bolts, and cast saddles. You can put the wire rope in the bolt and then place the saddle over the bolt’s rope. By using the nuts, you can then secure the rope in its place.

There are a couple of ways to make the process stronger. For example, if you have a cable coated with vinyl, then you can take off the vinyl in the place where you put it in the wire rope clip.

We offer our clips in a range of materials, which gives you more options. You can use the clips for semi-permanent or permanent applications, or just temporary ones. You can use your hand tools to secure them to your stainless steel wire rope. They are also cost-effective.

You can count on our company to offer sturdy and long-lasting clips, so you can secure your loose ends well. We have good knowledge of the requirements of various industries, allowing us to offer you the best products. You can expect our wire rope clips to last for a long time.

With so many different kinds of rope clips and ropes to choose from, we know making a choice can be difficult. Luckily, Murphy Industrial Products, Inc. is here to help. Feel free to contact us today if you want to know more about our stainless steel wire rope clips and related products.

Wire Rope Clamps are frequently used on building sites for fastening and securing rebar steels together as well as with wire ropes to form loops etc. commonly used in the domestic, theatre and industrial industries. Conforming to both DIN 1142 and BS EN 13411-5 Type A make our Wire Rope Grips best in class. Also known as Bulldog Grips, each gripper features two bolts that when tightened increase the pressure applied and tighten down the top oval. A galvanised finish provides added resistance to corrosive environments.

Wire rope clips are widely used for making end terminations. Clips are available in two basic designs; the U-Bolt and fist grip. The efficiency of both types is the same.

When using U-Bolt clips, extreme care must be exercised to make certain that they are attached correctly; Incorrect installation can reduce the working load limit by 40%. Below are general guidelines for installing wire rope clips.

The saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—Remember the well-known saying: “Never saddle a dead horse.” Use at least two or three wire rope clips to secure the ends properly to the length of the rope, and tighten nuts evenly one by one until reaching the recommended torque.

Step 1. Turn back a specified amount of rope from the thimble or loop. The first clip must be placed one bridge width from the turned back rope tailor dead end of the rope, Apply U-Bolt over dead end of wire rope – live end rests in the saddle (Never saddle a dead horse!) Tighten nuts evenly, alternate from one nut to the other until reaching the recommended torque.

Step 3. When three or more clips are required, space additional clips equally between the first two – take up rope slack – tighten nuts on each U-Bolt evenly, alternating from one nut to the other until reaching recommended torque.

In accordance with good rigging and maintenance practices, the wire rope end termination should be inspected periodically for wear, abuse, and general adequacy. Periodically re-tightening of the nuts must be done at 10.000 cycles (heavy usage), 20.000 e.g. every 3 months, 6 months, annually.

Malleable clips are to be used for making eye termination assemblies only with the right regular lay wire rope and only for light-duty uses with small applied loads, such as handrails, fencing, guard rails, etc.

If you have any wire rope clips questions, you can contact us by email at info@hilifting.com. We will be glad to share with you more useful information.

Why don"t we supply clamps with safety locking nuts? We fully understand these concerns. In reality, if the clips are used properly – and that means properly tightened, it is not possible for the nuts to spontaneously loosen. The reason is that there is always strong counter-pressure caused by elasticity of ropes. The fact is that the clips were designed by much smarter people than we are without washers or locking nuts - and this applies to all types of rope grips. Also, we have never received any feedback that nuts were loosening when installed on the rope, on the other hand, losing nuts during transportation in a pack or pocket is quite common. My personal experience (OL5Y) proves that they will not loosen on the rope, if properly tightened.

8613371530291

8613371530291