wire rope clips how to use pricelist

The stainless steel wire rope clip is a stop that is used on the cables, mostly when you need to make aneyelet with one of them. In our range we have different types of wire rope clips depending on the use to which we must do.

On Inoxmare web shop you can discover real-time prices, availability and discount. Try the Fast Order option and you will be able to add with a simple click the files of your orders.

While these clips are not designed to be used in an overhead lifting situation (swage sleeves should be used instead), wire rope clips are heavy-duty wire rope clips that used for sustaining overhead loads. Examples include guy lines, support lines, scaffolding, etc.

U.S. Cargo Control offers two types of clips: standard (or U-Bolt) and fist-grip (or "double saddle"). Our line includes high-quality clips that work for any situation, including:

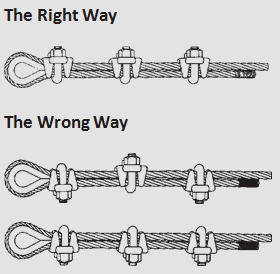

Install the first clip at the dead end side of the rope. The "U" side of the clip must always cover the dead end of the rope, and the "saddle" side of the clip on the live end of the rope. Place the nuts of the clip and tighten them using a torque wrench.

Next, apply the second clip and place it as close to the eye loop as possible. Same application for the clip. Tighten the nuts of the clip with a wrench. (If you"re planning on using more than two clips, do not tighten the nuts on the clip.)

Place more clips on the rope if you need more than two on the wire rope. Be sure to space them evenly between the end clips. Finally, tighten the end clips and apply tension to reach the recommended torque for the wire rope.

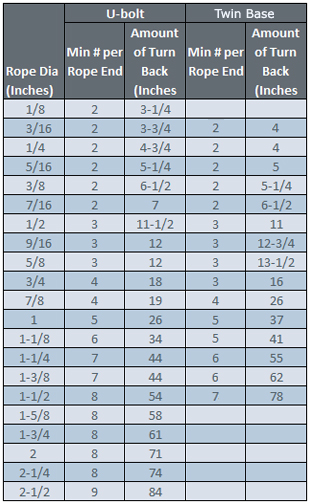

Wire rope clips are widely used for making end terminations. Clips are available in two basic designs; the U-Bolt and fist grip. The efficiency of both types is the same.

When using U-Bolt clips, extreme care must be exercised to make certain that they are attached correctly; Incorrect installation can reduce the working load limit by 40%. Below are general guidelines for installing wire rope clips.

The saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—Remember the well-known saying: “Never saddle a dead horse.” Use at least two or three wire rope clips to secure the ends properly to the length of the rope, and tighten nuts evenly one by one until reaching the recommended torque.

Step 1. Turn back a specified amount of rope from the thimble or loop. The first clip must be placed one bridge width from the turned back rope tailor dead end of the rope, Apply U-Bolt over dead end of wire rope – live end rests in the saddle (Never saddle a dead horse!) Tighten nuts evenly, alternate from one nut to the other until reaching the recommended torque.

Step 2. When more than two clips are required, apply the second clip as near the loop or thimble as possible, tighten the nuts firmly but not yet to the specified torque.

Step 3. When three or more clips are required, space additional clips equally between the first two – take up rope slack – tighten nuts on each U-Bolt evenly, alternating from one nut to the other until reaching recommended torque.

Step 4. Apply the first load to test the assembly. This load should be of equal or greater – weight than loads expected in use. Next, check and retighten nuts to recommended torque.

In accordance with good rigging and maintenance practices, the wire rope end termination should be inspected periodically for wear, abuse, and general adequacy. Periodically re-tightening of the nuts must be done at 10.000 cycles (heavy usage), 20.000 e.g. every 3 months, 6 months, annually.

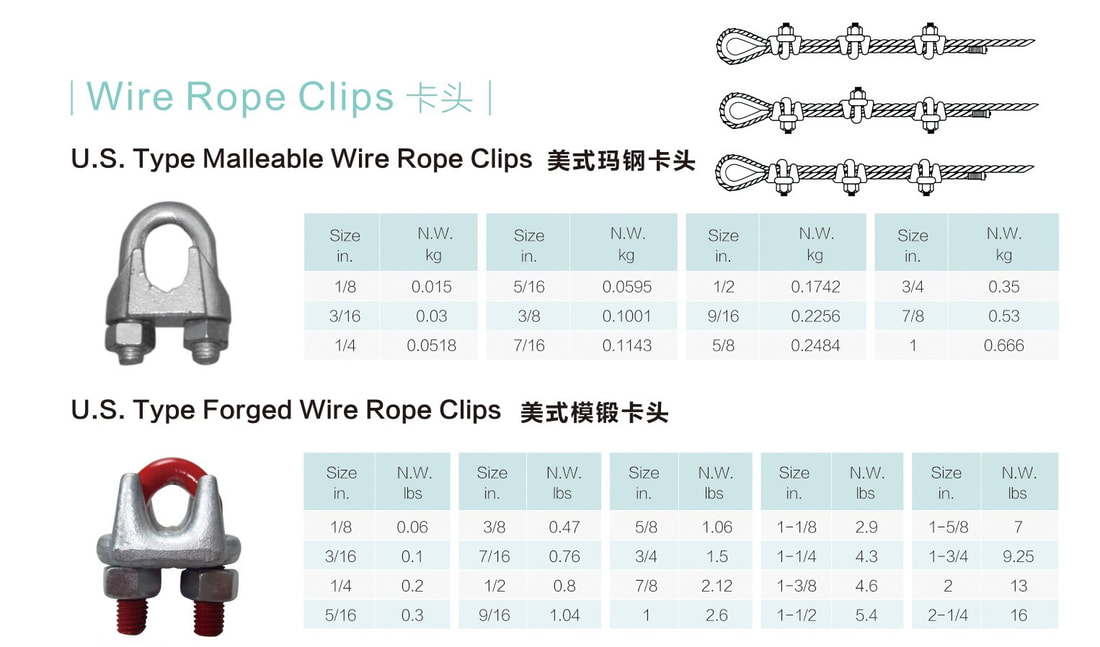

Malleable clips are to be used for making eye termination assemblies only with the right regular lay wire rope and only for light-duty uses with small applied loads, such as handrails, fencing, guard rails, etc.

If you have any wire rope clips questions, you can contact us by email at info@hilifting.com. We will be glad to share with you more useful information.

We have invested millions of dollars in our own test labs and factories, so our tools will go toe-to-toe with the top professional brands. And we can sell them for a fraction of the price because we cut out the middleman and pass the savings on to you. It"s just that simple!

The Stainless Malleable Wire Rope Clips secures the end of the wire rope cable to the wire rope cable. Made from stainless steel. Saddle and nuts should be on the opposite side of the terminated end and make sure that all the clips are on the same side and loops are on the side of the terminated end. No warranty or liability for cable, clips, fasteners, or any other rigging past the purchase date. Only used in non-critical applications. ASME, OSHA, & ASTM recommend only forged clamps for critical applications.

BH-USA recommends 7 x 19 aircraft cables for boat lift applications. 7 x 19 means the rope has seven strands and there are nineteen wires in each strand. Always consider at least a 5:1 safety factor when figuring working loads. A test certificate for all cables sold by BH-USA is available upon request. Aircraft cables are not suitable for use in aircraft controls.

Drop Forged – Heated steel hammered into shape giving linear grain structure and greater strength. In the drop-forged clamps, the saddles are the drop-forged parts. Saddle pieces hot-dipped galvanized. Electro-galvanized (zinc plated) nuts and bolts.

Malleable Iron – Saddles made from a poorer strength grade of steel cast into shape. Cast malleable saddles can also yield under greater loads and cause the wire rope or cable to slip through and potentially fail. Also malleable clamps, saddles, u-bolts, & nuts are stainless steel.

ASME, OSHA, & ASTM recommend only forged clamps for critical applications. For 112ant or critical applications for overhead lifting or suspending always use standard drop-forged type or drop-forged grip type clips.

Made from 304 stainless steel wire rope clamps, corrosion resistance, long life span for maximum corrosion resistance and durability. Consists of a U-shaped bolt, a forged saddle and two nuts. The two layers of wire rope are placed in the U-bolt and clamped into place for a tight connection.

Perfect for rigging rope, wire and cable in unlimited applications mainly in rigging, securing loads, hanging flags, banners and basically anything that involves cables.

Rope clamps are robust but very simple components; they are usually not used with fine architectural cables. We use them with our "easy" construction design (easy kit). For 2mm cables, we use which generate high clamping forces (very secure) with minimal installation effort and cost. They are already included in our pre-assembled kits. The decorative ovoid (egg shaped) clamps are particularly good for use in or near playgrounds-- the smooth, rounded form minimises risk of injury. They require, however, an additional rope tensioning device or turnbuckle because the two rope strands cannot be tightened against each other. The additional use of thimbles with 3 and 4mm rope is functional and aesthetically pleasing, but not essential. Before mounting in eyebolts or similar, the small thimble eyes must be opened; or, you can order our already-open thimble eyes for a slightly higher price.

Upon request, you can also order, as an alternative to cable clamps, inexpensive metal sleeves (similar to the Nicopress ferrule) for 3 and 4mm. This method of fastening requires a special crimping tool/pliers; once fixed, the sleeve cannot be removed.

At FassadenGrün, we prefer to avoid the use of tensioners and turnbuckles, and favour tightening cables by hand. In exceptional cases, as with cable systems like 0040 and 0010 (sometimes also 0050), or generally when very long cables are spanned, a turnbuckle is useful. Tensioners are screwed far apart before assembly, then fastened with the assistance of two cable clamps, then screwed on to tighten the cable segment.

We offer two types of tensioners, both of which can be used with 3 mm and 4 mm ropes: 1. rope tensioners or "turnbuckles" with open sleeves and 2. "shroud tensioners" with closed sleeves. The individual sizes fit different rope diameters. The first group (including SP 05160) is less expensive and made of stainless steel V2A; the second group (including turnbuckle SP 06190) is more attractive, and the tightened state can be permanently fixed with a lock nut; loosening of the rope tension through movements by wind, etc., is then not possible. SP 08280 is suitable for particularly heavy or massive applications. The GS wire tensioner SP 03000 is a special case, used rather for re-tensioning already mounted cables up to 3 mm in diameter.

Load-relieving springs SF 02530 are recommended only in exceptional cases, e.g. when it is already clear that an anchoring (plugging/dowelling) will not provide the required holding values with regard to transverse forces (approx. 250 kg with 3 mm rope). This can be the case with very loose, soft masonry as well as with clay building-materials. Additional cable clamps (grips) will be required for the mounting.

All Departments1x19 Stainless Steel Strand1x7 Guy Strand6x26 Wire RopesApparelBlocks and PulleysCable RailingClearanceCordageDecalsFall ProtectionGrade 70 Transport ChainHard Hat StickersHeadwearLIFTGEAR MerchRotation Resistant Wire RopesSafety MerchSynthetic Tycan® ChainSynthetic Tycan® Chain SlingsWashington Wire RopeIMPORT- WRCManual Chain HoistsGrade 70 Binder Chains7x19 Aircraft CableWire Rope SlingsLever Chain HoistsBeam ClampsG100 Chain SlingsGrade 100 ChainPlate Clamps6x36 Wire RopesDSS - DOUBLE SWIVEL SHACKLESEB - SWIVEL EYE BOLTWeb SlingsBest SellersOffroad RecoveryOffroad Recovery RopesTowing SuppliesLoad and TransportWire RopeChain and AccessoriesClampsDSR - DOUBLE SWIVEL HOIST RINGSRound SlingsAMHHoists and ClampsWire Rope ClipsSynthetic SlingsCODIPROLifting SlingsMade in USASafety ShacklesSUPER STRONG ShacklesShacklesRigging Hardware

8613371530291

8613371530291