wire rope conduit in stock

Edson Pull-Pull Conduit Systems are designed to provide the ability to run steering cables around spaces or structures that otherwise might be difficult or impossible with straight wire runs from sheave to sheave. Pull-Pull System components have been engineered to allow you to use stock parts that will result in a strong, reliable and sensitive steering system. However, you must carefully follow the guidelines at the right to insure a system that is free of friction. Two lengths are needed in most steering system installations. The length should be measured from end-to-end including 2-1⁄2”(64mm) for each end fitting.

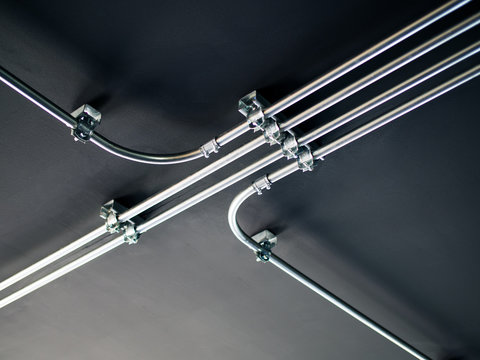

Edson’s #853-312 7/8-inch (22mm) Pull-Pull Conduit is designed for 5/16" Wire Rope. Sold in one foot increments, the conduit can easily be cut with a hacksaw to the specific length you need.

* Industrial cable conduit above available with Teflon, nylon or high density polyethylene liners. Outer cover materials include PVC, nylon and high density polyethylene. Certain conduit cable stock sizes are available immediately others have longer lead times.

For more information or inquiries about our steel conduit cable and conduit assemblies, get in touch with us today. Our team of experts are here to answer any of your questions. We look forward to hearing from you!

Flexible conduit is used for push-pull or pull-pull controls. Our conduit(s) are referred to as Bowden wire conduit(s). This is the most common type we carry and they can be used in almost any application. They consist of a bowden spring for structure and are covered and lined with HDPE (high-density polyethylene). This material offers the best abrasion resistance and protection for the cost. Currently we stock conduits for the following sizes and constructions of wire rope or solid wires: 3/64″, 1/16″, 3/32″ and 1/8″. We also can manufacture other styles of conduits such as flat wire, strand wire and braided. If you don’t see what you need here, please contact us so we can provide further information to service your needs. See our complete conduit fittings category for terminations of the conduit and our wire rope fittings sections for end fittings. The combinations for your assemblies are limitless.

MCT 70 Series Braided Reinforced Conduit is ideal for custom controls, push pull controls and cable assemblies. This conduit is a cost efficient conduit housing that…

At Carl Stahl Sava Industries, manufacturing a comprehensive family of cable, stainless steel wire rope fittings and tools only explain a portion of what makes us so special as a cable assembly manufacturer. In addition to possessing an ISO 9001:2015 certification, Sava is also FDA and ITAR registered, as well as RoHS and REACH certified. Our wire rope manufacturing process leverages almost 50 years of engineering and manufacturing expertise that customers around the world have grown to depend upon every single day. Additionally, Sava’s sales professionals boast over 100 years of combined technical experience helping organizations just like yours meet the most complex and sophisticated application requirements.

Continental Cable employs 65 people specializing in the manufacture of custom mechanical wire rope cable assemblies. Other product lines include stainless steel and galvanized aircraft cable, a complete line of cable related hardware and tools and plastic coated cable.

CED Can Provide You With the Highest Quality Elevator Wire Rope in the Industry. We Stock Large Quantities of Different Varieties to be Available for Whatever Type Job You May Have. All Cables are Cut to Length. Order Today, Ship Tomorrow! Call Today (866) CED-ELEV or request a quote at customerservice@cedelevator.com.

HSI is a leader in the wire rope manufacturing industry. Since 1930 when founder Ted Hanes began splicing wire rope for local contractors in Buffalo, we have been dedicated to constructing the highest quality wire rope available.

Wire rope is a durable piece of machinery consisting of several multi-wired strands wrapped around a central core. It is ideal for indoor and outdoor environments, as an incredibly strong and durable rope with resistance to environmental hazards like water, sunlight, heat, and chemicals.

Wire rope consists of a core around which a number of multi-wired strands are “laid” or helically bent. There are two types of cores for wire rope: fiber and wire cores. Fiber cores are made of synthetic fibers, while wire cores are either an Independent Wire Rope Core or a Strand Core. The core provides support and maintains the position of the outer strands during operation.

Any number of multi-wired strands can be laid around the core. The most common arrangement is six strands around the core, as this construction gives the best balance of positive attributes. In general, ropes constructed with more wires have increased flexibility, while ropes constructed with fewer wires have superior resistance to abrasion.

The size, grade, and construction of wire rope needed should be considered when choosing a rope for your application. To learn more about selecting the correct wire rope, wire rope design factors, and to see a comprehensive overview of wire rope, see our Wire Rope Information page.

If you have questions about which wire rope is best suited for your job, please call our product experts at 1-888-426-3755 and we will be happy to advise you on a solution.

HSI standard wire ropes come in a full range of sizes, grades, and constructions. The most common classifications for standard wire rope are 6x7, 6x19, and 6x37. They may be ordered in bright or galvanized finishes, IPS and EIPS grades, right or left lay, and regular lay or lang lay.

While all wire ropes are constructed of multi-wired strands wrapped around a core, cable laid wire ropes take this construction a step further, wrapping several wire ropes, each with their own core, around a central wire rope. This results in a rope constructed with very small wires in reference to its finished nominal dimension which will offer greatly improved flexibility and kinking resistance.

Compact wire rope consists of wire rope strands that have been compacted to reduce the diameter of the strand and increase its density. The resulting rope has superior strength and abrasion resistance compared to standard wire rope, as well increased lateral compression strength. Typical applications for compact wire rope include crane lines, as compact rope can more easily fit into a sheave; and logging applications.

Extra high strength and corrosion resistant galvanized guy strand cable is an extremely sturdy wire rope used to hold structures in place in the construction and transmission industries, as well as a safety barrier cable and guard rail strand. Typical applications include telephone poles and other positioning applications where a sturdy and non-flexible rope is needed.

Commercial grade galvanized aircraft cable is a general purpose wire rope that is used in many industries for its increased corrosion resistance and strength. The galvanized coating on this wire rope provides lubrication while adding a protective layer against abrasive environments. Contrary to its common name, aircraft control cable, commercial grade GAC cannot be used in aircraft control applications.

Rotation resistant wire ropes are constructed with outer strands twisted in the opposite direction of the inner strands, causing the layers to counteract each other’s twist. This prevents rotation of the load during applications where precise lifting or positioning is required. Rotation resistant ropes are available in a full range of sizes, grades and constructions. Swivels are not recommended for use with rotation resistant wire rope.

8613371530291

8613371530291