wire rope conduit pricelist

Edson Pull-Pull Conduit Systems are designed to provide the ability to run steering cables around spaces or structures that otherwise might be difficult or impossible with straight wire runs from sheave to sheave. Pull-Pull System components have been engineered to allow you to use stock parts that will result in a strong, reliable and sensitive steering system. However, you must carefully follow the guidelines at the right to insure a system that is free of friction. Two lengths are needed in most steering system installations. The length should be measured from end-to-end including 2-1⁄2”(64mm) for each end fitting.

Edson’s #853-312 7/8-inch (22mm) Pull-Pull Conduit is designed for 5/16" Wire Rope. Sold in one foot increments, the conduit can easily be cut with a hacksaw to the specific length you need.

Edson Pull-Pull Conduit Systems are designed to provide the ability to run steering cables around spaces or structures that otherwise might be difficult or impossible with straight wire runs from sheave to sheave. Pull-Pull System components have been engineered to allow you to use stock parts that will result in a strong, reliable and sensitive steering system. However, you must carefully follow the guidelines at the right to insure a system that is free of friction. Two lengths are needed in most steering system installations. The length should be measured from end-to-end including 21⁄2”(64mm) for each end fitting.

Edson’s #853-250 3/4-inch (19mm) Pull-Pull Conduit is designed for3/16" and 1/4" Wire Rope. Sold in one foot increments, the conduit can easily be cut with a hacksaw to the specific length you need.

Easy web site to order from its all user friendly. By far the best prices. It even tells you a little about what the wire is used for. This is great for the DIY like me. Book mark this site for your next DIY job. Thanks to Wire & Cable Your Way I saved 150.00 $ buying my # 6 wire.

I am very happy with my purchase from Wire & Cable Your Way. The ordering process was easy, and I received exactly what I expected, although it came about 3 days before I thought it would! I would certainly recommend this company to anyone.

Talk about fast - my wire arrived the next day. Also the customer service people were extremely helpful and returned my phone call quickly and helped me out. Buying from these guys was easy and their pricing was very competitive.

Rigid PVC conduit is commonly used for embedded on concrete during construction. It can also be laid and embedded on ground when crossing from building to building is required but depth and back fill requirement and standard must be followed as well as support saddles. The listed price ranges from DN 15 (20 inches) up to DN100 (4 inches). PVC conduit price is based on the standard length of 3 meters.

Stock up on every variety of steel wire rods at the Alibaba metalworking store. Our listings feature wholesale steel rods from a network of dependable Chinese manufacturing partners. If you need to source steel rods for construction projects, you"ll find products that are robust and durable. And if you need welding rods, they are easy to find via our search engine. Track down the steel wire rope price you need at affordable prices at Alibaba.com.

What can you do with the steel wire rods available from Alibaba"s wholesale store? One common use for steel rods is in the welding sector. Steel works well as a welding rod material thanks to its high ductility, meaning that welds are relatively strong and long-lasting. Choose a low carbon rod and you"ll be all set for successful welds in industrial settings and workshops alike. However, steel wire also has applications beyond welding. You can use it as wiring in electronic circuits and power distribution systems and it works especially well in high temperature settings as armored cabling. Find the ideal steel wire rope price for every industrial use at Alibaba.com.

Steel wire rods also have applications in everyday life. For example, you can use coils of steel wire to construct fences and barriers both inside and outside homes. It"s a common material in agricultural businesses thanks to its toughness and resistance to oxidation. Use it to create reinforcement cages, enclosures for equipment, or add it to concrete to add extra strength where it really matters. From welding to concrete reinforcement, steel wire rope price will always find a use. And whether you need small batches or huge bulk orders, our metallic materials catalog is the ideal place to look.

US Producer Price Index: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms Strand is at a current level of 374.05, up from 373.69 last month and up from 316.95 one year ago. This is a change of 0.09% from last month and 18.02% from one year ago.

Conduit provides a secure barrier between electrical wiring and exterior conditions that could damage or corrode it over time. A wide variety of conduit is available for both interior and exterior applications, including flexible conduit that allows wires to curve around obstacles. However, rewiring these conduits during repairs and renovations can be challenging. With conduit sometimes running hundreds of feet long, it can be difficult to ensure that wiring runs all the way through without getting caught. Fortunately, there are several methods to pull wire through conduit, and some of the best are covered here.

In ideal situations, you’ll work with a conduit that still has old wire running through it. In these cases, you can simply attach the end of the old wire to the end of the new wire and use it as a pull wire, pulling the new line through the conduit. However, this is not always an option, especially when working with new conduit or severely damaged old wiring.

If you find yourself needing to pull wire through conduit, you can choose from multiple methods. Some of the best methods for pulling wire through electrical conduit are listed below, along with their advantages and limitations.

The string method is the simplest technique for pulling wire through conduit and relies on a strong string called a pull string. The method works as follows:

This method works best on pieces of conduit that are short and straight. Longer pieces of conduit or lengths with more curvature will require an alternative method.

The mouse method is a variation of the string method that uses a tool called a conduit mouse or conduit piston instead of a rod. This tool is a small foam cylinder that is slightly smaller in diameter than the interior of the conduit. It is used in tandem with a shop vacuum. The method for using this tool is detailed below:

Insert the mouse: Place the mouse into the conduit opposite from the side you plan to pull from. Fit the mouse so that it fills the conduit space and so that the string follows behind it.

Apply the vacuum: Take the shop vacuum and apply it to the opposite end of the conduit. Make sure that the vacuum hose is fitted to the conduit so that it creates the best suction.

Pull the wire: Pull the opposite end of the string to pull the wire into the conduit. For longer conduits, have a partner feed the wire into the conduit.

Tie the weight: Tie a heavy fishing weight to the end of the wires using string or fishing wire to give the weight a 2- to 3-inch lead in front of the wiring. Be sure to choose a fishing weight that is thin enough to run through the conduit but heavy enough to pull lubricated wire.

Drop the weight: Drop the fishing weight into the conduit. If you are working with a free-moving length of conduit, lift the end of the conduit higher than the weight so that gravity can pull the weight along. When necessary, adjust the conduit orientation to get the weight around curves in the conduit. Continue this process until all the wire has been pulled through the conduit.

This method is somewhat limited in its applicability. It works best for straight, vertically-run conduit, though it can be applied to almost any conduit that is free to move around. It is not ideal for a conduit that is fixed in a horizontal position or has excessive curves.

The above methods are excellent for straight conduits but are much more difficult for pulling through conduits with more curvature. So how do you pull wire through flexible conduit with multiple turns? The fish tape method is the most common solution. This technique uses fish tape, a tool commonly used by electricians for pulling wire. Fish tape is a long, flat metal wire wound inside a spool with a hook at the end. To use fish tape, you’ll also need wire strippers and linesman pliers. The fish tape method works as follows:

Feed the tape: Feed the end of the tape into the end of the conduit you wish to pull from. Continue pushing the tape through the conduit and unwind the spool as you go. When the end of the fish tape emerges from the end of the conduit, stop feeding the tape.

Strip insulation: Strip insulation from the end of the wire using wire strippers. If you are feeding multiple wires, strip each wire a different amount, leaving one wire longer than the others.

Attach the wires: Hold the wires together so that the insulation is aligned and twist them together with pliers. Bend the longest wire so that it forms a hook and attach it to the hook on the end of the fish tape. Once these are attached, wrap the attachment point with electrical tape to ensure that they don’t detach during the pull process.

The fish tape method can be applied to nearly all types of conduit. Note that fish tape is available in a range of lengths from 25 feet to 100 feet, so be sure to get one appropriate for your application. For shorter lengths or small jobs, nylon tape is an economical option that works just as well.

Pulling wire through conduit with existing wires is difficult because any technique you use may get caught on the existing wires — the conduit mouse and fishing weight method are completely unuseable in these cases for this reason.

Pulling cable through conduit bends can also prove problematic. For most conduit, the more severe the angle, the more difficult it is to get a pull string or fish tape in place. This problem is even more pronounced with PVC conduit, as the angle joints can easily catch fish tape as it works through the conduit.

One method to get around these problems uses two fish tapes run at each end of the conduit. Note that this method does require working with a partner. The method goes as follows:

Feed the tapes: Have you and your partner stand at the two ends of the conduit, each with one of the two modified fish tapes. Begin to feed the tapes at each end. Plan it so that your tapes meet at the problem point in the conduit.

Hook and pull: When the tapes meet, spin the hooked end so that it is more likely to grab one of the loops. Once you think you have caught the other line, tug to test. When the two lines are attached, pull one end of the fish tape to pull the other all the way through the conduit.

Once you’ve caught and pulled one fish tape through the entire conduit, you can continue with the normal fish tape technique for pulling wires through. It’s important to note that conduit with severe turns or existing wires will require thorough lubrication to get the wires all the way through without catching.

Before you pick one of the above techniques for pulling wire through conduit, it is important to analyze your conditions and adequately prepare for the process. Some essential tips include the following:

Look for existing tools: While examining your conduit, check for any existing wires or cables in the conduit, as these can be used as pull strings for the new wiring. Also, check to see if these wires are intact — broken wires can pose obstacles during the wire pulling process.

Check local codes: Sheathed cables are an alternative to insulated wiring and are permitted by the National Electrical Code. However, they aren’t universally allowed to be used in interior conduits and should never be used in outdoor applications. Even if they are allowed, the size of the sheathed cable makes it nearly impossible to run it through anything other than short, straight conduits. If you are thinking about rewiring with non-metallic cable, be sure to check local laws and codes to make sure this is acceptable and ensure that your application will be compatible.

Lubricate the wiring: Pulling wires is difficult enough when working with straight conduit. However, bends and turns increase friction on the wire, making pulling more difficult. If your conduit has bends and curves, lubricate your wiring with a non-conductive lubricant as you feed it into the conduit. This gel or soap substance coats the wiring, making it slick enough to slide through the conduit more easily. Apply the lubricant directly to the wire before pulling it through, using less toward the end of the pull. As with any lubricant, follow the manufacturer’s instructions for optimal functionality.

Work with a partner: While you can theoretically pull wire yourself, it is best to work with at least one other person, no matter what method you choose. This person can help by pulling the wiring while you add lubricant or vice versa. This is especially recommended for longer and more complicated runs of conduit.

Examine your conduit: By far the most important preparation tip is to inspect the length of your conduit from end to end. Measure the length of the conduit and make note of any curves that may pose problems. Be sure that whatever method you decide to use is appropriate for the length and shape of the conduit in question. Also take note of the type of conduit you are running — conduit with corrugated edges will catch wires more easily across the length of the conduit, while smooth PVC conduit may only catch at joints.

One of the important things to consider when preparing to pull cable is the type of conduit you’ll be working with. The thickness of the conduit, as well as the texture, will help determine the best method for pulling wire through the conduit. Thinner conduits may not allow for the use of fishing weights or conduit mice, while larger conduits may support these methods.

AerosUSA is a leading supplier of high-performance conduit systems for industrial applications. As the exclusive U.S. representative of world-renowned manufacturer Flexa GmbH, we carry an extensive and exclusive inventory of high-quality conduits.

Of particular note are our polyamide conduits and galvanized conduits, made to fit the needs of various industries. Our corrugated polyamide conduits provide excellent impact and UV protection and feature snap-on connectors that are easy to use. Our metallic galvanized conduits, on the other hand, provide corrosion protection and shielding needed for the most demanding industrial environments.

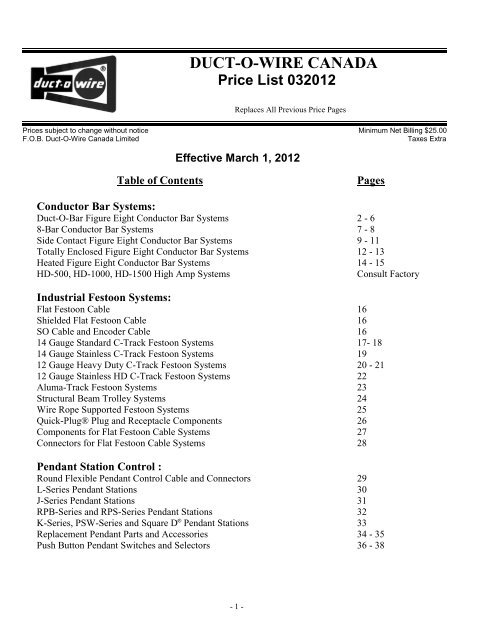

DUCT-O-WIRE CANADAPrice List 032012Replaces All Previous Price PagesPrices subject to change without notice Minimum Net Billing $25.00F.O.B. Duct-O-Wire Canada LimitedTaxes ExtraEffective March 1, 2012Table of ContentsPagesConductor Bar Systems:Duct-O-Bar Figure Eight Conductor Bar Systems 2 - 68-Bar Conductor Bar Systems 7 - 8Side Contact Figure Eight Conductor Bar Systems 9 - 11Totally Enclosed Figure Eight Conductor Bar Systems 12 - 13Heated Figure Eight Conductor Bar Systems 14 - 15HD-500, HD-1000, HD-1500 High Amp SystemsConsult FactoryIndustrial Festoon Systems:Flat Festoon Cable 16Shielded Flat Festoon Cable 16SO Cable and Encoder Cable 1614 Gauge Standard C-Track Festoon Systems 17- 1814 Gauge Stainless C-Track Festoon Systems 1912 Gauge Heavy Duty C-Track Festoon Systems 20 - 2112 Gauge Stainless HD C-Track Festoon Systems 22Aluma-Track Festoon Systems 23Structural Beam Trolley Systems 24Wire Rope Supported Festoon Systems 25Quick-Plug® Plug and Receptacle Components 26Components for Flat Festoon Cable Systems 27Connectors for Flat Festoon Cable Systems 28Pendant Station Control :Round Flexible Pendant Control Cable and Connectors 29L-Series Pendant Stations 30J-Series Pendant Stations 31RPB-Series and RPS-Series Pendant Stations 32K-Series, PSW-Series and Square D ® Pendant Stations 33Replacement Pendant Parts and Accessories 34 - 35Push Button Pendant Switches and Selectors 36 - 38- 1 -

System Components8-A Anchor Clamp Set (2 pcs. Included) $7.008-1GC Rubber End Cap 1.508-908-IS Isolating Section - 8” length with cover 9.008-758-GCT Transfer Cap - For use with 8-758 Bar only 4.808-758-GCTL Transfer Cap - Cut 45° for Left Hand Curves (8-758 Bar only) 6.608-758-GCTR Transfer Cap - Cut 45° for Right Hand Curves (8-758 Bar only) 6.608-908-GCT Transfer Cap - Use with 8-908, 8-1608, 8-2008, 8-3008 Bar only 4.808-908-GCTL Transfer Cap - Cut 45° for Left Hand Curves (see above) 6.008-908-GCTR Transfer Cap - Cut 45° for Right Hand Curves (see above) 6.008-2E Insulating Cover Only - Orange - per foot 2.408-2E-G Insulating Cover Only - Green - per foot 2.408-2ER-EX Extra Splice Cover 1.80Note: See Duct-O-Wire Figure Eight Systems for all other componentspages 3 thru 6.- 8 -

HEATED FIGURE EIGHT CONDUCTOR SYSTEMSUnitCatalogue No. Description List PriceComplete 10’ Conductor Assemblies with Heater Wire and Splice CoverFor Indoor Locations with Heating Temperatures less than 160° F (Orange)HFE-758-2 90 Amp - Figure Eight Rolled Galvanized Steel – per foot $7.25HFE-908-2 110 Amp - Figure Eight Rolled Galvanized Steel – per foot 7.60HFE-1608-2 160 Amp - Figure Eight Rolled Stainless Steel / Copper – per foot Consult FactoryHFE-2008-2 250 Amp - Figure Eight Rolled Copper / Galvanized – per foot Consult FactoryHFE-3008-2 350 Amp - Figure Eight Rolled Electrolytic Copper – per foot Consult FactoryComplete 10’ Conductor Assemblies with Heater Wire and Splice CoverFor Outdoor Locations with Heating Temperatures less than 160° F (Gray)HFE-758-2-SC 90 Amp - Figure Eight Rolled Galvanized Steel – per foot $7.95HFE-908-2-SC 110 Amp - Figure Eight Rolled Galvanized Steel – per foot 8.30HFE-1608-2-SC 160 Amp - Figure Eight Rolled Stainless Steel / Copper – per foot Consult FactoryHFE-2008-2-SC 250 Amp - Figure Eight Rolled Copper / Galvanized – per foot Consult FactoryHFE-3008-2-SC 350 Amp - Figure Eight Rolled Electrolytic Copper – per foot Consult FactoryComplete 10’ Conductor Assemblies with Heater Wire and Splice CoverFor Locations with Heating Temperatures up to 280° F (Yellow)HFE-758-2XHT 90 Amp - Figure Eight Rolled Galvanized Steel – per foot $9.35HFE-908-2XHT 110 Amp - Figure Eight Rolled Galvanized Steel – per foot 9.70HFE-1608-2XHT 160 Amp - Figure Eight Rolled Stainless Steel / Copper - per foot Consult FactoryHFE-2008-2XHT 250 Amp - Figure Eight Rolled Copper / Galvanized – per foot Consult FactoryHFE-3008-2XHT 350 Amp - Figure Eight Rolled Electrolytic Copper – per foot Consult FactoryComplete Expansion Gap Assemblies with Heater Wire and Splice CoverFor Indoor Locations with Heating Temperatures less than 160° F (Orange)HFE-758-2H10 90 Amp - Figure Eight Rolled Galvanized Steel – 10 ft. Section $154.00HFE-908-2H10 110 Amp - Figure Eight Rolled Galvanized Steel – 10 ft. Section 170.00HFE-1608-2H10 160 Amp - Figure Eight Rolled Stainless Steel / Copper – 10 ft. Section Consult FactoryHFE-2008-2H10 250 Amp - Figure Eight Rolled Copper / Galvanized – 10 ft. Section Consult FactoryHFE-3008-2H10 350 Amp - Figure Eight Rolled Electrolytic Copper – 10 ft. Section Consult FactoryComplete Expansion Gap Assemblies with Heater Wire and Splice CoverFor Outdoor Locations with Heating Temperatures less than 160° F (Gray)HFE-758-2H10-SC 90 Amp - Figure Eight Rolled Galvanized Steel – 10 ft. Section $166.00HFE-908-2H10-SC 110 Amp - Figure Eight Rolled Galvanized Steel – 10 ft. Section 177.00HFE-1608-2H10SC 160 Amp - Figure Eight Rolled Stainless Steel / Copper – 10 ft. Section Consult FactoryHFE-2008-2H10SC 250 Amp - Figure Eight Rolled Copper / Galvanized – 10 ft. Section Consult FactoryHFE-3008-2H10SC 350 Amp - Figure Eight Rolled Electrolytic Copper – 10 ft. Section Consult FactoryComplete Expansion Gap Assemblies with Heater Wire and Splice CoverFor Locations with Heating Temperatures up to 280° F (Yellow)HFE-758-2H10XT 90 Amp - Figure Eight Rolled Galvanized Steel – 10 ft. Section $175.00HFE-908-2H10XT 110 Amp - Figure Eight Rolled Galvanized Steel – 10 ft. Section 191.00HFE-1608-2H10XT 160 Amp - Figure Eight Rolled Stainless Steel / Copper – 10 ft. Section Consult FactoryHFE-2008-2H10XT 250 Amp - Figure Eight Rolled Copper / Galvanized – 10 ft. Section Consult FactoryHFE-3008-2H10XT 350 Amp - Figure Eight Rolled Electrolytic Copper – 10 ft. Section Consult Factory- 14 -

Mounting BracketsSee Pages 3 and 4 (Figure Eight Systems)Insulated Hanger Clamp AssembliesSee Page 4 (Figure Eight Systems)Note: All Heated Conductor Systems Require Insulated Hanger Clamp AssembliesPower Feed AssembliesHFE-908-2CP 90 Amp Rated Center Power Feed for FE-758 Systems $10.85HFE-1158-2CP 110 Amp Rated Center Power Feed for FE-908 Systems 12.40HFE-2008-2CP 250 Amp Rated Center Power Feed for FE-1608 and FE-2008 Systems 35.00HFE-3008-2CP 350 Amp Rated Center Power Feed for FE-3008 Systems 50.00Additional System ComponentsB-100-1GC Rubber End Cap for Heated Conductor Systems $2.10HFE-2ER-EX Splice Cover Assembly 3.90HFE TAPE Weather Protection Tape for HFE System Splice Covers (100’) 35.00Additional Heater Wire ComponentsHFE-MJW24 Jumper Wire with Male Terminator - 24 inch $7.20HFE-FJW24 Jumper Wire with Female Terminator - 24 inch 7.20HFE-ADAPTOR 2 Piece Adaptor Set to Connect New Style Wires to Older Systems 10.50Heated Conductor Control CabinetsHFE-30 Thermostatic Control - To 30 Amp - NEMA 12 Indoor Mounted $1,240.00HFE-30-4 Thermostatic Control - To 30 Amp - NEMA 4 Outdoor Mounted 1,550.00HFE-30-4X Thermostatic Control - To 30 Amp - NEMA 4X Stainless Steel 2,295.00Control cabinets are complete with applicable thermostat control, sensing probe,pilot light, transformer with fused secondary, 600 volt fuse block and fuses, DINtype terminals, and 3-pole contactor with 120VAC control.Heated conductor systems must be designed for specific heating capabilitiesbased upon length and number of conductors. The heating elements arecalculated by the factory to produce the desired wattage output.Wiring diagrams and external circuit layouts are provided with each completesystem.All Heated Conductor Systems are F.O.B. Burlington, ON- 15 -

WIRE SUPPORTED FESTOONUnitCatalogue No. Description List PriceSlide Wire Kits for Flat CableFC-WS1 20 Foot Travel Slide Wire for Flat Cable to #10 AWG $90.00FC-WS2 30 Foot Travel Slide Wire for Flat Cable to #10 AWG 118.00FC-WS3 40 Foot Travel Slide Wire for Flat Cable to #10 AWG 145.00Wheel Trolley Kits for Flat CableFC-WS4 20 Foot Travel Wheel Trolley Kit for Flat Cable to #10 AWG $131.00FC-WS5 30 Foot Travel Wheel Trolley Kit for Flat Cable to #10 AWG 178.00FC-WS6 40 Foot Travel Wheel Trolley Kit for Flat Cable to #10 AWG 224.00FC-WS7 50 Foot Travel Wheel Trolley Kit for Flat Cable to #10 AWG 271.00FC-WS8 60 Foot Travel Wheel Trolley Kit for Flat Cable to #10 AWG 317.00Wheel Trolley Kits for Round CableR-WS1 20 Foot Travel Wheel Trolley Kit for Round Cable (.45"-.91" dia.) $173.00R-WS2 30 Foot Travel Wheel Trolley Kit for Round Cable (.45"-.91" dia.) 237.00R-WS3 40 Foot Travel Wheel Trolley Kit for Round Cable (.45"-.91" dia.) 301.00Consult Factory for Stainless Steel Wire Supported SystemsHardware Components for Wire Supported SystemsFC-SRC1 3/16" dia. Steel Cable – per foot. $1.05FC-SRC2 1/4" dia. Nylon Coated Cable – per foot 1.75FC-SRCC1 U-Bolt for 3/16" dia. Cable 2.10FC-SRCC2 U-Bolt for 1/4" dia. Cable 2.10FC-SRCE1 Eyebolt Assembly with Small Thimble 4.20FC-SRCE2 Eyebolt Assembly with Large Thimble 4.20Standard Trolleys For Wire Supported SystemsFC-TR4 Single Wheel Trolley Assembly, 3" dia. Saddle $12.95FC-TR9 Slide Wire Trolley and Saddle Assembly (for use with 3/16" dia. Steel Cable) 7.85Control and Tow Trolleys, End Clamps - Wire Supported SystemsFC-TR5 Two Wheel Lead Trolley Assembly $35.00FC-CS4 End Clamp Assembly with Nylon Saddle 10.50Standard Trolleys For Round Cable and Air HoseR-TR4A Single Wheel Trolley for Round Cable (.45"-.91" dia.) $22.30R-TR4B Single Wheel Trolley for Round Cable (.91"-1.25" dia.) 23.00Control and Tow Trolleys, End Clamps - Round Cable and Air HoseR-TR5A Two Wheel Trolley/Lead Trolley (.45"-.91" dia.) $44.80R-TR5B Two Wheel Trolley/Lead Trolley (.91"-1.25" dia.) 45.50R-CS4A End Clamp Assembly for Round Cable (.45"-.91" dia.) 19.60R-CS4B End Clamp Assembly for Round Cable (.91"-1.25" dia.) 20.30Tow Bar for Round Cable and Air HoseR-TB4A Tow Bar Assembly with Swivel for Round Cable (.45"-.91" dia.) $31.80R-TB4B Tow Bar Assembly with Swivel for Round Cable (.91-1.25" dia.) 32.50- 25 -

ROUND FLEXIBLE PENDANT CONTROL CABLESUL LISTED AND CSA APPROVED - YELLOW PVC JACKET -40ºC TO 105ºCUnit Price perUnit PriceCatalogue No. Description Foot - Full Reel Foot - Cut*RPC-414 4 Conductor - # 14 AWG Nominal O.D. .460" $3.75 $4.15RPC-816 8 Conductor - # 16 AWG Nominal O.D. .640" 4.55 5.00RPC-816-SR 8 Conductor - # 16 AWG /w External Strain Cable 5.40 5.95RPC-1216 12 Conductor - # 16 AWG Nominal O.D. .745" 5.15 5.70RPC-1216-SR 12 Conductor - # 16 AWG /w External Strain Cable 6.00 6.60RPC-1616 16 Conductor - # 16 AWG Nominal O.D. .840" 6.80 7.50RPC-1616-SR 16 Conductor - # 16 AWG w/ External Strain Cable 7.85 8.65RPC-2416 24 Conductor - # 16 AWG Nominal O.D. .890" 9.65 10.65RPC-2416-SR 24 Conductor - # 16 AWG w/ External Strain Cable 10.65 11.75RPC-3616 36 Conductor - # 16 AWG Nominal O.D. 1.050" 13.95 15.35RPC-316-S2 3 Conductor - # 16 AWG w/ Internal Strain Cable .520" Nom. 3.35 3.70● Any cable order totalling 1,000 ft. or more will receive the Full Reel pricing.● Shielded Round Pendant Cable (SRPC) also available. Consult factory.ROUND PENDANT CABLE CONNECTORSUnitCatalogue No. Description List PriceRSR-1209 1/2" Conduit Size for .390” to .560" Diameter Cable - plastic $13.00RPC-CG000 1/2" Conduit Size for .380" to .500" Diameter Cable 30.00RPC-CG00 3/4" Conduit Size for .430" to .563" Diameter Cable 17.00RPC-CG0 3/4" Conduit Size for .560" to .687" Diameter Cable 17.00RPC-CG1 1" Conduit Size for .560" to .687" Diameter Cable 17.00RPC-CG2 1" Conduit Size for .625" to .750" Diameter Cable 17.00RPC-CG3 1" Conduit Size for .750" to .825" Diameter Cable 17.00RPC-CG4 1-1/4" Conduit Size for .625" to .750" Diameter Cable 23.00RPC-CG5 1-1/4" Conduit Size for .750" to .875" Diameter Cable 23.00RPC-CG6 1-1/4" Conduit Size for .875" to 1.000" Diameter Cable 23.00RPC-CG7 1-1/4" Conduit Size for 1.000" to 1.125" Diameter Cable 23.00RPC-CG8 1-1/4" Conduit Size for 1.125" to 1.250" Diameter Cable 23.00STRAIN RELIEF CABLE AND ACCESSORIESUnitCatalogue No. Description List PriceRPC-SRC 1/8" dia. Nylon Coated Steel Cable - 480# Rated - per foot $1.15RPC-SRCC U-Clamp for Strain Relief Cable (4 Required per Cable) 1.20RPC-SRCE Eye Bolt with Hardware 2.40RPC-SRCT Steel Thimble for Cable Bend 2.40RPC-SR HDW KIT Strain Relief Hardware Kit 9.20- 29 -

REPLACEMENT PARTS AND ACCESSORIESUnitCatalogue No. Description List PriceAll Duct-O-Wire Pendant Stations (1)LP-17 Complete Legend Plate Set (specify pendant series) $12.00LP-SPECIAL Custom Legend Plate (Adhesive stick on - specify custom words) 8.00WARNING LABEL Operator Warning Label (English and Spanish) 7.00● Consult Factory for special Selector switch Legend RingsExcept PSW-Enclosures and Square D ® PendantsJ and RPS Series PendantsPBW-3 Black Neoprene Boot $8.00PBW-3R Red Neoprene Boot 10.00J-RPS-TS Duplex Tie Strap and Hardware (for tandem pendants) 124.00RPS-MG Wire Mesh Cord Grip Upgrade (supplied in lieu of standard) 117.00RPS-MG-C Wire Mesh Cord Grip with connector and Bushing 129.00RPB-Series PendantsRP-1F 2 Button Front Cover with Legend Plate Set $57.00RP-2F 4 Button Front Cover with Legend Plate Set 63.00RP-3F 6 Button Front Cover with Legend Plate Set 70.00RP-4F 8 Button Front Cover with Legend Plate Set 99.00L and PPS Series PendantsSP-B Black Neoprene Switch Button Boot $6.00SP-B-G Green Neoprene Switch Button Boot 7.50SP-B-R Red Neoprene Switch Button Boot 7.50PPS-BC Legend Plate Inserts for Switch Button Boot (set) 15.00PPS-PC Clear Plastic Lens for Switch Button Boot 2.00LS-BLANK Hole Blank (Plastic 22mm) 9.00LS-TOOL Tool for Installing Accessory Switch 12.00L-MSCG Multi-Step Cord Grip (For L - Series Only) 12.00L-CG1 Weather-tight Cord Grip in lieu of standard Multi-step Cord Grip (.422"-.827") 18.00L-CG2 Weather-tight Cord Grip in lieu of standard Multi-step Cord Grip (.699"-.984") 18.00L-CG3 Internal Strain Relief and Cable Clamp Set (L - Series Only) 9.00HOOK External Strain relief Hook and Hardware 8.00L-4DM 4 Button Replacement Back Only Deep (L - Series Only) 46.00L-4SM 4 Button Replacement Back Only Slim (L - Series Only) 42.00L-6DM 6 Button Replacement Back Only Deep (L - Series Only) 65.00L-6SM 6 Button Replacement Back Only Slim (L - Series Only) 62.00L-8DM 8 Button Replacement Back Only Deep (L - Series Only) 111.00L-8SM 8 Button Replacement Back Only Slim (L - Series Only) 102.00L-10DM 10 Button Replacement Back Only Deep (L - Series Only) 153.00L-10SM 10 Button Replacement Back Only Slim (L - Series Only) 143.00L-CG1-EX Weather-tight Cord Grip, Bushing for Cable Size .422"-.827" 24.00L-CG2-EX Weather-tight Cord Grip, Bushing for Cable Size .699"-.984" 24.00- 34 -

UnitCatalogue No. Description List PriceK Series PendantsK-CG-B-2 Multi-Step Cord Grip Boot (for cable O.D. .420" to .695") $14.40K-CG-B-3 Full Shroud Boot (for cable O.D. .420" to .695") 14.40KW-2 Black Neoprene Boot 8.00KW-2R Red Neoprene Boot 9.00RPB Series PendantsRPB-MG-1 Wire Mesh Cord Grip Upgrade for (RP-1,2, & 3) $68.00RPB-MG-1C Wire Mesh Cord Grip with Connector and Bushing for (RP-1,2, & 3) 80.00RPB-MG-2 Wire Mesh Cord Grip Upgrade for (RP-4 only) 80.00RP-MG-2C Wire Mesh Cord Grip with Connector and Bushing for (RP-4 only) 90.00Square D ® Pendants (SKYP Series)9001SKN201 Legend Plate - HOIST: UP - DOWN $15.009001SKN202 Legend Plate - TROLLEY: EAST - WEST 15.009001SKN203 Legend Plate - TROLLEY: FWD - REV 15.009001SKN204 Legend Plate - TROLLEY: NORTH - SOUTH 15.009001SKN205 Legend Plate - BRIDGE: FWD - REV 15.009001SKN206 Legend Plate - BRIDGE: EAST - WEST 15.009001SKN207 Legend Plate - BRIDGE: NORTH - SOUTH 15.009001SKN208 Legend Plate - START - STOP 15.009001SKN210 Legend Plate - AUX. HOIST: UP - DOWN 15.009001SKN211 Legend Plate - POWER: ON - OFF 15.009001SK52 Hole Blank for Square-D Pendants 26.00CT-STYLE IN-LINE QUICK PLUG ® DISCONNECTSUnitCatalogue No. Description List PriceCT-8 PNR 8 Conductor with Dust Cover and Strain Relief Hardware $250.00CT-16 PNR 16 Conductor with Dust Cover and Strain Relief Hardware 270.00CT-24 PNR 24 Conductor with Dust Cover and Strain Relief Hardware 285.00CT-WIRING Factory Pre-Wiring per Connection (Hood, Base or Panel base) 78.00PRE-WIRING CHARGES FOR PENDANT STATIONSUnitCatalogue No. Description List Price2 BUTTON WIRING K2, L2, RP-1 and BW Series Consult Factory4 BUTTON WIRING K4, L4, RP-2 and 9001SKYP4 Consult Factory6 BUTTON WIRING J-6, K-6, L-6, PSW-3, RP-3 and 9001SKYP6 Consult Factory8 BUTTON WIRING J-7, J-8, L-8, RPS-3 and 9001SKYP8 Consult Factory10 BTN WIRING J-9, J-10, L-10 and 9001SKYP10 Consult Factory12 BTN WIRING J-11, PT-6L Consult Factory- 35 -

8613371530291

8613371530291