wire rope corp factory

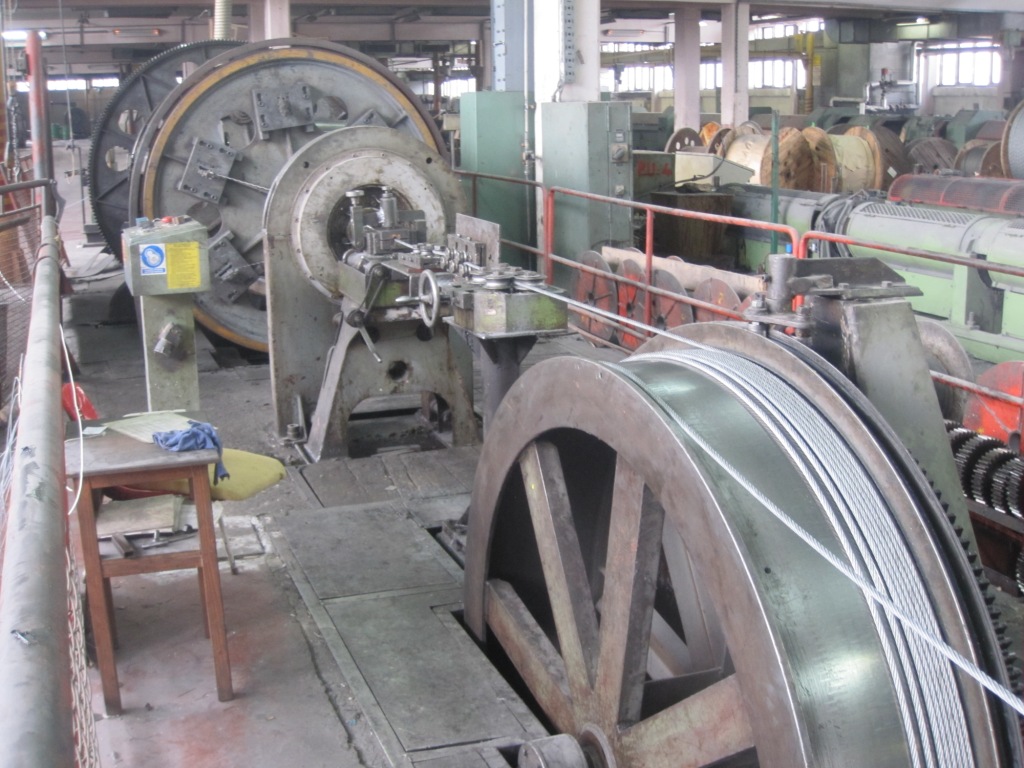

Our factory is located in Valenzuela City and was constructed in the early part of 1963. It immediately began manufacturing wire ropes in November 1963. British technical experts from Bridon International Ltd. of the United Kingdom supervised its initial manufacturing operations.

WRCP’s factory can produce wire ropes at 300 MT per month working on three shifts and can manufacture wire rope with a maximum diameter of 2-1/4 inches.

We strive to create premium products in a class all their own, but we believe our global impact is so much bigger than that. Press play to learn what makes WireCo a world ahead of other companies.

As family-owned wire rope manufacturers, St. Pierre Manufacturing provides a variety of products and services for a wide range of satisfied customers around the world. A leader amongst companies of its kind, St. Pierre Manufacturing offers high-performance fittings at affordable prices. Products and services from St. Pierre Manufacturing are always top of the line and on time.

Wire rope manufacturers produce their products in order to provide a high load capacity, versatile alternative to weaker ropes like manila rope or hemp rope. Wire rope products are used for a wide variety of motion transmission applications, among them: lifting, baling, tie down, hoisting, hauling, towing, mooring, anchoring, rigging, cargo control, guidance and counterbalance. They can also be used as railing, fencing and guardrailing.

Wire rope is a must-have for many heavy duty industrial applications. From mining to forestry to marine and beyond, there’s wire rope for almost every job. Some of the many industries in which wire rope is popular include: construction, agriculture, marine, industrial manufacturing, fitness, sports and recreation (plastic coated cables for outdoor playground equipment and sports equipment), electronics, theater (black powder coated cables for stage rigging), mining, gas and oil, transportation, security, healthcare and consumer goods.

Wire rope as we know it was invented just under 200 years ago, between 1831 and 1834. At that time, the goal was to create a rope strong enough to support work in the mines of the Harz Mountains. Invented by Wilhelm Albert, a German mining engineer, this wire rope consisted on four three-stranded wires. It was much stronger than older rope varieties, such as manila rope, hemp rope and metal chain rope.

While studying at Freiburg School of Mines, a man named L.D.B. Gordon visited the mines in the Harz Mountains, where he met Albert. After he left, Gordon wrote to his friend Robert Stirling Newall, urging him to create a machine for manufacturing wire ropes. Newall, of Dundee, Scotland, did just that, designing a wire rope machine that made wire ropes with four strands, consisting of four wires each. After Gordon returned to Dundee, he and Newall, along with Charles Liddell, formed R.S. Newall and Company. In 1840, Newall received a patent for “certain improvements in wire rope and the machinery for making such rope.”

In 1841, an American manufacturer named John A. Roebling began producing wire rope for suspension bridges. Soon after, another set of Americans, Josiah White and Erskine Hazard, started incorporating wire rope into coal mining and railroad projects, forming Lehigh Coal & Navigation Company (LC&N Co.). In 1848, wire rope from their wire rope factory in Mauch Chunk, Pennsylvania provided the lift cables needed to complete the Ashley Planes Project. This project sought to improve the performance and appearance of the freight railroad that ran through Ashley, Pennsylvania, by adding lift cables. This increased tourism and increased the railroad’s coal capacity. Before, cars took almost four hours to return; after, they took less than 20 minutes.

Wire rope likewise changed the landscape (again) in Germany, in 1874, when an engineering firm called Adolf Bleichert & Co. used wire rope to build Bi-cable aerial tramways. These allowed them to mine the Ruhr Valley. Several years later, they also used wire rope to build tramways for the German Imperial Army and the Wehrmacht. These tramways were wildly successful, opening up roads in Germany and all over Europe and the USA.

Since the 1800s, manufacturers and engineers have found ways to improve wire rope, through stronger materials and material treatments, such as galvanization, and different rope configurations. Today, wire rope makes possible many heavy industrial processes. It has become a necessity of the modern world.

Strands are made by tightly twisting or braiding individual wire together. One strand could have anywhere between two and several dozen wire filaments depending on the necessary strength, flexibility, and weight capacity.

One of the most dynamic elements of wire cables is the inner core. The strands are wrapped around the core, and it can be made of different metals, fibers, or even impregnated fiber materials. For heavy applications, cores are often made of a different strand of wire called an independent wire rope core (IWRC). An IWRC has a considerable amount of flexibility and it is still very strong. In fact, at least 7.5% of the strength increase in a wire rope can be attributed to an IWRC.

While they sometimes use other metals, like aluminum, nickel, copper, titanium, and even bronze for some applications, manufacturers primarily produce wire rope from steel. This is because steel is very strong and stretchable. Among the most common types they use are: galvanized wire, bright wire, stainless steel and cold drawn steel.

Of the wire rope steels, cold drawn carbon steel wire is most popular, although stainless steel wire rope is sometimes employed as well. Stainless steel rope is most popular for its anti-corrosive properties. Bright wire rope, a type of ungalvanized steel wire rope, is also popular. For added strength and durability, galvanized steel wire rope/galvanized steel cables are a very popular choice. Galvanized aircraft cable, for example, is always a must in aerospace.

When choosing or designing a custom wire rope for your application, suppliers consider factors such as: the environment in which the rope will function, required rust resistance, required flexibility, temperature resistance, required breaking strength and wire rope diameter. To accommodate your needs, manufacturers can do special things like: make your rope rotation resistant, color code your rope, or add a corrosion resistant coating. For instance, sometimes they specially treat and coat a cable with plastic or some other compound for added protection. This is particularly important to prevent fraying if the wire rope is often in motion on a pulley.

Manufacturers and distributors identify the differences in wire cable by listing the number of strands and the amount of wires per strand so that anyone that orders understand the strength of the cable. Sometimes they are also categorized by their length or pitch. Common examples of this include: 6 x 19, 6 x 25, 19 x 7, 7 x 19, 7 x 7, 6 x 26 and 6 x 36.

More complex wire rope identification codes connote information like core type, weight limit and more. Any additional hardware like connectors, fasteners, pulleys and fittings are usually listed in the same area to show varying strengths and degrees of fray prevention.

Cable wire rope is a heavy-duty wire rope. To give it its high strength, manufacturers construct it using several individual filaments that are twisted in strands and helically wrapped around the core. A very common example of cable wire rope is steel cable.

Spiral rope is made up an assemblage of wires with round or curved strands. The assemblage features at least one outer layer cord pointed in the opposite direction of the wire. The big advantage of spiral ropes is the fact that they block moisture, water and pollutants from entering the interior of the rope.

Similarly, stranded rope steel wire is made up of an assemblage of spirally wound strands. Unlike spiral rope, though, its wire patterns have crisscrossing layers. These layers create an exceptionally strong rope. Stranded rope may have one of three core material types: wire rope, wire strand or fiber.

Wire rope chain, like all chains, is made up of a series of links. Because it is not solid, wire rope chain is quite flexible. At the same time, it is prone to mechanical failure.

Wire rope slings are made from improved plow wire steel, a strong steel wire that offers superior return loop slings and better security. The plow wire steel also shields rope at its connection points, which extends its working life. Wire rope slings, in general, provide their applications with increased safety, capacity and performance. Wire rope sling is a rope category that encompasses a wide range of sub-products, such as permaloc rope sling, permaloc bridle slings and endless slings. These and other wire rope slings may be accompanied by a wide variety of sling terminations, such as thimbles, chokers and hooks.

Wire rope offers its user many advantages. First, design of even distribution of weight among strands makes it ideal for lifting extremely heavy loads. Second, wire rope is extremely durable and, when matched properly to the application, can withstand great stress and elements like corrosion and abrasion. In addition, it is very versatile. Its many iterations and the ways in which the rope can treated means that users can get rope custom fit for virtually any application.

Depending on the type of wire rope with which you are working and your application, you may want to invest in different accessories. Among these accessories are: wire rope clips, steel carabiners, fittings, fasteners and connections.

To ensure that your wire rope quality remains high, you must regularly inspect them for wear and degradation. The right wire rope should be selected for a particular use. Watch out for performance-impacting damage like: rust, fraying and kinks. To make sure that they stay in tip-top shape, you should also clean and lubricate them as needed. Check for this need as a part of your regular inspection.

Rope care is about more than inspection. It’s also about making an effort to use and store them properly every time you use them. For example, never exceed your rope’s rated load and breaking strength. Doing so will not only cause the weakening of your cable, but it may even cause immediate breakage. In addition, always store your wire rope cable in a dry and warm area, away from those elements that could cause premature rusting or other damage. Finally, always carefully wind your wire rope when you’re done with it, so as to avoid kinks. If you follow all these tips and treat your wire rope assemblies well, they will reward you with a long and productive service life.

Always make sure that you purchase wire rope that matches your industry and regional standards. Some of the most widely referenced standards organizations for wire rope include: ISO, ASTM International and OSHA. Talk over your specifications and application with your wire rope supplier to figure out what’s best for you.

If you’re in the market for a wire rope or a wire rope assembly, the best way to know you’re getting something that will both perform well and be safe if by working with a vetted professional. Find one among the list we’ve provided on this page. Check out their profiles to get an idea of the services and products they offer. Pick out three or four to whom you’d like to speak, and reach out. Talk to them about your specifications, standard requirements and budget. Ask about lead times and delivery options. Once you’ve spoken with all of them, compare and contrast their answers. You’ll know you’ve found the one when you talk to a wire rope company that is willing to go above and beyond for your satisfaction.

Wirerope Works, Inc. manufactures Bethlehem Wire Rope®, the trade name under which we produce, sell and service our wire rope and strand products. The name "Bethlehem Wire Rope" represents the most complete facility and experienced personnel in North America. Our 46-acre manufacturing complex in Williamsport, Pennsylvania, with over 620,000 square feet under roof, is the single largest wire rope manufacturing facility in North America. Wirerope Works, Inc. manufactures its own wire, wire rope, structural strand, and all fabricated products such as pendants and other assemblies on the same premises.

Bethlehem brand wire rope and strand products have long been recognized worldwide for superior quality. Used for both lifting and stabilizing, Bethlehem Wire Rope products are used in a wide variety of applications ranging from crane and elevator hoist ropes to bridge suspension and anchoring offshore platforms. Wirerope Works, Inc. serves many industries including construction, logging, marine, mining, oil and gas, and steel.

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. Wire ropes are attached to a crane or hoist and are fitted with swivels, shackles or hooks. These are suitable for lifting or lowering elevators and are also used for supporting suspension bridges or towers.

In this article, we"ll cover details on the top U.S. providers of wire ropes, along with our featured list of top wire rope suppliers on Thomasnet.com.

Below is a list of featured suppliers of wire rope from our platform. Included with these companies is their location, year established and the number of employees.

Below we have assembled information on the top suppliers of wire rope in the U.S. based on currently available public sales data. The table also includes the company name, location and the number of employees.

With the help of the provided details on the wire rope suppliers in the United States in the above tables and descriptions, we hope you can use this data to further aid your sourcing decisions.

Union wire ropes reflect the people who make it. People of character, full of grit and determination. Tough-minded individuals who never cut corners or take shortcuts. We’ve matched science of design with the art of skillful manufacturing craftsmanship to build the best wire rope in the world.

No matter where you are in the world, Union delivers hard-working products, exceptional service and unmatched support. At Union, we’re with you in the field, on the rig and in the mine, getting our hands dirty to supply tough ropes that help you get the job done - better. Being part of the global leader, WireCo WorldGroup, our expertise is unmatched. Whether it"s manufacturing, design, troubleshooting or logistics, Union wire rope support is unsurpassed.

Reliability, experience and exceptional customer service for more than 50 years has made Sandin Manufacturing the leading supplier to the wire rope and cable industry in USA and Canada. With one of the most diverse inventories of bare galvanized and stainless steel wire rope, as well as the ability to extrude numerous thermo-plastic coatings, our capabilities are second to none.

Sandin Manufacturing specializes in custom-designed mechanical cable assemblies. Utilizing our extensive inventory of wire rope fittings in addition to our CNC machining capabilities, we have the ability to fabricate your custom cable solution quickly.

Consider Sandin Manufacturing for Galvanized and Stainless Steel cable, Mechanical Cable Assemblies, Can Conveyor Rope, Coiled Cable Assemblies, Cable Railings, Exercise Cable, and Marine Rigging.

Some set out to dominate their industry with their size, but not Alps Wire Rope Corp. “We’re not trying to be the biggest company,” President Brad Benner says. “We’re trying to be the best company that we can be. That’s our goal.”

Based in St. Charles, Ill., Alps Wire Rope manufactures wire ropes and wire rope fabrications for clients in the United States, Canada, Mexico and the Caribbean. The company started operations in 1968 as part of Tokyo Rope Manufacturing Co. Ltd.

“We’ve been just selling wire rope ever since, throughout the United States,” Benner says, noting that Alps Wire Rope sells its products to the crane, oil and gas, marine and general industry markets.

Although wire rope has many applications, its use often goes unnoticed in applications such as railing systems, Benner says. “That’s the beauty of wire rope,” he describes. “It’s one of those products that everyone sees all the time, but no one knows it’s there.”

Benner says he appreciates Alps Wire Rope’s commitment to quality and delivering products immediately. But, he asserts, this would not be possible without Alps Wire Rope’s suppliers.

Over the years, Alps Wire Rope has built strong relationships with them “so we get some favorable responses,” he says, noting that its largest supplier is Kiswire Ltd., headquartered in Seoul, Korea. “We supply their elevator rope throughout North America.”

Some industries are enjoying an economic recovery, and Alps Wire Rope is still finding the market to be difficult, Benner admits. “Competition is tough,” he says. “Everyone’s fighting over a smaller piece of the pie.”

But even in the face of the competition, Alps Wire Rope has still thrived. In the past five years, “We’ve been able to achieve 10 percent growth for every year,” he says.

Alps Wire Rope manages this with its product quality and by forming strong bonds with clients, Benner says. “We try to have good, solid relationships with our customers so we can understand and maintain a cognizance of what’s happening in the industry,” he says. “Then, we try and make sure we’re providing those products at a high-quality level.”

Alps Wire Rope has seen a drive among its customers in the past decade to manufacture to international standards, which includes the use of metric measurements, Benner says. Although the company is based in the United States, it was in an ideal position to serve this need.

“We’ve been providing metric ropes to the industry for over 20 years, which gave us a great advantage when all this started happening,” he explains. “We’re familiar with all the international standards.”

This allows its clients to enjoy more convenience, instead of ordering parts from Europe or Japan, Benner says. “[It] is a great savings for them,” he says. “They’re not paying urgent freight charges.”

Alps Wire Rope realigned its facilities to “be more relevant in the marketplace,” Benner says. This spring, the company moved its Jacksonville, Fla., location to Houston, so it could better serve the oil and gas markets.

It moved its Columbus, Ohio, site to Harrisburg, Pa., bringing it closer to New York’s metro area, “the largest elevator rope market in the world,” he says. “Since it’s a big part of our business, we needed to be closer.”

Alps Wire Rope is reorganizing its management structure so it can better support its new facilities, he says. “We’re going to be … more regionally oriented so that each facility can be able to support their markets better,” he says. This will enable the facilities to react quickly to market changes and maintain a competitive advantage. “That’s our goal for the next five to 10 years,” he states.

BC Wire Rope & Rigging is a full service provider of wire rope, slings, chain, hoists, and rigging equipment. BC Wire Rope has served the heavy lifting needs of customers throughout Los Angeles, San Diego, Las Vegas, Tucson and the Western United States since 1974. Specializing in lifting products ranging from fall protection to synthetic slings, BC Wire Rope & Rigging carries products from the industry’s most reputable vendors including Crosby, Slingmax, Campbell, and Bridon American. With ample testing and manufacturing capabilities, BC Wire Rope is also the manufacturer of KWIK synthetic slings.

BC Wire Rope was onsite as the last steel beam was raised by Schuff Steel at the new, future home of the Los Angeles Rams and LA Chargers at SofFi Stadium in Inglewood, California. The raising of the last beam is marked by the raising of a ceremonial Christmas Tree, […]

Established nearly 40 years ago in Southern California, BC Wire Rope now manufacturers and distributes wire rope from 5 locations to strategically serve customers across the West Coast. Headquartered in a 35,000 square foot warehouse and manufacturing facility in Anaheim, BC Wire Rope is the premier provider of rigging throughout the greater Orange County and Los Angeles area and also has branches in Tucson, Las Vegas, San Diego, and Elko. These locations allows BC to stock a full inventory of specialty lifting products and enables BC to efficiently meet a wide range of manufacturing needs.

Full in-house testing and wire rope manufacturing capabilities help ensure that BC Wire Rope can meet or exceed its customers’ needs. BC Wire Rope can press wire rope slings and swaged boom pendants, splice slings and soft rope, and can fabricate special end fittings. BC also manufacturers its own line of synthetic slings through its KWIK Products division. KWIK Products include nylon eye & eye endless flat slings, high performance fiber slings, polyester round slings, and choker and basket hardware slings. BC Wire Rope also provides customers with proof testing through use of its 4 test beds that can test slings, blocks, and hardware with up to 1 million pounds of force.

BC Wire Rope & Rigging’s unrelenting focus on customer service and industry leading products is evidenced by its ‘Quality – No Compromise’ motto. BC Wire Rope has been a proud member of the wire rope industry’s trade association—Associated Wire Rope Fabricators (AWRF)—for over 35 years. The commitment to longstanding industry relationships is also demonstrated by the fact the more than half of BC Wire Rope’s employees have remained with the company for over 18 years.

With years of industry knowledge and a full product inventory, chances are that BC Wire can meet your lifting needs. Contact the specialists at BC Wire Rope today to find out more about what BC Wire Rope can do for you.

It is now an ugly building, a dilapidated reminder of Luzerne County"s past manufacturing diversity. But this structure"s occupant had a world-wide wallop.Those who have an interest in recording regional history would be wise to take photos now, because the Hazard Wire Rope building in Wilkes-Barre is destined for demolition. The old coal breakers, railroad stations, hotels and industrial sites are disappearing; the Hazard building can be added to the list.The building at South Pennsylvania Boulevard and Ross Street once was part of a larger industrial complex. Much of the property is vacant, off Hazle Street to the south and running north to the South Street Bridge. Wire rope was the mainstay of the company for decades. Later, insulated wire in many gauges and lengths was manufactured there.Hazard"s products reached across the nation. Hazard and Hazard-Okonite products include the Golden Gate Bridge, oil wells in Texas, fire alarm systems in cities nationwide, the famous Ashley Planes, coal mines throughout Northeast Pennsylvania and the Wilkes-Barre/Scranton International Airport.The company"s founders forged cannonballs used in the War of 1812 and later, the output of the massive brick buildings in Wilkes-Barre included anti-submarine nets for U.S. harbors, placed during World War I and World War II.Peak employment was 794 people in 1951. Closing of the Hazard Insulated Wire Division of the Okonite Company came shortly thereafter, in December 1956.Most recently known as the Murray Complex, the roughly 14-acre site is destined to become the new headquarters of the Luzerne County Transportation Authority. LCTA acquired the former Hazard site through eminent domain, paying $1.55 million to the former owner, Siniawa 16 LP.The new facility would merge LCTA bus and shared-ride operations in an expanded terminal, garage and administrative complex. A compressed natural gas fueling station also is planned. LCTA buses use that fuel. LCTA has about 40 buses and some 50 shared-ride vehicles.Late last year, Wilkes-Barre City began legal action to abandon sections of South Pennsylvania Boulevard and Ross Street.The site was eyed once by Wilkes-Barre Area School District as a location for the new merged high school now being built in Plains Township.LCTA and the Pennsylvania Department of Transportation looked at several sites before choosing the Murray complex. Two key factors were the proximity to the Intermodal Transportation Center on Washington Street and the nearby railroad tracks that could provide future transportation options, perhaps tied to joint Luzerne County and Lackawanna County public transit operations.In its heyday, the Hazard operations benefited from the proximity of the Lehigh Valley Railroad, Pennsylvania Railroad and Central of New Jersey Railroad that ran through Wilkes-Barre. Connections also were available to the Erie Lackawanna and Delaware & Hudson freight operations.Erskine Hazard and Josiah White began the Hazard Wire legacy in 1812 when they formed a partnership to manufacture wire and nails. They found a buyer for cannonballs in the U.S. military as the War of 1812 began with Great Britain.Hazard and White were engaged in the early years of the anthracite industry. They burned coal in their mill in 1812 (four years after Judge Jesse Fell burned coal on his grate in Wilkes-Barre) and constructed the Lehigh Canal to haul coal, rapidly becoming the fuel of choice of American industry. The 46-mile towpath was considered an engineering marvel. The partners then organized the Lehigh Coal & Navigation Co. in 1820 and that entity built another marvel, the Ashley Planes that opened in 1843.Railroads were used mainly to get coal to the canals. The Ashley Planes were needed to get coal over the mountain via rail to White Haven and to the Lehigh River. Civil engineers used three inclined planes, one at 5,000 feet, the middle 3,000 feet, and the third 3,700 feet. Wire ropes were attached to the railroad cars which were drawn up each plane.Hazard and White manufactured the first cables, 2.5 inches in diameter and 3,670 to 5,780 feet long. Earlier, the men made cables for the canal boat portages.Erskine Hazard had observed French bobbin machines and he perfected the manufacture of wire rope. All of the wire rope used by the company for many years was manufactured in house.In 1846, Hazard Wire Rope Works was created in Mauch Chunk, to serve Lehigh Coal & Navigation. LCN. Because the company wanted to sell wire rope also, the works were leased in 1852 by Fisher Hazard, son of Erskine. In 1867 the Hazard Manufacturing Company was formed as a stock company and moved to Wilkes-Barre. One year later, Hazard Manufacturing was chartered.Wire rope was the company"s staple until 1898 when the insulated wire department was started to meet the demand for electrical wires and cables.The insulated wire division was separated from the wire rope division in 1927. The former became a unit of the Okonite Co. and for many years the names Hazard Wire or Hazard-Okonite were used to refer to the Wilkes-Barre plant. The wire rope division became an arm of American Chain & Cable Co. which had a presence in the Wyoming Valley through 1986.The history of the Hazard company was detailed in April 1952 by Thomas R. Weichel, a Hazard mining and electrical engineer, in a speech to the Wilkes-Barre Kiwanis Club. He cited the "outstanding contribution of the company"" in the power distribution business.Four years later, Hazard Wire departed the city, transferring some operations to a plant at North Brunswick, N.J.Hazard electrical wires and cables were used in construction of the bi-county airport, Veterans Administration Medical Center, many local municipal fire alarm systems, new schools, sports venues, Pennsylvania Turnpike interchanges, outdoor theaters, hospitals and mines. National uses of Hazard products included the Golden Gate Bridge in California, further military applications and in the vast Texas oil fields.The local plant had bowling teams, a softball team, credit union, social club and in-house newsletter.During World War II, Hazard Wire was presented two "E"" flags by the U.S. Navy Board for Production Awards for its "splendid production" of war materiel.The Hazard time line1812 — White & Hazard partnership formed.1812 — In a first, anthracite is burned in a wire mill.1812 — Company forges cannonballs for U.S. use in War of 1812.1816 — first U.S. suspension bridge, 410 feet long, built at Schuylkill Falls.1818 — Lehigh Canal constructed.1820 — White and Hazard organize Lehigh Coal & Navigation Co.1843 — Ashley Planes completed by Lehigh Coal & Navigation.1846 — Hazard Wire Rope Works created in Mauch Chunk, to make rope for LCN.1852 — Fisher Hazard leases wire rope works, sells wire rope.1849-1948 — Hazard wire rope used to haul coal cars on Ashley Planes.1867 — Hazard Manufacturing Co. stock company formed, moved to Wilkes-Barre.1868 — Hazard Manufacturing is chartered.1898 — Insulated wire department started.1916 — Anti-submarine nets build for U.S. harbors, World War I.1927 — Insulated wire department becomes part of Okonite Co.1928 — Wire cable division spun off to American Chain & Cable Co.1942-44 — Anti-submarine nets built for U.S. harbors, World War II.1956 — December) Wilkes-Barre plant of Okonite closes.

WireCo World Group, now based in Prairie Village, announced that it will sell its steel wire rope manufacturing plant in St. Joseph to Hillyard Industries, which will repurpose the building.

The 25-acre WireCo property is directly to the north of Hillyard"s current facilities. Hillyard plans to build a new manufacturing and national distribution center there.

Hillyard explored undeveloped greenfield opportunities that were less expensive and easier to build but agreed to the redevelopment of the WireCo property. That"s why Hillyard plans to request public incentives to make the downtown redevelopment project more financially feasible.

"When conversations with WireCo began, it was immediately apparent that we shared the same vision and goal of making decisions that benefit downtown St. Joseph," Hillyard President Jim Carolus said in a release. "We want to provide opportunities for growth and reinvestment among our employees and in the downtown area where Hillyard has thrived for several generations. We are excited about this project and the vitality it will add to our local community."

"It is difficult to close any manufacturing plant because of the impact to good people, their families and the community," Ayers said in a release. "The harsh reality is the global oil, gas, and crane rope markets are facing economic challenges, and every company in these industries is being affected. This sale and consolidation of our production facilities enable us to continue to service our customers at the highest quality level despite an increasingly challenging market for WireCo and our customers."

WireCo will continue to operate its fabricated products facility in St. Joseph at its existing site. Those operations will not be affected by the sale of the wire rope manufacturing plant.

8613371530291

8613371530291