wire rope crane hoist free sample

Maintain a record for each rope that includes the date of inspection, type of inspection, the name of the person who performed the inspection, and inspection results.

Use the "rag-and-visual" method to check for external damage. Grab the rope lightly and with a rag or cotton cloth, move the rag slowly along the wire. Broken wires will often "porcupine" (stick out) and these broken wires will snag on the rag. If the cloth catches, stop and visually assess the rope. It is also important to visually inspect the wire (without a rag). Some wire breaks will not porcupine.

Measure the rope diameter. Compare the rope diameter measurements with the original diameter. If the measurements are different, this change indicates external and/or internal rope damage.

Visually check for abrasions, corrosion, pitting, and lubrication inside the rope. Insert a marlin spike beneath two strands and rotate to lift strands and open rope.

Assess the condition of the rope at the section showing the most wear. Discard a wire rope if you find any of the following conditions:In running ropes (wound on drums or passed over sheaves), 6 or more broken wires in one rope lay length; 3 or more broken wires in one strand in one rope lay. (One rope lay is the distance necessary to complete one turn of the strand around the diameter of the rope.)

Corrosion from lack of lubrication and exposure to heat or moisture (e.g., wire rope shows signs of pitting). A fibre core rope will dry out and break at temperatures above 120°C (250°F).

Kinks from the improper installation of new rope, the sudden release of a load or knots made to shorten a rope. A kink cannot be removed without creating a weak section. Discarding kinked rope is best.

Are you looking for the best hoist solution for your factory or plant? Not sure whether a wire rope hoist or chain hoist is the right choice? We will explain all of the differences and applications to help you make the best decision.

Each hoisting system is intended for different purposes and consequently will have benefits and drawbacks in different scenarios. This article is going to take a deep dive into their applications and how you can make the best investment decisions for your workspace.

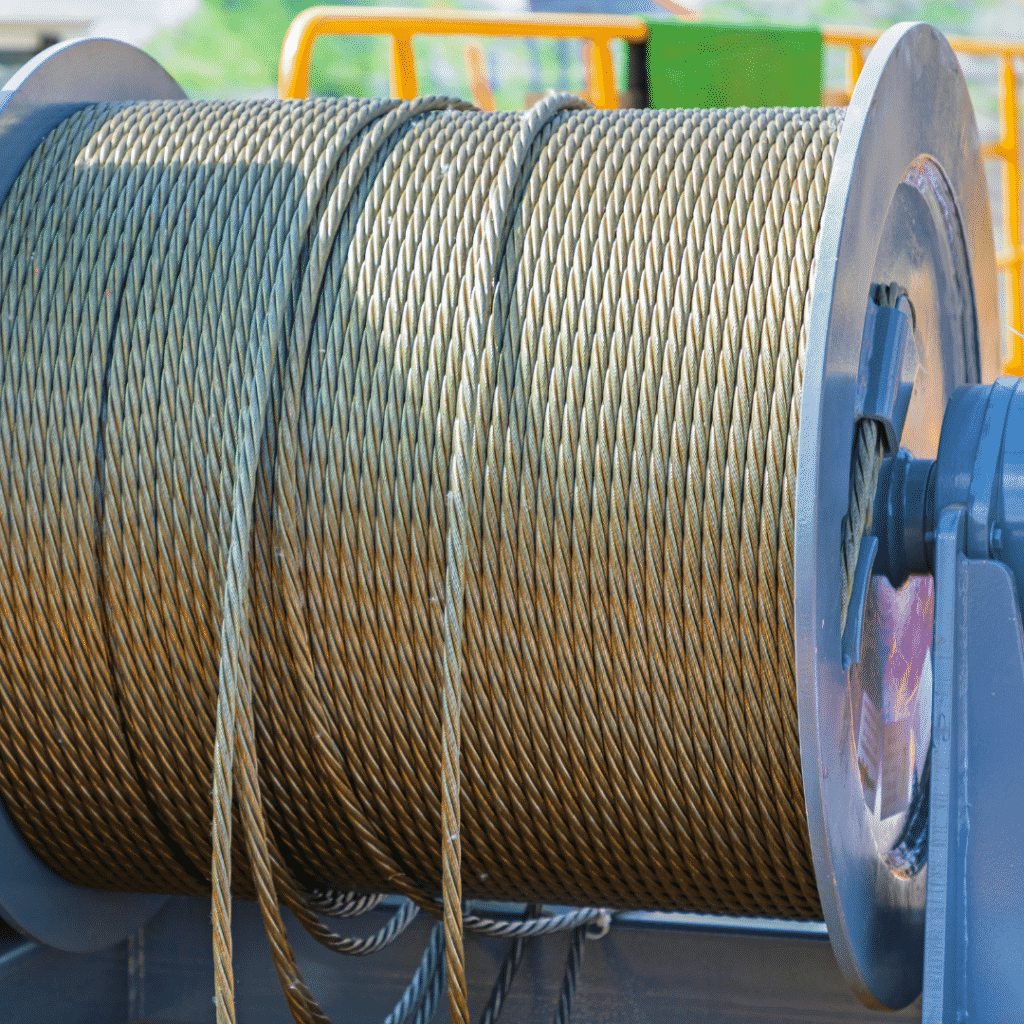

A wire rope is made up of multiple strands of wire that are coated with zinc or galvanized. The composition of the rope is quite complex with individual strands twisting around each other.

This complex and dense structure, combined with the treatment of each strand adds to the highly resistant properties of a wire rope hoist system making it ideal for use in extreme environments. The multiple strand form also helps to distribute loads better.

The system can be upgraded and made more efficient using a reeving system. This is where the wire rope travels around multiple drums with sheaves (a grooved pulley wheel) to hoist heavy items.

With reeving, heavier loads can be hoisted and moved because the hoist’s mechanical advantage is increased by spreading the load evenly across separate parts of the reeving system. The amount will depend on how many parts you have but, for example, in the case of a two-part single reeving system (2PS) the load capacity will be doubled across the two parts, however, it will consequently halve the lifting and lowering speed of your reeving system.

The use of reeving can also be important when you have a requirement to lift a load with a high level of accuracy. For example, the sheaves will maintain the linear position of a hook to hoist a machine or stack of materials in a smooth and straight vertical line reducing unnecessary force on the system thus ensuring safer and more efficient activity.

Another advantage of wire rope hoists is the increased headroom created by the design and particularly how the rope comes off the drum. This is especially true for 2, 3, and 5-ton wire rope hoists.

Chain hoists are an electric (or manual) hoisting solution that generally suits situations where the lifting requirements are not as significant such as smaller factories, work stations, and maintenance shops.

Their smaller physical size and maneuverability make them more flexible for different lightweight lifting and depositing applications. For professionals who work in various locations, this is a highly practical hoist solution because the crane can be transported more easily between sites. They can also be used to facilitate the use of a jib crane, hand-push crane, and gantry cranes.

Electric chain hoists will come as standard with vertical lift that is made possible by a simple reeving system and a dedicated chain container. (In order to achieve the same true vertical lift with a wire rope hoist, you would need to upgrade to a double reeved system.)

A wire rope hoist, however, with its dense multi-strand structure, is generally designed for loads of up to 50 tons. We at PWI Works have previously built wire rope hoists capable of lifting 50-ton loads and it’s not uncommon to see over 100-ton capacities!

We can’t talk about the durability of either system without mentioning reeving (again), because it has a direct bearing on the ability to lift material in a more controlled way that reduces stress on other parts of the crane.

It reduces the amount of load and therefore wear on the drivetrain components of each hoist system. The motors, clutches, and brakes are able to perform more efficiently because of the controlled motion of the chain and wire rope.

The assemblage of a chain hoist includes an effective reeving system where the chain passes through a single sheave. This means that the vertical load hoisting is conducted in a more accurate motion.

A wire rope hoist does not use the same mechanical method as the standard. The wire rope is instead wound around a single drum. The motion of hoisting therefore will cause some lateral movement as the wire ‘naturally’ finds its place on the drum as the hoist is operated. Reeving can be used to maximize lifting capacity and stability with the use of multiple drums with up to two lengths of wire rope fed from the drum and combined with pulleys. The only consequence is that this will reduce lifting speed because the wire has to travel a further distance.

Because chain hoists do not have as much flexibility in the way in which they are reeved and considering the material properties of a chain, the chain and parts (motor, clutch, brakes) are more likely to wear at a faster rate than a wire rope hoist system.

Commenting on the performance of both systems is again dependent on reeving. When you increase the number of pulley components in a reeving system, the speed will be drastically reduced to allow for the additional distance the rope (wire or chain) needs to travel to lift the load.

We can’t say that one system performs better than another because they have very different purposes. If you are looking for a higher-performing hoisting system in terms of lifting speed, your best option would be to implement minimal reeving.

With their higher load capacity, wire rope hoists are an invaluable part of any heavy machinery maintenance shop, casting and stamping plant, and any facility that handles heavy steel bundles.

They are also the preferred option for use in extreme environments because of their corrosion resistance (by treatment of the individual wire strands) which makes them more suitable for changeable weather and environmental conditions.

It needs to be mentioned that both systems will perform in extreme environments. However, prolonged use will take its toll and therefore the other components of the hoist, such as the electrical components, gearboxes, and motors also need to be capable of withstanding extreme conditions.

As we mentioned above, one of the biggest assets of a chain hoist system is its maneuverability. For this reason, they are best suited to a small part or component manufacturers. You will commonly find chain hoists in body shops as they are used to lift and maneuver engine blocks and other components in cars, trucks, and RVs.

The most important consideration is the duty cycle of the hoist. The duty cycle is the proportion of time when the hoist will be in operation and it is expressed as a ratio or percentage.

Imagine that your hoist will operate for one minute and then it is switched off for 49 minutes, then on for another minute and idle for another 49. This means that it is running for two minutes every 100 minutes, and therefore its duty cycle would be expressed as 2/100 or 2%.

You should also consider the maintenance intervals of the hoist, how long the hoist can be out of service, and how this will affect the operations in your factory or plant.

This factor is more important fundamentally to the type of hoist that will be best suited, and the weight will affect decisions in planning regarding future maintenance and how this will affect plant operations.

If the load is smaller (¼ - 2 tons) and the application will be using a workstation crane, then a chain hoist will likely be the best solution. If your requirements are for loads of 3 tons and up using a motorized bridge crane, you should use a wire rope hoist.

Electric chain hoists are less expensive, ranging from $2K-10K. Wire rope hoists can be anywhere between $5K-100K depending on the application and what upgrades you choose.

You should also think about the implications of adding a new system to your plant and the additional training that your staff will require. This is generally more important when switching from chain hoists to wire rope hoists, but nevertheless, even a chain hoist will require some training.

Don’t forget to think about maintenance costs which are generally far higher for wire rope hoists. Even though a wire rope hoist is more expensive, when it is properly maintained it can have a lifespan of 20+ years compared to 10 years for an electric chain hoist.

We are committed to helping American businesses maximize production. Call our main office at (574) 646-2015 to talk to an overhead crane expert or get a free quote.

When it comes to the relationship between lifting products and rigging a crane, a rope on a crane is selected to provide the best performance to the load and cycle requirements the crane is designed for, according to Christian Schorr-Golsong, director product marketing, WireCo WorldGroup.

With an abundance of rigging products on the market, one of the important decisions riggers are faced with today is choosing between wire or synthetic rope.

“This typically leads to compacted ropes with a high metallic area,” said Schorr-Golsong. “Those ropes have the needed high breaking strength and are also perfect for the mostly required multi-layer spooling. Each time the rope has to go over a sheave it gets bended and straightened. For this some flexibility is needed.”

With an abundance of rigging products on the market, one of the important decisions that riggers are faced with is choosing between wire or synthetic rope.

“Steel ropes stand for a well-proven, rugged solution with high radial stiffness and optimal spooling behavior,” added Schorr-Golsong. “There is not such a temperature restriction as for synthetics (at least for the ones using Dyneema) and the sensitivity to cuts or damages is much lower. I wouldn’t name it a safer solution but over the long time of use in the industry there is general knowledge in the market how to handle, inspect and discard a steel wire rope. For synthetic, such a perception must first be generated. But this is for all new technologies and shouldn’t block technological progress.”

The popularity of synthetic rope as an alternative to wire rope continues to grow as technological advances continue. However, many companies still steadily produce steel/wire rope due to its respected track record and reliability. Both are seen utilized on mobile and crawler cranes, and for a variety of applications such as construction, rigging and lifting. Check out the latest product rope and lifting solutions from some of the industry’s leading manufacturers and distributors.

Synthetic hoist ropes for crane applications have already been successfully in use at WireCo for many years, for example, in ship cranes and various lifting devices. Their use in mobile cranes, however, represents a special challenge as the rope must be able to provide an optimal balance between breaking load and weight. Both the limited axle load of road-approved vehicular cranes as well as the limitation on transport weight for crawler cranes has led to a steadily increasing breaking load combined with a constant rope diameter. Replacing these high-performance steel ropes with ones made of synthetic materials requires special fiber materials with a tensile strength similar to that of steel. Ropes made of such special fibers are already available and WireCo already offers the rotation-free hoist rope LankoLift S.

The bright yellow rope, made by Lankhorst Ropes, consists of 12 braided outer strands made of the high-tech material Dyneema. The properties of these special fibers result in a breaking strength equal to a steel rope of the same thickness. The construction of the rope core is designed to achieve the required resistance to transverse pressures, the company said. Laboratory tests have produced excellent results for breaking strength and projected service life based on the reversed bending cycles completed during testing. An additional noteworthy feature is the special coating treatment applied to the fibers to reduce interior friction and increase UV resistance. The rope’s low weight and flexibility enable an easier handling of the product during installation and hook block changes. They are also suitable for higher payloads, especially with higher lifting heights and longer jib lengths. The low maintenance requirements are a further advantage as synthetic ropes of this type are corrosion-proof and require no further lubrication.

When trying to meet the technical lift specifications of larger and more challenging lifts, synthetic rope lifting solutions surpass traditional steel wire sling solutions through strength, weight, handling and storage efficiencies, according to Cortland.

Cortland’s Plasma UHMWPE synthetic fiber rope slings are lighter than wire rope, offer greater flexibility both in design and use and are less labor intensive to move.

Cortland’s patented Plasma UHMWPE (Ultra High Molecular Weight Polyethylene) synthetic fiber rope slings are lighter than wire rope, offer greater flexibility both in design and use and are less labor intensive to move. Plasma rope slings have been successfully replacing steel wire rope in lifting applications for more than 25 years. Cortland Plasma rope slings are manufactured in the USA and tag certified to meet all ASME B30.9 lifting standards (other certification standards met upon request).

One of the biggest developments in the rope sector in recent times comes from a co-operative relationship between Austria-based rope manufacturer Teufelberger and Liebherr. Together they developed Solite fiber rope which went was unveiled at Bauma 2019 along with Liebherr’s new Solite-equipped EC-B ‘Fibre’ flat top tower cranes (240 EC-B 10 Fibre/240 EC-B 12 Fibre/ 370 EC-B 12 Fibre).

Both companies believe Solite will prove to be a game-changer, especially for the tower crane sector, by enabling the current boundaries of possibility, particularly with tower crane applications, to be pushed. The companies also say Solite has multiple benefits for mobile crane and crawler crane applications.

According to Teufelberger, the safety and operational advantages Solite offers include an up to 80 percent lower rope weight, the crane components do not wear, and the rope does not need to be lubricated. The rope’s point of discard is easy to determine, it adds, as it is indicated via the rope’s red core. When this can be seen the rope must be discarded, even though it still maintains 100 per cent of its breaking load at this point.

Teufelberger also says Solite’s life cycle is much longer than wire rope. Björn Ernst, R&D manager for Solite at Teufelberger says, “Solite can, compared to a steel cable, reach up to ten times the service time in multi-layer windings.”

Yale Cordage’s newest product, Sierra 78, was created with bio-based ultra-high molecular weight polyethylene Dyneema SK78 fiber. This marks one of the first partnerships with DSM Protective Materials to create a ‘green’ synthetic rope product manufactured in the USA.

The Mazzella 7-Part wire rope sling is constructed from one continuous piece of wire rope which results in a sling solution that is ultra-flexible and ergonomic for the end-user. A 7X19 construction contains seven strands with nineteen wires per strand. A mechanical (flemished) splice provides added strength compared to a hand splice and the eye and eye configuration allows it to be used in vertical, choker and basket hitches.

For large lifts, the Mazzella 7-Part wire is a more manageable sling at a cost savings versus standard wire rope slings, the company said. The Mazzella 7-Part wire rope sling can be made in equal capacities as any single-part wire rope sling. It ranges from 1/8-inch to 2-3/4 inches component rope with vertical capacities anywhere from 1.2 tons to over 400 tons.

8613371530291

8613371530291