wire rope crimp connectors quotation

The functionality and working life of your applications depend on the quality of your cable fittings, whether you need custom aircraft cable fittings and aircraft cable connectors for rigging, aircraft cable thimbles, crimpable fittings, medical cable fittings or fittings for another industry. All of Sava"s miniature cable fittings are held to our unwavering commitment to quality assurance. That’s because we don’t simply possess expertise in custom cable assemblies, but also the design of the cable eyelet fittings, and the ball stops they include.

During the manufacturing process, each production run undergoes careful scrutiny to ensure our wire rope hardware and fittings demonstrate the precision, break strength, and reliability your applications require.

Additionally, we tailor our miniature wire rope fittings for industry-specific needs, a capability that has made us the global cable manufacturer we are today. Thanks to our in-house engineering expertise, Sava is easily able to design customized solutions, such as cable eyelet crimping and other wire crimping services, fittings for large-diameter cables in mechanical control cables, fittings made of specially requested materials, flexible wire rope fittings, cable pulley fittings, or fittings that meet other unique application requirements.

At U.S. Rigging, we offer a wide selection of wire rope and wire rope fittings. Whether you"re in need of hand swagers, wire rope cutters, or wire rope and custom cable assemblies, we offer the best rigging hardware in our DuraBrite™ brand.

Similar to a ball end fitting, a ball shank fitting is sphere-shaped, and when crimped on to the end of a wire rope or cable, can fit into a socket. Most ball shanks are made using stainless steel for added durability and have a hole that goes all the way through the end fitting. This along with the added shank part to the ball allows the ball shank to bond well enough to hold to the cables breaking strength. Ball end fittings on the other hand can only hold to 60-80% of cable breaking forces.

Whether you are looking just for ball shank fittings, aircraft cable crimps, steel cable crimp ends or complete cable assemblies, Tyler Madison is the place to turn. Our years of expertise on stainless steel wire rope fittings and our many quality products make us a manufacturer that you can trust.

We manufacture cable crimp ends, complete cable assemblies and many other products for all of your needs. Our other products include:Wire rope lanyards

At Tyler Madison, we are committed to meeting the unique and ever-changing needs of our customers by making use of advanced technology and industry expertise. If you need steel cable crimp ends or custom wire rope cable assemblies, we can work with and help design and engineer new products with your specific application in mind.

2. (A) All goods supplied by us shall remain the sole and absolute property of us until such time as the customer shall have paid us the agreed price together with the full price of any other goods the subject of any other contract with us.

8. If the buyer shall make default in or commit a breach of the contract, or of any other of his obligations to the seller, or if any distress or execution shall be levied upon the buyer’s property or assets, or if the buyer shall make or offer to make any arrangement or composition with creditors, or commit any act of bankruptcy, or if any petition or receiving order in bankruptcy shall be presented or made against him if the buyer is a limited company and any resolution or petition to wind-up such company’s business (other than for the purpose or amalgamation or reconstruction) shall be passed or presented, or if a receiver of such company’s undertaking, property or assets or any other part thereof shall be appointed, the seller shall have the right forthwith to determine any contract then subsisting and upon written notice of such determination being posted to the buyer’s last known address any subsisting contracts shall be deemed to have been determined without prejudice to any claim or right the seller may otherwise make or exercise.

2. (A) All goods supplied by us shall remain the sole and absolute property of us until such time as the customer shall have paid us the agreed price together with the full price of any other goods the subject of any other contract with us.

8. If the buyer shall make default in or commit a breach of the contract, or of any other of his obligations to the seller, or if any distress or execution shall be levied upon the buyer’s property or assets, or if the buyer shall make or offer to make any arrangement or composition with creditors, or commit any act of bankruptcy, or if any petition or receiving order in bankruptcy shall be presented or made against him if the buyer is a limited company and any resolution or petition to wind-up such company’s business (other than for the purpose or amalgamation or reconstruction) shall be passed or presented, or if a receiver of such company’s undertaking, property or assets or any other part thereof shall be appointed, the seller shall have the right forthwith to determine any contract then subsisting and upon written notice of such determination being posted to the buyer’s last known address any subsisting contracts shall be deemed to have been determined without prejudice to any claim or right the seller may otherwise make or exercise.

Want us to provide your full assembly? Our architectural design team will collaborate with you to understand the cable and wire rope fittings you require for your application.

Once our team have helped to define the perfect components and confirmed the lengths for your wire rope assembly, our expert manufacturing team and in-house rigging team will get to work assembling your bespoke assembly.

Need assistance in specifying your cable requirements and knowing what wire rope fittings to use? Take a look at our guide on How To Order, Measure and Specify Your Wire Rope Assembly.

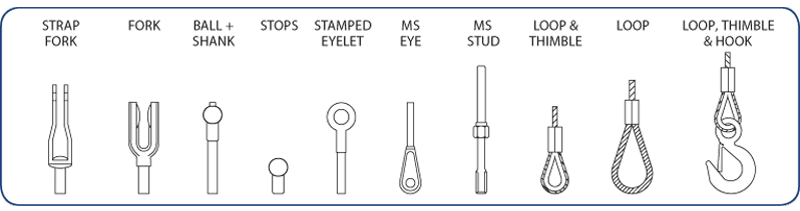

We offer a wide variety of eye end wire rope fittings options, including stamped eyelets, marine eyes, strap eyes, ring eyes, and more for use in a variety of industries with both commercial and military specifications available.

Lexco® Cable carries a variety of cable crimping tools designed for use with cable from 1/32” to 3/8" in diameter. From the best-selling, versatile, 5-cavity Model 1SC (HSC600) to single cavity models to battery operated models to specialty architectural (cable railing) models, Lexco® offers a wide selection.

These hand crimp tools are designed for crimping sleeves, crimping aluminum and copper button stops, and select other fittings, but are not universal and cannot be used to swage every wire rope fitting we offer. For example, some fittings that are typically not designed for manual or simple crimping include ball ends, stamped eyelets, and many threaded studs/plugs. If you are unsure which cable crimping tool your application requires, or if you have questions about tools for specialty applications, please contact Lexco® Cable for assistance.

Our simple, hand-operated cable crimping tools are ideal for prototypes and limited low-volume production. However, crimping is best done by machine—Lexco® Cable has the equipment, the tooling, the experience, and the personnel to provide our customers with top quality, mechanically swaged assemblies in high quantities.

Our in-house assembly and production processes are fast, efficient, and cost-effective enough to cancel out savings customers may realize by performing their crimp operations manually. Machine swaging also provides higher and more consistent holding strength and cleaner crimp markings. Contact Lexco® for more information, or request a quote on crimping and swaging for your project.

Wire rope swage sleeves and fittings are used to terminate the ends of wire ropes to prevent fraying, and to securely form lifting eyes in wire ropes. Cable swage sleeves and wire rope end fittings are very versatile and are an essential part of many wire rope rigging applications.

Here at Tri-State Rigging Equipment we pride ourselves on providing only the highest quality swage sleeves and wire rope end fittings to our customers, from only the most reputable manufacturers. We can provide you with any rigging equipment on the market, so if you cannot find what you are looking for or don’t know exactly what you need, call or email our sales team to speak with a rigging product specialist.

Wire rope swage sleeves, sometimes referred to as cable ferrules or duplex / crimp sleeves, are used to form eyes on the end of wire ropes. Wire rope swage sleeves are a more secure and more permanent alternative to wire rope clips. Cable swage fittings and sleeves are available in a variety of materials to fit any wire rope rigging application:

To properly fit and secure a cable swage sleeve, most use a hydraulic swaging press, while others can be hand crimped using a special hand swage crimping tool. Cable swage sleeves are available in bulk, but we specialize in manufacturing them into complete wire rope assemblies.

These wire rope end fittings are used to allow wire rope to be used in a large variety of rigging applications. Wire rope end fittings are available in bulk, but we specialize in manufacturing them into complete wire rope assemblies.

Tri-State Rigging Equipment is a service provider and distributor for all wire rope cable swage sleeves and wire rope end fittings for rigging and lifting serving clients from coast to coast, Canada, Mexico and especially focused in the states of Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

Continental Cable employs 65 people specializing in the manufacture of custom mechanical wire rope cable assemblies. Other product lines include stainless steel and galvanized aircraft cable, a complete line of cable related hardware and tools and plastic coated cable.

Fortune Rope is an industry-recognized supplier of aircraft cable, wire rope, chain, coated cable, and hardware fittings to a wide range of industrial and commercial customers who has the in-house capability to fabricate the custom cable assemblies you need — from one assembly to medium or high volume production runs.

Swaging is a method of securing cable railing wire with a permanently fitted cable or sleeve. The connection typically exceeds the rated breaking strength of the wire rope or cable. This is accomplished using fittings known as swages.

A railing system secured with swage fittings is called a swaged system. Swaged systems have been around since cable railing systems were invented. Initially, railing cable installers hand-swaged the fittings using a variety of hand crimping tools and smaller swaging tools.

Hand crimpers (which look like bolt cutters) smash the swage fitting onto the cable with manual force, creating a seal. And it generally takes multiple crimps to achieve a proper connection.

Later, however, machine-swaged fittings were invented. These fittings are created in a shop by a fabricator using either a press swagger or a rolling swagger. The process cold-forms the fitting around the cable using much more force than hand crimpers can manage, resulting in a much stronger connection. This resulted in a more secure cable railing system.

As technology advanced even further, a new evolution of fittings known as swageless systems arrived. Swageless fittings don’t require any form of swaging or crimping. Instead, the fittings features a small one-way locking mechanism. This locking mechanism secures the railing system by allowing cables to enter in only one direction. It then grabs the cable if it is pulled in the opposite direction.

Quick Attach™ fittings are precision machined from grade 316 stainless steel and are rated to 75% of the working load of the wire rope, when installed properly.

The advantage of Quick Attach™ fittings over conventional fittings is the arrangement of the wedges on the outside of the cable. This makes assembly much easier and allows different types of wire to be used with the same fitting.

Please note Quick Attach™ fittings should never be used with standing rigging or where shock loads are common. Also, the reuse of wedges should not be attempted more than 1 time and not with any application requiring greater than 50% of the wire rope work load limit.

Stake eyes are used on one or both ends of a lanyard. They are one of the most common end-fitting. Stake eyes, also known as stamped or crimp eyes, or eyelets, are fittings swaged onto the ends of the cable. Stake eyes come in various sizes according to the wire diameter, and the diameter of the eye hole allows the user to insert screws to attach to surfaces. These cannot be swage by hand, and must be swaged by hydraulic swagers with dies to achieve the full wire strength.Stainless Steel and Zinc-Plated Copper.

8613371530291

8613371530291