wire rope dallas free sample

Nantong Fasten Metals Products Co., LTD is located in the coastal open city—Nantong which is in the lower area of the Yangtze River. We are a professional corporation which produces a variety of standards and types of galvanized steel wire rope, ungalvanized steel wire rope, steel-wire, stranded wire and spring steel wire. Our products mainly exported to Southeast Asia, the United States, Europe, the Middle East, Africa and other countries.

ESTA"s published American National Standards are free to download from tsp.esta.org.ANSI E1.1, Entertainment Technology - Construction and Use of Wire Rope Ladders. ESTA Technical Standards Program Rigging Working Group

Distributor of material handling and rigging equipment. Products include slings, chains, wear pads, load binders, shackles, straps, hoists and trolleys. Types of slings are web, round, alloy chain and wire rope. Recovery and tow straps are available. Other services such as OSHA training, crane and hoists repair, material handling, rigging and inspection are also offered. Serves the automotive, foundry, steel processing and stamping industries. 24-hour emergency services.

Part of the development included construction of a barrier to the atrium, in which Tensile played a major role. Our brief was to engineer and install the vertical cabling system, which involved over 1,500 cables made from 5mm wire rope.

This is a real resume for a Shop Hand in Farmington, New Mexico with experience working for such companies as Zia Wire Rope And Supply, Wsi, High Tech Rental Tools. This is one of the hundreds of Shop Hand resumes available on our site for free. Use these resumes as templates to get help creating the best Shop Hand resume.

Rules differ if you’re building a fence in a residential or nonresidential area. But let’s imagine your proposed fence is around your own house. If you live in a single family home or a duplex, you can build a front yard fence up to four feet tall, and a backyard fence up to nine feet, without a permit. If you want to keep desperadoes out of your yard by topping your fence with barbed wire, it must be at least six feet above the ground and not project past your property line. Sorry, this rules it out barbed wire for the front yard fence, but we don’t think it looks that welcoming anyway.

You can’t build a fence in an easement – that is, where other people have a legal right to cross property – nor can you block visibility triangles at intersections. Swimming pool fences carry an additional set of rules.

Fort Worth has a different set of rules surrounding building fences. If you want to build a solid fence that tops six feet, or an open fence taller than eight feet, you’ll need to apply for a permit. Front yard fences can only be four feet tall, and of an open design with 50% density. You’re not allowed to use chain link in your front yard. As in Dallas, historic districts in Fort Worth may have additional rules about fencing. Here’s more Fort Worth building code info.

The city of Arlington has no tolerance for shoddy fences. City building codes include detailed descriptions of dilapidated and nuisance fences, including ones constructed with plywood, corrugated steel panels, or fiberglass panels and other inappropriate fence materials. Property owners of multi-family units also must keep fences structurally sound. Examples of violations include fences with more than 20 % damage to any eight-foot section, or a fence leaning more than 15 degrees at any point.

In residential front yards, fences must be no taller than four feet and be at least 75 % transparent. Chain link is not an approved building material, unless you’re replacing an existing chain link fence. Only very low fences are allowed on the side property lines of corner lots, to prevent impinging on visibility triangles. Expect to be quizzed on all details of your proposed fence when you file your fence permit.

Grand Prairie is determined to have a good-looking city. The city requires fences to be weather-tight and free from blight or deterioration. Property owners may build residential fencing from wood, masonry, chain link, cinder block, wood slats, and wrought iron. They’re not allowed to build fences using R-Panel, metal and plywood. All fences require an approved building permit, even if you’re replacing an old fence, or panel sections thereof. The permit fee is $25.

The city of Irving bans fences constructed from string, rope, wire products like chicken or hog wire, broken glass, plywood, galvanized sheet metal, and other materials not manufactured specifically for fencing. Barbed, concertina and razor wire are also prohibited, except in special cases. See additional city of Irving fence codes here.

It’s illegal to build a fence higher than eight feet above the adjoining ground level of the owner or lessee’s property. In a front yard, the maximum height is only 30 inches. The city of Bedford also stipulates that the nice smooth side of a fence face outward if your property is on a thoroughfare or public property, and that posts and support beams be on the inside, or be an integral part of the design of the finished surface. Their fence regulations also have very specific instructions on the size and placement of slats and posts on wood fences.

You can probably do this legally if you’re moving the fence farther away from the property line. However, many fences won’t stand up to being moved. You may need to construct a new section.

As the worldwide leader in wire rope pressure lubrication, The Kirkpatrick Group, Inc. has offered training to our worldwide users at our Training Facility on the outskirts of Dallas, Texas USA. The cost is minimal and in many cases no charge at all. Established in 2012, our customers have arrived from locations around the world to benefit from this hands on and classroom experience, that educates them in the operational understanding of wire rope pressure lubrication.

Southwest Wire Rope"s Engineering Services Department provides engineered lifting devices, lift plans, and engineered load testing services under the leadership of experienced Professional Engineers with extensive experience in heavy lifting.

We fabricate wire rope slings and assemblies to your custom needs. We take wire rope from the manufacturer and terminate the end whether it is Flemish or hand spliced loops, thimbles solid thimbles, swage fittings (Open or Closed swage sockets, buttons, threaded studs etc), multi-leg bridles or spelter sockets.

Nantong Fasten Metals Products Co., LTD is located in the coastal open city—Nantong which is in the lower area of the Yangtze River. We are a professional corporation which produces a variety of standards and types of galvanized steel wire rope, ungalvanized steel wire rope, steel-wire, stranded wire and spring steel wire. Our products mainly exported to Southeast Asia, the United States, Europe, the Middle East, Africa and other countries.

Since 1951, the family at Union Sling Company in Dallas, Texas has provided rigging products and services to the North Texas area. Our experience allows us to provide dependable, quality service. We sell strong, safe rigging products.Our experience means we have worked with a variety of industries. We don"t just sell products. We can answer questions too. We have the know-how to provide the right rigging for the job.

In October, Southwire recognized Breast Cancer Awareness Month and LGBTQ+ history month by hosting efforts across the company that provided resources and opportunities to get involved and learn more about both topics.

Use our thorough list of wire rope manufacturers and suppliers in Texas to examine and sort top wire rope manufacturers with previews of ads and detailed descriptions of each product. Any wire rope manufacturers can provide wire rope products to meet your company"s specific qualifications. An easy connection to reach wire rope manufacturers through our fast request for quote form is provided as well. This source is right for you whether it"s for cable railing, marine rigging, or any other wire rope needs.

Industrial wire ropes are designed for extreme resilience and strength. They can withstand thousands of pounds of pressure and be used on all types of applications. However, issues with the wire rope installation process can significantly decrease its longevity and even its capacity and durability.

When wire ropes are not used properly, it can create an unsafe environment. The rope can snap, even if the load it’s supporting is below its maximum load limit. In anoted by the IMCA (International Marine Contractors Association), a wire rope sling rope broke due to improper installation. A crew member was seriously injured after the sling disconnected and hit the worker.

Many of these common accidents are easily avoidable through correct wire rope installation. Here are five of the most common mistakes made and how to prevent them on your worksite.

Determining the diameter of the wire rope is an essential step of the installation process. Installers are required to double-check that the correct diameter rope is being used, as this impacts the rope’s breaking strength and load limit.

Wire ropes are measured with a parallel-jawed caliper (also called a machinist’s caliper). This is placed over the wire rope to measure the diameter – but if the rope is inserted at the wrong angle, you will get an inaccurate result.

The strands of a wire rope must be flush against the measuring portion of the caliper. If a raised strand is at the top, the measurement will have a smaller dimension, which could affect breaking strength calculations.

Wire ropes are reeled onto these spools for easy handling and shipments, as it prevents the rope from getting tangled or crushed. But unreeling the wire rope incorrectly can cause severe damage, such as snagged wires, twists, kinks, or unraveled strands.

A common mistake that is often made is to unreel the wire rope by laying the spool vertically on its axis. The wire rope has to be yanked off of the spool, which increases the likelihood of it getting kinked or twisted. The wire rope should also not touch the ground as it is unreeled, as this could damage the wires as well.

Instead, the reeled wire rope should be placed on a shaft that allows the spool to turn 360°. It also should require two people, one to slowly pull the rope off of the spool in a straight line and another to regulate the speed by controlling the turn rate.

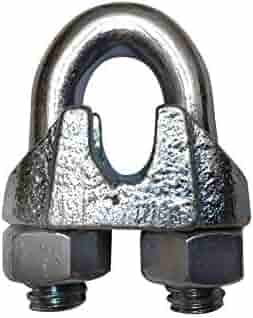

Occasionally ais added during wire rope installation to create a load-bearing eye or to connect two cables together. These small but mighty pieces only diminish a wire rope’s strength by around 10%, if they are added correctly.

These little issues can cause the wire rope to slip out of the clip. It is very important to follow the directions and use the right number of clips with the correct spacing in-between, depending on the rope’s diameter and approximate load weight.

Sometimes a damaged wire rope can be repaired through a method called seizing. First, the rope is cut at a straight angle, then a wire is tightly wound around this end to prevent the strands from unraveling.

Two methods can be used to securely seize a wire rope. First, it can be placed at a right angle between the starting and ending point of the seizing. The wire is then wrapped around this angled piece to hold it in place, and the ends are twisted together to secure it. Another option is to wrap the seizing wire around and twist the two end pieces together, creating a tourniquet type of attachment.

The type of end preparations recommended depends on several factors. This includes the diameter of the rope and the number of wires and strands. In some cases, double seizing and fuse welding is required for additional securement. Failing to follow these instructions could result in the core or strands of the wire rope to slip and unravel.

Although wire ropes are usually damaged due to improper use, they can get ruined during storage as well. Failing to follow through with routine maintenance and storage recommendations could cause the wire rope to rust, unravel, or kink. Further, keeping your wire rope on the ground, in wet areas, or directly in hot sunlight can cause it to break down faster.

the right way can improve their long-term performance and use. This includes following all instructions during wire rope installation, as well as storage and upkeep. Wire ropes should be cleaned before going into storage and may need lubricant from time to time to protect the wires from drying out.

Wire ropes are intended to be a strong, reliable piece of industrial hardware. There is no reason to compromise its durability due to simple installation mistakes. By avoiding these common mishaps, you can ensure a far safer work environment and also extend the use of your wire ropes.

Another tip is to start by purchasing top-quality hardware from a trusted wire rope supplier. Elite Sales is proud to carry a vast selection of wire rope sizes, styles, and finishes that are made to fit many applications.

8613371530291

8613371530291