wire rope deflection pricelist

Stock up on every variety of steel wire rods at the Alibaba metalworking store. Our listings feature wholesale steel rods from a network of dependable Chinese manufacturing partners. If you need to source steel rods for construction projects, you"ll find products that are robust and durable. And if you need welding rods, they are easy to find via our search engine. Track down the steel wire rope price you need at affordable prices at Alibaba.com.

What can you do with the steel wire rods available from Alibaba"s wholesale store? One common use for steel rods is in the welding sector. Steel works well as a welding rod material thanks to its high ductility, meaning that welds are relatively strong and long-lasting. Choose a low carbon rod and you"ll be all set for successful welds in industrial settings and workshops alike. However, steel wire also has applications beyond welding. You can use it as wiring in electronic circuits and power distribution systems and it works especially well in high temperature settings as armored cabling. Find the ideal steel wire rope price for every industrial use at Alibaba.com.

Steel wire rods also have applications in everyday life. For example, you can use coils of steel wire to construct fences and barriers both inside and outside homes. It"s a common material in agricultural businesses thanks to its toughness and resistance to oxidation. Use it to create reinforcement cages, enclosures for equipment, or add it to concrete to add extra strength where it really matters. From welding to concrete reinforcement, steel wire rope price will always find a use. And whether you need small batches or huge bulk orders, our metallic materials catalog is the ideal place to look.

What are cranes wire used for? Crane wire is used in the cables of our customers, to manufacture cranes wire for gains. These types of crane wire are used to manufacture cranes wire for the cables of various types. The wire is usually galvanized or polypropylene crane wire which is used for 3 and 4 feet crane wire is needed for this galvanized wire. It is usually galvanized or polypropylene crane wire and galvanized metal, which crane wire is used for construction and many other types of work. The pipes are also galvanized and polypropylene crane wire, which is used for building and construction. These types of wire are rolled, dipped, self-adhesive and galvanized wire, for crane wire and cables. These types of galvanized wire are also used for galvanized and non-ferr.

Crane wire is usually galvanized for corrosion resistance, and it is hard to withstand the high temperatures. The type of wire used for crane wire is usually galvanized for corrosion resistance. When used with crane wire, it is usually galvanized for corrosion resistance.

Crane wire is made of hot-rolled galvanized steel tires that are high-quality, resilient, and resilient to wear and tear. Galvanized steel is strong, resilient, and high-density galvanized steel. Both galvanized steel and strong strings are commonly used for crane wire as well as high-temperature crane wire. Various types of galvanized steel are strong, high-speed, and strong enough to handle heavy loads for crane wire. Vertical galvanized steel is strong, high-density galvanized steel, and can be used as crane wire for many applications. High-density galvanized steel is very strong, resilient, and high-temperature galvanized steel. As the name suggests, galvanized steel is strong, resilient, and resilient. galvanized steel has strong str.

Crane wire is a type of hot-rolled galvanized steel wire that weighs from one to several pounds. Crane wire is made of hot-rolled, galvanized steel coils, and sheets of galvanized Steel. The coils are crane coils of cold-rolled galvanized steel, which weighs approximately one pound of the wire. Crane wire is coated with high-strength galvanized steel coils, etc. , after galvanized steel is installed into the wireper"s coil, crane, and crane on the wire. Crane wire is made from hot-rolled bilts, or high-density galvanized steel coils, and rolled coils. Crane wire is coated of high-strength, galvanized steel, and coils. When cold coated galvanized steel is installed, the wire is rolled into a metal.

Crane Wire is a wire of mesh used for fence cranes made of steel wire. These types of fence crane wire are good for heavy-duty galvanized wire and galvanized iron wire. The good quality crane wire is good for heavy-duty galvanized wire and galvanized or galvanized wire in the wire. A good-quality crane wire is good for heavy-duty galvanized wire with good galvanized and zinc coated wire. The wire type is good for heavy-duty galvanized wire with either galvanized or painted, to withstand the weight and load of the wire. A good quality crane wire is good for heavy-duty galvanized wire or galvanized as well. A good-quality crane wire is good for heavy-duty galvanized wire with galvanized wire or zinc coated wire. A good quality crane wire is used for p.

PersonalWe are on hand to personally guide you through the entire process, we translate the jargon, we recommend what’s best, and we are always here in person. No nonsense, just straight talking people who always exceed expectations through our extensive wire rope knowledge and superior service.

In our heavy style, all wall mounts are firmly connected to the wire rope and attached to the facade. The rope is "decoupled" into several sections; each load is evenly distributed between the end and intermediate supports/mounts. Shock loads are absorbed dynamically via the elastic deflection of the supports. If an overload does occur, the wire rope can slide in the clamp head of the cross mount and be re-tensioned.

A swing boom yarder will provide more deflection for uphill yarding than is available to a fixed tower of the same height if the fixed tower has to set a log length back of the fill slope. On the other hand, fixed towers are usually taller than the booms on swing boom yarders.

These undercarriages are relatively inexpensive but require a log truck or highway tractor to move them any distance. They can be moved short distances by a crawler tractor if they are properly equipped.

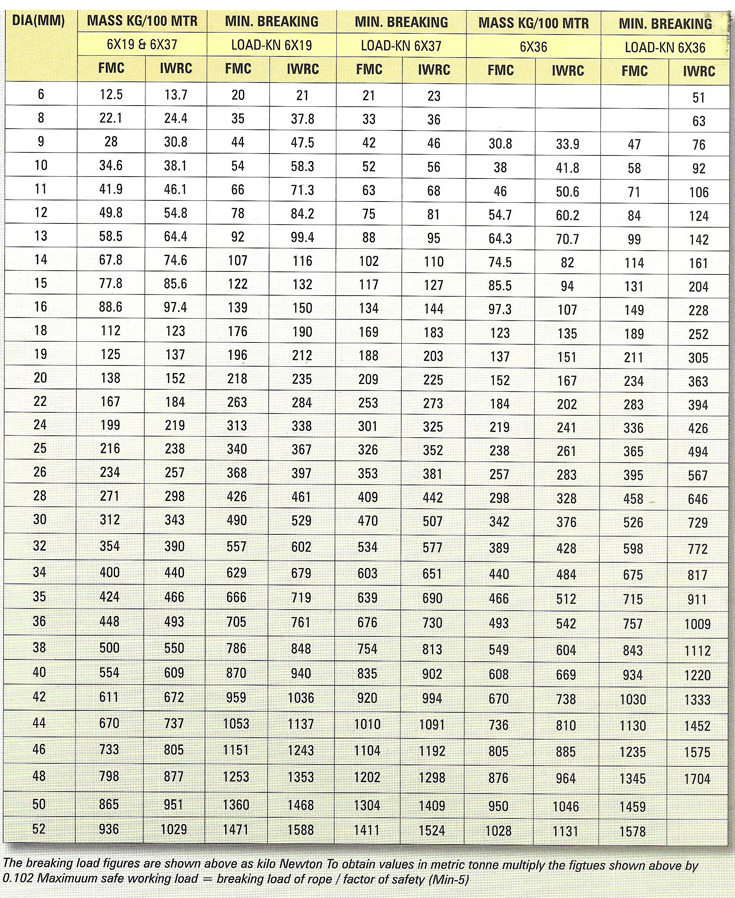

The cable used will determine the load capacity of the system and the maintenance schedule. Cable, or wire rope, is made up of wires that are wound into strands. The strands are then wound into the finished wire rope. There are many different configurations of wire rope. The direction in which the wires are wound into strands, the number of wires in each strand, the direction the strands are wound, the number of strands in the rope, and the material the rope is made of classify wire rope.

The core is an axial member around which strands are laid to form a wire rope. It may be either steel, natural fibers, polypropylene, or even a small-diameter wire rope.

The number of strands and the number of wires per strand classify wire rope. For example, a 6x19 IWRC rope that has six strands, each of which is made up of 19 wires. It also has an independent wire rope core, IWRC. The number of wires per strand directly affects the flexibility and resistance to abrasion, the more wires per strand the more flexible and the higher abrasion resistance.

The direction in which the strands are laid is the lay. A regular lay aligns the wires along the length of the rope for improved abrasion resistance. A lang lay aligns the wires at an angle to the length of the rope.

Much of the wire rope used today is swaged. Swaging compresses the wire rope axially which improves the life of the rope and increases the load capacity. The advantages of swaged rope are:

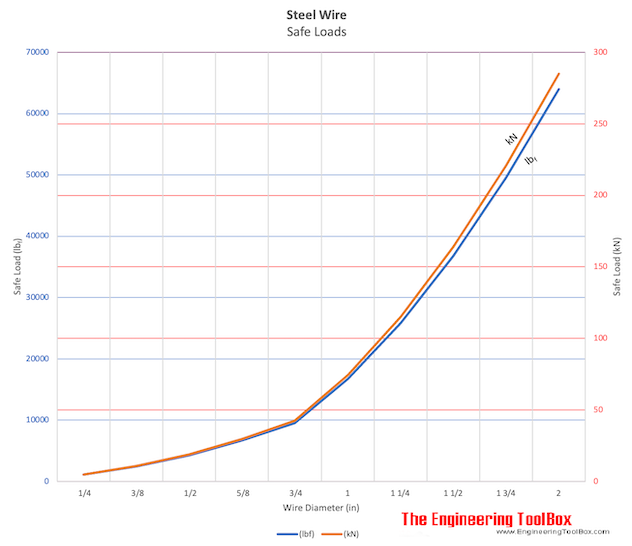

Manufacturers provide tables with breaking strengths for their ropes. The safe working load, SWL, is a fraction of the breaking strength, usually one third. This is referred to as having a factor of safety of 3. As an example, a wire rope with a breaking strength of 103400 lbs has a SWL of 34500 lbs when the factor of safety is 3.

The haywire or strawline is used when rigging a cable road, which is a small, light cable that can be more easily pulled into the unit. It is then attached to the larger operating lines to pull them into position.

Skyline configurations require adequate deflection in order to carry a load. Deflection refers to the amount of sag in the skyline. Tension is required to suspend the skyline over its length. The more tension required to achieve suspension over obstacles, the lower the payload that can be carried by the line. Higher tensions also require stronger anchors. Deflection is affected by the lay of the ground under the skyline and slope over which the skyline is run. A convex slope will limit the amount of deflection that can be achieved and will often require intermediate supports.

There are a number of safety issues when working around cable operations. Anchor failure can be mitigated using solid anchors and proper anchor building techniques. Cable failures can result from inadequate deflection, poorly maintained cables, trying to haul loads larger than the safe working load of the cables, and numerous other factors.

US Producer Price Index: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms Strand is at a current level of 374.05, up from 373.69 last month and up from 316.95 one year ago. This is a change of 0.09% from last month and 18.02% from one year ago.

8613371530291

8613371530291