wire rope diameter and capacity made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

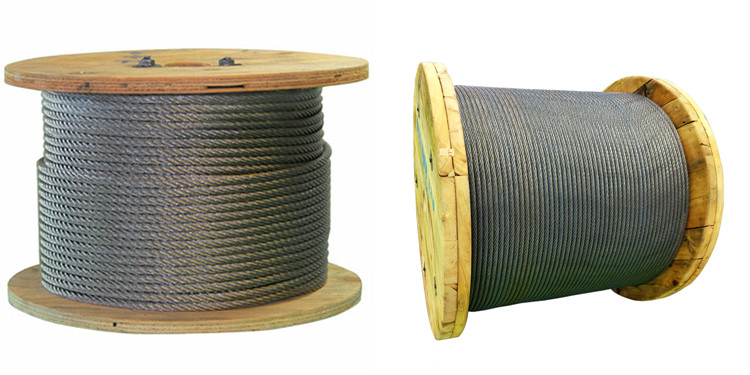

Wire ropes can be seen everywhere around us, they are made of strands or bundles of individual wires constructed around an independent core, suitable for construction, industrial, fitness, commercial, architectural, agricultural, and marine rigging applications.

Wire rod is made from high carbon steel wires(0.35 to 0.85 percent carbon) in a hot rolling process of a required diameter, usually from 5.5mm to 8 mm.

Wire rod is drawn to the required diameter by the 1st drawing machine after descaling dust and rust, adding mechanical properties suitable for application.

Positioning the wires different or the same size lay in multiple layers and same direction, or cross lay and diameter is maintained by one-third of the rope size.

So in theory, it is very simple to manufacture wire ropes. However there are many more details that must be closely monitored and controlled, and this requires time and experienced personnel since it is a super complicated project you cannot imagine.

CIVMATS produces high quality stainless steel wire rope. Our annual production capacity is roughly 8000 tons, among which stainless steel wire rope amounts to 400 tons per month. The tolerance of our stainless steel wire rope can be as small as ±0.01mm. CIVMATS produces strictly according to ISO9001:2000. Every product delivered from CIVMATS is a reputation warranty.

Wire rope can be divided into multi-strand wire rope and single-strand wire rope. It is structured with at least two layers of steel wire or a plurality of strands spirally wound around a center or a core. Stainless steel wire rope refers to a steel wire rope made of stainless steel. In dynamic systems, stainless steel wire ropes are widely applied in the lifting of cranes and elevators, the transmission of mechanical power, the control of automobile cockpit poles and the operation of aircraft control systems, etc. In static systems, stainless steel wire ropes are also employed in various industries such as the stability of the sling bridge"s pulling support tower and the design of new railings.

Stainless steel wire rope features high temperature resistance, good fatigue resistance, excellent breaking force, long service life and durability. It is widely used in coal, petroleum, metallurgy, chemical industry, shipbuilding, bridge, electric power, rubber, military, tourism, water conservancy and light industry. The products can be produced according to ISO, BS, DIN, JIS, ABS, LR and other international and foreign advanced standards

In CIVMATS, all of our stainless steel wire ropes are packaged as per international standard to prevent any possible damage or loss. They are neatly wrapped in accurate length with securely tied rope ends. For enhanced customer experience, we also provide dedicated package as per your special requirements.

By default, we will quote based on sea transportation, such as FOB, CFR, CIF and the like for most enquiries or orders. Quotation based on air transportation is also optional upon your request for urgent demands.

Our main grades for stainless steel wire rope are 304 and 316. We can also customize stainless steel wire rope as per your specified grades and sizes for your reference.

1. Point contact: The adjacent stainless steel wires contact in the form of point in the strands. The diameters of all the stainless steel wires, excluding the central wire are equal, and the strands are formed by layering.

2. Line contact: There is a linear contact between the adjacent layers of stainless steel wire in the strand, and the strands are made of stainless steel wires of different diameters in one process.

4. Point and line contact: There are two kinds of contact forms between the adjacent layers of stainless steel wires in the strand. The strands are made of wires of different diameters.

1. In the equipment reform of chemical, fertilizer, chemical fiber and other industries, stainless steel wire rope was used for the deployment of the updated equipment.

2. Stainless steel wire ropes are used in the applications of popular stainless steel welding rods and a considerable number of stainless steel components, springs, connecting parts, etc.,

5. Stainless steel wire ropes are also extensively used in railway electrification, decoration industry, rigging industry, fishing gear industry, automobile and motorcycle industry and other industries.

When autocomplete results are available use up and down arrows to review and enter to select. Touch device users, explore by touch or with swipe gestures.

6×19 construction wire rope is available with either FC (fibre core) or WSC (wire strand core). When supplied with a wsc the rope is more commonly referred to as 7×19. The rope is very popular in diameters from 3mm to 16mm and is used on a variety of applications. 6×19 FC and 6×19 WSC (7×19) is very flexible in diameters 3mm to 6mm and is used for many requirements where wire ropes are running over pulleys. 7×19 construction is readily available in both galvanised and marine grade stainless steel.

Established in 2005, Jiangsu Safety Steel Wire Rope Co., Ltd. is a professional steel wire rope manufacturer and exporter with a profound experience. The company is located in Wuxi, Jiangsu, China covering an area of 57,108.70 square meters. They have a total annual production of steel wire rope is 25000 to 30000 tons and a registered capital 13 million U.S. dollars. Jiangsu Safety Steel Wire Rope Co., Ltd. has plenty of high-quality products to offer.Toho-Rongkee

Chongqing Toho-Rongkee Electronic and Machinery Co., Ltd is one of the best wire rope manufacturers in China that follows ISO 9001:2008, TUV, CE, SGS qualification standard on every production method and fabricated. Also offer a wide range of lifting tools, equipment, and various riggings that meet your standards. Employs over 1000 skilled workers and staff in 7 advanced factories in China.Tianli Stainless Steel Products Co., Ltd

Tianli Stainless Steel Products Co., Ltd is specialized in manufacturing steel wire ropes headquarters in Dainan Town, Jiangsu Province China. Currently having more than 50 existing employees in over 6600 square meters factory area. They can provide excellent advice and assistance to ensure you obtain the right products at the lowest cost.Guizhou Wire Rope Incorporated Company

With more than 40 years of manufacturing and technique experience, you can totally rely on Guizhou Wire Rope Incorporated Company, they have excellent production lines, modern production techniques, and excellent quality control systems. All products such as steel wire, pre-stressed wire rope, PVC coated wire rope, etc. are not only famous with excellent quality but in reasonable prices and considerate services in China. This company also receives good popularity in the overseas market.Nantong Jiaan Metal Material Co., Ltd.

Established in 2013, Jiaan Metal Material is one of the respected manufacturers of steel wire rope located in Nantong, Jiangsu, China. All the production methods, from raw material smelting, heat treatment, wire drawing, and rope twisting to physical and chemical performance examining, are under strict and scientific control based on ISO 9001 certification standard.Nantong Lili hardware products Co., Ltd.

Started in 1998, Nantong Lili hardware products Co., Ltd. continually improving and striving to provide high-grade wire rope to customers worldwide. ISO9001:2008, ISO14001:2004 certified company located in Jiangsu, China. They mainly engaged in producing steel wire rope, stainless steel wire, steel strip, stainless steel strip, spring steel strip, spring steel wire, carbon steel wire, and more.Nantong New Jianghai Internation Trade Co., Ltd.

Set up in the year 2016, Nantong New Jianghai Internation Trade Co., Ltd is an expert wire rope provider situated in Nantong, China. Owns advanced technologies and machinery to manufacture a high-class and comprehensive quality solution. They have more than 70 professional employees working and improving products according to ISO9001:2015 authentication.Jiangsu Zhongying Steel Cable Co., Ltd.

Established in 2004, Zhongying Steel Cable is one of the leading manufacturers and reputable provider of steel wire ropes situated in Nantong, Jiangsu, China. Their factory has 80, 000 square meters and the building area is about to 65,000 square meters. Workshops are equipped with advanced producing equipment and comprehensive testing facilities that’s why the partnership with them will bring business satisfaction for you.Qingdao Haito Rigging Hardware Co., Ltd

A large enterprise located in Qingdao, Shandong, China, which engaged in manufacturing rigging hardware such as steel wire rope accessories, wire rope clips, load binder, chain, wire rope, and more. They have an abundant supply of superior quality products. Founded in 2009, Haito Rigging Hardware continuously developed and improving products supported by good experience and professional employees.Gustav Wolf

With over 130 years of experience and development, Gustav Wolf is a leading superior steel wire and steel wire ropes manufacturer associated with quality and safety. Produced products according to ISO9001:2015, ISO14001:2015 certification which can meet your requirements and demands. Employs over 115 hardworking workers and staff who aim to serve customers with honesty, loyalty, and perseverance.Jiangsu Xiangchuan Rope Technology Co., Ltd.

Specialized in manufacturing high-standard wire rope, Xiangchuan Rope Technology is a dedicated supplier and manufacturer with vast experience in the field. Own a modern facility with an area of about 38, 000 square meters and employs 138 staff members and workers. Their advanced production equipment, technical know-how, skilled workers guarantee that in Xiangchuan Rope Technology you have a reliable partner.JULI SLING CO., LTD.

For more than 33 years of experience in creating comprehensive products such as wire rope, JULI SLING earned a good reputation in the steel industry appreciated by foreign and domestics customers. JULI is recognized as a pioneer in China’s lifting and rigging industry, the standard makers in rigging field, the advocate of worldwide rigging civilization. Partnership with this company will skyrocket your business project.Nantong Julong Metal Products Co., Ltd

Nantong Julong Metal Products Co., Ltd is a large private enterprise founded in 2009 that specialized in producing any types of wire rope, headquarters in Jiangsu, China. Get 100% ideal products, at a cost-effective price here in Julong Metal. Be one of their satisfied customers such as in Europe, Africa, North America, South America, Asia, the Middle East, etc.YunFeng Steel Wire Rope Products Ltd.

Located in Jiangsu province, China, YunFeng Steel Wire Rope is a professional manufacturer of all kinds of wire rope offer in excellent quality and reasonable price to customers. They can meet customers’ demands and requirements by manufacturing all kinds of products with international standards.Sinounion Industries

Founded in 1999, Sinounion Industries is a professional Steel Wire Rope manufacturer in China. Also offer Rigging Hardware, Lifting Equipment, and various Forging & Casting products. All products are manufactured according to ISO9001, ISO14001, CE, and GS standards. The company owns a wide factory area in Qingdao, Shandong province with about 35000 square meters.Ningbo BST Metal Products Co., Ltd.

Established in 2002, BST Metal Products is one of the largest and reputable steel wire rope manufacturers in China with an area of 78,000 square meters factory workshop. Backed up by more than 350 professional people & technical engineers who have a vast experience in the field, BST Metal Products ensure great and fast production exceed the national and international guidelines.Jiangsu Yasheng Metal Products Co., Ltd.

As an ISO9001:2015, ISO/TS16949:2009, ISO9001: 2000 certified company, Jiangsu Yasheng Metal Products Co., Ltd. devoted itself to producing excellent products at a favorable cost. If you`re looking for a wire rope manufacturer, then Yasheng Metal Products is the best choice! Get 100% quality products prepared by solid technical strength and professional service team.Chongqing Geyo Machinery corporation

Geyo Machinery corporation a reliable manufacturing company that focuses on research, production, sales, and service of high-quality products. Mainly engaged in manufacturing wire rope, wire rope slings, tamping rammer, power trowel, scarifying machine, etc. They have their own advanced production facilities, expert technical team, and a professional quality control team.SHANGHAIMETAL

Started in the year 1980, SHANGHAIMETAL is a premier wire rope provider. Together with a team of experts, innovative machinery, and dedicated workers, they guarantee absolute customer satisfaction. Shanghai Metal is always passionate about working and supplying excellent services to clients throughout the world. All their products are manufactured with high-quality at a reasonable cost.Huazhuo HD Machinery

Established in 1958, Qingdao Huazhuo HD Machinery Co., Ltd. is a trusted wire rope manufacturer with a profound experience, strong workmanship, and professional service team that ensures the best product at best price offer to clients around the world. A leading supplier of high-standard wire rope, rigging hardware, marine hardware, chain, lifting tools, and other high-grade metal products.

Xinghua City Guangtong Metal Products Factory is a stainless steel wire rope and stainless steel cable supporting rigging products and other professional production and research and development of high-quality manufacturers. The company was founded in 2005,has advanced production equipment,complete testing equipment and strong technical force. The company mainly produces high-quality stainless steel wire rope,coated steel wire rope(PVC,TPU,PP),stainless steel wire rope,jump rope,climbing steel wire rope,new invisible protection mesh steel wire rope,water proof corro

CIVMATS produces high quality stainless steel wire rope. Our annual production capacity is roughly 8000 tons, among which stainless steel wire rope amounts to 400 tons per month. The tolerance of our stainless steel wire rope can be as small as ±0.01mm. CIVMATS produces strictly according to ISO9001:2000. Every product delivered from CIVMATS is a reputation warranty.

Wire rope can be divided into multi-strand wire rope and single-strand wire rope. It is structured with at least two layers of steel wire or a plurality of strands spirally wound around a center or a core. Stainless steel wire rope refers to a steel wire rope made of stainless steel. In dynamic systems, stainless steel wire ropes are widely applied in the lifting of cranes and elevators, the transmission of mechanical power, the control of automobile cockpit poles and the operation of aircraft control systems, etc. In static systems, stainless steel wire ropes are also employed in various industries such as the stability of the sling bridge"s pulling support tower and the design of new railings.

Stainless steel wire rope features high temperature resistance, good fatigue resistance, excellent breaking force, long service life and durability. It is widely used in coal, petroleum, metallurgy, chemical industry, shipbuilding, bridge, electric power, rubber, military, tourism, water conservancy and light industry. The products can be produced according to ISO, BS, DIN, JIS, ABS, LR and other international and foreign advanced standards

In CIVMATS, all of our stainless steel wire ropes are packaged as per international standard to prevent any possible damage or loss. They are neatly wrapped in accurate length with securely tied rope ends. For enhanced customer experience, we also provide dedicated package as per your special requirements.

Our main grades for stainless steel wire rope are 304 and 316. We can also customize stainless steel wire rope as per your specified grades and sizes for your reference.

1. Point contact: The adjacent stainless steel wires contact in the form of point in the strands. The diameters of all the stainless steel wires, excluding the central wire are equal, and the strands are formed by layering.

2. Line contact: There is a linear contact between the adjacent layers of stainless steel wire in the strand, and the strands are made of stainless steel wires of different diameters in one process.

4. Point and line contact: There are two kinds of contact forms between the adjacent layers of stainless steel wires in the strand. The strands are made of wires of different diameters.

1. In the equipment reform of chemical, fertilizer, chemical fiber and other industries, stainless steel wire rope was used for the deployment of the updated equipment.

2. Stainless steel wire ropes are used in the applications of popular stainless steel welding rods and a considerable number of stainless steel components, springs, connecting parts, etc.,

5. Stainless steel wire ropes are also extensively used in railway electrification, decoration industry, rigging industry, fishing gear industry, automobile and motorcycle industry and other industries.

Wire ropes can be seen everywhere around us, they are made of strands or bundles of individual wires constructed around an independent core, suitable for construction, industrial, fitness, commercial, architectural, agricultural, and marine rigging applications.

Wire rod is made from high carbon steel wires(0.35 to 0.85 percent carbon) in a hot rolling process of a required diameter, usually from 5.5mm to 8 mm.

Wire rod is drawn to the required diameter by the 1st drawing machine after descaling dust and rust, adding mechanical properties suitable for application.

Positioning the wires different or the same size lay in multiple layers and same direction, or cross lay and diameter is maintained by one-third of the rope size.

So in theory, it is very simple to manufacture wire ropes. However there are many more details that must be closely monitored and controlled, and this requires time and experienced personnel since it is a super complicated project you cannot imagine.

In stricter senses, the term wire rope refers to a diameter larger than 9.5 mm (3⁄8 in), with smaller gauges designated cable or cords.wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically, wire rope evolved from wrought iron chains, which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure, flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. While friction between the individual wires and strands causes wear over the life of the rope, it also helps to compensate for minor failures in the short run.

Wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators, and for transmission of mechanical power. Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an airplane connected to levers and pedals in the cockpit. Only aircraft cables have WSC (wire strand core). Also, aircraft cables are available in smaller diameters than wire rope. For example, aircraft cables are available in 1.2 mm (3⁄64 in) diameter while most wire ropes begin at a 6.4 mm (1⁄4 in) diameter.suspension bridges or as guy wires to support towers. An aerial tramway relies on wire rope to support and move cargo overhead.

Modern wire rope was invented by the German mining engineer Wilhelm Albert in the years between 1831 and 1834 for use in mining in the Harz Mountains in Clausthal, Lower Saxony, Germany.chains, such as had been used before.

Wilhelm Albert"s first ropes consisted of three strands consisting of four wires each. In 1840, Scotsman Robert Stirling Newall improved the process further.John A. Roebling, starting in 1841suspension bridge building. Roebling introduced a number of innovations in the design, materials and manufacture of wire rope. Ever with an ear to technology developments in mining and railroading, Josiah White and Erskine Hazard, principal ownersLehigh Coal & Navigation Company (LC&N Co.) — as they had with the first blast furnaces in the Lehigh Valley — built a Wire Rope factory in Mauch Chunk,Pennsylvania in 1848, which provided lift cables for the Ashley Planes project, then the back track planes of the Summit Hill & Mauch Chunk Railroad, improving its attractiveness as a premier tourism destination, and vastly improving the throughput of the coal capacity since return of cars dropped from nearly four hours to less than 20 minutes. The decades were witness to a burgeoning increase in deep shaft mining in both Europe and North America as surface mineral deposits were exhausted and miners had to chase layers along inclined layers. The era was early in railroad development and steam engines lacked sufficient tractive effort to climb steep slopes, so incline plane railways were common. This pushed development of cable hoists rapidly in the United States as surface deposits in the Anthracite Coal Region north and south dove deeper every year, and even the rich deposits in the Panther Creek Valley required LC&N Co. to drive their first shafts into lower slopes beginning Lansford and its Schuylkill County twin-town Coaldale.

The German engineering firm of Adolf Bleichert & Co. was founded in 1874 and began to build bicable aerial tramways for mining in the Ruhr Valley. With important patents, and dozens of working systems in Europe, Bleichert dominated the global industry, later licensing its designs and manufacturing techniques to Trenton Iron Works, New Jersey, USA which built systems across America. Adolf Bleichert & Co. went on to build hundreds of aerial tramways around the world: from Alaska to Argentina, Australia and Spitsbergen. The Bleichert company also built hundreds of aerial tramways for both the Imperial German Army and the Wehrmacht.

In the last half of the 19th century, wire rope systems were used as a means of transmitting mechanical powercable cars. Wire rope systems cost one-tenth as much and had lower friction losses than line shafts. Because of these advantages, wire rope systems were used to transmit power for a distance of a few miles or kilometers.

Steel wires for wire ropes are normally made of non-alloy carbon steel with a carbon content of 0.4 to 0.95%. The very high strength of the rope wires enables wire ropes to support large tensile forces and to run over sheaves with relatively small diameters.

In the mostly used parallel lay strands, the lay length of all the wire layers is equal and the wires of any two superimposed layers are parallel, resulting in linear contact. The wire of the outer layer is supported by two wires of the inner layer. These wires are neighbors along the whole length of the strand. Parallel lay strands are made in one operation. The endurance of wire ropes with this kind of strand is always much greater than of those (seldom used) with cross lay strands. Parallel lay strands with two wire layers have the construction Filler, Seale or Warrington.

In principle, spiral ropes are round strands as they have an assembly of layers of wires laid helically over a centre with at least one layer of wires being laid in the opposite direction to that of the outer layer. Spiral ropes can be dimensioned in such a way that they are non-rotating which means that under tension the rope torque is nearly zero. The open spiral rope consists only of round wires. The half-locked coil rope and

Wire rope is often used in slings because of its strength, durability, abrasion resistance and ability to conform to the shape of the loads on which it is used. In addition, wire rope slings are able to lift hot materials.

Wire rope used in slings can be made of ropes with either Independent Wire Rope Core (IWRC) or a fiber-core. It should be noted that a sling manufactured with a fiber-core is usually more flexible but is less resistant to environmental damage. Conversely, a core that is made of a wire rope strand tends to have greater strength and is more resistant to heat damage.

Wire rope may be manufactured using different rope lays. The lay of a wire rope describes the direction the wires and strands are twisted during the construction of the rope. Most wire rope is right lay, regular lay. This type of rope has the widest range of applications. Wire rope slings may be made of other wire rope lays at the recommendation of the sling manufacturer or a qualified person.

Wire rope slings are made from various grades of wire rope, but the most common grades in use are Extra Improved Plow Steel (EIPS) and Extra Extra Improved Plow Steel (EEIPS). These wire ropes are manufactured and tested in accordance with ASTM guidelines. If other grades of wire rope are used, use them in accordance with the manufacturer"s recommendations and guidance.

When selecting a wire rope sling to give the best service, consider four characteristics: strength, ability to bend without distortion, ability to withstand abrasive wear, and ability to withstand abuse.

Rated loads (capacities) for single-leg vertical, choker, basket hitches, and two-, three-, and four-leg bridle slings for specific grades of wire rope slings are as shown in Tables 7 through 15.

Ensure that slings made of rope with 6×19 and 6x37 classifications and cable slings have a minimum clear length of rope 10 times the component rope diameter between splices, sleeves, or end fittings unless approved by a qualified person,

Ensure that braided slings have a minimum clear length of rope 40 times the component rope diameter between the loops or end fittings unless approved by a qualified person,

Ensure that grommets and endless slings have a minimum circumferential length of 96 times the body diameter of the grommet or endless sling unless approved by a qualified person, and

Perform welding of handles or other accessories to end attachments, except covers to thimbles, before assembly of the sling. Ensure that welded end attachments are proof tested by the manufacturer or a qualified person. Retain the certificates of proof test and make them available for examination.

Do not use wire rope clips to fabricate wire rope slings, except where the application precludes the use of prefabricated slings and where the sling is designed for the specific application by a qualified person,

Although OSHA"s sling standard does not require you to make and maintain records of inspections, the ASME standard contains provisions on inspection records.[3]

Use damaged slings only after they are repaired, reconditioned, and proof tested by the sling manufacturer or a qualified person using the following criteria:

Ensure that wire rope slings have suitable characteristics for the type of load, hitch, and environment in which they will be used and that they are not used with loads in excess of the rated load capacities described in the appropriate tables. When D/d ratios (Fig. 4) are smaller than those listed in the tables, consult the sling manufacturer. Follow other safe operating practices, including:

When D/d ratios (see Fig. 6) smaller than those cited in the tables are necessary, ensure that the rated load of the sling is decreased. Consult the sling manufacturer for specific data or refer to the WRTB (Wire Rope Technical Board) Wire Rope Sling Users Manual, and

Ensure that all portions of the human body are kept away from the areas between the sling and the load and between the sling and the crane or hoist hook,

Before initial use, ensure that all new swaged-socket, poured-socket, turnback-eye, mechanical joint grommets, and endless wire rope slings are proof tested by the sling manufacturer or a qualified person.

Permanently remove from service fiber-core wire rope slings of any grade if they are exposed to temperatures in excess of 180 degrees F (82 degrees C).

Follow the recommendations of the sling manufacturer when you use metallic-core wire rope slings of any grade at temperatures above 400 degrees F (204 degrees C) or below minus 40 degrees F (minus 40 degrees C).

We don"t collect information from our users. Only emails and answers are saved in our archive. Cookies are only used in the browser to improve user experience.

Some of our calculators and applications let you save application data to your local computer. These applications will - due to browser restrictions - send data between your browser and our server. We don"t save this data.

Google use cookies for serving our ads and handling visitor statistics. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected.

Wire rope slings adopt precast concrete construction and the main parts include wire rope, inner core, strand, center, steel wire, steel stocks and others.

We can customize various kinds of rigging according to customers’ requirement. Usually, the minimum circumference S of the sling is 50 times the wire rope diameter and the bending radius must be not less than 4 times of the wire rope diameter. The zone between the clamps can’t be bent under lifting force and the length is intended to be the dimension measured between the bearing points of the slings and the measured length of a ferrule-secured sling shall not differ from the nominal length by more than two rope diameters or 1% of the nominal length.

There are various sockets available such as open socket, closed socket and others. Also, the eye type include Flemish eye, pressed soft eye, spliced eye, thimble eye, standard eye, hard eye at both end.

①Vertical hitches are made directly from the crane hook to the load. Full rated capacity of the slings may be used but never exceeded. A tagline should be attached to prevent rotation which can damage the sling. A sling with a hand-tucked splice can’t lay and fail if the sling is allowed to rotate.

②Choker hitches reduce lifting capability of a sling, since this method of rigging affects the ability of the wire rope components to adjust during the lift, places angular loading on the body of the sling, and creates a small diameter bend in the body at the choke point.

There are various lays including right hand regular lay, left hand regular lay, right hand Lang lay, left hand Lang lay, right alternative regular lay and left alternative regular lay.

Wire rope slings are always packaged in plywood reel/plastic reel/wooden reel/coil in container, and then they will be palletized or put into a crate or a box.

There are various types of wire rope slings including slings with soft eye, hoist slings, slings with soft eye and two legs, steel ferrule secured slings, slings with Flemish eyes, ferrule secured endless slings, slings with steel-ferrule secured end stops, slings with swaged steel tie rod, slings with single hook, slings for crane, slings with sockets, slings with master link and two legs, slings with cuneiform connector, flat wire rope mesh slings, slings with master link and four legs, endless wire rope slings, container lifting slings for sea oil platform, large diameter cable laid slings, slings for lifting reinforcing steel bars, cable laid grommet slings, cable stocking, slings with spliced eye termination and others, and the main products are as following.

2-Leg bridle slings constructed of two wire rope assemblies that are attached to an oblong ring are designed for general lifting when the attachment can be made directly to the load. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object. The advantage of wire rope slings is that they are resistant to corrosion, heat, sunlight and most chemicals and they are custom built to meet your specific needs for any application.

3-Leg bridle wire rope slings constructed of three wire rope assemblies that are attached to an oblong ring are designed to handle unbalanced loads. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object. We carry a range of wire rope slings in our hire fleet with soft eye configurations at each end, available in various capacities and effective working lengths.

4-Leg bridle wire rope lifting slings constructed of four wire rope assemblies that are attached to an oblong ring are designed for balanced or unbalanced loads and for heavy lifts when the weight can easily be distributed over four points. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object.

The endless wire rope slings are orbicular, economical and adaptable slings with no fixed wear points, using special technology and the most advanced equipment and known for its softness, high tension and increased suspension points. They are suitable to lift and move tubes, pipes and long metal parts which suited in small and limited spaces and for high/large lifting loads, they are also adaptable for special bulk hoisting requirements of different conditions, such as transformers, shipbuilding and special machinery (where the warning mark locates cannot be used as lifting point)

Slings can be realized with galvanized or ungalvanized wire rope, special rope protected by strong PVC sleeve to resist against sharp edges without damaging the goods surface is also available as per your request.

7. According to the strength, wire rope slings can be divided into vertical breaking strength, chocker breaking strength, basket breaking strength, and except for standard eye size, thimble eye size, there are others of different eye hook capacity.

④Evidence of heat damage or if a wire rope sling having a fiber core is exposed to temperatures in excess of 200° F or if a wire rope sling having a steel core is used at temperatures above 400° F or below minus 60° F.

⑤Corrosion of the rope or end attachments or not laying and opening up of a tucked splice. Also, when end attachments that are cracked, deformed, or worn.

⑥Deformation—any visibly apparent bend or twist from the plane of the unbent hook. Throat opening—any distortion will cause an increase in throat opening of 5% not to exceed capacity.

⑦Avoid twists, kinks and knots before lifting, store wire rope slings where they will not be subjected to dirt, moisture, extreme heat, corrosion or mechanical damage.

⑧Protect the sling body against sharp edges and corners of loads, protrusions or abrasive surfaces. Sharp bends can distort wire rope and reduce its strength.

⑨Never "shock load" wire rope slings, the actual force caused by a sudden application of load can easily exceed rated capacities and damage slings and abruptly releasing a load can also damage the slings.

Warn Industries" 26502 M8000 vehicle recovery winch is an outstanding value for trucks, sport utility vehicles and Jeeps. Featuring a 4.8-hp series wound motor packing and a 8,000 pounds pull rating, as well as a 3-stage planetary geartrain, it provides advanced pulling power that is efficient yet quiet. Add this to its 100 feed of 5/16 wire rope with standard roller fairlead, a sliding ring gear freespooling clutch and wired remote and you have the perfect winching tool for work or play.

The Premium Series 26502 M8000 vehicle recovery winch from Warn Industries features the classic design that has been the staple of Warn"s longtime best selling winch lines. The M8000 has an 8,000 pound line pull rating and is just the right size for Jeeps, trucks, and SUVs. Its high power 4.8-hp series wound motor is powered via 72 inches color-coated leads attaching to your vehicle"s 12 volt battery, while its 3-stage planetary geartrain ensures that it is capable of getting any job done fast and quietly. The unit comes standard with 100 feet of 5/16 inches wire rope and a roller fairlead, but can also be fitted with a hawse fairlead (sold separately), and also includes an automatic brake and a handheld rubber controller with a 12 feet lead cord making for easy and safe operation in all scenarios. Additional features include a sliding ring gear freespooling clutch with stainless steel hardware and lever, a remote mount control box that allows for a variety of mounting options and a limited lifetime warranty*.

Shipyard Jib CraneDouble Girder EOT CraneHarbor Portal CraneContainer SpreaderElectromagnetic Spreader for Steel PlateHydraulic Grab Scrap GrappleCable reelDouble Flap Hydraulic GrabLifting Magnetic SpreaderCrane Hook BlockCrane Rail ClipsGB Standard Crane RailWire RopeLifting Belts SlingWire Rope SlingSingle Pole Slide Bus BarElectric Transfer CartWire Rope DrumRemote Wireless ControllerEnd CarriageSingle Girder Overhead CraneExplosion-proof CraneLadle Crane - for Molten Metal HandlingSuspended Overhead CraneGarbage Grab CraneElectromagnetic Crane for Steel SlagElectromagnetic Crane for Steel PlateC Hook Type Bridge Crane for CoilInsulation Bridge CraneHydropower Station Bridge CraneLow Clearance Overhead Crane1t~32t Gantry Crane5t~800t Gantry CraneSemi-Gantry CraneHydropower Station Gantry CraneHydraulic Gantry CraneGrab Bucket Gantry CraneFast Carrier 3t~20tFR model - RTG Crane 5-100tDB-Mobile Ganry CraneBS-Mobile Gantry CraneBH model - Side Lifting CraneCustomized RTG CraneRubber Tyre Double Beam Gantry CranePortable Gantry CraneFloor Mounted Jib CraneWall Traveling Jib CraneWall Mounted Jib CraneWire Rope Hoist - for Single Girder CraneWire Rope Hoist - for Double Girder Crane5t-41m Wire Rope HoistElectric Wire Rope HoistElectric Chain HoistFloating Dock CraneDock ArmShipbuilding Gantry CraneMobile Boat HoistBoat Jib Crane 1~12tBoat Jib Crane - with 4 HoistsRMG Crane for ContainerEL Container RTG CraneFixed Jib CraneOther

8613371530291

8613371530291