wire rope encoder manufacturer

Wire draw encoders consist of a wire draw mechanism and an encoder. The rotation of the drum, which is proportional to the length being measured, is recorded and output by an encoder. This facilitates positioning on linear measuring paths. SICK"s wire draw encoders support a large selection of interfaces and facilitate easy system integration for applications in challenging industrial settings. Different performance classes make it possible to select the ideal device for the application at hand.

A draw-wire encoder is a linear measuring device that consists of a spring-wound cable reel with a rotary encoder mounted on the hub of the reel. The cable is attached to a load which draws out the wire as the reel turns causing the encoder to rotate and transmit the amount of rotation either as a voltage pulse stream (incremental encoder) or digital word (absolute encoder). Alternatively, output can also be provided as an analog linear voltage output or even as output from a resolver.

Draw wire encoders are also commonly known as draw string encoders or string pot encoders, after a previous configuration known as a string potentiometer. Draw wire encoders are compact, easy to mount, and highly portable. They are tough, making draw wire encoders good solutions for environments like shop floors, manufacturing lines, and off-road vehicles. Common applications include telescoping cranes and industrial equipment like forklifts, oil and gas drilling equipment, and wood- and stone-working machines.

Other alternative names for draw wire encoders in addition to draw string encoders include rope-length transmitters, rope-length transducers, cable-length transducers, and yo-yo encoders after the way the spring-wired drum pulls the wire back when it is removed from the load.

The basic operating principle of a draw wire encoder is simple; a rotary encoder is coupled to a spring loaded-reel using a mechanical coupling device, internal to the housing of the reel. A cable is wound around the reel, usually a metal braid type. The braided cable is anchored to the drum of the reel and wrapped many times around it. The opposite end of the cable passes through an exit port of the draw wire encoder housing and is terminated with an anchoring device such as a clevis or loop to attach to the moving mechanism being measured. As the cable is pulled, the drum is rotated and the linear motion is translated into rotary motion, at which point the draw wire encoder encodes the information into an electric signal. In simplistic terms, the concept of a draw wire encoder can be likened to a fishing reel.

However, unlike the fishing reel analogy the drum is spring loaded to eliminate cable slack and therefore ensure accurate length measurement. Depending upon the linear distance being measured and the diameter of the draw wire encoder drum and cable, a multi-turn absolute encoder is used to provide a true absolute measurement over the entire range of the linear motion. Draw wire encoder measurement lengths can range from a few inches to tens of feet.

Resolution: the smallest increment the system can measure. For draw wire encoders, this will be determined by the smallest increment of linear measurement desired

It is important to note that the accuracy and repeatability of the draw-wire encoder as a system is not the same as the accuracy and repeatability of the encoder itself. Mechanical issues introduced by improper installation and alignment can compromise both operation and measuring performance.Learn the difference between encoder resolution, encoder accuracy and repeatability here

Draw-wire encoders are largely mechanical devices, so they suffer from many of the same error sources and failure modes as typical mechanical components. Both wire hub and encoder have frictional components that require regular lubrication and maintenance. The wire stretches over time, causing measurement error to drift.

Pay attention to duty cycle when considering a draw-wire encoder. They provide a good solution for a measurement or two per day but would not be recommended for the use case that requires them to move back and forth repeatedly throughout a shift. Because the assemblies are dependent upon lubrication, very cold temperatures can introduce error.

The right draw-wire encoder for every application. From precise to compact to robust and cost-optimized. Kübler offers a comprehensive portfolio based on different measuring lengths. In addition to all common interfaces, innovative features such as integrated inclinometers or redundant sensors make the difference. From analog to fieldbus – draw-wire mechanisms can be combined with a wide variety of Sendix encoders according to customer requirements. That"s why we offer countless ordering options and are ready to realize modifications and special solutions for you.

If you select “Type” and then select “Absolute Rotary Encoder” from the “Drop Down Menu”, you will now see only a small portion of the product offerings on the right side under the heading “Product Selector”

Company Eltra s.p.a. manufactures two series of wire encoders. These devices have already proven themselves in storage systems, extruders, elevators, presses, etc. Due to simplicity and compactness, they can be used in almost all industrial applications where linear measurement is present.

One of the main differences between the models is the rope material. The FE series uses a Dyneema rope, while the FES series uses a steel one. Both models consist of a rotary encoder and a wire draw mechanism.

After mounting the encoder to the reel letter "F" is added to its ordering code. For example, the encoder of the EL 53B series will become FEL 53B, and the EH 30 M will become FEH 30 M.

FE 1500 has a wire length of 1500 mm and a linear error of ± 0.75 mm. Drum circumference of the model is equal to 120 mm. The housing is made of painted aluminum and can work optimally at temperatures up to 70 °C (158 °F). The weight of the entire structure (without encoder) is only 500 g.

FE 4000 has a wire length of 4000 mm and a linear error of up to 2 mm. The housing mechanical characteristics is similar to the previous model. The IP protection level for both series is depend on encoder type. The final weight of the assembly with the case is 1100 g.

The devices of the FES seriesare available with a steel rope with length of up to 15 m and can be paired with an incremental or absolute encoder. This type is perfect solution for harsh environment as it has high resistance against mechanical damage.

FES 3000 has a wire with length of 3 m and diameter of 0.87 mm. Drum circumference is 200 mm. The maximum travel speed can reach up to 0.8 m / s. The main body may be made of aluminum or plastic. Its total weight is 350g (without sensor).

FES 6000 uses a rope with length of 6 m and diameter of 0.54 mm. The repeatability of the results here is identical to the previous series and equal to + -0.15 mm. However, it has faster traveled speed, which can reach up to 3 m/s. The housing is made of aluminum or plastic and has a weight up to 700g.

FES15000 has a 15 m wire with a diameter of 0.87 mm in its design. That feature makes series the owner of the biggest stroke length in entire manufactured products. This is the maximum distance that standard models can work with. The speed of movement can reach up to 2.4 m / s. The housing is made of aluminum die-casting. Available two models: with standard steel or synthetically coated rope. The total weight of the structure is 2500 g (without sensor).

All three series may work with temperatures up to +80C (176F). Before starting, it is recommended to make a 5 mm wire extension before starting point. This will help to prevent wire from snapping. Work should be carried out only along one axis, that is, along single line.

The SL 30 is designed for many years of use with a high activity rate. With a big number of options, the system can be adapted to many applications. Those wire draw mechanics are available as well approved for applications in explosive atmospheres, compatible with our AE _ 70.

The WPS are cost-effective products for simple measuring applications with lower accuracy requirements. In terms of precision it is compatible with our rotary encoders with magnetic scanning.

Empower devices to communicate alone analog or digital channels using wire rope encoder from our wholesale partners. We are ready to meet your incremental or absolute encoding needs. We"ve got software and hardware wire rope encoder for streaming as well as HD, HDMI, IP, and IPTV types. So much of our world is digital and these are the very components responsible for harnessing those signals, invisible to the naked eye, as they pass from the analog world into our integrated digital surroundings.

We have you covered whether you are supporting fully digital systems or mechanical systems communicating with the digital world. Be sure to keep absolute encoders on hand to support stable systems and incremental wire rope encoder on hand to support responsive, rapid-change systems. We have linear encoders to support mechanical application such as inkjet printers, machining tools, and semiconductors. But we also stock HD, HDMI, IP, and IPTV encoders for data streaming scenarios. In our world, data needs to keep moving, and we"ve got the wire rope encoder to help.

Act now to stock up on our wholesale quantities and competitive prices. These wire rope encoder are ready to ship to you so that your inventory is always ready for repairs or for new smart builds, from city planners and engineers, to the home hobbyist, these electrical components are fundamental to a smart, integrated digital system, machinery and devices from small to massive, and the internet of things.

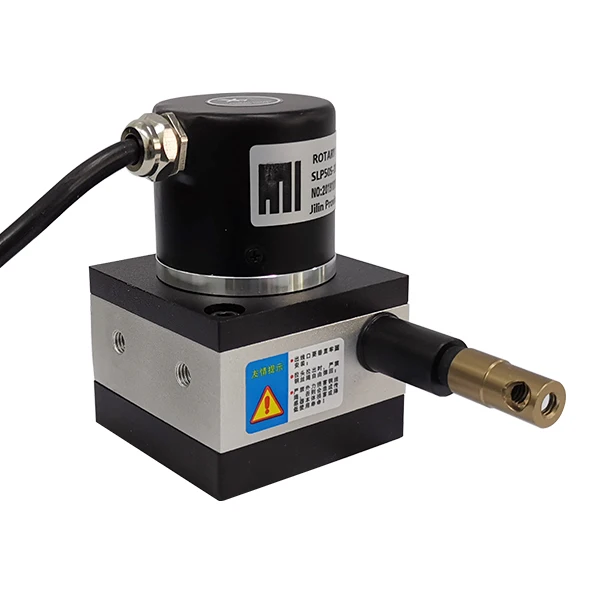

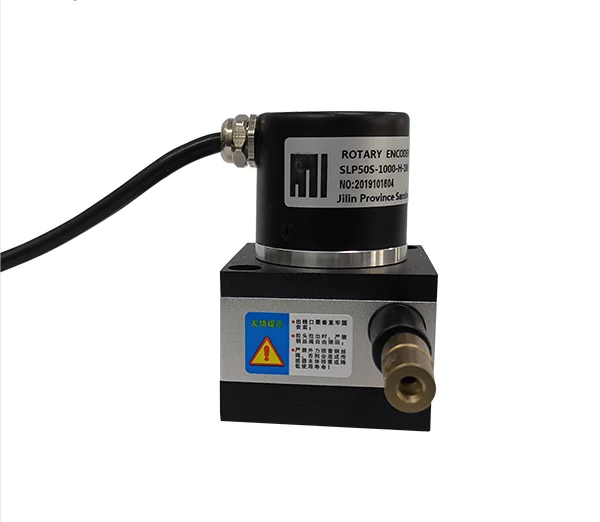

JILIN SANSHENG Technology CO., LTD. Is a high-tech enterprises, focus on R&D, manufacturing and sales for industrial encoder. The company strictly implement ISO 9001:2000 quality management system and CE certification, is leading technology, most complete varieties, most cost-efficient domestic encoder manufacturers.

As an important device of control system ,SANSHENG has more than 20 series and more than 100 varieties high quality products: incremental photoelectric encoder, magnetoelectric incremental encoder, photoelectric absolute encoder, magnetoelectric absolute encoder etc. Products are widely used in motor, CNC machine, packaging and printing, textiles, wind power, aerospace, turntable, servo control, divided circle, automated assembly line, turret tools and some industrial automation control field. Constant innovation and research are the most important magic weapon to success. SANSHENG technology team had visited to Germany, the United States, South Korea and other countries for learning and communication many times, introducing advanced encoder technology, promoting the product technology development, rapid achieve technology internationalization and product branding.

With advanced production equipment and exquisite production environment, SANSHENG had achieved the high quality production. Two newly developed automated assembly lines will better ensure product quality, improve production capacity. The technology had filled up the blank of domestic encoder industry, which will be put into use at the end of 2018.

Keeping the track of latest happening of this domain, we offer the best quality of Cable Encoder. Clients based across the country can avail these from us at industry leading prices.

Unbeatable economic pricing in large quantities and a small footprint makes this tough draw wire encoders the preferred OEM customer selection. Well engineered mechanics in combination with POSITAL’s fully digital rotary encoders means these draw wires do not loose accuracy even after one million strokes. Available in 2.4 m [94.49 in] and 7.5 m [295.28 in] measuring lengths.read more...

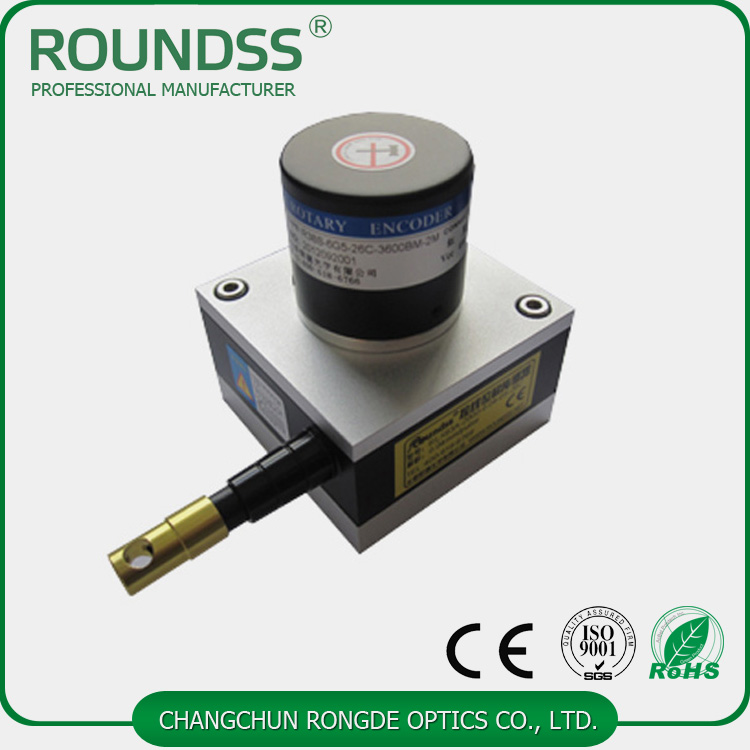

Wire-acuated encoder uses a highly flexible steel cable to measure linear positions. The cable drum is attached to a sensor element which provides a proportional output signal. The wire-actuated encoder has the features of sturdy and durable, easy to install, optional various output mode, small installation size, compact structure, large measuring stroke and high precision. Position measurements are performed with high accuracy and high dynamic response.

The wire rope displacement sensors use a high elasticity wire rope to measure linear motion. The steel wire scroll drives the wire rope displacement sensor device to transmit the same proportion of the output signal. The displacement, direction or speed of the moving object can be derived by measuring the output signal which is sent by the potentiometer.

Number of sensors can be connected in daisy chain mode of 4 wire or (n+3 wire connection). please contact Mr. Pavan Kinariwala(pavankinariwala@gmail.com) for more information on the same.

YUEQING YUMO ELECTRIC CO.,LTD is one of the China Linear Encoder manufacturer and supplier, as a professional Linear Encoder company, we have our own Linear Encoder factory. Welcome to buy our Linear Encoder products in wholesale. Our Linear Encoder products are cheap but we have good quality.

main including:linear encoder,incremental optical linear encoders,Draw Wire Displacement Encoder,Optical String Sensor,linear rope encoder,rotary encoder,incremental rotary encoder,coupling,Manual Pulse Generator,Solid Shaft Rotary Encoder,Hollow Shaft Rotary Encoder,Manual Encoder,With UVW Signals Encoder,Linear Encoder,Motor Encoder,Encoder Wheel,Encoder coupling and etc. Welcome to contact us.

8613371530291

8613371530291