wire rope failure analysis pricelist

Due to the wide variety of service conditions for wire ropes, they are susceptible to many types of inadequacies and failures. It is important for consumers to frequently inspect wire ropes for signs of wear and fatigue. Wire ropes will inevitably fail if not used according to manufacturing limitations or when routine inspections for fatigue and wear are not properly performed. Eventually, all wire ropes are removed from service when they meet established discard criteria.

Alps Wire Rope Corporation is herein referred to as the “Seller” and the customer or person or entity purchasing products (“Products”) from Seller is referred to as the “Buyer.” These Terms and Conditions, any price list or schedule, quotation, acknowledgment or invoice from Seller relevant to the sale of Products and all documents incorporated by reference herein or therein, constitute the entire agreement (“Agreement”) between Buyer and Seller regarding such sale. These Terms and Conditions shall be deemed to be an integral part of all acceptances by Seller. Seller reserves the right in its sole discretion to refuse orders.

6. FORCE MAJEURE. Seller shall not be liable for any act, omission, result or consequence, including but not limited to any delay in delivery or performance or non-performance due to acts of God; acts of Buyer; war; weather; sabotage; civil disturbances or riots; the prior performance of any government order; any order bearing priority rating or order placed under any allocation program (mandatory or voluntary) established pursuant to law, local labor shortage; fire; flood or other casualty; governmental regulation or requirement; shortage or failure of raw material, supply, fuel, power or transportation, breakdown of equipment; strikes, labor disputes or difference with workmen, regardless of whether or not Seller is capable of settling any such labor problem; unforeseen circumstances or any events beyond Seller’s reasonable control whether of similar of dissimilar nature than those above enumerated. If Seller determines that its ability to supply the total demand for the Product, or to obtain material used directly or indirectly in the manufacture of the Product, is hindered, limited or made impracticable due to causes set forth above in this section, Seller may allocate its available supply of the Product or such material (without obligation to acquire other supplies of any such Product or material) among itself and its purchasers on such basis as Seller determines to be equitable without liability for any failure of performance which may result therefrom.

9. MECHANICAL PROPERTIES; CHEMICAL ANALYSES. Data referring to mechanical properties of chemical analyses are the result of tests performed on specimens obtained from specific locations of the Product(s) in accordance with prescribed sampling procedures; any warranty thereof is limited to the values obtained at such locations and by such procedures. There is no warranty with respect to values of the materials at other locations.

14. BUYER’S RIGHT OF TERMINATION. Buyer may terminate the Agreement in whole or in part only upon reasonable advance written notice and upon payment to Seller of the sums below set forth; provided, however, that Buyer’s orders for non-standard Products are non-cancelable and nonreturnable after Buyer places its purchase order with Seller. Seller shall thereupon, as directed, cease work and transfer to Buyer title to all completed and partially completed Products and to any raw materials or supplies acquired by Seller especially for the purpose of performing the Agreement and Buyer shall pay to Seller the sum of the following: (a) the contract price for all Products which have been completed prior to termination; and (b) the cost to Seller of the material or work in process as shown on the books of Seller in accordance with the accounting practice consistently maintained by Seller plus a reasonable profit thereon, but in no event more than the contract price; (c) the cost F.O.B. Seller’s plant of materials and supplies acquired especially for the purpose of performing this contract; and (d) reasonable cancellation charges, if any, paid by Seller on account of any commitment(s) made hereunder. The provisions of this paragraph shall be without prejudice to the rights of either party for failure on the part of the other party to comply with the provision of the Agreement.

16. WAIVER. Failure or inability of either party to enforce any right hereunder shall not waive any right in respect to any other or future rights or occurrences.

18. RETURNS. Except as otherwise provided with respect to warranty defects in Section 7, advance written permission to return Products must be obtained from Seller. Such Products must be current, unused, catalogued Products and must be shipped, transportation prepaid as directed in Seller’s written permission to return such Products. Returns made without proper written permission will not be accepted by Seller. Credit for such returned Products will

A. Alps Warrants the Products only on the following conditions: (a) that the published strengths and other specifications apply only to new, unused rope; (b) that the mechanical equipment on which such Products are used is properly designed and maintained; (c) that such Products are suitable for the mechanical equipment on which they are used; (d) that such Products are properly stored, handled, used and maintained; and (e) that such Products are properly inspected and maintained on a regular basis during the period of use.

This warranty does not extend to any losses or damages due to misuse, accident, abuse, neglect, normal wear and tear, negligence (other than Seller’s), unauthorized modification or alteration, use beyond rated capacity, unsuitable power sources or environmental conditions, cosmetic damages, improper installation, repair, handling, maintenance or application or misused, abused, or operated on mechanical equipment improperly designed or maintained or which are used, supplied for use or made available for use in any nuclear application of which Seller has not been notified in writing by Buyer at the time of Buyer’s offer for the Products sold hereunder or any other cause not the fault of Seller. To the extent that Buyer or its agents has supplied specifications, information, representation of operating conditions or other data to Seller in the selection or design of the Products and the preparation of Seller’s quotation, and in the event that actual operating conditions or other conditions differ from those represented by Buyer, any warranties or other provisions contained herein which are affected by such conditions shall be null and void. If within thirty (30) days after Buyer’s discovery of any warranty defects within the warranty period, Buyer notifies Seller thereof in writing, Seller shall, at its option and as Buyer’s exclusive remedy, repair, correct or replace F.O.B. point of manufacture, or refund the purchase price for, that portion of the Products found by Seller to be defective. Failure by Buyer to give such written notice within the applicable time period shall be deemed an absolute and unconditional waiver of any Buyer’s claim arising from such defects. All costs of dismantling, reinstallation and freight and the time and expense of Seller’s personnel and representatives for site travel and diagnosis under this warranty shall be borne by Buyer unless accepted in writing by Seller. Products repaired or replaced during the warranty period shall be covered by the foregoing warranty for the remainder of the original warranty period or ninety (90) days from the date of shipment, whichever is longer. Buyer assumes all other responsibility for any loss, damage, or injury to persons or property arising out of, connected with, or resulting from the use of Products, either alone or in combination with other products/components. Section 8 applies to any entity or person who may buy, acquire or use the Products, including any entity or person who obtains the Products from Buyer, and shall be bound by the limitations therein, including Section 7. Buyer agrees to provide such subsequent transferee conspicuous, written notice of the provisions of Sections 6 and 7.

20. LIMITATION OF REMEDY AND LIABILITY. THE SOLE AND EXCLUSIVE REMEDY OF BUYER FOR BREACH OF ANY WARRANTY HEREUNDER SHALL BE LIMITED TO REPAIR, CORRECTION OR REPLACEMENT OR REFUND OF THE PURCHASE PRICE UNDER SECTION 7 OF PRODUCTS PROVEN TO HAVE FAILED TO MEET THE SPECIFICATION OR TO HAVE BEEN DEFECTIVE IN MATERIAL OR WORKMANSHIP AT THE TIME OF DELIVERY AT SELLER’S OPTION. SELLER SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY DELAY IN PERFORMANCE AND THE REMEDIES SET FORTH IN THESE TERMS AND CONDITIONS ARE EXCLUSIVE. IN NO EVENT, REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION (WHETHER BASED IN CONTRACT, INFRINGEMENT, NEGLIGENCE, STRICT LIABILITY, OTHER TORT OR OTHERWISE), SHALL SELLER’S LIABILITY TO BUYER AND/OR ITS CUSTOMERS EXCEED THE PRICE PAID BY BUYER FOR THE SPECIFIC PRODUCTS PROVIDED BY SELLER GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. BUYER AGREES THAT IN NO EVENT SHALL SELLER’S LIABILITY TO BUYER AND/OR ITS CUSTOMERS EXTEND TO INCLUDE INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES. The term “consequential damages” shall include, but not be limited to, loss of anticipated profits, business interruption, loss of use, revenue, reputation and data, costs incurred, including without limitation, for capital, labor, fuel, power and loss or damage to property or equipment. Buyer expressly acknowledges and agrees that Seller has set its prices and entered into the Agreement in reliance upon the limitations of liability and other terms and conditions specified herein, which allocates the risk between Seller and Buyer and form a basis of this bargain between the parties. It is expressly understood that any technical advice furnished by Seller with respect to the use of the Products is given without charge, and Seller assumes no obligation or liability for the advice given, or results obtained, all such advice being given and

Unfortunately, many phone calls into ITI Field Services begins this way, “We have had an incident with a wire rope and we believe the rope failed. How do we determine the cause of failure?”

Fortunately, the calls come in because wire rope users want to determine cause of failure in an effort to improve their crane, rigging and lifting activities.

A wire rope distributor received a hoist rope and sockets from a rubber-tired gantry. The rope and sockets were returned by the customer who believed the rope and sockets failed. The distributor hired ITI Field Services to conduct an analysis on the rope and sockets to determine the cause of the failure and to produce written documentation.

Based on the findings of the examination, fatigue-type breaks in the wires indicated that the wire rope lost significant strength due to vibration. There was no indication that the rope was overloaded. The poured sockets showed no evidence of abnormalities in the pouring method, wire zinc bonding length or the materials used in the speltering process. The conclusion of the inspection is that rope failed due to fatigue.

Wire rope examination is just one of the many services that is offered by ITI Field Services. ITI has some of the most highly-regarded subject-matter experts in the crane and rigging industry with experience in performance evaluations, litigation, accident investigations, manual development and critical lift planning reviews.

The CSIR is the recognised custodian of in-service mine rope technology, and performs the bulk of the statutory tests required for hoist ropes in the mining industry.As a National Key Point, the Wire Rope Testing Laboratory also maintains the largest historical database of rope tests in Africa.

Access to rope test data and certificates are provided via a user-friendly web-based system. Through this facility clients can get direct access to their test results, and the Department of Minerals and Energy can draw lists of tests performed by the various mines. Registered users can follow the link below to access the rope test database. (Rope Certificates) The rope test prices are also provided.

Safety is a crucial factor in the profitability of the mining industry. With thousands of workers transported up and down mine shafts each day, measuring the safety of hoisting ropes form an integral part of mine management.Strict laws cover the maintenance and testing of steel wire ropes.The Wire Rope Testing Laboratory focuses mainly on the destructive testing of these ropes.

For each hoist rope tested, the customer is provided with a detailed report that includes the breaking force, absorbed strain energy, force vs. elongation curve and an assessment of the condition of individual strands and wires at the point of failure.The report also alerts the customer to rope characteristics that breach, or are approaching, accepted performance standards. For example, a breaking force that is 90% or less than the new rope-breaking force. An assessment of corrosion and general rope lubrication is also provided.

The Laboratory is an advanced technology facility housing state of the art wire rope testing equipment.The machines used in the destructive testing of steel wire ropes have capacities ranging from 1 MN for small diameter ropes, to 15 MN for ropes up to 160 mm in diameter.

A 15 MN MFL tensile test machine which is able to accommodate large-diameter ropes as used in the oil drilling, bridge and shipping industries.It also caters for tensile tests on conveyor belts up to 1.2m wide and large-link chains as used on coal mine draglines and;

The CSIR Wire Rope Testing Laboratory is the government approved facility for statuary testing of winding ropes. Because of the CSIRs impartiality, professionalism and technical expertise, rope manufacturers locally and abroad also choose to have their wire rope samples tested by the CSIR. Existing clients include, but are not limited to, the following:

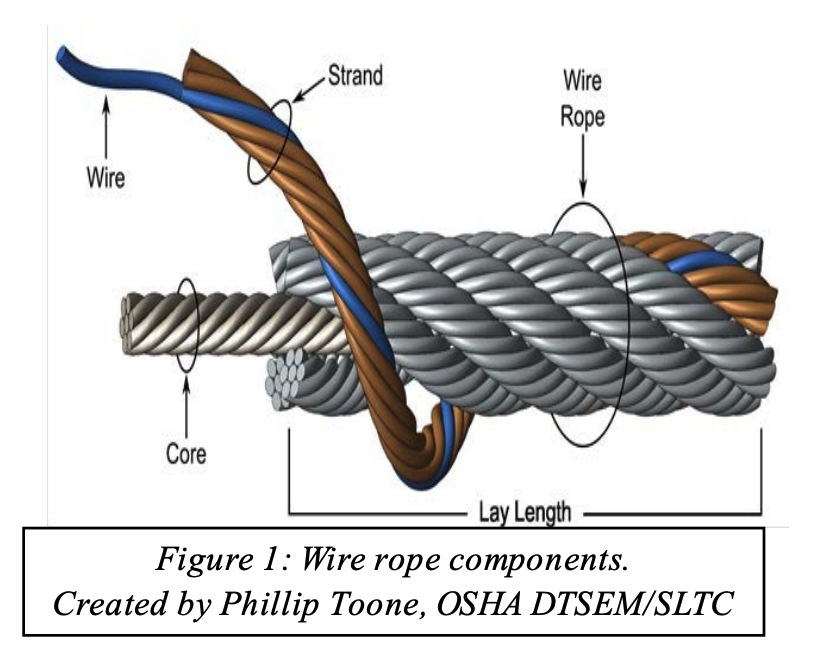

Wire rope isa type of cablewhich is made up of several strands of metal wirelaid or twisted into a braid or helix.Do you know how often your wire rope needs to be inspected? Wire rope inspections are vital to industries that use wire rope.

One of the most important purposes of carrying out wire rope inspections or testing is to oversee the process of depreciation in the wire rope. When any depreciation or deterioration is identified these wire ropes can cease to be used immediatelybefore it becomes a hazard. A great advantage of conducting these examinations is to analyse and identify if there is unexpected corrosion and destruction.

Commonly, there is a constant increase rate in the amount of wire rope breaks, during the lifespan of that wire rope. Wire ropes need to be inspected and tested as they have a limited life, like all consumable products. Early in the life of the wire rope (when it is starting to be used), the wires and strands of the rope settle into position and the breaking strength increases. Once it has hit its maximum, the breaking strength then decreases rapidly.

Wire rope inspections should only be carried out by highly trained professionals. There are 2 ways that these inspections are carried out on crane wire rope: Visual and Non-Destructive. Visual and no-destructive examinations are equally as important but a non-destructive wire rope test is a lot less frequent than a visual wire rope inspection. Destructive testing only takes place when specifically required by a company to find out what type of wire rope something is that has not been labelled and is not common practice in the general testing/inspections.

Visual inspection of wire ropeThe visual method is a simple yet effective method to check for external damage to a crane wire rope. Visually inspecting the entire length of rope is very important. The rope should be inspected 2 to 3 feet at a time and examined carefully at each stop. Whilst inspecting the wire rope it also cleaned with Lanotec and a wire brush.

Although tedious, it can determine many visual signs of wire rope damage, such as; kinks, bird caging, cutting, knots, flattening, crushing & heat damage (burn marks, discolouration of the metal). Wearing heavy duty gloves, an inspector will grab the rope and lightly move a rag slowly along the length of rope. Broken wires will often stick out (porcupine) and will therefore snag on the rag. Should the rag snag on a wire, the inspector should the stop and visually assess the rope condition. Broken wires do not always ‘porcupine’. Visual inspections should not be the only method relied on for inspecting crane wire ropes.

Due to the composition of a wire rope, the outer layer only represents approximately 40% of the metallic cross section of the rope and only approximately half of this is visible due to the strand twisting inside and out. That means you are only able to visually examine approximately 20% of the entire rope composition. You can only assume that the other 80% is in good condition.

Although the external 20% may look in good condition it may be concealing a great number of wire breaks and internal damage. Wire ropes with internal damage that have no signs of external damage can be extremely dangerous. This is why an internal wire rope inspection should also be completed. Internal deterioration is the primary cause of many rope failures, mainly due to corrosion and the normal progress of fatigue. Single-layer stranded ropes may be opened up slightly to allow an assessment of their internal condition, provided that they are at zero tension; though, some restrictions occur with large rope sizes. Permanent damage can be caused to multi-layer wire ropes if they are opened.

Internal inspection should always be carried out by a capable person. The method of inspection consists of firmly attaching two clamping jaws of appropriate size at a suitable distance apart to the rope. During the inspection of sections of rope adjacent to terminations, it is adequate to use a single clamping jaw, since the end anchorage system, or a bar suitably located through the end portion of the termination, may be used as the second clamp.

By the application of a force to the clamping jaws in the opposite direction to the rope lay, the outer strands separate and move away from the core. Care should be taken during the opening process to ensure that the clamping jaws do not slip about the outside of the rope. The strands should not be displaced excessively. When a limited opening is achieved, a small probe, such as a screwdriver, may be used to remove grease or debris that could obstruct observation of the interior of the rope. The crucial points that should be observed are as follows:

After inspection, a service dressing should be introduced into the opened part and the clamping jaws rotated with moderate force to ensure correct replacement of the strands around the core. After removal of the jaws, the outer surface of the rope should be greased. Since it is impossible to inspect the interior of the wire rope over the whole of its length, suitable sections shall be selected.

For wire ropes that wind onto a drum, or pass over pulleys or rollers, it is recommended that the lengths that engage the pulley grooves when the appliance is in a loaded condition be inspected. Those localised lengths in which shock forces are arrested (i.e., adjacent to drum and jib head pulleys) and those lengths that are particularly exposed to the weather for long periods should be inspected. Attention should be given to the length of rope close to its termination, and this is particularly important for fixed ropes, such as stays or pendants. This is where a visual inspection is complimented by a non-destructive test. .

WIRE ROPE 13133 b lr. nu••1t •. I" HoI,II.,

-. I USE OF WIRE ROPE .0.1,,1 ... Sir•• , .., Cot. COLUMBIA STEEL COMPANY 111 a d d itio n to Wire Rope. Columbia St ••l Com--.~ pany manulac:tur•• many other a, ••1 p roduct. on the Pacific Coaa" a nd alao aerv •• Cia di,lribulor lor Ih, following- Uni ted Slat •• St ••1 Corporation-.~ S u b,idiariet: Ame rican Brid g _ C o. C arne gie· lllinoh St •• l C o rp U."NUO,

WIIU": l"ltQDUC"TS""AII.II (STJ:EL Al

HopI.- U~r8 nee<1 no introduction to U"S"S Amcrican Wi re Hope. Not only i~ i\.i:! P:l.~t reputation for strength und d("p("udability knOlln to th("m, but new records for long life lire bringing back to tl](,111 nell" profits through ...... "- [o,r. FI .. lblo lowef op("rntinlo( costs. U"S"S Amefican Wi re Hope main- Hol.ll nl I • II tain~ t his lelldcT8hip in its field through the nlcrtncs."S of its mnkcr8 in lllltieipating the Ullin}" Hnd compl!"x nc{"ds of modern indu>;lry. The rop£"il iJ1uiitrntoo in this catalog are the ones most rrequently u~1. Special gmdes llml eoll~tructionij Clln be furnished Oil npplication. " "hutel"{"r the 1IC<"d may be, there is a TIg<"r Brand Wire n ope eon.!;truction especially .." a_".1 n •• H, """"• •• ,,"

=:t built to lbt mect that need, and our Engin("("ring and T echnical Department will gilldly COOIM"r.ltc Ilith you ill N o~·"I ... ~, !!Cle<:tin,l[ the right construct ion for {"very job. We have H.I.II", availnblc ~pe<"ial cntalogs co\"("ring Elevator Wire Hopc and Wire Li nes for the Oil Fit"lds, which we Shllll be glad to II<"nd you upon requcst l ....oli .. ...lIthl_, ond S.I: ••, U· S-S EXCE L.L.AY (llrc fo rm cd) W IIH~ nOI"E Un l."~or G.I•• nl .. ~ The datil on the following pages is bMCd on our Standard Wire HopeI!. In addition to the stlllldard constn;ction ". we 3re Ilrclmrcd to furnish ExC("lIay ( Prcformcd) Wire Hope. In making Exccll."lY Wire Hope available to indus- try-the Columbia SI("("I ComlxHlY wj",hes to emphllllize ... lttl"" s ...... that bnek of it lire the unexcelled 1113nufncluring facilities of this orgn nizlltion. "of c... Where indieated by service conditions-Exct"ll"ly Wire Hope offers exceptional operating find economy advan-;::.1 tages. Becllu;;e the wires used in its construction !Ire Prcfonllt"(l hefore assemhly th ey lie inert. nnd will not. fly a•••,h C. II T .... SIr.. d npnrt. T hioi fellture enllblcs cutting Of spliCing without ncce8$ity of seizing-no displacement of wircoi or stfllnds. UO"Hlio. 0" We are prcparcd to furnish Excelluy Wi re ltopcs in Uooellio. the sizes, COIISlructiOmi nnd grades dcsigl1:1ted by foot- notcs tit the bottom of IlInny 1>ageI! in this Clltnlog. Prices will be furnishro on req uest.

~ 18-8 STAINLESS STEEL WIRE ROPE, CORDS AND STRAND The resistance of U "S"S 18-8 Stainless Steel Wire Rope to hightempe ratures and other corrosive conditions is unique. These productsnot only offer marked resistance to oxidation at elevated tempera-tures, but also possess outstanding creep strength at high temperatures.At 1650 degrees F. U"S"S 18-8 scales comparatively little. It resistseven a moderate sulphur content in gases below 1500 degrees. In theprocess industries, where acids, fumes and steam play havoc withthe ordinary rope construction, U "S"S 18-8 Wire R ope is especiallydesirable. I t is immune to t hese industrial influences and this, com-bined with its resistance to fatigue, results in longer useful wire ropelife. The broader application of U"S"S 18-8 Stainless Steel Wire R opeto Industrial tasks is a move for lower maintenance and more de-pendable service. It is especially adaptable for use in connection withthe followin g elements : Acetic Acid (cold at any Ferrous Sulphate con centration) H y drogen P eroxide Acetic Acid (hot-up to Hydrogen Sulphide approxima t e ly 10 % ) Nitric Acid Ammonium Hydroxide P otassium Chloride Ammonium Salts Potass ium H ydroxide Alcohol Potassium Sulphate Acid Mine Water Photogra phi c Solution Acetone Salt Solution Bichloride of M e r cury (di- lute-anti septic strength) Sea W ater Carbolic Acid Sodium Sulphate Carbonated Water Sulphur Dioxide Citric Acid Sulphuric Acid (cold) Copper Sulphate Sulphurous Acid (cold) Calcium Brine Tanning Liquor C r eosote Wood Pulp Crude Oil Zinc Chlor ide Fruit Juices Zinc Nitrate U ·S·S 18-8 Stainless Steel Wire Rope, Cords and Strand are avail-able in Excellay Preformed construction-the wires and strands arepreformed-making splicing easie r. eliminating crankiness and theneed for seizing. Call or wri te your nearest Columbia Steel Company office for furtherinformation or catalog covering U"S"S 18-8 Stainless Steel Wire Rope,Cords and Strands. , Gen e ra] J nfor ma tion . T,u •• t..,.. ... H . ..... " s•••••,. H.I.II.I Lny of Wi re n Olle • • I.

-- Wire Rope is usua lly laid up Ill! follows: Ilcgular l.ay, lI ight Lay 1101"<: Wu-.. in ,beA" ra,,,!. laid to h l.o n .. H.hllo, i".the ldt,l,ra""" • • I.l aidri&bl. "0 tbe

Uo...II •• The diamelU of a ,,-i,e fOIN b Ihe dilmete. of tbe ", •• It ... hleb c.......ill end.....11 the II .. oo;b. hou]d be tabn jn ,au~n, a tri.. ••• U...I"••rope 10 lake Ihe I"eatell ao

General Information (Co.dnued) -= Wir., no pe G rllti COl Columbia Steel Compnnr American Wire Hope!! are pro-duced in IIbe: grades. These III t he order of increasing tensile8trengths ll re: Iron l\lild PLo w Steel Traction Steel Plow Sud Cast Steel StainiC!!8 Steel i\!onitor Steel I ro n Iron ill a Iol\" tensile strength material, vcry 80ft andductile a nd du e to its colUJlUrutively low tensile strengthis of limited usefulness. It IS used ror some guy ropes andto alimitcd extent for elevator ropes. T ra c tio n S teel Traction Steel is the latest addition to t he grades inwhich the Columbia Steel Company ropes arc produced.It. was originated to meet the requirements of ropes rorhigh speed electric traction elcvatol"ll. It i8 of sllCCiallyIIClectcd stock with n tcn.si lc strength approximate y twice that of iron. ClIst Steel A minimum tensile strength material toup; h and pliablennd of g-;neral utility, I t I\"M origina!l y enlled CrucibleCast Steel because of the ea rly method of mnking carbonsteel in slna]] han d operBted crucibles, It is harder thaniron and better resiiltll cxtemal ""car, "lilt! Plow S leel T his il! a grad c midway belll"een Cast Sleel and PlowSteel in temi lc strf"ngth and i:l tough and /lliablc, Thestrength is about two and one-half times t lat of Iron, .. I"low S ICt::1 T his is a tough, strong steel of highcr strength t han •Mild 1"10 "" Steel or ainlO8t three times M st rong M i ron , Stainless S tt:t:1 .. U"S"S 18-8 Stainless Steel iii next to the strongest ma-terial Ui!Cd in wire TOpe, It is of higher strength thnn •plow steel nnd only slightly exceeded in brea king strengthby Monitor Steel. ) n add ition to this ])ropcrty, U"S"S 18-8Stainless Steel is highty l"CI!.l!;ta nt to high tcmperaluree •and other corl"Ol!ive conditions, See pnge 2 for particulars,

•~ ___________C~O~L~U""~""""A~S~T~"~"~L~C~O"""~ "A~N~V"-______--"" T" •• •• I .. I0~ .,. Hu"... "" i\~ o .. itl)r S ted at,,4 ...4 Monitor Stet"l is the trade llIlIlIe fur Columbia Steel H...U •• • • It Comjltlny"s i mllrQ\"cd Plow Steel grade of rope. This is the strongcst KTade of sled used in wire rope manufacture

2. Diame te r of rope required. H, •• SoI ..I., H.I,U., 3. Cons tru ction - which means the com bination 01 st rand s nnd wircs-(6x7) , (6x19 ), (8x19), (6:1:37). L.....II .. (Ir on ), (Trllc ti o n S l ed ). (CII ~ 1 Sh.."c l), S"",,,hl,, 4. ~r:e~ior (Mil.1 Plow S l eel ), (1"1.. w). (SlUi nle~ ... ond alll •• 1

a. Slate whether hemp center, wire rope center. or wire strand cen ter. 6. Purpose for which th e rope Is Intended. -", , A descripti on of the work for which the line Is In· •••Stt..c.r., lended will grea tl y assist us In filling the order cor· rill II.,. rectly. For example, "Main Line" or " lI nu l Back" In I..ogglng- "Hotnry Casing Line" Ill> the OU Country. S ... o"h <:"11 "Drag Line" 01" "I·Jolst Line" tor shove ls, etc. Trott aorond

Proper Working Loads for Wire Rope It is never advisable for the working load of a Wi~Rope for general purposes, to ClCceOO one-filth of thebreaking strength. This means that the fnctor of safetyshould be not less than live. To determine proper work-ing load, divide the breaking strength by the proper factorof ~nfcty; c.g., 1\ \ " diameter Oxl!) Monitor Sted RopeiU18 !I breaking strc ngth of 42 tons and with n fuctorof !!afcty of five the proper worki ng load would be notover 8.4 10118. Factol1l of safety in excess of five, varying up to eightsnd even morc, Brc often required for safe and economicaloperation. The proper facto r of safety for a wire ropeshould be determined by careful and thorough cotlllidcra-l ion of all pertinent data. Such data should include allloads, acceleration, deceleration, rope speed, rope attach-ments, the numbe r, 8i~e and arrangement of a ll shcavesand drums, existing conditions causing corrosion andabrasion, length of rope in service, economical rope lifeand thc degree of dangcr to lifc and propcrty. No fixed arbitrary values for factor of safcty can beproperly set for yarious c1assifications of service. Theseclln 8IIfely wry, within limits, with thc conditions presenton individual illlltallutions and should any doubt a risc, WI:suggest that you consult \\1th us. • • • • COLllM lJl A ST U: L C O~ " ",\ ",y

_.- Common U luses o f " ?ir e n ope Fili lu rc8 Sl...... " H... II_, or the many forms of abuse of wire ro]"X"l"l. the Illost I. ,. coillmonly encountered are: Hopes of incorrect size, construct ion, or grade, Hop"es IllIowed to dr:lg over obstncle~. Hopes not. properly lubricated. h". F ... lb •• H01X!8 opernting over sheaves lind drums of innde- quate size. .. t. Hohtl .,

llolX!8 overwinding or crosswinding on druills. t~.1 HOIX!8 operating o\"er sheaves a nd drurns out of Flultl. alignment. H .."I •• , . 37 HOIX!8 operating over sheavcs a nd drums with im- properly fining groovcs or broken fl unges. ROIX!8 permitted to jUIllJl lihea\"cs. Hopes subjected to moisture or acid fUIllC$, HOIX!8 with improperly attached fitting.<. No.· S.I .. I ... H.. ,tl., HOIX!8 perillitted to untwist. Hopcs subjected to exCCS!;ivc he"lt. Hopes kinked, Hopes subjected to severe overloads due to ineflkielll lO"lnoli .. "wllCftln, opcmtion, • • , 0011. " Hopes destroyed by internal wear cn u>:!Cd by grit pcnetrtlting betwccn strands and wires. .. (l.,•• ... lI.I"~""

Lubrication of Wire ROI)C WiTe Hope may be considered to be a fine machine.T he individulLI wires, strands, and center urc the workingp:LTt!> of this machine. 1\ 8 one would not expet::t flny othertype of machine to operate !\:Itisfactorily without periodiclubrication one cnnnot expect to obhlill IlH,xim um ropeservi ce un lcss wire ropes arc properly preserved andlubricated. When selecting a wire rope lubricant, considerationshould be given to the type of work performed by the rope.The lubricant should not t"Onlaill aCids or other iU!,redieutsthat might corrode the Sled. It should be capable ofready penetrat ion through the spaces ootwecn the struuds.T he film of lubricant should be readily self-spreading andhighly adhesive and watef fepelbnt. A general rule for selecting II wire rope lubricnnt is thatthe highe r the speed at which the rope operatcs, thelighter the lubricant, or, technically speaking, the lowerthe viscosity of the lubricant. For low speed installations, such as shovels, cratlcs, andderricks, a heavy pctroleum oil or grefllSC with viscosity ofapproximately 1000 seconds at 210" Ie. applied hot willgive good lubrication. This same lubricant will also give satisfactory lubrica-tion to stationary fOpCS. Either an oil or grease can beused for stationary ropes provided it adheres to the ropeundcr aU conditions. For heavy haulage installations, such as slofJC ropes andlogging ropes, a lighter lubricant with a vi&."osity of from500 to 800 seconds at 210" .F . should be used. leor high speed hoisting ropes, such as mine hoists aneven lightcr lubricant is recommendcd. One with avistosily of 400 to 500 seconds at 100° Ie. givcs goodservice when automatic lubrication is employed. J n all cases, viscosity should be such that the lubricantwill cover the rope lind penetrate thoroughly, and with-stand pressures, but not be thin enough to run off the rope. Crude oils arc in most cases dctrimental to both the steel wires and the heml,l core of wire ropes, and therefore should not be used as Wife rope lubricantil. , T •• " •• l .. ~ •

, Only lIew oils Bnd gtetLSe3llhould be used for lubricating wi re ropes. It is poor erooomy 10 UI!() old lubricanl8. ." ... H. ~ l l"

Only by the u.se of IIew lubriCllnts is the wire rope user S........ H...II n, certain thnt. he i8 applying lubricantll free from grit and I . If acid contamination.

, Applying n wire rope lubricant hot will incrt"1I1lC illl penetration, nnd when cooled the lubricant will exist liS 0. plastic filler to lubricate the wires and st rnnds and keep ......t.,"-•• moisture from penctfllting to the core of the rope. This n ulbl . is most easily accomplished by pnssing n rope t hrough n Hol. II n, bath of hented oil. When this i~ not feasible, the rope I K" cn.n be lubricated by placing n drum of hCfllcd lubricant o\"cr the rope Ij() that the oil will run on to the rope 88 the ro\>C Pll88C8 bencll.th it. T his method is wasteful in that S_I., n .. IMo on y a portion of the lubricant running on to the rope Hol.II" ., rt"msiIl/J there. Wire ropes may be lubricated by Imnd applicstion of lubrictlnts. Whe n this mcthod is used, a I . J1

PIece of 8heepskin with the wool coat. on the imide is ~ommellded na a wiper. The wool should be thorough ly 6Ilturat(!d v.ith the wIre rope lubricant, and the flheepskin,, held around the rope which passes 810wly through it. H..... I•• I.. 1101.11., Wire rope is not necessnrily properly lubricated whe n, t h(! outside appears grel1sy. To be properly luhriCl11ed, the lubricant Illust \>cnet rate to the core. It is better to lI.. h C.."

• use a lighter oil or UbTicant that witt penetratc than to t HaIlOIl .. usc iL hCJlvy grease tha t will IIOt. tw lt.hl", In " 8 111.., Un l. .d .. While in 8torage, wire ropes should be ].:ept in a d ry ~.Iv.nl .. " place protected from the wcather, weH COUtoo with oil, and away from acid and acid fumes. When a used rope is 8tored, it should be thoroughly cieane

an example of rope 111 this c1assification. Special instruc4 l ions oovering lubrication of these ropes ncoomJlany each shipment, nnd should be carefully foHowed, 1I ", O. 1~COli T .... ",ront U..otll., n" UoooJ lI . ,

Drilling Lilies for S tanda rd Rig S l nlld ard tin es: ThCf!C lint"ll are usually made inCIIJl~ Steel grade. The Coarse or " lIard laid" has sixslralldll.IICV("fl wires 10 the strand, onc hemp core, and th ..."Soh L!lid" has six strands, ninctC("n wires to the strand,one h<"lI1p oore (either right or Idt lay). Orders shouldspecify "hich lay is desired. Standard linC8 are also made in Mild Plow Stecl, PlowSteel and ro lonitor Sleel, where gJ"("lltcr tellsile strengthis desired. Monitor Stl"<"i- lin("S nrc n."CQrnmend("{i for dN;"pholt"ll.

S t undll rd Cus illg Lines : ClIsing Lines, as thename indicatcs, are ul!e(l to handle the <"aSing. They aT.!gcnemlJy rec\"cd thro ugh wire rope blocks, known flSCl\sing blocks or sheavCII. }"or this purpose, ClIsl SteelnOlle may be used, six strands, 19 wires to the stlll.nd orCast Steel, Non-e:pinning 18 x 7 Hemp Core. Whl"f("greater strength is required i\ lild Plow Steel, Plow Steel orMOIlitor Steel should be u...-ru. Ori1ling o r Ca s illg Lines for HOlu ry Higs n ." T " . . . . I ..I •• ... Hu l •••

.....- • • It either Reguhr or Lang Lay. mnde up 6 strands, 19 wires each, with hemp center. Under certain conditions the rollowing gllld("8 Ilnd ("()Il- hlro IJ{ruclions are reoommcndcd: n .. lbl. 1001,110, For drums 20" in d inmcter nnd 1<"88, 6x21 TYI~ :\ 1 • • II

Lines, are used to operate II bailer in the hole to remove """J t he debris lind water from the hole IlS it is being drilled by standard cable too ls Ilnd to remove the muddy fluid after a hole is finished if drilled with rotary equipment. .0.1"01 • • • T hese linea are always right Illy and in si!ea ~ in. and smaller, six strands, 8Cven wires to the strand, h<"mp ...,,""" ,e..., centcr. Cast Sled grnde is gen<"Tftlly u/JC(1. FlOI Ro ..

I" COLUM IIIA sn : t!I. COM PA NY -= Cross Sect iolls of Wire Hope ConslruClions -= -= -= ~~,w -= J,"7 WIRC S TA,lI"lD GuARD RA IL Ihl2 GUY Rope -=• -= ~~, , :19 WIRe 51""1<10 "" Gu..."o Roll\. 7xl9 BFIlOCC CA81..£ -= .: .: ~~ .: 6xtO A[RO C~D .:

6 x 17 Sr:••U : F"AJ[NT COLUMU IA STEEL COM PA N Y . T.o.,.""""". ", Hul ... " ........ - Cross Sections of Wire n Oire Constructions HoItU., • 0 ••

AI"OI •• o " ..... d ondCord exIO"TvPE Nt~ WIRE ROPE COile "1 •• Ito..

5_h, n ..I~. U·S·S AMERICAN Hlhll . 1 ,.n WIRE ROPE AND STRAND MANUFAOURED on the PACIFIC COAST H •• "a." .."." H.hll., by S..h C.. ,

Trans tnis sion or Haulage Rope "Transmission" and "Haulage" are terms that areapplied to rope composed of six strands-seven wires tothe strand. The demand for rope of this construction fortransmission of power has lessened appreciably in recentyears. The principal use to which it is now put is forhaulage in mines, on inclined planes, on tramways and inthe yards of manufacturing plants. It is also used for drill-ing and Sand Lines in certain districts by well drillingcontractors. By comparing the cut, page 15, with the Hoisting Ropecut on page 20 you will note the coarseness of wires. Theyare nearly twice as large. This is a desirable feature, as inhaulage work for which service it is particularly applicable,it is dragged along the ground and over rough rollers, etc.,being subjected to much abrasive wear. Finer wires wouldwear through and break much more quickly. While the coarseness of the wires is an asset so far asabrasion is concerned, the rope is less flexible than one ofthe Hoisting Rope designs. This should be taken intoconsideration if tile rope is to be subjected to much bend-ing. For bending, where greater flexibility is required,ropes composed of finer wires are usually preferred. Made in five grades, or strengths, as follows:

The TIGER TRADE MARK is a symbol of Strength and Dependahility THE MARK FOR GENUINE AMERICAN WIRE ROPE Tra n s mission or Haula:;e Rope 15

3 .57 "lr,I... Stra nd .057!1 .29 2 .76 ond cord .04 7!1 . 21 2 .05 .03 ~ . 1" 1.43 FIOI R ••• .0374 . 12 1.17 S. ...h C.U I otem,<"

l~ no, lilted alxwe ooml>

W1 ~or:.,::gJ;:\~·I;~~=c\"."..f:~(~~y~:t~::

lnterm(!d l.A~ 11_"" wlrfl..,.,..,anto Uk~ the , .. , prleeol tbe "Ullalf:""!se. ".",~ C.II S"OTF..--Wl>en I"OPf>II ... me<1 above ....... Ivanl"""" add 26"\ to .t>o~e Tr •• ~ Itt.. d It.r.In~~!!.srl":;. ~"lI:"~ u.,"tI., , _ ~ ""t lilted ._e EItJ>et Wire Stn.1>4 of w ..... "Ope Cellle" ... n 111_ !.be b l"etltlllC I tf"fIIf\lI by about 7 )i <;" . eQlDr-d 0" ....... 1!wI 7 .. It. ADd kM lban " wtlllill. ueep\!oa ot ed talIe ,t w1re un. U-.lII.,

E:n:ellay Preformed Wire Rope can be furnillhed in tbe above colI, truetion and , i:«, . Prleet on reqUelt.. D.\. loa •• TrUlls nlission or IhlllJage Hope n".... p Co r.. 6 S .und_7 Wlr.,. 10 110" Si ra nd- I

IJlwn>O

...n.~"""!:e::~"I~~:C~D~:::~!"!.~~S"o!~·:.rt{~ ::"W:p: Ellher W"" Btnnd or W ..... Rope ~otcr w1J1 1DCf"ftM llIe ~-"

Tn",N "Standard lloitti . .·· .. I term I ppliM to rope ""In~ of .u.trando. nil>eteen ."j...., to tbe .trand. "!"he ""j...., btin, .",aIIer tb. nthOde in tb. tid oo".truction .ho,",,, o n P140 16, tbe rope i. moraftuible, and ~.n be ""..... readily pa.Med aronnd .heu. . .nd dr .......of moae •• t. aile. The .... mponent .. i ..... beln, fine" bo ... yer tb,6%ll} I. not upeeted to Itand .. much .b...... ion ... tbe "".fU. li.ul-ece Rope. Th, 6d9 rope b b:r f.r tb, moot nnlverully "oed. It iI employedrno", utenalvely .nd in • ,,~.~. veriety 01 wo. k tbln .ny eOn-.Unction tb.t .... n .. ""r•• t" ..... I n tb, Iron .nd Trec tion 81..,l l r"deeIt iI oom"" only lW!d 0" _lUlU and frei,b! eleval ....: ... bil, In tb.e ..t St..,l, Mild 1"1",," St..,l. 1"10"" Ind Monilo< iIt..d ... il .. _ I iomi".... quarri .... Ore dc><=k •• co.l d .... k•• 0" em" .... d m::l~ .., .t-eam.ho" ... ,". pi"" drh·e ... d e.ritke, t .. m ... ~... .,.blu"."" ,"d. in r..,t, onaimoot e"eO")" k"",,-n 1)1"" cI modem WIre ""I"" !,lSi",appa .. tUl •• Iao10. well drilling. A eemul ..",tillY 01 the c-roee """tion 01 the ,tandud boietin,rope iUUlt .. ~ abo ..... 0li0.-. iii. indlvMIual II ....... a",und • hen" p:~:""bt;~ :~~~ :in" I~m~c<>°:lt~":t~: :If..~J~ "~t,!I1".~WUllnti ..... of two typel the t ~ .. metimee need, vii .:

Three-e i.e

~ "" .0" 1)4 .31 2. 70 .07 . 23 2 .05 Fl •• fl .... .06 ~ 1 . 16 1.43 .06}i U . 10 .07 Soo, . l h Coli lo ""~a", ",..,."r on,.., rope ..... ttl lake the lIot!>rI..,,,r the """l&l1e" "" .... T... _ 8.,a. d NOTt; -Wbe" ""Pee named ab,w e a ,e ralvanbe

Wb"tI Rope Cea\el" will I _ tboo b l"flU.lol: ... Ua" MII • • u...mo. otl"C~tb J"or ,.19 b y . _ , 1 )S"~.. £len .or 1"0"""", _e :n. E.ceJlay Preforrned Wire Rope call be furnished in tbe abo ..., coo.structiou a nd s i3:es. Pri ~ on request. Dala luI .." S tandard El e vator Ho is ting R ope (0 S ... .. , I. - 19 Wir ,"" "0 "h " Sua nd _ 1 H e mp Co • .,

Tb_ oablta ..... Kenor&lLy ..,p!ll!t!d In.tHo " ", l{" "0" ,.;;,,11 •. Two"""""ru.. Io"" ... lnoonlTnon ...... I.o.. "I"M 1101 prt_ lor 6.111 "1"0 .ho.... """"" ~."9."dh l. under labl. M. 1"01" h19. _ n- II-!>&lIe 28 E!{cdlu y I"re (orllu...J Wire HOlle can be (u r ni s ht.-d intb e .. h..,·c c ..... struc tion and 8;"_. l)rices On re

t )1)of M. \110 e~li lll~ 1)_" ob...... . . - . Exc~lIa y P rerormed Wire Ro pe can be furni shed in ~th e a h(...", colilltr-uction and lI ize&. i"ricefli o n ~u ea t.

3 ." S ... oth Coli .12 li . 10 2." T... k StroM" In~.n"e

~ 3 2% 2),( I . 60 I .23 .90 42 . 32 2 237 ~ • "" . 227ol % 2 .63 10 . 0 .10 .51 135 .17 .15~ ~ I" l )j 1),( .40 .31 10 .8 li. 8. " IYs .23 0 .3 . 14 70l .137ol It. I . 16 10 "5 I u: . 13 " ),( 2 .!1 Intermedl.Ot.coi ... o! ",I.o""",.,e to ta~c .he Un,,"l"""! .he neUlal1lc,"I... .... NOT~;-When """""""" na lllf"(l a bove .. re I!lllvanl..,.! add 25% "0 above ...IIotll and a,,~lY brLan. ",pe dieC<>unt. however .hlo .·ILL lower the b",. klngI.",,,,,tn bY about 10% ..,..,~orn:e::~e~t~I:W:.~~~~~ya!~

8613371530291

8613371530291