wire rope failure causes price

In 1998, a crane load line broke while lifting the south topside module of the Petronius platform, dropping the module into the Gulf of Mexico. The cost was estimated to be around 116 million US dollars. Since 1999 more than 60 people have been killed as a result of wire ropes breaking and more than 65 associated injuries.

Not many people appreciate that there are literally thousands of wire rope designs, most of which can be put into a specific category. According to BS ISO 4309 2010 there are currently more than 25 categories of crane wire rope, each with differing characteristics and also different discard criteria. Deterioration can be measured, counted or calculated and the wire rope eventually taken out of service based on sophisticated discard criteria published in chosen standards, codes of practice or users handbooks.

Unfortunately there is no simple answer to either of these questions. All wire ropes will eventually break due to corrosion, wear or fatigue even if they are maintained and used properly. Unpredictable wire rope failures will inevitably occur, quite often when you least expect it if the discard criteria is ignored, or those using the equipment are ignorant of it.

James Dawes of Topeka, Illinois, was killed in 2008 after being struck by the boom of a Link-Belt crane; the accident was caused by the boom hoist wire rope breaking. The crane rope had been inspected, but a report said that the inspector failed to reject the rope showing a high number of visible wire breaks. Premature or unexpected wire rope failures can also be attributed to poor manufacture, incorrect handling and storage, poor installation technique, poor selection or fitting of its termination, infrequent or inadequate inspection and poor maintenance. Of course there is always the possibility that mechanical damage can occur and this is usually attributed to human error.

It is necessary, particularly during offshore operations that frequent inspections are carried out over the whole length of the working part of all steel wire ropes. The frequency of inspections should be based on the severity of use and risk assessment and particular attention should be paid to the critical areas of the wire rope; areas that are frequently running over sheaves, compensating sheaves and the rope termination to name a few.

If a wire rope has not been subjected to an abnormal environmental condition such as excessive heat, chemical attack or any corrosive solution and it has not been the victim of any form of mechanical damage, then trained operatives and inspectors can reasonably predict the length of time the steel wire rope is likely to last. That prediction, of course, will be dependent on the knowledge and experience of those making it coupled with known facts about the rope, its current condition and the application it is running on. The Inspector should be aware of the previous rope’s history, capacities of loads and the reeving systems employed together with the frequency of use etc.

Various standards and codes of practice have been written by recognized bodies and institutes based on the experience of experts or representatives of corporate organizations who have a vested interest. These standards do offer guidance on when a wire rope should be removed from service based on wear, abrasion and fatigue amongst others things, but none of these standards have any legal status except when they are called up by contract. Indeed they can all be supported or overturned in a court of law by an expert.

The users handbook, or more importantly the safe use instructions do have legal status. In many parts of the world these days, suppliers of cranes or any machinery for that matter, issue safe use instructions with new equipment. Modern applications employ modern wire rope and, in some cases, sheaves and pulleys that are made with materials other than steel. Original equipment manufacturers of such applications may impose discard criteria for the wire rope that is stricter than those in chosen standards. By law the user must follow manufacturers’ instructions.

Wire ropes will deteriorate much more quickly if they go dry and are allowed to remain in that condition. Tests have proven that a dry rope will lose up to 60 % of its expected life if it is not re-lubricated. There are differing schools of thought as to how wire rope should be lubricated. Some believe that a thin lubricant should be applied using a paintbrush. It is thought that this method allows the lubricant to penetrate. Experience has proven however, that thin penetrative lubricants will easily drain away or fly off in hot climates.

Another school of thought, and the one I stand on, is that grease should be pressure lubricated into the rope. This method, if applied properly, will ensure that the grease penetrates the rope pushing out the old lubricant with it and any possible corrosive agents such as salt water and sand. Any lubricant that is used must be compatible with the type that was applied previously and it is a good idea to consider the environment as well.

In any event, wire ropes usually announce that they are about to break. A series of individual wire breaks can be heard. These are likely to go on over several seconds and continuing for up to ten minutes before ultimate failure. Therefore, if operatives understand the warning signals, expensive incidents could be avoided.

Figure 2 shows two pieces of the same rope, the bottom portion quite clearly shows a progression of wire breaks. The operator was able to put the load down before disaster struck. The root cause of this fault was core deterioration brought about by internal corrosion.

To answer the other question on accountability, the list is extensive. Usually the first suspect is the wire rope manufacturer and that may be where the problem lies, but very often that is not the case. What if you were supplied the wrong rope for the application? Maybe you ordered the wrong rope or your buyer bought it from a cheap unapproved manufacturing source.

Perhaps your supplier is responsible, maybe he provided you with a rope that was produced to the wrong specifications. Would you know the difference? Perhaps you were sold a rope that had been stored in the suppliers or manufactures stock for a number of years and, whilst it was there, it hadn’t been properly maintained. Maybe the rope had been badly handled or installed incorrectly. The list of possibilities is endless.

In 1999 a ropeway in the French Alps snapped causing 21 deaths. In 2003, a ropeway wire rope snapped and 7 people died and a further 42 were injured. In 2007 a crane wire rope snapped at New Delhi’s metro, the entire structure tumbled down crushing workers underneath, six people were killed and 13 more were injured. In 2009 26 people were killed and 5 people were injured when a rope failed in a mine and a further 6 people were injured when a lift rope broke inside London’s Tower Bridge.

If you find yourself in the unfortunate situation after the unthinkable premature failure of a wire rope, then you might like to know that there are independent analytical services capable of determining probable cause. One of these is Doncaster Analytical Services Ltd (DAS), they have an independent metallurgical laboratory providing factual analysis and testing of wire rope for any reason (contact Mr Shui Lee, Technical Director, Tel +44(0)1302 556063, email: shui.lee@doncasteranalyticalservices. com).

You do not need a wire rope to fail in order to learn. Careful analysis of discarded ropes can also give you valuable information about your application, the way it operates, and the rope you have been using.

Based on this information, a trained, skilled and experienced inspector will be able to advise on a better crane or wire rope design, or to an improvement in maintenance procedures and safety.

Safety should be the top concern of anyone employed in rigging. When working a job where so many lives could be cut short due to carelessness, there is no excuse for laziness or distraction. Rigs should be inspected thoroughly for any potential areas of breakage. It is important for employees to gain a fluency in the causes of wire rope damage and failures so they can spot areas of weakness and fix them before they grow into a dangerous problem.

Corrosion issues in wire ropes are one of the most difficult causes of wire rope damage and failures to identify, which is why it is one of the most dangerous. Wire rope failures due to corrosion are typically the result of poor lubrication. You can measure some amount of the lubrication by looking at the pitted surface of every individual rope, but this tells us little of the damage done to the core. Since it is difficult to identify the full spectrum of corrosion, this break stands apart as mysterious and deadly.

Abrasion-caused failure occurs when the wire rope has been damaged by irregular contact with hoist sheaves and drums or when it awkwardly rubs against an object such as shelving or a crane girder. It is also often caused by poorly grooved drums and sheaves. You know the wire ropes have experienced abrasions when the wire ends are worn thin.

When hoist ropes go through repetitive bending over sheaves, cracks will eventually develop in the individual wires. Sections of the wire that move over the sheaves develop the worst fatigue. The damage can often be seen by the naked eye. Whenever one broken wire appears due to fatigue, more will follow. Since these issues are essentially the result of wear and tear on the rope wire, they are considered a normal part of operating a crane.

Being fluent in safety measures is just as valuable to an employer as competency with cable rigging hardware. People who know how to spot areas for potential failures can keep themselves and their coworkers secure, which saves time, money, and even lives.

Unfortunately, many phone calls into ITI Field Services begins this way, “We have had an incident with a wire rope and we believe the rope failed. How do we determine the cause of failure?”

Fortunately, the calls come in because wire rope users want to determine cause of failure in an effort to improve their crane, rigging and lifting activities.

A wire rope distributor received a hoist rope and sockets from a rubber-tired gantry. The rope and sockets were returned by the customer who believed the rope and sockets failed. The distributor hired ITI Field Services to conduct an analysis on the rope and sockets to determine the cause of the failure and to produce written documentation.

Based on the findings of the examination, fatigue-type breaks in the wires indicated that the wire rope lost significant strength due to vibration. There was no indication that the rope was overloaded. The poured sockets showed no evidence of abnormalities in the pouring method, wire zinc bonding length or the materials used in the speltering process. The conclusion of the inspection is that rope failed due to fatigue.

Wire rope examination is just one of the many services that is offered by ITI Field Services. ITI has some of the most highly-regarded subject-matter experts in the crane and rigging industry with experience in performance evaluations, litigation, accident investigations, manual development and critical lift planning reviews.

The often solid structure of cranes makes them subject to abuse, error and neglect. Usually this does not create immediate problems or failures. Heavy duty cranes, in particular, normally have a relatively higher rated capacity and even a 100% overload would probably not be of any immediate danger. However, the degradation of wire rope will dramatically increase as a result of the overload. Wire ropes are already exposed to considerable wear in normal use. The wire rope is the most vulnerable part of the hoist.

Several studies of overhead travelling cranes show that the large majority of dropped loads are caused by one of two types of wire rope failure: rope damage and overstressing. Preventing these two causes would reduce the frequency of load drops by about 90%.

Often the operator is to blame - trying to lift loads that are too heavy, or operating with the rope out of the sheaves. Insufficient maintenance is also a frequent cause. Whatever the reason, if the load drops it is usually because the wire rope has failed.

Wire rope will break if it is structurally damaged or if it is overloaded. Damage will be caused if the rope is misreeved, with the rope leaving its grooves on the drum and/or sheaves. This is usually caused by off-centre lifts, hoisting while the load is swinging, or by slack in the rope system, which can cause the rope to leave a groove and be cut or "kinked" under load, or wrap around the drum shaft or sheave axle and cause rope breakage or shaft failure.

• Over capacity lifts: sometimes over capacity lifts are unintentional, as when the weight of the load is unknown or when the load is attached to something. Unfortunately many overloads are intentional and condoned or even mandated by management. Over capacity lifts are frequently rationalised by the misconception that cranes are so conservatively rated that even a 200% overload is not a real problem. Even if this was true the wire rope is subject to wear and degradation in use, which can substantially decrease its safety factor. Overloads can cause immediate failure but, more often, they have a cumulative effect on wear and fatigue. Wire rope is subject to considerable degradation over time even in normal use. Overloads increase rope wear and eventually become the immediate cause of failure.

• Load hang up: this happens when a load in motion snags on something or when a load is stuck. The kinetic energy of the moving and/or rotating machinery causes overstress on the crane machinery, construction and on the wire rope.

• Two blocking: this is when the hoist upper limit switch is not functioning or another malfunction results in overhoisting to the point where the load block runs into the hoist trolley structure. The inertia of the rotating machinery and the stall torque of the hoist motor cause an immediate wire rope failure. A likely consequence is that the load block and any suspended load will fall.

Wire rope is the most vulnerable part of the overhead travelling crane"s load carrying system. It accounts for a considerable part of the maintenance cost of overhead travelling cranes. How can wire ropes be better protected and thereby increase the safety and cut the maintenance costs of crane operations?

The second way to protect wire rope is to use overload guards. Experiences and studies from many years of using overload guards in overhead travelling cranes in Scandinavia and Western Europe confirm the safety and financial benefits of using them. The overload guard makes the responsibilities, decisions and work less of a burden for the crane operator. It can also protect the hoist against two-blocking if the hoisting speed is low.

When selecting an overload guard certain characteristics should be sought. It must be easy to install, sealed to protect it from dust and humidity, and tamper-proof. It should also be easy to adjust the settings. High accuracy (±2% of maximum capacity of the device) and repeatability of the set tripping are also important. Finally, overload guards installed directly on the wire rope must themselves be designed to cause a minimum of wire rope wear.

They work in one of two ways. The tension meter type of load guard is made for controlling cranes, lifts, tension control of belt conveyors and for other automatic power-sensing load control. The pull rod movement operates one to five switches through spring-loaded contact points. Normally this instrument is built into the dead end of the wire rope i.e. the stationary part.

The second type of mechanical overload guard is based on rope deflection. The limiter is attached to a stationary part of the wire rope and the rope is deflected through a slight angle between the two wheels and the clamping jaw. When loaded the rope has a tendency to straighten and the pull-rod will start to move out when the tension in the rope exceeds the calibrated force of the load cell. This movement actuates the limit switch.

Usually this type of overload guard is calibrated at the factory but it can easily be reset at the crane site. An advantage of this system is that it does not need to be recalibrated when the wire rope is changed.

It is important that the deflection angle of the wire rope is small, otherwise it will influence the wear of the wire rope. This type of overload guard does not affect the construction of the crane, and so the crane does not need to be re-certified.

A constant voltage is fed to the foil gauge from the transducer amplifier. A signal is received in return, which is proportional to the force in the load cell. The signal can be processed in the electronic unit for such functions as slack rope switching, overload control, load indication, and recording the number of hoist operations.

An advantage of electronic overload guards is that intelligent technical solutions can be created. One load cell connected to an electronic unit can, as previously mentioned, control against slack rope, give a warning when approaching overload, switch off the hoist at overloading, and provide a voltage or current signal for load indication instruments.

There are two types of electronic transducer: load pins and those that work according to the rope deflection principle. The latter type is attached to a stationary part of the wire rope and the wire rope is deflected through a slight angle between the two wheels and the clamping jaw, the same as with the mechanical overload guard.

The difference is that the force applied by the tendency of the rope to straighten under load is transmitted to the load cell instead of straight to a switch. The load cell could also be a bending beam. Normally the output is amplified and converted into a 4-20mA signal before being processed in the electronic unit. This type of power transducer does not affect the construction of the lifting equipment and many load cells of this type can be set at the factory which reduces the amount of installation work on site.

In many types of load pin the strain gauge foils measure the shear forces in the section between the face of the load (the rope wheels) and the support.

Whatever system you choose, go to an experienced supplier for maximum reliability. A reliable overload guard will protect your people, your property and avoid losses.

But on one particular day in early May of 2009, it wasn’t a boom reaching toward the big Texas sky that was causing people to stop and stare; it was one that was lying in a heap just beside the water, lattice sections bent and lacings twisted into mess of mangled steel and frayed wire rope. “I got the call to investigate the cause of loss on a Manitowoc 888 that was being used to drive underwater pilings at a dock in Port Isabel,” says JR Bristow, of Bristow Truck and Equipment Specialists, an organization based in Ridgewood, NJ that provides failure analysis and appraisals, among other things, for heavy equipment. “The operator was hoisting the boom when it just sort of gave out and crashed to the ground. No one was hurt, but the boom was in bad shape. The initial reserve was set at $500,000.”

Though a half million dollars wasn’t a total loss – the crane was valued at $1.5 million – it was a pretty hefty price to pay for something that, as it turned out, could have been avoided. On lattice-type cranes, booms are raised and lowered using boom hoist wire rope, and when that wire rope shows surface wear or corrosion, or worse, has broken wires within the rope strand, it can fail. It’s usually just a matter of time.

The subsequent investigation that followed revealed that the wire rope used to hoist the boom of the Model 888 had been in an out-of-service condition for quite some time, due to lack of proper lubrication.

“An examination of the failed boom hoist wire rope revealed that the wire rope had gone without the proper lubrication, which was the responsibility of the insured per the attached lease agreement,” Bristow remembers. “I also noted significant broken wires within the rope strands at an average of six to 12 per strand lay. Clearly, if the insured had performed a daily inspection of the boom hoist wire rope as required, that incident would not have happened.”

The broken strand condition that Bristow observed was caused by load cycles that occurred during boom up and boom down functions that were part of the daily operation of the crane. Simultaneous compression and expansion of the wire rope usually occurs as it travels over the hoist sheaves, and that causes the gradual deterioration of the strand wires.

Like many other segments of the crane and rigging industry, the nuances of wire rope are complicated and varied. Considerable time, money and resources have been invested in new technology, new inspection suggestions and new manufacturers. And rightly so. As was the case in Bristow’s example earlier, there’s quite a bit at stake in terms of both human capital and equipment cost.

Python High Performance wire rope, a wire rope manufacturer that has produced a number of resources to assist people in understanding and ultimately purchasing wire rope, clarifies the structure of wire rope on its website www.pythonrope.com.

Python’s site explains that a typical wire rope can contain hundreds of individual wires. These wires are fabricated and formed to operate at close bearing tolerances to one another. When a wire rope bends, each of its many wires slides and adjusts in the bend to accommodate the difference in length between the inside and the outside bend. The sharper the bend, the greater the movement, and the greater capacity for stress on the wire rope.

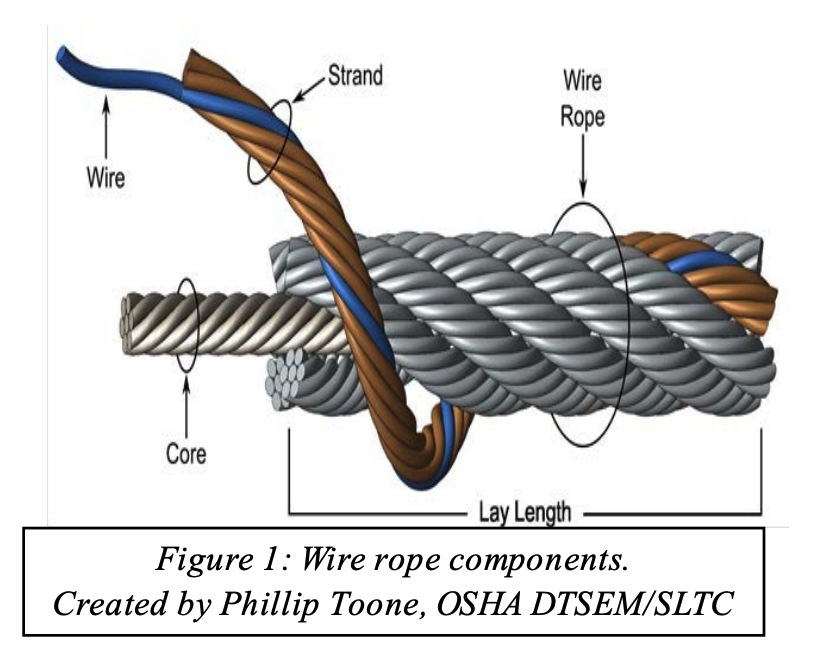

While manufacturers of wire rope are many and varied, each of the wire ropes they produce have three basic components:The wires, which form the strands and collectively provide the rope strength

According to Python’s site, the greatest differences in wire ropes are found in the number of strands, the construction of strands, the size of the core and the lay direction of the strand versus the core. But what does that mean for the layperson? What should he or she look for when purchasing wire rope?

Tony Fastuca, vice president Python America & High Performance Products, says that most people buy rope based on four ideal standards. “Abrasion resistance, fatigue resistance, flexibility and strength. Those four typical standards often weigh into a purchase decision: he says. “A buyer sometimes has to give a little in one area to get a bit more in another, but a lot of buyers are looking for a good balance of those four standards.”

Whereas other products usually come with an expected lifespan, wire ropes don’t really have an average operational life. “There are records that exist of wire ropes getting two to three years of use, sometimes longer,” says Fastuca. ”But it’s about the level of wear on the rope, not the length of time it’s been in service.”

Just as the crane itself needs to undergo frequent and period inspections, the wire rope does, too. Fastuca talks of the so called “A,B,Cs” of wire rope abuse – abrasion, bending, crushing.

The principle goal of a wire rope inspection is to find potential problems before they manifest into incidents or serious accidents. Inspections should be performed slowly and methodically, with a keen eye for corrosion or broken wires or sections of rope that look questionable. Because the reality of wire rope is that it will fail if it becomes worn out, overloaded, damaged, misused or improperly maintained. It can lead to huge headaches for companies that try to take shortcuts or don’t properly maintain it – a risk that just isn’t worth taking.

The wire rope is the most critical functioning component on a rig crane, and lack of proper inspection procedures is the root cause of 90% of cable failures, said Andy Schott, senior mechanical supervisor for Diamond Offshore Drilling, during a panel sessionat the 2012 IADC Lifting and Mechanical Handling Conference & Exhibition, 18-19 July in Lafayette, La. “The key word is accountability,” said Mr Schott, who oversees more than 115 cranes worldwide. “All the paper rules and procedures won’t stop wire rope failures. Only you as individuals can stop failures by improving operator awareness and competency requirements for operators and mechanics. This involves everyone from the operator to the offshore installation manager (OIM) to the mechanic to third-party inspectors.”

Joining Mr Schott on the panel were Leon Schopping, lifting & hoisting principle technical expert for Shell, and Roman Predl, offshore crane rope manager for TEUFELBERGER Seil GmbH,a manufacturer of products for lifting, conveying and securing cargo. The three experts emphasized that pre-inspection and ongoing inspection procedures, proper lubrication and tension maintenance, along with an awareness of crane type and usage can minimize wire rope failures, enhance safety and reduce costs.

“The cost of not doing a 30-minute or hourlong inspection can result in millions of dollars of downtime and transportation expenses,” Mr Schott said. He noted that API’s recommended procedures call for visual inspections of wire rope by a qualified crane operator prior to use, monthly and during quarterly and annual inspections. But operators also should take into account specific circumstances, such as weather conditions and degree of use, in establishing inspection protocols. They should routinely check the mechanical aspects of the wire rope path, remove lubrication to check groove depth, inspect the sheave bearings, retainers, fleet angles and how the wire is laying on the drum.

To increase accountability for wire rope safety and performance, Diamond Offshore has enhanced reporting procedures with a Daily Crane Operators Report that requires the signature of the operator, rig mechanic, OIM and barge supervisor after every shift. “We have had a reduction in wire rope failures and reductions in crane problems and breakdowns, downtime and costs associated with these issues,” Mr Schott said.

Among the challenges in inspecting wire ropes is knowing when and what to look for when only 20% of the 10,000 ft (30,000 meters) of cable on a fully rigged crane is visible, Mr Schopping said. A key component of the wire that is not visible is the core.

“Inspect the wire where it is expected to fail,” he suggested. “Wire rope is good at handling tension. The problems start when the wire bends. Determine where most of the bends occur during the lifting operation, for example, the end terminations.”

He also cautioned against routinely replacing wire ropes as an alternative to inspections or investing in quality. He cited the case of a North Sea operator that routinely replaced wire rope every year, yet experienced an increase in incidents because inspection procedures became lax. “Crews must conduct routine inspections because lives depend on them. A broken wire rope will result in fatalities.”

Proper wire rope installation procedures are also critical, Mr Predl said. “Before installing the wire rope, inspect the complete conveying system to ensure there are no negative imprints, avoid fleet angles and check the groove sizes of the sheaves or drum (if grooved, which is common in the US) and the actual diameter.” Other factors to consider include:

“Lubrication is important because it protects the wire rope from corrosion and reduces friction,” Mr Predl advised. “Keeping the rope lubricated will extend the life of the cable.”

Wire ropes are largely used in marine environment or for rigging purposes. They receive considerable loads and thus suffer a great deal of mechanical damage throughout their service life. Moreover, research has shown that the major cause of wire rope failure is excessive deterioration and corrosion, lack of maintenance and inspection, and wrong usage resulting in early discarding, reduced safety and replacement cost increase.

Sometimes damage can be easily detected, while in other cases fractured wires may occur on the inside. Hence, wire ropes should be inspected and maintained by the right person (competent person assigned by the company), to assure they’re in perfect condition. Regular inspectionsensure high rope performance, long service lifetime , safety of personnel and equipment, and reduced operating costs.

All ropes (synthetic, high modulus and wire ropes) should be inspected before and after an operation. This guideline ensures maximum safety for both a ship’s personnel and equipment. Even though it’s difficult to determine the exact service life span of ropes, there is a way to have a more precise estimation about their efficient lifecycle. Calculating the exact time ropes have been in use (e.g mooring time, mooring conditions, weather and tidal conditions) is the answer. All in all, rope inspections should occur at least once a year.

Inspecting wire ropes in particular, comes with great responsibility. Inspection results should be recorded, and any defects noticed have to be reported and addressed properly. Some defects can be repaired, while in some cases replacing a wire rope is inevitable.

Periodical inspections ofvessel deck equipment is also crucial for maintaining the good condition of wire ropes. The condition of the drum, chocks, bitts, rollers, sheaves, cable clamps and other end fittings, affect the rope’s performance, threads and cords. Make sure to mark these parts during your overall inspection.

In order to help marine officers and staff conduct successful wire rope inspections – and keep an up-to-date record of them – we have created an inspection solution that helps in maintaining and monitoring a ship’s ropes and deck equipment.Learn more about Katradis inspection Neptune Solution

When calculating mass using F = Minimum Breaking Force, according to the wire rope’s diameter, you can determine the Minimum Breaking Massand therefore the wire’s max strength. When calculating mass using F = Safe Load according to the wire rope’s diameter, you can determine the Safe Load Mass,which is the advised load for this rope diameter.

The strands of a wire rope absorb the majority of the tensile force applied on the rope. Their design and manufacturing standards affect the level of fatigue resistance and resistance to abrasion. An easy way to understand which rope design is suitable for each purpose, is the wire rope classification.

Wire ropes are classified according to the number of strands in each construction and the number of wires in each strand. For example, a classification of 6X19 means that a wire rope of this type always has six strands, but its wires could be 15-26 per strand. This is because 19 is not the exact number of wires, but the classification of a wire number range.

Visual inspections are a common and fast way to assess wire rope condition. Both the standard and rotation resistant wire rope inspectionprocesscomply with the same four steps of examination. A ship’s crew can perform them as follows:

Steel wire rope distortion is obvious in most cases and can easily be identified by the inspector or the ship‘s crew. It usually occurs if load is suddenly applied or abruptly released (shock loading), or even if swift torque is forcefully induced.

Although not all of these deformations make the rope absolutely dangerous to use, they all may cause ropes to wear unevenly in time. This means inspections should take place more often, and distorted ropes should be handled with caution.

The rag and visual inspection is a good method for regular inspection intervals. The inspector pulls a rag along the rope trying to find broken wire cords. If the rug gets snagged by the rope, the inspector has to stop and assess the wire rope’s condition. Extreme caution should be exercised during the visual inspection, and under no circumstances should this method be the only one used to inspect wire ropes.

Tip: When you encounter a protruding wire end, bend it back and forth manually, until it separates from the wire. This will protect neighboring wires from wearing out.

Diameter reduction is a critical factor in steel wire rope wear and if not properly taken care of, it can result in rope breakage. Excessive abrasion, loss of core mass, corrosion or inner wire failure are all factors that contribute to diameter reduction.

To get an accurate measurement of the rope’s diameter, measure the rope at three different points at least 5 feet apart. Take the average of these three measurements to determine the true diameter.

Any measurements showing a reduction of ⅓ or more, indicate that a replacement should follow without delay. A diameter reduction of less than 1/3 still requires attention, and the inspector or the ship’s crew should be on guard in the next scheduled wire rope inspection.

Failure from abrasion or corrosion is a result of deficient deck equipment inspection or insufficient wire rope lubrication respectively. Internal corrosive damage is more difficult to identify than any other types of degradation. In most cases, the damage has progressed more than the external signs suggest.

Wire rope storage plays a significant role in the rope’s operation life.Wire rope corrosion and pitting can be avoided if ropes are safely stored in a clean, cool, dry and well-ventilated place. Steel wire ropes should not by any means rest on the floor, and should be protected from water, dust or any chemical fumes. Long term storage requires periodic greasing, turning the reel upside down for preventing grease dripping and possibly re-winding to another reel with larger inner tube diameter.

Wire ropes should be maintained with periodical lubrication. In order to prevent internal corrosion, a pressure lubricator is suggested to be used. In this case, a small amount of grease is used to lubricate the rope internally, while the deck stays grease-clean. Pressure lubricators clean the rope before they grease it so that the new grease enters a clean rope. The type of grease used is very important for maximum protection and greasing efficiency.

Steel wire ropes exposed to dirt, grime and other contaminants, have to be cleaned with a wire brush and petroleum (unless a pressure lubricator is used). Optimal cleaning of wire ropes can extend their service life and guarantee safe operations.

The reeling process is of high importance for the longevity of wire ropes. To protect them from being damaged, it is important that the surface of the drum is clean, smooth and dry. Improper reeling may cause wire-rope strands to spread or get flattened, when in contact with one another, as successive layers are being spooled and upper layers apply pressure on the lower ones.

Katradis S.A. offers a wide range of top quality wire ropes for shipping (mooring and hoisting operations), fishing and construction purposes. Our wire ropes have greater resistance to fatigue, and they distribute tension force equally among the rope strands. They are less likely to kink, providing higher staff safety and assuring operation success.Choose your new wire ropes

In October 2018, a hoist rope on a tower crane at a construction site broke while lowering a load which then fell to the ground. Although no-one was injured, this was a dangerous incident that could have had very serious consequences. Investigations are continuing.

This information applies to running ropes on tower and mobile cranes (i.e. hoist and luffing ropes), and primarily to hoist ropes – as the latter are typically exposed to greater wear rates.

rope sheave dimensions including diameters and sheave profiles—a rope sheave needs to match the rope profile as much as practicable. If the sheave is too tight or too loose the rope will be damaged

tensile grade of the rope wires—higher tensile strength wires may appear to provide longer life, but in reality this may not always be the case. The individual wires may be less flexible and prematurely fail depending on factors such as the numbers of operational cycles, working loads applied and potential shock loading

Crane owners are encouraged to only use steel wire ropes of a specification (make, construction, strength) that is both approved and supplied by the tower crane manufacturer for the particular make and model of crane. Where rope of an alternative specification is used:written verification from the crane manufacturer that this rope may be used with the tower crane should be obtained

an inspection of the rope should be carried out by a third party competent person with expertise in the inspection of steel wire rope (National Association of Testing Authorities accreditation of the company carrying out the inspection is one way of helping to demonstrate the quality of this inspection).

It should be noted that internal damage to steel wire ropes can occur without obvious external indicators and is not always readily detectable by visual examination. The competent person may specify non-destructive testing on the rope in addition to a visual examination. The competent person may also prescribe an enhanced inspection program.

While it is acknowledged that the crane operator carries out a basic pre-start examination of the ropes on the crane, additional examination of the rope for internal damage will require the input of people who have greater skill and experience in wire rope inspection.

In 2018, a company was fined $50,000 after a fatal incident involving an 8 tonne mobile yard crane. Although they did not contribute to the fatality, the crane had multiple defects: defective wheel brakes; a defective park brake; broken boom operating wire lifting cables; non-operational headlights, taillights, warning light; and a non-operational horn. Systems were in place for maintenance of plant, but this crane had not received appropriate mechanical repair for a long time.

8613371530291

8613371530291