wire rope flexibility chart factory

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility, and the ability to handle bending stresses. Different configurations of the material, wire, and strand structure will provide different benefits for the specific lifting application, including:Strength

However, selecting the proper wire rope for your lifting application requires some careful thought. Our goal is to help you understand the components of a wire rope, the construction of wire rope, and the different types of wire rope and what they might be used for. This will allow you to select the best performing and longest-lasting wire rope for the job at hand.

A wire rope is, in reality, a very complicated machine. A typical 6 x 25 rope has 150 wires in its outer strands, all of which move independently and together in a very complicated pattern around the core as the rope bends. Clearances between wires and strands are balanced when a rope is designed so that proper bearing clearances will exist to permit internal movement and adjustment of wires and strands when the rope has to bend. These clearances will vary as bending occurs, but are of the same range as the clearances found in automobile engine bearings.

Understanding and accepting the “machine idea” gives a rope user a greater respect for rope, and enables them to obtain better performance and longer useful life from rope applications. Anyone who uses a rope can use it more efficiently and effectively when they fully understand the machine concept.

Wires are the smallest component of wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, monel, and bronze. The wires can be manufactured in a variety of grades that relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire rope.

Strands of wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope.

The core of a wire rope runs through the center of the rope and supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibers and steel.

Lubrication is applied during the manufacturing process and penetrates all the way to the core. Wire rope lubrication has two primary benefits:Reduces friction as the individual wires and strands move over each other

The number of layers of wires, the number of wires per layer, and the size of the wires per layer all affect the strand pattern type. Wire rope can be constructed using one of the following patterns, or can be constructed using two or more of the patterns below.Single Layer – The most common example is a 7 wire strand with a single-wire center and six wires of the same diameter around it.

Filler Wire – Two layers of uniform-size wire around a center with the inner layer having half the number of wires as the outer layer. Small filler wires, equal to the number in the inner layer, are laid in valleys of the inner wire.

Seale – Two layers of wires around a center with the same number of wires in each layer. All wires in each layer are the same diameter. The large outer wires rest in the valleys between the smaller inner wires.

Warrington – Two layers of wires around a center with one diameter of wire in the inner layer, and two diameters of wire alternating large and small in the outer later. The larger outer-layer wires rest in the valleys, and the smaller ones on the crowns of the inner layer.

On a preformed wire rope, the strands and wires are formed during the manufacturing process to the helical shape that they will take in a finished wire rope.

Preformed rope can be advantageous in certain applications where it needs to spool more uniformly on a drum, needs greater flexibility, or requires more fatigue-resistance when bending.

Direction and type of lay refer to the way the wires are laid to form a strand (either right or left) and how the strands are laid around the core (regular lay, lang lay, or alternate lay).Regular Lay – The wires line up with the axis of the rope. The direction of the wire lay in the strand is opposite to the direction of the strand lay. Regular lay ropes are more resistant to crushing forces, are more naturally rotation-resistant, and also spool better in a drum than lang lay ropes.

Lang Lay– The wires form an angle with the axis of the rope. The wire lay and strand lay around the core in the same direction. Lang Lay ropes have a greater fatigue-resistance and are more resistant to abrasion.

A steel core can be an independent wire rope or an individual strand. Steel cores are best suited for applications where a fiber core may not provide adequate support, or in an operating environment where temperatures could exceed 180° F.

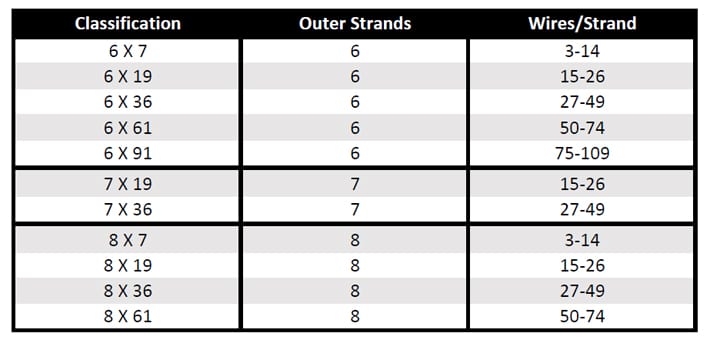

The classifications of wire rope provide the total number of strands, as well as a nominal or exact number of wires in each strand. These are general classifications and may or may not reflect the actual construction of the strands. However, all wire ropes of the same size and wire grade in each classification will have the SAME strength and weight ratings and usually the same pricing.

Besides the general classifications of wire rope, there are other types of wire rope that are special construction and designed for special lifting applications.

Some types of wire rope, especially lang lay wire rope, are more susceptible to rotation when under load. Rotation resistant wire rope is designed to resist twisting, spinning, or rotating and can be used in a single line or multi-part system.

Special care must be taken when handling, unreeling, and installing rotation resistant wire rope. Improper handling or spooling can introduce twist into the rope which can cause uncontrolled rotation.

Compacted strand wire rope is manufactured using strands that have been compacted, reducing the outer diameter of the entire strand, by means of passing through a die or rollers. This process occurs prior to closing of the rope.

This process flattens the surface of the outer wires in the strand, but also increases the density of the strand. This results in a smoother outer surface and increases the strength compared to comparable round wire rope (comparing same diameter and classification), while also helping to extend the surface life due to increased wear resistance.

A swaged wire rope differs from a compacted strand wire rope, in that a swaged wire rope’s diameter is compacted, or reduced, by a rotary swager machine after the wire rope has been closed. A swaged wire rope can be manufactured using round or compacted strands.

The advantages of a swaged wire rope are that they are more resistant to wear, have better crushing resistance, and high strength compared to a round strand wire rope of equal diameter and classification. However, a swaged wire rope may have less bending fatigue resistance.

A plastic coating can be applied to the exterior surface of a wire rope to provide protection against abrasion, wear, and other environmental factors that may cause corrosion. However, because you can’t see the individual strands and wires underneath the plastic coating, they can be difficult to inspect.

Plastic filled wire ropes are impregnated with a matrix of plastic where the internal spaces between the strands and wires are filled. Plastic filling helps to improve bending fatigue by reducing the wear internally and externally. Plastic filled wire ropes are used for demanding lifting applications.

This type of wire rope uses an Independent Wire Rope Core (IWRC) that is either filled with plastic or coated in plastic to reduce internal wear and increase bending fatigue life.

Remember, wire rope is a complex piece of mechanical machinery. There are a number of different specifications and properties that can affect the performance and service life of wire rope. Consider the following when specifying the best type of wire rope for your lifting application:Strength

When you select a piece of rope that is resistant to one property, you will most likely have a trade-off that affects another property. For example, a fiber core rope will be more flexible, but may have less crushing resistance. A rope with larger diameter wires will be more abrasion resistant, but will offer less fatigue resistance.

At Mazzella Companies, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

If you’re looking for a standard or custom specified wire rope for your lifting project, contact a Lifting Specialist at a Mazzella Companies location near you.

We stock well over 2,000,000 feet of wire rope in our various locations … ready for immediate delivery! We provide wire rope assemblies, and manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies.

Wire rope and cable are each considered a “machine”. The configuration and method of manufacture combined with the proper selection of material when designed for a specific purpose enables a wire rope or cable to transmit forces, motion and energy in some predetermined manner and to some desired end.

Two or more wires concentrically laid around a center wire is called a strand. It may consist of one or more layers. Typically, the number of wires in a strand is 7, 19 or 37. A group of strands laid around a core would be called a cable or wire rope. In terms of product designation, 7 strands with 19 wires in each strand would be a 7×19 cable: 7 strands with 7 wires in each strand would be a 7×7 cable.

Materials Different applications for wire rope present varying demands for strength, abrasion and corrosion resistance. In order to meet these requirements, wire rope is produced in a number of different materials.

Stainless Steel This is used where corrosion is a prime factor and the cost increase warrants its use. The 18% chromium, 8% nickel alloy known as type 302 is the most common grade accepted due to both corrosion resistance and high strength. Other types frequently used in wire rope are 304, 305, 316 and 321, each having its specific advantage over the other. Type 305 is used where non-magnetic properties are required, however, there is a slight loss of strength.

Galvanized Carbon Steel This is used where strength is a prime factor and corrosion resistance is not great enough to require the use of stainless steel. The lower cost is usually a consideration in the selection of galvanized carbon steel. Wires used in these wire ropes are individually coated with a layer of zinc which offers a good measure of protection from corrosive elements.

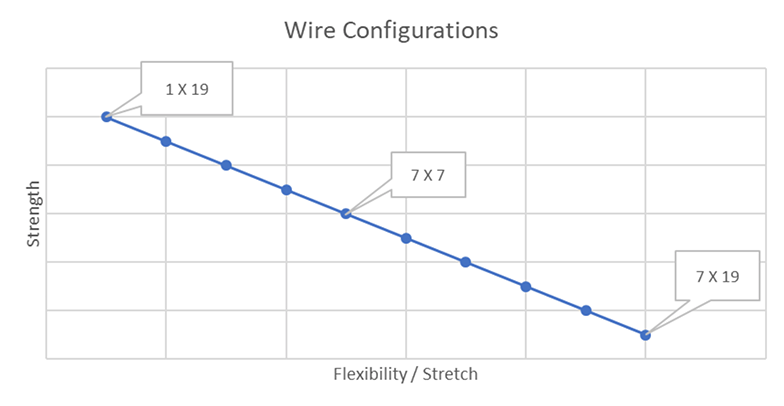

Cable Construction The greater the number of wires in a strand or cable of a given diameter, the more flexibility it has. A 1×7 or a 1×19 strand, having 7 and 19 wires respectively, is used principally as a fixed member, as a straight linkage, or where flexing is minimal.

Cables designed with 3×7, 7×7 and 7×19 construction provide for increasing degrees of flexibility but decreased abrasion resistance. These designs would be incorporated where continuous flexing is a requirement.

Selecting Wire Rope When selecting a wire rope to give the best service, there are four requirements which should be given consideration. A proper choice is made by correctly estimating the relative importance of these requirements and selecting a rope which has the qualities best suited to withstand the effects of continued use. The rope should possess:Strength sufficient to take care of the maximum load that may be applied, with a proper safety factor.

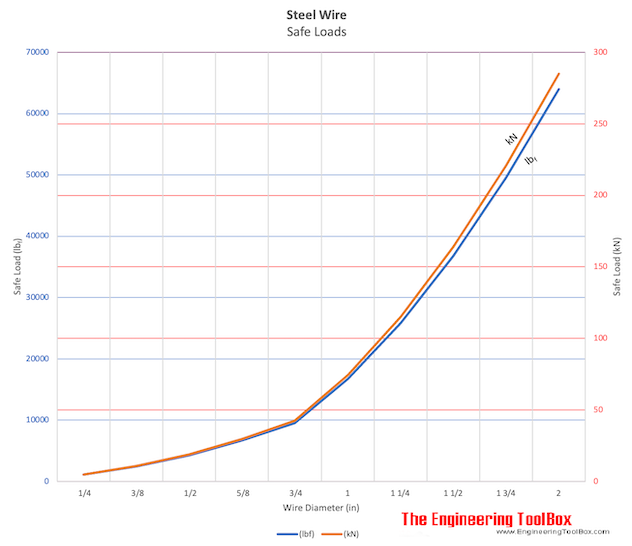

Strength Wire rope in service is subjected to several kinds of stresses. The stresses most frequently encountered are direct tension, stress due to acceleration, stress due to sudden or shock loads, stress due to bending, and stress resulting from several forces acting at one time. For the most part, these stresses can be converted into terms of simple tension, and a rope of approximately the correct strength can be chosen. As the strength of a wire rope is determined by its, size, grade and construction, these three factors should be considered.

Safety Factors The safety factor is the ratio of the strength of the rope to the working load. A wire rope with a strength of 10,000 pounds and a total working load of 2,000 pounds would be operating with a safety factor of five.

It is not possible to set safety factors for the various types of wire rope using equipment, as this factor can vary with conditions on individual units of equipment.

The proper safety factor depends not only on the loads applied, but also on the speed of operation, shock load applied, the type of fittings used for securing the rope ends, the acceleration and deceleration, the length of rope, the number, size and location of sheaves and drums, the factors causing abrasion and corrosion and the facilities for inspection.

Fatigue Fatigue failure of the wires in a wire rope is the result of the propagation of small cracks under repeated applications of bending loads. It occurs when ropes operate over comparatively small sheaves or drums. The repeated bending of the individual wires, as the rope bends when passing over the sheaves or drums, and the straightening of the individual wires, as the rope leaves the sheaves or drums, causing fatigue. The effect of fatigue on wires is illustrated by bending a wire repeatedly back and forth until it breaks.

The best means of preventing early fatigue of wire ropes is to use sheaves and drums of adequate size. To increase the resistance to fatigue, a rope of more flexible construction should be used, as increased flexibility is secured through the use of smaller wires.

Abrasive Wear The ability of a wire rope to withstand abrasion is determined by the size, the carbon and manganese content, the heat treatment of the outer wires and the construction of the rope. The larger outer wires of the less flexible constructions are better able to withstand abrasion than the finer outer wires of the more flexible ropes. The higher carbon and manganese content and the heat treatment used in producing wire for the stronger ropes, make the higher grade ropes better able to withstand abrasive wear than the lower grade ropes.

Effects of Bending All wire ropes, except stationary ropes used as guys or supports, are subjected to bending around sheaves or drums. The service obtained from wire ropes is, to a large extent, dependent upon the proper choice and location of the sheaves and drums about which it operates.

A wire rope may be considered a machine in which the individual elements (wires and strands) slide upon each other when the rope is bent. Therefore, as a prerequisite to the satisfactory operation of wire rope over sheaves and drums, the rope must be properly lubricated.

Loss of strength due to bending is caused by the inability of the individual strands and wires to adjust themselves to their changed position when the rope is bent. Tests made by the National Institute of Standards and Technology show that the rope strength decreases in a marked degree as the sheave diameter grows smaller with respect to the diameter of the rope. The loss of strength due to bending wire ropes over the sheaves found in common use will not exceed 6% and will usually be about 4%.

The bending of a wire rope is accompanied by readjustment in the positions of the strands and wires and results in actual bending of the wires. Repetitive flexing of the wires develops bending loads which, even though well within the elastic limit of the wires, set up points of stress concentration.

The fatigue effect of bending appears in the form of small cracks in the wires at these over-stressed foci. These cracks propagate under repeated stress cycles, until the remaining sound metal is inadequate to withstand the bending load. This results in broken wires showing no apparent contraction of cross section.

Experience has established the fact that from the service view-point, a very definite relationship exists between the size of the individual outer wires of a wire rope and the size of the sheave or drum about which it operates. Sheaves and drums smaller than 200 times the diameter of the outer wires will cause permanent set in a heavily loaded rope. Good practice requires the use of sheaves and drums with diameters 800 times the diameter of the outer wires in the rope for heavily loaded fast-moving ropes.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results, because of the other factors affecting the useful life of the rope. If the loads are light or the speed slow, smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are heavy or the speed is fast. Reverse bends, where a rope is bent in one direction and then in the opposite direction, cause excessive fatigue and should be avoided whenever possible. When a reverse bend is necessary larger sheaves are required than would be the case if the rope were bent in one direction only.

Stretch of Wire Rope The stretch of a wire rope under load is the result of two components: the structural stretch and the elastic stretch. Structural stretch of wire rope is caused by the lengthening of the rope lay, compression of the core and adjustment of the wires and strands to the load placed upon the wire rope. The elastic stretch is caused by elongation of the wires.

The structural stretch varies with the size of core, the lengths of lays and the construction of the rope. This stretch also varies with the loads imposed and the amount of bending to which the rope is subjected. For estimating this stretch the value of one-half percent, or .005 times the length of the rope under load, gives an approximate figure. If loads are light, one-quarter percent or .0025 times the rope length may be used. With heavy loads, this stretch may approach one percent, or .01 times the rope length.

The elastic stretch of a wire rope is directly proportional to the load and the length of rope under load, and inversely proportional to the metallic area and modulus of elasticity. This applies only to loads that do not exceed the elastic limit of a wire rope. The elastic limit of stainless steel wire rope is approximately 60% of its breaking strength and for galvanized ropes it is approximately 50%.

Preformed Wire Ropes Preformed ropes differ from the standard, or non-preformed ropes, in that the individual wires in the strands and the strands in the rope are preformed, or pre-shaped to their proper shape before they are assembled in the finished rope.

This, in turn, results in preformed wire ropes having the following characteristics:They can be cut without the seizings necessary to retain the rope structure of non-preformed ropes.

They are substantially free from liveliness and twisting tendencies. This makes installation and handling easier, and lessens the likelihood of damage to the rope from kinking or fouling. Preforming permits the more general use of Lang lay and wire core constructions.

Removal of internal stresses increase resistance to fatigue from bending. This results in increased service where ability to withstand bending is the important requirement. It also permits the use of ropes with larger outer wires, when increased wear resistance is desired.

Outer wires will wear thinner before breaking, and broken wire ends will not protrude from the rope to injure worker’s hands, to nick and distort adjacent wires, or to wear sheaves and drums. Because of the fact that broken wire ends do not porcupine, they are not as noticeable as they are in non-preformed ropes. This necessitates the use of greater care when inspecting worn preformed ropes, to determine their true condition.

Wire rope is a collection of metal strands that have been twisted and wound to form the shape of a helix with the purpose of supporting and lifting heavy loads and performing tasks that are too rigorous for standard wire. On shipping docks, rigging, and load bearing equipment, wire rope is attached to swivels, shackles, or hooks to lift a load in a controlled, even, and efficient manner.

The uses for wire rope include adding support to suspension bridges, lifting elevators, and serving as additional reinforcement for towers. The design of wire rope, with its multiple strands wrapped around a stable core, provides strength, flexibility, and ease of handling for applications that have bending stress.

Individual designs of wire rope involve different materials, wire, and strand configurations as a means for supporting and assisting in the completion of lifting or supportive applications.

The term wire rope encompasses a wide range of mechanical tools that are made to perform heavy and extreme lifting jobs. Wire rope is a complicated and complex tool with multiple moving parts capable of moving in unison. A 6 by 25 wire rope has 150 outer strands that move as one in an intricate pattern supported by a flexible core.

An essential part of the design of wire rope is the required clearance between the strands to give each stand the freedom to move and adjust when the rope bends. It is this unique feature that differentiates wire rope from solid wire and other forms of cable.

The basic element of wire rope is wire that is used to configure, shape, and form the rope. Typically, steel, stainless steel, and galvanized wires are the first choice with aluminum, nickel alloy, bronze, copper, and titanium being second possibilities. The choice of wire is dependent on the type of work the wire is going to be used to perform with strength, flexibility, and abrasion resistance being the major determining factors.

Stainless steel wire rope has all of the basic qualities of galvanized and general wire rope with the added benefits of corrosion and rust resistance; this makes it the ideal choice for harsh and stressful conditions.

Steel wire rope is classified as general purpose wire rope and comes in a wide variety of sizes, diameters, and strengths. It is the most common type of wire rope and is used for several industrial, manufacturing, and construction applications.

Before going further into the discussion of how wire rope is made, it is important to understand the numbers used to describe each type. All wire ropes have a core around which wires are wound. The various styles of cores vary according to the construction and design of the requirements of the wire rope that is being produced.

Wire rope is classified by the number of strands it has as well as the number of wires in each strand. The most common classification is a seven wire rope that has one strand in the center and six around its circumference. This type of wire rope is lightweight with a very simple construction. The majority of wire ropes are more complex and intricate with multiple intertwining strands and wires.

What must be understood about wire rope is that it has a complicated configuration. It is actually wires wrapped around wires to form bundles that are wrapped around other bundles. In the case of a seven wire wire rope, the core has bundles of wires wound around it; this can be seen in the image below.

The first step in wire rope creation is the production of wire strands where wires are wound around a single core wire. The number of wires included in the strand is dependent on the specified strength, flexibility, and size requirements of the rope. Once the strand is completed, it is straightened before being moved to wire rope construction.

Like wire ropes, strands have different patterns; patterns are the arrangements of the wires and their diameters. Though most strands have a core, there are strand patterns that have three or four wires without a core that are referred to as centerless strands. The design of each strand pattern is meant to enhance the strength of the wire rope and improve its performance.

For a multiple layer strand, the layers of wire are placed over one another in successive order. The placement of the wires on top of each other must be such that they fit smoothly and evenly.

The Warrington pattern is like the multiple layer pattern with one variation. Like the multiple layer pattern, the inner wires and the core are the same and have the same diameter. The difference is in the outer layer, which has wires of alternating sizes of large and small with larger diameter wires laying in the valleys of the inner wires.

All of the wires of a filler pattern are the same size. What makes this pattern unique is the insertion of small wires in the valleys of the inner wires to fill the gap between the inner and outer layer.

The flattened strand pattern is also known as the triangular strand, which can be triangular or oval. Three round wires form the core. The outer flattened surface has a greater sectional metallic area; this makes this pattern stronger and longer lasting.

The core of a wire rope runs through the center of the rope and can be composed of a variety of materials, which include synthetic fibers, natural fibers, a single strand, or another wire rope. The core supports the wound strands, helps maintain their position, is an effective lubricant carrier, and provides support.

Wire ropes with fiber cores are restricted to light loads and are not used in severe, harsh, or stressful conditions. Polypropylene and nylon are types of synthetic fiber cores and can be used in conditions where there is exposure to chemicals.

Cores made of wire are classified as independent wire cores. The core of a wire rope with a wire core is actually a wire rope with another wire rope serving as the core, as can be seen in the diagram below. These types of wire ropes are used where the rope will be exposed to exceptional resistance and crushing.

A strand, or wire strand core, is exactly like the rest of the strands of the wire rope with wires of the same diameter and size as the other strands.

The choice of core and creation of the strands are the simplest yet most essential parts of wire rope construction. Wire rope lays, the method used to wind the strands, is more complex and involves several choices.

Lay is a term used to describe three of the main characteristics of wire rope: direction, relationship, and linear distance. The strands can be wrapped around the core going right or left. Right or left refers to the direction of the strands wrapped around the core and the wires within the strands. The linear distance is how far a strand moves when it is making a revolution around the core.

In a regular lay, the wires and strands spiral in opposite directions. With a right hand regular lay, the wires spiral to the left and the strands to the right. In the left hand regular lay, the wires spiral to the right and the strands to the left. This type of lay is easy to handle but wears out quickly because the crown wires are in contact with the bearing surface.

In the Lang, or Albert, lay, the wires and strands spiral in the same direction with right hand lay being the most common. The wires in a Lang lay appear to run parallel to the center line of the rope. The difficulty with Lang lay wire ropes is handling since they tend to kink, twist, and crush.

Wire rope is an exceptionally strong tool that has been configured and designed to withstand the stress placed upon it through rigorous and continual use. In most applications, wire rope has to endure extreme stress and strain. It is for these reasons that coatings have been developed to protect wire rope from abrasions, corrosion, UV rays, and harmful and damaging chemicals.

Three main types of coatings are used to protect wire rope: polyvinyl chloride (PVC), polypropylene, and nylon. Of the three types, PVC is the most popular.

In cases where there are severe and hazardous working conditions, polypropylene is the recommended choice since it is capable of protecting wire rope against corrosion and chemical leaching. Additionally, it is resistant to impact damage and abrasion. Polypropylene is a tough, rigid, and crystalline thermoplastic that is made from a propene monomer and is resilient as well as inexpensive.

Braided wires are electrical conductors made up of small wires that are braided together to form a round tubular braid. The braiding and configuration of braided wire makes them very sturdy such that they do not break when flexed or bent. Braided wires are widely used as conductors, are commonly made from copper due to copper"s exceptional conductivity, and can be bare or coated depending on the application.

Braided wire can be round and tubular or flat. Round tubular braids fit in most spaces where flat braided wire will not. Flat braided wire begins as round braided wire which is flattened on a capstan. They are exceptionally strong and designed for medical and aircraft applications.

Metals used to make wire rope are various grades of stainless steel, bright steel, and galvanized steel. Though the majority of wire rope manufacturers use these three metals, other metals such as copper, aluminum, bronze, and monel are also used on a limited basis.

The most important aspect of wire rope is the wire and the metal from which it is made. The strength and resilience of wire rope is highly dependent on the quality of metal used to make it, and these are essential factors to be considered when purchasing it.

Bright steel wire does not have a coating and is rotation resistant, (designed to not rotate when lifting a load). It is drawn from hot rolled rods that are put through a die to match its specific dimensional tolerances, mechanical properties, and finish. Bright wire is used as a single line in conditions that require a rope that will resist cabling.

Galvanized steel has a zinc coating for corrosion resistance and has the same strength and durability as bright steel. Environmental conditions determine the use of galvanized steel. In mildly severe and slightly harsh conditions, galvanized steel wire is an economical replacement for stainless steel.

In the manufacturing process, galvanized wire goes through the process of galvanization, a method of coating steel wire with a protective and rust resistant metal. Galvanized wire is exceptionally strong, rust resistant, and flexible enough to meet the needs of a variety of applications.

Wire rope made from copper is mostly used for electrical applications due to its exceptional electrical characteristics. The benefits of copper wire rope are its durability, flexibility, and resilience compared to standard copper wire. The strength of copper wire rope is seen in its use in applications where there are vibrations and shaking.

The wire rope lubrication process begins during its fabrication and continues during its use. Lubrication of wire rope is designed to lower the amount of friction it endures and provide corrosion protection. Continued lubrication increases the lifespan of wire rope by preventing it from drying up, rusting, and breaking.

The types of lubricants for wire rope are penetrating or coating with coatings covering and sealing the outside of the rope. Penetrating lubricants go deep into the rope and seep into the core where they evaporate to form a thick coating or film.

The application of the lubricant is dependent on the type of core. Fiber cores absorb the lubricant and serve as a reservoir that retains the lubricant for an extended period of time. With metal cores, the lubricant is applied as the wire is twisted into strands to give complete saturation and coverage of the wires.

There are several types of greases that are used as wire rope lubricating agents and are made up of oil, a thickener, and additives. The essential components are the base oil and additives, which influence the behavior of the grease. The thickener holds the base oil and additives together. The amount of base oil in a grease is between 70% and 95% with an additive of 10%.

The additive in grease enhances the positive properties of the oil and suppresses the negative properties. Common additives are oxidation and rust inhibitors as well as pressure, wear, and friction reducing agents.

Of the many choices for lubricants, vegetable oil is the easiest to use and penetrates the deepest. The design of the additives for vegetable oils gives them the necessary qualities required to penetrate deep into a wire rope. The exceptional penetration provides protection against wear and corrosion. Since vegetable oil is a fluid, it helps in washing the wire rope to remove external abrasive contaminants.

Wire rope is widely used in machines, structures, and varied lifting applications. Its type, size, and requirements are determined by how it will be used. Regardless of its use, wire rope guarantees exceptional strength and provides high quality and excellent performance.

The lifting of heavy loads for centuries involved the use of hemp rope or chains, neither of which was a guaranteed or substantial method. Early in the 18th Century, between 1824 and 1838, Wilhelm Albert, a German mining engineer, combined the twisting of hemp and strength of chains to create today‘s wire rope.

The most common use of wire rope is as a part of a crane hoist wherein it is attached to the hook of the hoist and wrapped around a grooved drum. The tensile strength and durability of wire rope makes an ideal tool for lifting and keeping loads secure. Though it is used in several industries, it is very popular for production environments wherein materials need to be lifted quickly and efficiently.

In addition to its many lifting applications, the strength and stability of wire rope is useful in other applications, especially in the aerospace industry. Pedals, levers, and connectors in the cockpit of an aircraft are connected with wire rope. The wires provide for the passage of power between systems and mechanisms; this allows control of the aircraft. Wire rope is used to control propeller pitch, cowl flaps, and the throttle. It also assists in lowering and minimizing vibrations.

Tires are reinforced with wire rope to increase their durability and strength. All automotive production environments make use of wire ropes for supplying materials, moving heaving loads, and positioning equipment. Wire rope can be found in the production of steering wheels, cables, exhausts, springs, sunroofs, doors, and seating components.

As surprising as it may seem, the place that wire rope has the greatest use is in the home, where its strength, long life, endurance, and resilience provide guaranteed protection and performance. The main reason wire ropes are so popular for home use is cost.

Inexpensive, easy to obtain, easy to install, and easy to maintain, wire ropes provide an additional method for performing home repairs and structural support. Their excellent flexibility and sturdiness combined with their invisibility has made wire rope an ideal solution to several home maintenance issues. It is used to support staircases, fences, decks, and hang plants.

The search and production of crude oil has relied on wire ropes for centuries to lift drill bits, insert shafts, and support oil rigs on land and the water. When equipment, machinery, and tools have to be lowered into the depths of the earth and sea, wire ropes are the tool that the oil industry relies on to do the job.

Many of the tasks of oil production require tools that are capable of enduring severe and harsh conditions. Wire ropes have to withstand enormous pressure, extraordinary stress, and a wide range of temperatures. The use of wire rope includes maintaining oil rig stability and moorings for offshore rigs.

Wire rope has long been a standard component for the transportation industry, from the cable cars of San Francisco to the lift chairs for ski resorts. For many years, cable cars have relied on heavy duty cables (wire ropes) to be pulled by a central motor from multiple locations. It is a method of transportation that has existed for centuries.

In Europe, funiculars use cables that hang from a support to move cars up and down a mountain with cables moving in opposite directions. The word funicular is from the French word funiculaire, meaning railway by cable. The terms wire rope and cable are used interchangeably when discussed by professionals. The first part of funicular, or funiculaire, is from the Latin word "funis," meaning rope.

The major use for wire ropes in the food and beverage industries is as a means for lifting and moving heavy loads. Wine barrels and containers full of ingredients are lifted and placed through use of cranes and wire ropes. They are also part of conveyor systems that move products from one station to another.

From the beginnings of amusement rides up to the present, wire ropes have been an essential part of attraction construction and safety. They pull cars on roller coasters, hold cabins that swing, and move carriages through haunted houses. The main concern of amusement parks is safety. The strength, stability, and guaranteed performance of wire ropes ensures that people who attend amusement parks will have a good time and stay safe.

The rigging used to complete the stunts in modern movies depends on wire rope for safety. Much like in amusement rides, wire ropes protect performers from injury and harm as they hang above a scene or carry out an impossible move.

The live theater industry uses wire ropes to raise and lower curtains, support overhead rigging, and hold backdrops and scenery pieces. During a production, rapid and efficient movement is a necessity that is facilitated by the use of wire ropes.

Wire rope is a tool that we tend to envision as indestructible, unable to succumb to any form of damage. Though it is exceptionally sturdy and strong as well as capable of enduring constant use, it is just as susceptible to breakdown as any other tool.

To avoid serious harm and damage, wire ropes should be scheduled for regular inspections. There are situations that can damage or break a wire rope; these should be understood prior to the problem arising.

Guide rollers have the potential to damage and cause abrasions on wire rope if they become rough and uneven. Of the various elements of a crane and lift, guide rollers have the greatest contact with the mechanism‘s wire rope. Regular inspection of guide rollers will ensure they are not damaging the rope or causing abrasions.

Bending is normally a regular part of wire rope usage; this occurs repetitively as the rope passes through a sheave. As a wire rope traverses the sheave, it is continually bent and develops cracks or breaks. The cracking and breaking are exacerbated by movement on and off the groove of the drum. Normally, the breakage happens on the surface and is visible. Once it appears, it accelerates to the core of the rope.

A bird cage is caused by a sudden release of tension and a rebound of the rope. This type of break requires that the rope be replaced since the place of the break will not return to its normal condition.

Wire ropes are multi-layered; this makes them flexible and torque balanced. The layering inside and outside creates flexibility and wear resistance. Relative motion between the wires causes wear over time, which leads to internal breakage. The detection of these breaks can be indicated by an electromagnetic inspection that calculates the diameter of the rope.

Kinked wire rope is caused by pulling a loop on a slack line during installation or operation; this causes a distortion in the strands and wires. This is a serious condition that necessitates rope replacement.

Corrosion damage is the most difficult cause of wire rope damage to identify, which makes it the most dangerous. The main reason for corrosion is poor lubrication that can be seen in the pitted surface of the rope.

The types of damage and problems listed here are only a small portion of the problems that can be caused if a wire rope is not regularly lubricated and inspected. Various regulatory agencies require that wire ropes be inspected weekly or monthly and provide a list of factors to examine.

As with any type of heavy duty equipment, wire rope is required to adhere to a set of regulations or standards that monitor and control its use for safety and quality reasons. The two organizations that provide guidelines for wire rope use are the American Society of Mechanical Engineers (ASME) and the Occupational Safety and Health Administration (OSHA).

All wire rope manufacturers and users closely follow the standards and guidelines established by OSHA and ASME. In the majority of cases, they will identify the specific standards they are following in regard to their products.

OSHA‘s regulations regarding wire rope fall under sections 1910, 1915, and 1926, with the majority of the stipulations listed in 1926 under material handling, storage, use, and disposal.

"Running rope in service shall be visually inspected daily, unless a qualified person determines it should be performed more frequently. The visual inspection shall consist of observation of all rope that can reasonably be expected to be in use during the day‘s operations. The inspector should focus on discovering gross damage that may be an immediate hazard."

"The inspection frequency shall be based on such factors as rope life on the particular installation or similar installations, severity of environment, percentage of capacity lifts, frequency rates of operation, and exposure to shock loads. Inspections need not be at equal calendar intervals and should be more frequent as the rope approaches the end of its useful life. Close visual inspection of the entire rope length shall be made to evaluate inspection and removal criteria."

ASTM A1023 covers the requirements for steel wire ropes with specifications for various grades and constructions from ¼ in. (6 mm) to 31/2 in. (89 mm) manufactured from uncoated or metallic coated wire. Included are cord products from 1/32 in. (0.8 mm) to 3/8 in. (10 mm) made from metallic coated wire.

United States Federal Spec RR W 410 covers wire ropes and wire seizing strands but does not include all types, classes, constructions, and sizes of wire rope and strands that are available. The purpose of Spec RR W 410 is to cover more common types, classes, constructions, and sizes suitable for federal government use.

Wire rope and wire seizing strand covered by United States Federal Spec RR W 410 are intended for use in general hauling, hoisting, lifting, transporting, well drilling, in passenger and freight elevators, and for marine mooring, towing, trawling, and similar work, none of which are for use with aircraft.

API 9A lists the minimum standards required for use of wire rope for the petroleum and natural gas industries. The types of applications include tubing lines, rod hanger lines, sand lines, cable-tool drilling and clean out lines, cable tool casing lines, rotary drilling lines, winch lines, horse head pumping unit lines, torpedo lines, mast-raising lines, guideline tensioner lines, riser tensioner lines, and mooring and anchor lines. Well serving wire ropes such as lifting slings and well measuring are also included in API 9A.

Wire rope is a collection of metal strands that have been twisted and wound to form the shape of a helix with the purpose of supporting and lifting heavy loads and performing tasks that are too rigorous for standard wire.

Individual designs of wire rope involve different materials, wire, and strand configurations as a means for supporting and assisting in the completion of a lifting or supportive task.

Wire rope is constructed of multiple strands of wire that are twisted and braided together to form a spiral design or helix. Once the separate wires are shaped into a solid form, they become a single wire with greater strength because the individual wires equalize pressure and have greater flexibility than the individual strands.

To further enhance the strength of wire ropes, they are grouped and wound together to produce cables, which adds to their usefulness as a means of support, ability to lift, and give structural stability.

A key factor in wire rope is the lay of the strands, which can be regular or lang. With regular lay, or right and ordinary lay, the strands are wound from left to right with the wires laid in the opposite direction of the lay of the strands. With lang lay, the wires are wound in the same direction.

The structure and design of wire rope produces a final product that has superior strength, excellent strength flexibility, and the ability to handle constant bending stress as well as being weather resistant.

Wire rope is one of those products that has found a place in a wide variety of industries since it can be adapted and shaped to fit several applications. It can be found as a tow cable for boats and airplanes or in the movie industry as a harness for stunt artists. The varied uses of wire rope have made it an essential part of operations that require a rope with strength, endurance, and flexibility.

In the aerospace industry, wire ropes, or Bowden cables, connect pedals and levers in the airplane cockpit to send power to aircraft systems to control the airplane. The things that are controlled by wire ropes are propeller pitch, cowl flaps, and throttle. Wire ropes on aircraft are insulated to avoid vibrations.

Wire rope is extensively used in the auto industry for a wide variety of applications due to its versatility and strength. It is used for raising windows and opening and closing sunroofs. Other uses include steering wheels, cables, exhausts, springs, sunroofs, doors, and seat components. In the manufacturing process, wire rope is used to hoist vehicles, move large body parts, and on hoists and cranes.

The construction industry has a greatest reliance on wire rope because of the need to lift and lower heavy loads. Wire rope used in construction must have extremely high strength and exceptional performance for safety reasons and efficiency. Larger versions of wire rope are used for suspension bridges and supporting concrete columns.

The main use of wire rope in food processing is for lifting, moving loads, and other heavy tasks. Finished products or raw materials require being moved in storage units and processing centers. The strength and endurance of wire rope makes it possible to move these materials. Wire rope for food processing must be able to withstand regular chemical cleaning.

As with other industries, the oil and gas industry needs strong and reliable equipment for moving heavy equipment. In ocean drilling, machinery is dropped into the ocean using wire rope to securely hold devices to be dropped to extreme depths. Wire ropes are designed to withstand the extreme pressure and stress required. A further use of wire ropes for drilling operations is to maintain stability in the drilling lines. One of the unique features of oil rig wire rope is its length, which can exceed 10,000 feet.

A very common use for wire rope is mooring and towing of sea and freshwater boats and vessels. In the shipbuilding industry, wire rope is used to secure lifeboats as well as lower them into the water. On sailboats, wire rope is used to lift and lower sails. The benefit of using wire rope is its resistance to corrosion and rust caused by salt water and ocean mist.

The skiing industry, much like heavy equipment industries, uses wire rope to hold cars, lifts, or chairs to transport skiers up the mountain. This type of wire rope comes in several varieties depending on the size of the mountain. The benefits of wire rope for skiing is its dependability, guaranteed safety, and reliability. The main challenge of wire rope for use in sports is the weather conditions it must endure.

Since the beginnings of amusement parks, wire rope has been an essential part of attraction construction. It is used to bring roller coaster cars to the top of the ride, hold swings, and pull various vehicles through attractions. One of the main concerns of public amusement parks is safety since rides are filled with powerful machinery designed to operate continuously.

Making the dangerous and exciting shots in movies requires well planned safety precautions. One of the aspects of that planning is wire rope that is designed to protect performers when they are engaged in dangerous and life threatening shots. Dependable wire ropes are ideal since they have the flexibility, strength, endurance, and versatility to be adapted to any conditions.

In architecture and design, wire rope has been used for guard rails, balustrades, and roof construction. In innovative green buildings where plants grow along the surface of the building, the plants grow along specially designed vertical wire ropes that are capable of withstanding weather conditions.

A common use of wire rope is in railings, which are safe, durable, and provide a pleasing aesthetic appeal. The use of wire rope for railings provides protection without obstructing the view from a building. This aspect of wire rope is one of the reasons that it is used for large architectural projects since it blends into the structure without interiors with the architectural design.

The types of wire rope are determined by the number of wires in each strand and how many are in the rope, which is defined by a two number system with the first number being the number of wires and the second being the number of wires in each strand. For example, a 6x19 wire rope has 6 wires in 19 strands.

There are a wide variety of products that are produced using wire rope. The demand for wire rope products is due to its strength, durability, and reliability. Since the basic purpose of wire rope is to lift and move heavy materials and items, the most common type of wire rope product is the wire rope sling.

Though the construction of wire rope slings is very similar for all types, there are certain variations applied to slings to adjust them to fit different applications. Slings are configured in various ways to fit different types of loads. These changes are referred to as hitches.

Bridle Hitch: The multiple leg or bridle hitch style has more than one wire rope sling attached to equalize the load and control balance. They reduce load damage by using fixed points on the load and offer easier rigging when hooked into fixed lifting points. .

Single Part Wire Rope Sling: The eye for a single part wire rope sling is formed by looping the wire rope back on to the rope. The end of the rope is attached by a clamp or being woven by hand or mechanically into the rope body. Single part wire rope slings use a single wire rope to produce the sling.

Braided Wire Rope Sling: A braided wire rope sling is made by braiding wire ropes to form a sling. The increased number of strands enhances the strength of the sling and its load capacity. Braiding can be done with three to nine wire ropes.

Cable Laid Wire Rope Sling: Cable laid wire rope slings are made from combining several smaller wire ropes to form a flexible, easy to handle, and kink resistant sling.

Woven Eye Wire Rope Sling: For the woven eye version of a wire rope sling, the eye is formed by weaving the wire rope into itself after forming the loop. It is designed to reduce the chance of the sling catching or being hung up when lifting.

Thimble Wire Rope Sling: To add to the strength of wire rope slings and lessen the stress on a small area of the eye, a thimble, a U shaped piece into which the wire rope fits, is placed in the eye, which helps the sling to retain its natural shape. The thimble is positioned to prevent the hook or load from coming in contact with the wire rope.

Endless Wire Rope Sling:Endless wire rope slings are adaptable slings without a set wear point. They can be manufactured in a wide range of sizes and are used in applications where headroom may be a problem. Endless wire rope slings are made by splicing the ends of a piece of wire rope together or by tucking strand ends into the body to form a core with a tucked position the opposite of the core position. They are also referred to as grommet wire rope slings.

Coiled wire rope is made from bundles of small metal wires that are twisted into a coil. It comes in many varieties and is easy to store since it does not require a spool. Coiled wire rope is produced in coils. When it is not in use, it springs back into a coil, which makes it easy to handle.

Cable wire rope is a type of high strength rope, made of several individual filaments. These filaments are twisted into strands and helically wrapped around a core. One of the most common types of wire rope cable is steel cable.

Push pull wire rope assemblies are used to send force and are used in the aircraft, exercise, medical, automotive, and office equipment industries. Unlike using a single heavy wire, push pull assemblies made with wire rope are stiffer and have a larger bend radii for smoother motion of the wire.

Wire rope assemblies include wire rope and various parts and components that have been added to the wire rope to enhance its function. The connectors for a wire rope assembly are designed to connect the assembly to hooks, equipment, or machines as well as other wire rope assemblies. The central part of a wire rope assembly is the wire rope, which determines the type and kind of work the assembly can perform.

Wire rope lanyards are a standard wire rope product that have a multitude of uses. They are produced using the same process that is used to produce wire rope with the same numbering categorizing system. Lanyards are used to hold fasteners, hardware, or components to prevent loss of an item or prevent injury.

In many ways, wire rope is a form of machine with multiple moving parts. Normally, when we think of a machine, we imagine a device with a motor, drives, and gears. Wire rope does not have any of those components but does fit the definition of being a complex mechanism. It has moving parts that work together to move heavy materials and loads.

The main function of wire rope is to do heavy lifting, which is very dependent on wire rope slings. The type of sling is determined by the quality of the wire rope used to form them and whether several ropes have been braided or wound together.

Wire is the smallest part of wire rope but makes up the various strands. The composition of the wire can be steel, iron, stainless steel, copper, or other types of metal wires and are produced in different grades. The individual wires can be coated or bright, meaning uncoated.

Strands are sets of wires that are twisted together and are placed in a helical pattern around the core. The size of the wire determines its abrasive qualities with larger wires being more abrasive and less flexible than smaller ones.

The core is the center of the wire rope and serves as a support for the strands and helps the wire rope keep its position when it is under stress or bearing a load.

Lubrication is applied during the manufacturing process to reduce friction between the wires and strands as well as protection from corrosion and rust. The tight winding of the wires enhances the ability of the wire rope to retain the lubrication which is essential to its longevity.

The purpose of applying lubricant is to limit the friction between the cables to increase the useful life of the wire rope. In certain applications, such as space travel, lubricants can be hazardous and cause equipment to malfunction. In those instances, non-lubricated wire rope is used, which is referred to as dry wire rope or cable.

Of all of the products that are made from wire rope, slings are the most common and widely used. These looped wire ropes come in different varieties and grades depending on the type of wire used. Also, to enhance wire sling performance, several wire ropes may be wound together to form a sturdier and more reliable sling.

Flemish splicing is a method for repairing a wire rope and involves breaking the wire rope in half and tying it back together. In the Flemish method, the wire rope is tied back on itself and swaged down a sleeve over the unbroken wire rope to create the new eye.

Prior to placing the wire rope into the holding device used to shape the eye, a steel compression sleeve is placed on the rope, which will be used to secure and hold the eye.

Once the proper size is achieved, the unwound strands are rewound in the reverse order of their former positioning. If the wire rope has a right hand lay, it is rewound using a left hand lay. The opposite is true if the wire rope has a left hand lay, then it is rewound using a right hand lay. By using this technique, a friction mold is formed for the splicing of the sling.

Anti-rotational wire rope resists the forces of rotation by having opposing layers of helical stands. By winding the wire rope with oppositional strands, the wire rope is guaranteed to not unwind in clockwise or counterclockwise directions. The key to anti-rotational wire rope is to ensure that the outer diameter is static.

In the manufacture of anti-rotational wire rope, counter stranded filaments have vacant spaces between them. To make the wire rope anti-rotational, it is tightly twisted in the counterclockwise direction, which tightens the spaces between the filaments. If the wire rope is turned in a counterclockwise direction, the strands tighten around each other creating a spring force.

The tails and stray wires of the wire rope have to be straightened and properly formed before applying the compression sleeve. Once the sleeve has been placed, it is carefully checked to be sure that it is accurately engaged.

Prior to placing the wire rope sling in the swaging die, the die has to be thoroughly lubricated. Once the die is set, the wire rope‘s compression sleeve and the wire rope are compressed using several hundred thousand pounds of force. The swaging process alters the dimensions of the wire rope and compression sleeve to form a tight connection for the correct diameter for the sling connection. As force is applied, the compression sleeve is turned so that pressure is evenly applied.

There are several types of metal wires that are used to produce wire rope, which include steel, stainless steel, galvanized, aluminum, nickel alloy, bronze, copper, and titanium. Carbon steel is the most common type of wire rope material.

Wire ropes are made using uncoated bright wire, which is high-carbon steel. The type of steel depends on the requirements of the wire and its tensile strength and its fatigue and wear resistance.

Galvanized wire rope is treated with zinc to prevent corrosion and can be used in harsh conditions and environments. It is a cost effective alternative to stainless steel but does not have the same corrosion resistance. Galvanized wire rope is stronger than stainless steel of the same grade and size. Vinyl coated galvanized wire rope is easy to handle and flexible.

Stainless steel wire rope is corrosion and rust resistant. It is available in types 316 and 304 with 316 having greater corrosion resistance. Stainless steel wire rope can be used for marine applications, acidic environments, and other demanding conditions. It is produced with the appropriate tolerances and composition to meet the needs of the application.

Multiple strands of copper are braided into a round hollow shape, which is pressed into the desired width and thickness. Copper wire rope has exceptional flexibility, an exceptional life span and can be used as part of electrical components.

Bronze wire rope inhibits sparking and is corrosion resistant. It is made from preformed wire to ensure that it maintains its shape and does not unravel when cut. Bronze wire rope is abrasion resistant and very flexible with a crush resistant core.

Inconel wire can be used in applications that reach temperatures as high as 2000° F and is oxidation and corrosion resistant. It is non-magnetic and has excellent resistance to chloride based corrosion cracking. Inconel wire rope can be used with nuclear generators and chemical and food processing.

Titanium wire rope comes in several grades with grade two being 99% pure. It is easily formable and weldable. Titanium wire rope is commonly used in chemical processing and marine hardware.

For wire rope to perform properly, it needs to have proper care. Wire rope is an essential tool necessary to perform a wire range of lifting and moving jobs. It is important that it be handled, treated, installed, stored, and treated correctly to prolong its life and perform to the highest standards.

Seizing should be completed on both ends of the wire rope, which will protect it from loosening. If this is done improperly, the wire rope can become distorted. Wire rope that is properly seized evenly distributes the load.

Wire rope is stored on reels or coils and has to be carefully handled when it is being removed. To ensure excellent performance, the wire rope should not be dropped during removal. If the reel or coil is dropped or damaged, it can make handling the wire rope difficult and cumbersome. As the wire rope is removed from the reel, check to see that the reel is rotating as the wire is removed.

Wire rope is depended on for heavy lifting and is trusted to keep a load and people safe. As with all heavy duty equipment, wire rope must have a regular inspection schedule and be visually assessed during use.

Broken Strands – An easy way to check for broken strands is to run a cloth over the length of the wire. Broken strands that are found in critical areas, such as parts that pass through pulleys or sections that are regularly flexed, rubbed, or constantly worked must be replaced and repaired.

Internal wear – This can be tested by flexing the wire rope, which indicates if the interior has deteriorated, experienced fatigue, or become distorted.

For wire rope to perform at the highest level, it has to be stored in a well ventilated environment that is dry, covered, and not in contact with the floor. The avoidance of high moisture or damp conditions is an absolute necessity. While the wire rope is in storage, it should be moved regularly to keep the lubricant from wearing off.

Though lubricant is applied during the manufacturing of wire rope, it wears off during use. Lubrication is the key to the performance of wire rope because it helps prevent abrasion as the wires rub against one another. Relubrication should be applied after the original lubricant has worn off.

Wire rope is a tool and must be cleaned regularly as with any fo

8613371530291

8613371530291