wire rope flexibility chart pricelist

US Producer Price Index: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms Strand is at a current level of 374.05, up from 373.69 last month and up from 316.95 one year ago. This is a change of 0.09% from last month and 18.02% from one year ago.

If you’re in the rigging industry, you’ve likely had similar thoughts. Over the next few weeks, we’ll talk repeatedly about what the future of our field might look like. Today, we want to talk specifically about wire rope slings.

These flexible steel cords have become commonplace in hoisting, towing, and anchoring projects. However, a decrease in all rigging equipment purchases has many wire rope sling manufacturers asking, “What does the future of this product look like?”

As key producers of wire rope slings in the rigging industry, we at Holloway Houston Inc. want to take a look at the growing importance of wire rope slings and what we can expect from them over the next couple of years – if not longer.

The first thing we need to address is the division between galvanized wire ropes and stainless steel wire ropes in the sling industry. Wire rope slings might be an overall popular rigging tool, but in order for manufacturers to make smart bets about the future, we need to understand both types and how they’re useful.

Stainless steel wire ropes are also corrosion-resistant but more durable when it comes to harsh environmental conditions. Stainless steel can even withstand long exposure to saltwater and acid.

Generally, manufacturers who produce galvanized wire ropes sell predominantly to the aircraft industry. In fact, the 7×7 galvanized wire rope has been dubbed the “aircraft cable” because of its tough construction and flexibility.

On the other hand, stainless steel wire ropes are the best option for work sites that need the strongest product. It’s known for its high durability and safety features, which means many of the best brands for lifting accessories are interested in producing stainless steel options for years to come.

All things considered; we see places for both kinds of wire rope slings in the near future. Still, we’ll continue to monitor trends in one direction or the other.

A big part of understanding the future of wire rope slings is looking at their current usage. Right now, most companies are using wire rope slings because they are:

Wire rope slings, especially when made of stainless steel, are the perfect rigging slings for coastal or at-sea conditions. They’re resistant to salt abrasion and strong enough to handle the enormous loads of many marine job sites. There are even certified divers that use wire rope slings to confidently tackle difficult lifting operations under the ocean waves.

Still, between 2019 and 2025, it’s estimated that oil demand will increase. A higher increase for oil means more rigging projects on drilling platforms – and therefore more use of highly durable, strong wire rope slings.

You’ll also find that many construction sites rely heavily on wire rope slings. They need durability and resistance – especially in harsh weather conditions.

In the future, our teams at Holloway Houston Inc. predict that wire rope slings will continue to become increasingly customizable as we learn to make them more resistant to moisture, heat, UV rays, and a variety of chemicals.

The slowdown in world economic growth has certainly thrown a wrench into many manufacturers’ budgets and sales. However, wire rope slings sales have maintained a relatively optimistic growth rate for years, and we expect to see a steady demand for the product – pandemic or not.

Some experts, according to the Wire Rope Slings Sale Market Size 2020 Analysis, even believe that in the next few years, the wire rope slings sales market will rise at a considerable rate.

Considering that, our teams at Holloway Houston Inc. will continue to include wire rope slings in our rigging equipment designs and sales for the foreseeable future.

Making any kind of prediction is difficult during 2020, but we feel confident in the continuous demand for wire rope slings as one of the most reliable pieces of rigging hardware.

If you have any questions about wire rope slings or other kinds of rigging equipment, please call 713-674-8352. You can also reach out via our contact page. Our rigging and lifting manufacturing experts are always ready to help.

There are a variety of cables and wires that are used for various purposes. They can either be hidden underground or pass overhead. Crane Cable is one such cable wire rope made out of several strands of metal wires that are twisted together into a helix form to make them into a single rope. Initially, wrought iron was used to make these Crane Cables however, these days steel is the primary material used. Apart from this high carbon steel and galvanized steel are also used in manufacturing these cables. Dents or flaws in the ordinary link chain can lead to severe failure whereas, damage in these EOT Crane Cablecan be easily covered up. Ther are ideally used for lifting elevators, in the transmission of mechanical power, and in cranes.

Crane Lifting Cables are resistant to corrosion and have excellent ductility for optimal fatigue. They have a high breaking strength compared to steel crane wire rope. The radially elastic rope structure absorbs the dynamic force thus giving it high impact resistance. Crane Cable Wires are said to be cost-effective as a strong and durable structure helps in reducing maintenance costs and downtime. They can be coated with bright phosphate or galvanized depending upon the customers’ requirements.

Crane Electrical Cable is available in rotating, rotation, compact, or non-compact structures. Most of the wire ropes have the tendency of developing torque and are thus prone to rotation. However, non-rotation wires are designed in a way that their outer rotation naturally counteracts the inner strands rotation. Crane Hoist Cable can be used in tower crane ropes or offshore crane ropes.

Overhead Crane Cable reel should be capable of winding it automatically. The drive torque of the crane cable should not be less than the max winding torque of the winding crane cable. The cable conductor should be as small as possible when the Crane Rope laying acts on the traction force.

The Crane Wire Rope does not have a reinforcement core, the maximum tension allowed on the copper conductor cross-section is 20N/mm2. We at Bhuwal Insulation Cable Pvt. Ltd. not only provide you the best quality Tower Crane Cable but also the parts required to assemble them. Our long-standing reputation in providing the best quality product at a competent price has made us one of the leading Crane Cable manufacturers in India.

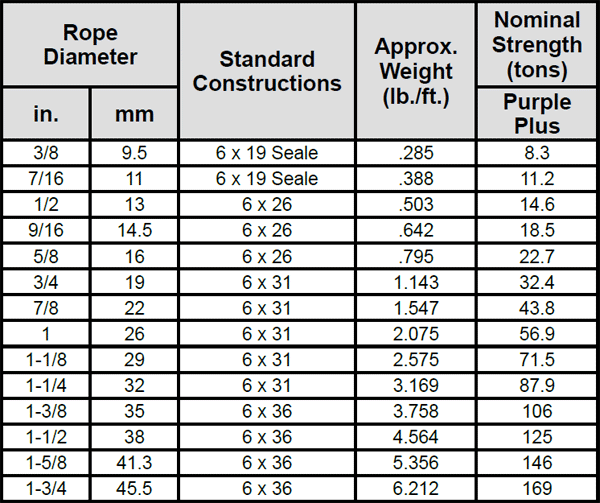

Cables or cords are the wire ropes which have diameters smaller than 3/8 inches, While wire ropes have diameters greater than 3/8 inches. if there are two or more wire concentrically laid then it is known as strand

Warrington: Two layers of wires around a center with one diameter of wire in the inner layer and two diameters of wire alternating large and small in the outer later

6 by 19 is a type of wire rope which can withstand fatigue resistance, abrasion and prevents crushing on drums. it is available in diatmeter range of 3mm to 6 mm. While 7 by 19 are wire rope which has diameters ranging between 3 mm to 16 mm which can be use in different applications.

We sell a lot ofwire rope and fittings through our online shop; and one of the main questions we get asked is, what is the difference between 7x7 and 1x19 wire. The answer is quite simple, but is also important to know, as some fittings will only suit a certain type of wire rope.

While stainless steel wire can be used for a variety of different purposes, we"ll specifially be talking about the differences in relation to wire balustrade.

In simple terms; 7x7 means 7 stands of wire twisted to form 1 strand, which is then combined with 6 more of these; 49 stands in total (ie 7x7=49). Whereras 1x19 is 19 stands of wire that are twisted to form 1 stand. A total of 19 strands in total (ie. 1x19=19). Despite the fact that the 7x7 has more than double the number of strands, the end product is still the same overall thickness.

As 7x7 is made up of thinner strands it is more flexible than the 1x19. This is important if you are using a hand swager combined with a ferrule and thimble, as the 1x19 will not be able to bend around the thimble without kinking. The 7x7 on the other hand is flexible enough to do the job properly.

With a reliable combination of flexibility and wear resistance, the 6x19 wire rope class can be suited to the specific needs of diverse kinds of machinery and equipment. Each strand has nine outer wires over nine smaller inner wires over one large center wire.

With the Seale construction—with its large outer wires—the 6x19 provides great ruggedness and resistance to abrasion and crushing. However, its resistance to fatigue is somewhat less than that offered by a 6x25 construction.

To most wire rope users, 6x19 means 6x25 filler wire. It’s a common rope in the 6x19 class, and possesses the best combination of flexibility and wear resistance due to the filler wires providing support and imparting stability to the strand. The 6x25 also boasts a good balance between both abrasion resistance and fatigue resistance in relation to other ropes.

Unlike galvanized wire rope (zinc coated), the bright class of industrial wire rope is produced without a surface treatment—making the rope less likely to untwist or kink while giving it a stronger crush resistance than lay ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion. Also available in USA-made.

8613371530291

8613371530291