wire rope industries atlantic quotation

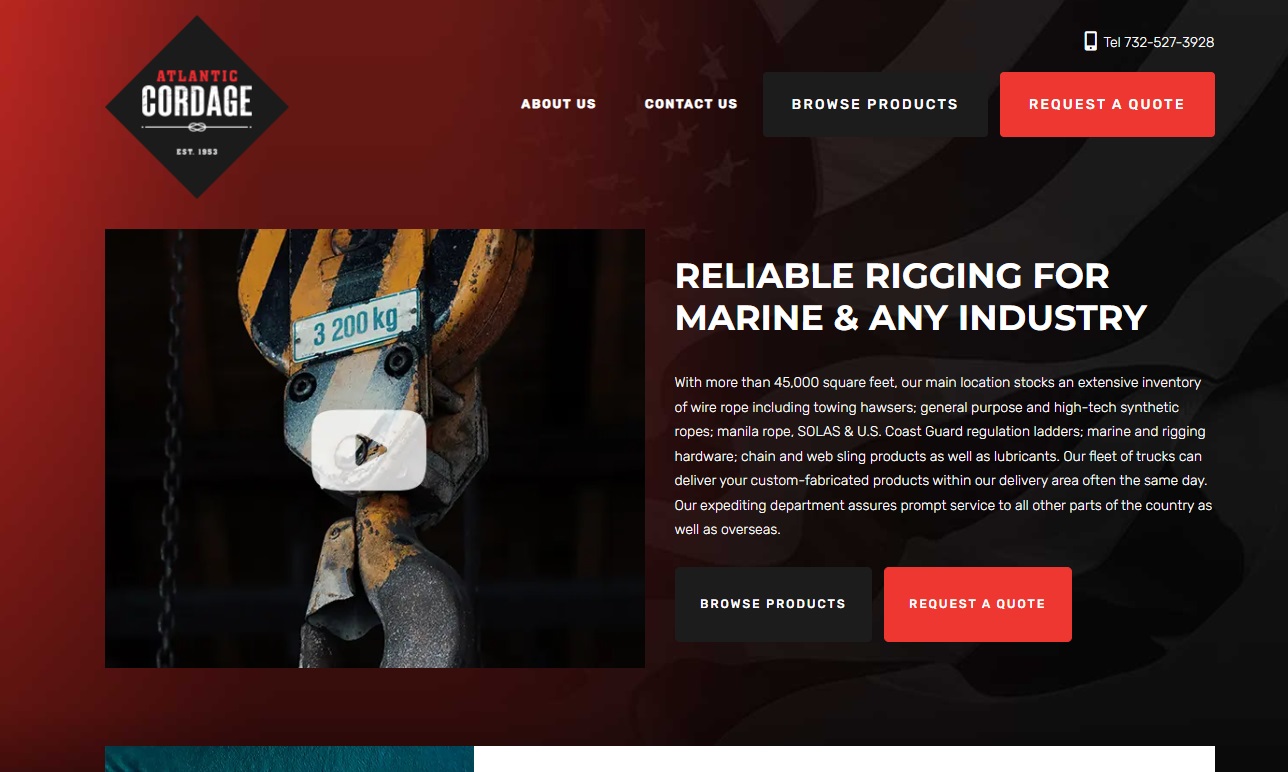

With more than 45,000 square feet, our main location stocks an extensive inventory of wire rope including towing hawsers; general purpose and high-tech synthetic ropes; manila rope, SOLAS & U.S. Coast Guard regulation ladders; marine and rigging hardware; chain and web sling products as well as lubricants. Our fleet of trucks can deliver your custom-fabricated products within our delivery area often the same day. Our expediting department assures prompt service to all other parts of the country as well as overseas.

Guy wires and structural wire rope add stability to structures such as telephone poles, radio towers, wind turbines, ship masts or tents. A lightweight, high strength, design makes guy & structural wire a popular choice in a variety of applications that require high strength and high tension.

Wishing everyone a wonderful Victoria Day weekend, from all the team at Wire Rope Industries Atlantic. Please note our store will be closed on on Monday for the holiday.Call now

This is Mike he is 65 years young and this year he will coil over 9 million feet of ¼” strand our most popular size. That’s enough to string from Halifax to Reykjavik Iceland (Or Halifax to Winnepeg). In his spare time he runs many different sizes and types of ropes.

We offer a solution with DEFIANCE Wire Rope, Fiber Ropes and Hardware…quality-consitent products that meet or exceed current specifications including but not limited to RRW-410-F, API-9A. Cordage Institute Specifications, OCIMF, SOLAS, IMO etc. relating to a broad spectrum of features aimed to ensure Quality, Reliability and Satisfaction to our customer. This is what differentiates Atlantic Cordage from its competition. DEFIANCE products are precision engineered and manufactured to assure withstanding of severe marine field applications. Close control over every phase of our operations is second to none. This excellence is not only achieved by having the product available when you need it, but by also providing a knowledgeable staff fully trained in the industry we excel in.

Atlantic Cordage carries an extensive inventory of wire rope, towing hawsers, synthetic and manila rope, Embarkation/Debarkation ladders, marine and rigging hardware, chain and anchor chain and web sling products. Our main 40,000 square foot location provides a complete rigging shop to handle your every splicing need from basic wire rope slings to mooring lines. Our own fleet of trucks stand ready to deliver custom work in a matter of hours within our own delivery area. Our expediting department assures prompt service to all other parts of the country.

Each product construction is comprised of different fiber properties, lays and twists enhancing the performance and quality of the rope as well as expanding our abilities to provide a variety of specific applications. Always focused on excellence, we received our ISO 9001-2008 in January 2013. We pioneered the development of specialized factory equipment to meet the ever-increasing high production, quality and safety standards, while at the same time holding plant costs down. Several of our machines and processes have been patented and these unique innovations assure consistent length and strength for each strand, resulting in a balanced and safer rope product. This efficiency explains our ability to provide a valued product with superior quality and short lead times, at lower prices.

Tyler Madison has earned its position as a leading custom manufacturer of wire rope cable assemblies through its commitment to quality and customer service. We always carry an extensive inventory of stock components to meet our customers’ simpler needs. But with an extensive background in wire rope design, we welcome the opportunity to design, engineer, and manufacture wire rope solutions to perfectly match our customers’ more specific applications. Our many industrial OEM and commercial customers have learned to expect the very best with on time deliveries and the highest quality wire rope.

Our ability to design and manufacture custom wire rope products allows us to serve a wide variety of industries. We serve the aircraft, automotive, electronics, and security industries as well as many others. Among our most popular products are our wire rope lanyards and our wire rope cable assemblies. Both these wire rope products can be manufactured with galvanized steel or stainless steel and are offered with a variety of coating options. Wire rope lanyards are commonly utilized for security, hanging, anchoring, and pulling applications, while our wire rope cable assemblies are for more heavy-duty applications. A variety of aircraft grade cables are also available including military specifications-cable.

We offer a solution with DEFIANCE Wire Rope, Fiber Ropes and Hardware…quality-consitent products that meet or exceed current specifications including but not limited to RRW-410-F, API-9A. Cordage Institute Specifications, OCIMF, SOLAS, IMO etc. relating to a broad spectrum of features aimed to ensure Quality, Reliability and Satisfaction to our customer. This is what differentiates Atlantic Cordage from its competition. DEFIANCE products are precision engineered and manufactured to assure withstanding of severe marine field applications. Close control over every phase of our operations is second to none. This excellence is not only achieved by having the product available when you need it, but by also providing a knowledgeable staff fully trained in the industry we excel in.

Atlantic Cordage carries an extensive inventory of wire rope, towing hawsers, synthetic and manila rope, Embarkation/Debarkation ladders, marine and rigging hardware, chain and anchor chain and web sling products. Our main 40,000 square foot location provides a complete rigging shop to handle your every splicing need from basic wire rope slings to mooring lines. Our own fleet of trucks stand ready to deliver custom work in a matter of hours within our own delivery area. Our expediting department assures prompt service to all other parts of the country.

Located in northwest New Jersey, Jersey Strand and Cable, Inc. has been the most diversified fine diameter strand and cable manufacturer of its magnitude in the world for over 30 years. Our highly skilled and experienced staff provides our customers with the highest-quality standard and custom cable and stranded wire products available, including wire rope. Our innovative product development and unique custom cable manufacturing techniques allow us to provide micro-miniature, miniature, and small diameter wire sizes up to 1/8-inch finished product diameter.

With two state-of-the-art facilities in New Jersey that total over 100,000 square feet, Jersey Strand and Cable, Inc. is fulfilling a need in the industry for specialty cable and wire strand made to exact customer requirements. Our modern testing and development laboratory, along with other peripheral equipment and 200+ production machines, helps ensure that each customer’s product is manufactured and delivered to meet their precise specifications. Spearheaded by a former IBM systems engineer, we have developed a computerized, fully integrated management control system that controls and records all details of the manufacturing process, from RFQs to shipping and invoicing, to ensure that our products are adhering to customer and Jersey Strand and Cable, Inc. specifications. This system is efficient and streamlined and has been a huge factor in our success as the leading manufacturer of strand and cables.

Fortune Rope & Metal Company, wire rope supplier & customer fabricator, serves various customer needs from one cable assembly to high volume production runs. Capabilities include custom cable assemblies, aircraft cable, wire ropes, coated cable, cut to length cable, chain, fittings, hardware & tools for many industrial & commercial sectors. 3 strategic locations with large stock to best serve you! Wire Rope in Rhode Island.

As family-owned wire rope manufacturers, St. Pierre Manufacturing provides a variety of products and services for a wide range of satisfied customers around the world. A leader amongst companies of its kind, St. Pierre Manufacturing offers high-performance fittings at affordable prices. Products and services from St. Pierre Manufacturing are always top of the line and on time. Wire Rope in Massachusetts.

Suncor Stainless manufactures an extensive line of superior stainless steel chain, wire rope assemblies and rigging hardware to serve the industrial and marine markets. Mil. Spec swage fittings and cable assemblies are also available. We are large enough to offer consistent top quality stock and custom-made products at economical prices, yet small enough to offer excellent customer service and technical expertise. Wire Rope in Massachusetts.

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions. Bergen will meet consumer needs for reliable fittings & provide prototypes & short runs to ensure top-quality. Let Bergen’s unmatched dedication to quality bring you the service you deserve. Wire Rope in New Jersey.

JSC, as one of the most diversified wire rope manufacturers, utilizes over 200 production machines to produce top rated wire products in ferrous and nonferrous materials. Industries that JSC serves include electronics, geophysical and communications. Their mission is to continually improve their expertise, capabilities, products and services for current and future worldwide customers. Wire Rope in New Jersey.

Since 1998, companies across a multitude of markets have relied on Motion Control Technologies to provide the best mechanical cable solutions in the industry. We offer commercial cable lanyards, galvanized wire rope cable lanyards, swaged fittings, and more. Whether the industry is automotive, medical, or sporting, we strive to build long-lasting relationships with our customers. Contact us today and tell us what we can do for you!Wire Rope in New Jersey.

Alan Baird Industries, Inc. is a leading manufacturer of wire rope assemblies, mechanical cable assemblies, plastic coated cables and aircraft cables. Established in 1973, we supply products for the medical devices, consumer items, mechanical devices, robotics and instruments markets. Wire Rope in New Jersey.

We are a reliable source for a wide range of wire rope needs. We provide wire rope assemblies that can be designed to fit your unique specifications, and are manufacturers of fiber rope in both natural and synthetic materials. We are a division of Steelstran/The Atlantic Group. Wire Rope in New Jersey.

Our doors opened in 1986, and we have grown to one of the largest stocking distributors of steel wire rope & submersible pump cable in the US. We offer shipping to your location, work site or shop and installation and removal of steel wire rope in select locations. We have the best prices on steel wire rope, submersible pump cable and manila rope. Wire Rope in New Jersey.

Metro Wire Rope Corp. is a leading supplier of wire rope, cable assemblies, wire rope assemblies and aircraft cables. We stock over 1,000 tons of wire rope and maintain large quantities of general-purpose wire ropes in bright, galvanized and stainless steel. Wire Rope in New Jersey.

Baco Enterprises, Inc. manufactures and distributes high strength and tension control bolts, hex tap bolts and high strength fasteners. As a top distributor of A325 and A490 structural bolts in the Northeast, we have all sizes in stock. We will produce specific requirements if needed. Wire Rope in New York.

Fehr Bros. Industries is a distributor of quality wire rope, wire rope assemblies, wire rope slings, stainless steel wire rope, aircraft cable, turnbuckles, rigging hardware, chains, and much more. Our name has been recognized in the U.S. since 1949.

As Sling Manufacturers, Hanes Supply"s sling production now includes chain slings, nylon slings, SlingMax slings and wire rope slings. Hanes Supply, Inc., has over 80 years experience splicing wire rope and manufacturing slings, as well as providing quality products to industry and the construction trades. Our expert staff is here to help you create lifting solutions for your lifting needs. Wire Rope in New York.

Leading the industry in the wholesale distribution of industrial rigging equipment and supplies, Peak Trading"s product line includes aircraft cables, wire rope, wire rope slings, wire rope assemblies and cable assemblies. We are committed to your 100% satisfaction, so call us today! Wire Rope in New York.

Manufacturer of standard and custom wire rope made from phosphorous bronze, Monel®, Inconel® and stainless steel. Available in 1/32 to 5/8 in. bare cable dia. Ropes are stranded, bright wire, galvanized and chemical, rotation and corrosion resistant. Suitable for straight line, medical device, standing rigging on sailboats, guy wire, push-pull assembly, cable railing, automotive control, winch, exercise equipment and lanyard applications. Serves the agricultural, automotive, construction, entertainment, lighting, marine, material handling, medical, military and security industries. Most items available in stock.

CED Can Provide You With the Highest Quality Elevator Wire Rope in the Industry. We Stock Large Quantities of Different Varieties to be Available for Whatever Type Job You May Have. All Cables are Cut to Length. Order Today, Ship Tomorrow! Call Today (866) CED-ELEV or request a quote at customerservice@cedelevator.com.

Wire rope strength in the United States is typically shown in tons of 2,000 lbs. The wire rope strength is shown as minimum breaking force (MBF). This is a calculated strength that has been accepted by the wire rope industry. When tested on a tensile machine, a new rope will break at a value equal to- or higher than – the minimum breaking force shown for that rope. The published values apply to new, unused rope. A rope should never operate at – or near- the minimum breaking force. The minimum breaking force of the rope must be divided by the design factor required for the application to determine the maximum load allowed on the rope. During its useful life, a rope loses strength gradually due to natural causes such as surface wear and metal fatigue.

Fatigue resistance involves fatigue of the wire used to make up a rope. To have high fatigue resistance, wires must be capable of bending repeatedly under stress – for example, as a loaded rope passes over a sheave during operation. Increased fatigues resistance is achieved in a rope design by using a large number of wires. It involves both the wire properties and rope construction. In general, a rope made of many wires will have greater fatigue resistance than a same – size rope made of fewer, larger wires because smaller wires have a greater ability to bend as a rope passes over a sheave or around drums. To overcome the effects of fatigue, ropes must never bend over sheaves or drums with a diameter so small as to bend wires excessively. Standard for specific applications contain requirements for minimum sheave and drum sizes. Every rope is subject to metal fatigue from bending stress while in operation, and therefore the rope’s strength gradually diminishes as the rope is used.

Crushing is the effect of external pressure on a rope, which damages it by distorting the cross-section shape of the rope, its strands or core -or all three. Crushing resistance therefore is a rope’s ability to withstand or resist external forces, and is a term generally used to express comparison between ropes. When a rope is damaged by crushing, the wires, strands and core are prevented from moving and adjusting normally during operation. In general, IWRC ropes are more crush

resistant than fiber core ropes. Regular lay ropes are more crush resistant than lang lay ropes. 6-strand ropes have greater crush resistance than 8-strand ropes or 19-strand ropes. Compacted strand ropes are more resistant than standard round-strand ropes.

When a load is placed on a rope, torque is created within the rope as wires and strands try to straighten out. This is normal and the rope is designed to operate with this load-induced torque. However, this torque can cause both single part and multiple part hoisting systems to rotate. Load induced torque can be reduced by specially designed ropes. In standard 6 and 8- strand ropes, the torques produced by the outer strands and the IWRC are in the same direction and add together. In rotation-resistant ropes, the lay of the outer strands is in the opposite direction to the lay of the inner strands, thus the torques produced are in opposite directions and the torques subtract from each other.

In stricter senses, the term wire rope refers to a diameter larger than 9.5 mm (3⁄8 in), with smaller gauges designated cable or cords.wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically, wire rope evolved from wrought iron chains, which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure, flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. While friction between the individual wires and strands causes wear over the life of the rope, it also helps to compensate for minor failures in the short run.

Wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators, and for transmission of mechanical power. Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an airplane connected to levers and pedals in the cockpit. Only aircraft cables have WSC (wire strand core). Also, aircraft cables are available in smaller diameters than wire rope. For example, aircraft cables are available in 1.2 mm (3⁄64 in) diameter while most wire ropes begin at a 6.4 mm (1⁄4 in) diameter.suspension bridges or as guy wires to support towers. An aerial tramway relies on wire rope to support and move cargo overhead.

Modern wire rope was invented by the German mining engineer Wilhelm Albert in the years between 1831 and 1834 for use in mining in the Harz Mountains in Clausthal, Lower Saxony, Germany.chains, such as had been used before.

Wilhelm Albert"s first ropes consisted of three strands consisting of four wires each. In 1840, Scotsman Robert Stirling Newall improved the process further.John A. Roebling, starting in 1841suspension bridge building. Roebling introduced a number of innovations in the design, materials and manufacture of wire rope. Ever with an ear to technology developments in mining and railroading, Josiah White and Erskine Hazard, principal ownersLehigh Coal & Navigation Company (LC&N Co.) — as they had with the first blast furnaces in the Lehigh Valley — built a Wire Rope factory in Mauch Chunk,Pennsylvania in 1848, which provided lift cables for the Ashley Planes project, then the back track planes of the Summit Hill & Mauch Chunk Railroad, improving its attractiveness as a premier tourism destination, and vastly improving the throughput of the coal capacity since return of cars dropped from nearly four hours to less than 20 minutes. The decades were witness to a burgeoning increase in deep shaft mining in both Europe and North America as surface mineral deposits were exhausted and miners had to chase layers along inclined layers. The era was early in railroad development and steam engines lacked sufficient tractive effort to climb steep slopes, so incline plane railways were common. This pushed development of cable hoists rapidly in the United States as surface deposits in the Anthracite Coal Region north and south dove deeper every year, and even the rich deposits in the Panther Creek Valley required LC&N Co. to drive their first shafts into lower slopes beginning Lansford and its Schuylkill County twin-town Coaldale.

The German engineering firm of Adolf Bleichert & Co. was founded in 1874 and began to build bicable aerial tramways for mining in the Ruhr Valley. With important patents, and dozens of working systems in Europe, Bleichert dominated the global industry, later licensing its designs and manufacturing techniques to Trenton Iron Works, New Jersey, USA which built systems across America. Adolf Bleichert & Co. went on to build hundreds of aerial tramways around the world: from Alaska to Argentina, Australia and Spitsbergen. The Bleichert company also built hundreds of aerial tramways for both the Imperial German Army and the Wehrmacht.

In the last half of the 19th century, wire rope systems were used as a means of transmitting mechanical powercable cars. Wire rope systems cost one-tenth as much and had lower friction losses than line shafts. Because of these advantages, wire rope systems were used to transmit power for a distance of a few miles or kilometers.

Steel wires for wire ropes are normally made of non-alloy carbon steel with a carbon content of 0.4 to 0.95%. The very high strength of the rope wires enables wire ropes to support large tensile forces and to run over sheaves with relatively small diameters.

In the mostly used parallel lay strands, the lay length of all the wire layers is equal and the wires of any two superimposed layers are parallel, resulting in linear contact. The wire of the outer layer is supported by two wires of the inner layer. These wires are neighbors along the whole length of the strand. Parallel lay strands are made in one operation. The endurance of wire ropes with this kind of strand is always much greater than of those (seldom used) with cross lay strands. Parallel lay strands with two wire layers have the construction Filler, Seale or Warrington.

In principle, spiral ropes are round strands as they have an assembly of layers of wires laid helically over a centre with at least one layer of wires being laid in the opposite direction to that of the outer layer. Spiral ropes can be dimensioned in such a way that they are non-rotating which means that under tension the rope torque is nearly zero. The open spiral rope consists only of round wires. The half-locked coil rope and the full-locked coil rope always have a centre made of round wires. The locked coil ropes have one or more outer layers of profile wires. They have the advantage that their construction prevents the penetration of dirt and water to a greater extent and it also protects them from loss of lubricant. In addition, they have one further very important advantage as the ends of a broken outer wire cannot leave the rope if it has the proper dimensions.

Stranded ropes are an assembly of several strands laid helically in one or more layers around a core. This core can be one of three types. The first is a fiber core, made up of synthetic material or natural fibers like sisal. Synthetic fibers are stronger and more uniform but cannot absorb much lubricant. Natural fibers can absorb up to 15% of their weight in lubricant and so protect the inner wires much better from corrosion than synthetic fibers do. Fiber cores are the most flexible and elastic, but have the downside of getting crushed easily. The second type, wire strand core, is made up of one additional strand of wire, and is typically used for suspension. The third type is independent wire rope core (IWRC), which is the most durable in all types of environments.ordinary lay rope if the lay direction of the wires in the outer strands is in the opposite direction to the lay of the outer strands themselves. If both the wires in the outer strands and the outer strands themselves have the same lay direction, the rope is called a lang lay rope (from Dutch langslag contrary to kruisslag,Regular lay means the individual wires were wrapped around the centers in one direction and the strands were wrapped around the core in the opposite direction.

Multi-strand ropes are all more or less resistant to rotation and have at least two layers of strands laid helically around a centre. The direction of the outer strands is opposite to that of the underlying strand layers. Ropes with three strand layers can be nearly non-rotating. Ropes with two strand layers are mostly only low-rotating.

Stationary ropes, stay ropes (spiral ropes, mostly full-locked) have to carry tensile forces and are therefore mainly loaded by static and fluctuating tensile stresses. Ropes used for suspension are often called cables.

Track ropes (full locked ropes) have to act as rails for the rollers of cabins or other loads in aerial ropeways and cable cranes. In contrast to running ropes, track ropes do not take on the curvature of the rollers. Under the roller force, a so-called free bending radius of the rope occurs. This radius increases (and the bending stresses decrease) with the tensile force and decreases with the roller force.

Wire rope slings (stranded ropes) are used to harness various kinds of goods. These slings are stressed by the tensile forces but first of all by bending stresses when bent over the more or less sharp edges of the goods.

Technical regulations apply to the design of rope drives for cranes, elevators, rope ways and mining installations. Factors that are considered in design include:

Donandt force (yielding tensile force for a given bending diameter ratio D/d) - strict limit. The nominal rope tensile force S must be smaller than the Donandt force SD1.

The wire ropes are stressed by fluctuating forces, by wear, by corrosion and in seldom cases by extreme forces. The rope life is finite and the safety is only ensured by inspection for the detection of wire breaks on a reference rope length, of cross-section loss, as well as other failures so that the wire rope can be replaced before a dangerous situation occurs. Installations should be designed to facilitate the inspection of the wire ropes.

Lifting installations for passenger transportation require that a combination of several methods should be used to prevent a car from plunging downwards. Elevators must have redundant bearing ropes and a safety gear. Ropeways and mine hoistings must be permanently supervised by a responsible manager and the rope must be inspected by a magnetic method capable of detecting inner wire breaks.

The end of a wire rope tends to fray readily, and cannot be easily connected to plant and equipment. There are different ways of securing the ends of wire ropes to prevent fraying. The common and useful type of end fitting for a wire rope is to turn the end back to form a loop. The loose end is then fixed back on the wire rope. Termination efficiencies vary from about 70% for a Flemish eye alone; to nearly 90% for a Flemish eye and splice; to 100% for potted ends and swagings.

When the wire rope is terminated with a loop, there is a risk that it will bend too tightly, especially when the loop is connected to a device that concentrates the load on a relatively small area. A thimble can be installed inside the loop to preserve the natural shape of the loop, and protect the cable from pinching and abrading on the inside of the loop. The use of thimbles in loops is industry best practice. The thimble prevents the load from coming into direct contact with the wires.

A wire rope clip, sometimes called a clamp, is used to fix the loose end of the loop back to the wire rope. It usually consists of a U-bolt, a forged saddle, and two nuts. The two layers of wire rope are placed in the U-bolt. The saddle is then fitted to the bolt over the ropes (the saddle includes two holes to fit to the U-bolt). The nuts secure the arrangement in place. Two or more clips are usually used to terminate a wire rope depending on the diameter. As many as eight may be needed for a 2 in (50.8 mm) diameter rope.

The mnemonic "never saddle a dead horse" means that when installing clips, the saddle portion of the assembly is placed on the load-bearing or "live" side, not on the non-load-bearing or "dead" side of the cable. This is to protect the live or stress-bearing end of the rope against crushing and abuse. The flat bearing seat and extended prongs of the body are designed to protect the rope and are always placed against the live end.

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands of the end of a wire rope are unwound a certain distance, then bent around so that the end of the unwrapped length forms an eye. The unwrapped strands are then plaited back into the wire rope, forming the loop, or an eye, called an eye splice.

A Flemish eye, or Dutch Splice, involves unwrapping three strands (the strands need to be next to each other, not alternates) of the wire and keeping them off to one side. The remaining strands are bent around, until the end of the wire meets the "V" where the unwrapping finished, to form the eye. The strands kept to one side are now re-wrapped by wrapping from the end of the wire back to the "V" of the eye. These strands are effectively rewrapped along the wire in the opposite direction to their original lay. When this type of rope splice is used specifically on wire rope, it is called a "Molly Hogan", and, by some, a "Dutch" eye instead of a "Flemish" eye.

Swaging is a method of wire rope termination that refers to the installation technique. The purpose of swaging wire rope fittings is to connect two wire rope ends together, or to otherwise terminate one end of wire rope to something else. A mechanical or hydraulic swager is used to compress and deform the fitting, creating a permanent connection. Threaded studs, ferrules, sockets, and sleeves are examples of different swaged terminations.

A wedge socket termination is useful when the fitting needs to be replaced frequently. For example, if the end of a wire rope is in a high-wear region, the rope may be periodically trimmed, requiring the termination hardware to be removed and reapplied. An example of this is on the ends of the drag ropes on a dragline. The end loop of the wire rope enters a tapered opening in the socket, wrapped around a separate component called the wedge. The arrangement is knocked in place, and load gradually eased onto the rope. As the load increases on the wire rope, the wedge become more secure, gripping the rope tighter.

Poured sockets are used to make a high strength, permanent termination; they are created by inserting the wire rope into the narrow end of a conical cavity which is oriented in-line with the intended direction of strain. The individual wires are splayed out inside the cone or "capel", and the cone is then filled with molten lead-antimony-tin (Pb80Sb15Sn5) solder or "white metal capping",zincpolyester resin compound.

Donald Sayenga. "Modern History of Wire Rope". History of the Atlantic Cable & Submarine Telegraphy (atlantic-cable.com). Archived from the original on 3 February 2014. Retrieved 9 April 2014.

Slip Op. 02-36 UNITED STATES COURT OF INTERNATIONAL TRADE Before: Judge Judith M. Barzilay ___________________________________ THE COMMITTEE OF DOMESTIC : STEEL WIRE ROPE AND SPECIALTY CABLE MANUFACTURERS, : Plaintiff, v. : Court No. 01-00209 Public Version : UNITED STATES, : Defendant, : and : COOPER TOOLS, INC., DRAGON TRADING INC., and THE INDUSCO GROUP, and USHA MARTIN INDUSTRIES, LTD and USHA MARTIN AMERICAS, INC., : : : : : and : NANTONG WIRE ROPE CO. and NANTONG ZHONGDE STEEL WIRE ROPE : : Defendant-Intervenors. ___________________________________ : [Plaintiff s Motion for Judgment Upon the Agency Record denied.] Decided: April 5, 2002 Harris Ellsworth and Levin, (Herbert E. Harris II), Jeffrey S. Levin, for Plaintiff. (Lyn M. Schlitt), General Counsel, (James M. Lyons), Deputy General Counsel, (Michael Diehl), Office of the General Counsel, U.S. International Trade Commission, for Defendant. Court No. 01-00209 Page 2 Grunfeld, Desiderio, Lebowitz, Silverman, & Klestadt LLP, (Bruce M. Mitchell), Jeffrey S. Grimson, for Defendant-Intervenors Cooper Tools, Inc., Dragon Trading Inc., and the Indusco Group. Wilkie, Farr & Gallaher, Christoper A. Dunn, for Defendant-Intervenors USHA Martin Industries, Ltd and USHA Martin Americas, Inc. Manatt, Phelps & Phillips, LLP, (Jeffrey S. Neely), for Defendant-Intervenors Nantong Wire Rope Company and Zhongde Steel Wire Rope. OPINION BARZILAY, JUDGE: I. INTRODUCTION Plaintiff in this case is a committee of domestic steel wire rope producers challenging the United States International Trade Commission"s ("ITC" or "Commission") final negative determination in Steel Wire Rope from China and India, 66 Fed. Reg. 18,509 (April 9, 2001), in which the Commission ascertained that steel wire rope imported from China and India caused neither material injury nor threat of material injury to the domestic industry. The Commission s reasoning was set forth in Steel Wire Rope From China and India,( Final Determination ), Inv. Nos. 731-TA-868-869, (Final), USITC Pub. 3406 (March 2001). Before the court is Plaintiff s USCIT R. 56.2 Motion for Judgment Upon the Agency Record. Plaintiff brings this action pursuant to 19 U.S.C. § 1516a(a)(2)(B)(ii) (1994); the ITC opposes Plaintiff s motion. Defendant-Intervenors Cooper Tools, Inc., Dragon Trading, Inc., and the Indusco Group ( Cooper Tools ) and Nantong Wire Rope Company and Nantong Zhongde Steel Wire Rope ( Nangtong ) also filed briefs opposing Plaintiff s motion. The court exercises jurisdiction Court No. 01-00209 Page 3 pursuant to 28 U.S.C. § 1581(c) (1994).1 For the reasons set out in the following opinion, the court denies Plaintiff s Motion for Judgment Upon the Agency Record. II. BACKGROUND On March 1, 2000, Plaintiff filed with the U.S. Department of Commerce ("Commerce" or "ITA") and the International Trade Commission a petition alleging that imports of steel wire rope from India, Malaysia, the People s Republic of China ( China ), and Thailand were being, or were likely to be sold, in the United States at less than fair value ( LTFV ) within the meaning of section 731 of the Tariff Act of 1930 and that such imports were the cause of material injury to an industry in the United States. See Committee of Domestic Steel Wire Rope and Specialty Cable Manufacturers Mem. in Supp. of Its Rule 56.2 Mot. for J. on the Agency R. ("Pl. s Br.") at 2-3. The ITC initiated a preliminary investigation on March 1, 2000, in response to the petition by instituting antidumping duty investigations Nos. 731-TA-868-871. On March 17, 2000, Commerce initiated antidumping duty investigations to determine whether imports of steel wire rope from China, India, Malaysia and Thailand were being sold, or were likely to be sold, in the United States at LTFV.2 Initiation of Antidumping Duty Investigations: Steel Wire 1 28 U.S.C. § 1581(c) provides: "The Court of International Trade shall have exclusive jurisdiction of any civil action commenced under section 516A of the Tariff Act of 1930." 2 Section 732(b)(1) of the Tariff Act of 1930, codified at 19 U.S.C. § 1673a(b)(1) (1994), provides: An antidumping proceeding shall be initiated whenever an interested party described in subparagraph (C), (D), (E), (F), or (G) of section 1677(9) of this title files a petition with the administering authority, on behalf of an industry, which alleges the elements necessary for the imposition of the duty imposed by section 1673 of this title, and which is accompanied by information reasonably available to the petitioner supporting those allegations. The Court No. 01-00209 Page 4 Rope From India, Malaysia, the People s Republic of China, and Thailand, 65 Fed. Reg. 16,173 (March 27, 2000). The Commission issued a preliminary injury determination on April 17, 2000, finding by a 6 to 0 vote that steel wire imports from China, India and Malaysia materially injured, or threatened to materially injure, the U.S. steel wire rope industry. Steel Wire Rope from China, India, Malaysia and Thailand, 65 Fed. Reg. 24,505 (April 26, 2000). On July 7, 2000, the Committee requested that Commerce postpone the issuance of its preliminary determination as to whether the steel wire rope was sold or likely to be sold in the United States at LTFV. On July 13, 2000, Commerce granted the request and postponed the issuance of its preliminary determination until September 25, 2000. See Notice of Postponement of Preliminary Antidumping Duty Determinations: Steel Wire Rope from India, Malaysia, and the People s Republic of China, 65 Fed. Reg. 45,037 (July 20, 2000). On September 25, 2000, Commerce issued an affirmative preliminary determination that steel wire rope from India and China were being sold in the United States for LTFV; however, Commerce issued a negative determination regarding steel wire imports from Malaysia. See Notice of Preliminary Determination of Sales at Less Than Fair Value: Steel Wire Rope From India and the People s Republic of China; Notice of Preliminary Determination of Sales at Not Less Than Fair Value: Steel Wire Rope From Malaysia, 65 Fed. Reg. 58,736 (October 2, 2000). In accordance with 19 U.S.C. § 1673d(b), Commerce notified the Commission of its preliminary determinations and the Commission began the final phase of its investigations. See Steel Wire Rope From China, India, and Malaysia, 65 Fed. Reg. 67,402 (November 9, 2000). petition may be amended at such time, and upon such conditions, as the administering authority and the Commission may permit. Court No. 01-00209 Page 5 In its final determination, Commerce found that steel wire rope from India and China was being sold, or was likely to be sold, in the United States at less than fair market value and that steel wire rope from Malaysia was not being sold in the United States at less than fair value. See Notice of Final Determination of Sales at Less Than Fair Value: Steel Wire Rope From India and the People s Republic of China; Notice of Final Determination of Sales at Not Less Than Fair Value: Steel Wire Rope From Malaysia, ( Commerce s Final Determination ), 66 Fed. Reg. 12,759 (February 28, 2001). Additionally, Commerce found that steel wire rope produced by one of the Chinese respondents, Fasten, was not being sold in the United States at LTFV. Commerce determined that the final estimated dumping margins on the subject imports from China ranged from 42.23% to 58% and the final estimated dumping margin for subject imports from India was 38.63%. Id. at 12,761. On March 21, 2001, the Commission determined by a vote of 6 to 0 that an industry in the United States was neither materially injured nor threatened with material injury by reason of imports of steel wire rope and transmitted its negative determination to Commerce. The Commission determined that a reasonable overlap of competition existed between the subject imports and the domestic like product and cumulated the subject imports from India and China. However, in its injury analysis, the Commission determined that the competition between the subject imports and the domestic like product was attenuated and therefore, did not materially injure or threaten to materially injure an industry in the United States. The Committee argues that the Commission: (1) applied varying, inconsistent and irreconcilable characterizations regarding the degree of competition which existed in the U.S. steel wire rope market between the subject imports and the domestic like product, (2) improperly Court No. 01-00209 Page 6 concluded that attenuated competition existed between subject imports and the domestic like product, and (3) failed to consider the magnitude of the dumping margins established by Commerce in its material injury and threat of material injury analysis. See Pl. s Br. at 6-8. Specifically, the Committee asserts that the Commission was inconsistent in determining that a reasonable overlap of competition existed for cumulation purposes, and at the same time finding that attenuated competition existed between the domestic product and subject imports, and therefore, concluding that the subject imports did not materially injure or threaten to materially injure the domestic industry. The Committee also asserts that the Commission s finding of attenuated competition between the subject imports and the domestic like product was flawed because it was not supported by substantial evidence. The Committee claims that [t]here is little or no evidence on the record to indicate that Indian imports carry the same qualitative shortcoming claimed by the exporters and importers of steel wire rope from China and the Commission s analysis did not account for substantial evidence on the administrative record that establishes subject imports from both China and India are in direct competition in the U.S. marketplace. Pl. s Br. at 7. Additionally, the Committee argues that the Commission failed to take into account the final estimated dumping margins that were determined by Commerce. The Commission and Defendant-Intervenors argue that the Commission s findings were consistent. The Commission argues that in both the cumulation and injury determinations the Commission found attenuated competition between the subject imports and the domestic like product. However, the statutory standards used for cumulation and injury determinations differ and it is consistent to find that the level of product fungibility and competition may satisfy the Court No. 01-00209 Page 7 reasonable overlap standard of cumulation yet still be insufficient to support a finding that the subject imports caused material injury to the domestic industry. See Def. s Br. at 13-18. The Commission asserts that substantial evidence on the record supports a finding that competition between subject imports and the domestic like product was attenuated due to differences in quality and product mix. Additionally, the Commission argues that its findings took into account all record evidence, which included the characteristics of the subject imports from India and all record evidence that was contrary to a finding of attenuated competition. See Id. at 17-18. In response to the Committee s claim that the estimated dumping margins were not considered in the Final Determination, the Commission claims [t]he Commission need not discuss every statutory factor or party argument. Rather, it must address the most relevant factors and arguments such that the agency s path can reasonably be discerned. Id. at 3. Therefore, the Committee s argument that the Commission did not take into account dumping margins determined by Commerce misapprehends the Commission s obligations in explaining the basis for its determinations. Id. III. STANDARD OF REVIEW The Committee asks the court to hold that the Commission s Final Determination is unlawful. The court must evaluate whether the finding in question is supported by substantial evidence on the record or is otherwise in accordance with law. See 19 U.S.C. § 1516a(b)(1)(B). Substantial evidence is [m]ore than a mere scintilla; it is such relevant evidence as a reasonable mind might accept as adequate to support a conclusion. Consolidated Edison Co. of New York v. NLRB, 305 U.S. 197, 229 (1938); Matsushita Elec. Indus. Co., Ltd. v. United States, Court No. 01-00209 Page 8 750 F.2d 927, 933 (Fed. Cir. 1984). This court noted, [i]n applying this standard, the court affirms [the agency"s] factual determinations so long as they are reasonable and supported by the record as a whole, even if there is some evidence that detracts from the agency s conclusions. Olympia Indus., Inc. v. United States, 22 CIT 387, 389, 7 F. Supp.2d 997, 1000 (1998) (citing Atlantic Sugar, Ltd. v. United States, 744 F. 2d 1556, 1563 (Fed. Cir. 1984). The court may not reweigh the evidence or substitute its own judgment for that of the agency. See Granges Metallverken AB v. United States, 13 CIT 471, 474, 716 F. Supp. 17, 21 (1989). Substantial evidence is "something less than the weight of the evidence, and the possibility of drawing two inconsistent conclusions from the evidence does not prevent an administrative agency"s finding from being supported by substantial evidence." Id., 13 CIT at 475, 716 F. Supp. at 21 (citations omitted). Additionally, absent a showing to the contrary, the agency is presumed to have considered all of the evidence in the record. Nat"l Ass"n of Mirror Mfrs. v. United States, 12 CIT 771, 779, 696 F. Supp. 642, 648 (1988). Thus, "to prevail under the substantial evidence standard, a plaintiff must show either that the Commission has made errors of law or that the Commission"s factual findings are not supported by substantial evidence." Id., at 774, 696 F. Supp. at 644. Court No. 01-00209 Page 9 IV. DISCUSSION A. The Commission s material injury and threat of material injury analysis was in accordance with law and supported by substantial evidence. To determine if the steel wire rope industry was materially injured by reason of the subject imports, the Commission had to first define the industry and the domestic like product.3 Additionally, the Commission was required by 19 U.S.C. § 1677(7)(G)(i) (1994) to cumulatively assess the volume and price effects of imports from all countries with respect to which petitions were filed and/or investigations self-initiated by Commerce on the same day, if such imports compete with each other and the domestic like product. In assessing whether to cumulate, the Commission applied the four-factor test it developed to determine if a reasonable overlap of competition existed between the subject imports and the domestic like product.4 See Final 3 19 U.S.C. § 1677(4)(A) states: [t]he term industry means the producers as a [w]hole of a domestic like product, or those producers whose collective output of a domestic like product constitutes a major proportion of the total domestic production of the product. 19 U.S.C. §1677(10) states: [t]he term domestic like product means a product which is like, or in the absence of like, most similar in characteristics and uses with, the article subject to an investigation under this subtitle. The Commission s definitions of the industry and domestic like product are not in dispute, therefore, the court need not focus on that portion of the Commission s determination. 4 The four factors considered are: (1) the degree of fungibility between the subject imports from different countries and between imports and the domestic like product, including consideration of specific customer requirements and other quality related questions; (2) the presence of sales or offers to sell in the same geographic markets of subject imports from different countries and the domestic like product; Court No. 01-00209 Page 10 Determination at 10. In the final phase of the antidumping investigation, the ITC was required to consider the volume of the subject imports, their effect on prices for the domestic like product and other economic factors that are relevant to its determining whether the steel wire rope industry in the United States was materially injured or threatened with material injury from the subject imports. See 19 U.S.C. § 1677(7)(B)(i) (1994); 19 U.S.C. § 1677 (7)(C)(iii) (1994). In determining to cumulate, the Commission analyzed the subject imports from China and India in relation to each other and the domestic like product and found that there was a reasonable overlap of competition. However, the Commission noted that [t]he record is . . . mixed regarding whether there is reasonable overlap of competition among the domestic like product and the subject imports from China and India. The subject imports and the domestic like product are sold through overlapping channels of distribution, and were present throughout the period of investigation, and in all geographic areas of the United States. Fungibility among the products is limited by the lower quality of subject imports from China and, to a lesser extent, subject imports from India. The subject imports higher concentration in galvanized carbon steel wire rope also limits fungibility. Nevertheless, producers, importers, and purchasers generally indicated that the subject product from China and India and the domestic like product are all at least sometimes interchangeable, and are often used in the same applications. Final Determination at 20. To support its conclusion, the Commission detailed the conditions of competition in the United States market and cited this information in its determination. See Final Determination at 19-20 n. 79-84 (citing to Part II of the Confidential Staff Report Steel (3) the existence of common or similar channels of distribution for subject imports from different countries and the domestic like product; and (4) whether the subject imports are simultaneously present in the market. Final Determination at 15 (citing Certain Cast-Iron Pipe Fittings from Brazil, the Republic of Korea, and Taiwan, Inv. Nos. 731-TA-278-280 (Final), USITC Pub. 1845 (May 1986), aff d Fundicao Tupy, S.A. v. United States, 12 CIT 231, 678 F. Supp. 898, aff d 859 F.2d 915 (Fed. Cir. 1988)). Court No. 01-00209 Page 11 Wire Rope From China and India, Inv. Nos 731-TA- 868-869 (Final) (March 9, 2001), Administrative Record, List 2, Doc. 169 ( Staff Report ). The Commission analyzed the channels of distribution, supply and demand considerations, substitutability issues, and the supply and demand elasticity in the United States market. Id. Although the Commission did find that there was reasonable overlap of competition which statutorily required that the subject imports from China and India be cumulated, the Commission recognized that competition between the domestic like product and the subject imports was attenuated due to quality and product mix issues. See Determination at 16. This finding became particularly relevant for the Commission s injury analysis in the final phase of the investigation. In the injury determination analysis, the Commission is required to consider (1) the volume of the imports, (2) their effect on prices for the domestic product, (3) their impact on domestic producers of the domestic like product, but only in the context of production operations within the United States, and (4) other economic factors that are relevant to the injury determination.5 In this case, the Commission determined that the domestic industry was not 5 19 U.S.C. § 1677(7)(B) (1994) provides: (B) Volume and consequent impact In making determinations under sections 1671b(a), 1671d(b), 1673b(a), and 1673d(b) of this title, the Commission, in each case-(i) shall consider-(I) the volume of imports of the subject merchandise, (II) the effect of imports of that merchandise on prices in the United States for domestic like products, and (III) the impact of imports of such merchandise on domestic producers of domestic like products, but only in the context of production operations Court No. 01-00209 Page 12 materially injured by reason of the subject imports sold in the United States at less than fair value. The Commission, in evaluating the volume of imports, found that the increase in volume of imports from China and India did not adversely affect the United States producers market share. It did, however, find that the market shares for nonsubject imports were negatively impacted by the increased volume of subject imports. The record also indicates that subject imports accounted for [ ] percent of U.S. apparent consumption in interim 1999, and [ ] percent in interim 2000. The U.S. producers share, however, remained [ ] during the same period, at [ ] percent in interim 1999, and [ ] percent in interim 2000. The increase in share by the subject imports between interim 1999 and interim 2000 therefore came at the expense of nonsubject imports. That subject imports displaced nonsubject imports is consistent with record evidence that galvanized carbon steel wire rope made up more than one-half of subject imports, and almost half of nonsubject imports, but only a small share of domestic production. Final Determination at 25-26 (footnotes omitted). The Commission also used record evidence to establish that the price of the subject imports did not have significant price depressing effects on the domestic like product. Final Determination at 28. The Commission cited to specific record evidence that substantiated its within the United States; and (ii) may consider such other economic factors as are relevant to the determination regarding whether there is material injury by reason of imports. In the notification required under section 1671d(d) or 1673d(d) of this title, as the case may be, the Commission shall explain its analysis of each factor considered under clause (i), and identify each factor considered under clause (ii) and explain in full its relevance to the determination. Court No. 01-00209 Page 13 finding that the subject imports did not negatively affect domestic like product prices. The Commission collected quarterly price information on seven types of steel wire rope, designated products 1 through 7. The volume of the sales of the domestic like product was very small in all but 1 and 2 (consisting of bright carbon steel wire rope) and product 5 (consisting of galvanized carbon wire rope). There was no clear downward trend in the price of domestically produced steel wire rope in any of these three product categories. For product 1, prices for the domestic product were highest at the end of the review. Prices for domestic product 2 increased and then fell during the period, but ended at a level [ ] above their starting point. Prices for the domestic product 5 ended [ ] lower than they began, but increased in each of the last three quarters. Final Determination 26- 27 (footnotes omitted). Additionally, the Commission noted that the substitutability between subject imports and the domestic like product was limited because subject imports generally are lower in quality than the domestic like product. Moreover, galvanized carbon steel wire rope accounts for over half of subject imports but only a small share of domestic production. These factors limit substitutability between the domestic like product and the subject imports, and therefore limit the potential effects on subject imports domestic prices. Final Determination at 26. Similarly, the record evidence demonstrated that (1) petitioners announced various price increases, (2) domestic producers cost of goods sold as a percentage of net sales increased minimally, while their operating income remained stable, and (3) the attenuated competition between the subject imports and the domestic like product limited the ability of the subject importers to suppress price increases of the domestic like product. We also found that subject imports did not have significant price depressing effects on the domestic like product. The record does not reflect any clear downward trend in prices for the domestic like product. Nor do we find that subject imports prevented to a significant degree price increases by the domestic industry that otherwise would have occurred. First, petitioners announced various price increases, which the record suggests were collected, in whole or in part, in at least some instances. Second, domestic producers cost of goods sold as a percentage of net sales increased very little, while their operating income was generally stable. Third, because competition between subject imports and domestic like product is attenuated, subject imports ability to suppress price increases is similarly limited. Court No. 01-00209 Page 14 Final Determination at 28-29 (footnotes omitted). In its impact analysis, the Commission must consider all the relevant economic factors that bear on the state of the industry in the United States. See 19 U.S.C. § 1677(7)(C)(iii) (1994). The Commission noted that although the industry s performance was not particularly strong, the cause of the weakness was not the subject imports. In fact, the Commission found that the major reason for the domestic industry s market share loss was caused by nonsubject imports. Subject imports market share increased less than [ ] from 1998 to1999, from [ ] to [ ] percent. While subject imports market share was the highest in interim 2000, that was also the period the industry was most profitable. In addition, prices collected on various subject products did not exhibit a clear downward trend, and AUVs (average unit values) for the subject imports decreased only [ ] from 1998 to 1999, from $[ ] per short to $[ ] per short ton. Previously, from 1997 to 1998, the domestic industry lost [ ] in market share, but nonsubject imports accounted for the bulk of the loss [ ]. Final Determination at 33-34 (footnotes omitted). In addition to the price, volume and impact analysis, the Commission also noted in its injury analysis important conditions of competition that supported its negative injury determination. The Commission found that although domestic and imported steel wire rope both generally conform to specifications, certain factors limit competition between them. More than onehalf of subject imports are galvanized carbon steel wire rope, while less than two percent of domestic production is galvanized. Many purchasers and distributors state that only domestic product is used for so-called critical applications: those in which failure of the rope could result in damage, injury or death. Similarly, various steel wire rope distributors expressed concern over liability arising out of any failure by imported steel wire rope they might sell, particularly imports from China. Final Determination at 22 (footnotes omitted). Similarly, a contributing factor to the domestic industry s drop in capacity, which caused a drop in production in 1999, could be attributed to Court No. 01-00209 Page 15 consolidation within the industry. In its impact analysis the Commission stated: [t]he decline in capacity in 1999 reflects the fact that domestic producer WRCA (Wire Rope Corporation of America) retired all but one of the production facilities it acquired from Rochester and Macwhyte. Domestic production capacity was 123,715 short tons in interim 1999 and 135,535 short tons in interim 2000, consistent with [ ]. The domestic industry s production fell from 127,833 short tons in 1997, to 118,047 short tons in 1998, and to 108,655 short tons in 1999. However, production was higher in interim 2000, at 80,801 short tons, than in interim 1999, at 78,955 short tons. Final Determination at 30-31 (footnotes omitted). Therefore, the Commission concluded that purchasers preference for domestic product and industry consolidation were significant factors that supported a finding that subject imports did not cause material injury to the domestic industry. Having determined that the subject imports did not cause material injury to a domestic industry, the Commission then focused its analysis to determine if the subject imports threatened material injury to the domestic industry. Under 19 U.S.C. § 1677(7)(F)(ii) (1994), the Commission is required to determine whether further dumped or subsidized imports are imminent and whether material injury by reason of imports would occur unless an order is issued or a suspension agreement is accepted. . . . 6 6 19 U.S.C. § 1677(F) states the factors the Commission is required to consider in its threat of material injury determination. F) Threat of material injury (i) In general In determining whether an industry in the United States is threatened with material injury by reason of imports (or sales for importation) of the subject merchandise, the Commission shall consider, among other relevant economic factors-- Court No. 01-00209 Page 16 (I) if a countervailable subsidy is involved, such information as may be presented to it by the administering authority as to the nature of the subsidy (particularly as to whether the countervailable subsidy is a subsidy described in Article 3 or 6.1 of the Subsidies Agreement), and whether imports of the subject merchandise are likely to increase, (II) any existing unused production capacity or imminent, substantial increase in production capacity in the exporting country indicating the likelihood of substantially increased imports of the subject merchandise into the United States, taking into account the availability of other export markets to absorb any additional exports, (III) a significant rate of increase of the volume or market penetration of imports of the subject merchandise indicating the likelihood of substantially increased imports, (IV) whether imports of the subject merchandise are entering at prices that are likely to have a significant depressing or suppressing effect on domestic prices, and are likely to increase demand for further imports, (V) inventories of the subject merchandise, (VI) the potential for product-shifting if production facilities in the foreign country, which can be used to produce the subject merchandise, are currently being used to produce other products, (VII) in any investigation under this subtitle which involves imports of both a raw agricultural product (within the meaning of paragraph (4)(E)(iv)) and any product processed from such raw agricultural product, the likelihood that there will be increased imports, by reason of product shifting, if there is an affirmative determination by the Commission under section 1671d(b)(1) or 1673d(b)(1) of this title with respect to either the raw agricultural product or the processed agricultural product (but not both), (VIII) the actual and potential negative effects on the existing development and production efforts of the domestic industry, including efforts to develop a derivative or more advanced version of the domestic like product, and (IX) any other demonstrable adverse trends that indicate the probability that there is likely to be material injury by reason of imports (or sale for Court No. 01-00209 Page 17 The Commission found that: [t]he record indicates that no significant increase in the volume or market penetration of subject imports is imminent. Although subject producers had the ability to increase significantly the volume of their exports to the U.S. market during the period of investigation, they did not do so. There is no persuasive evidence in the record that indicates that this behavior will change in the imminent future. We also find that subject imports are not likely to enter the United States at prices that will depress

8613371530291

8613371530291