wire rope inspection requirements price

This safety saying from the early 1900s applies well to the lifting and material-handling industries. And that is especially true for the inspection of specialty ropes used in overhead lifts on your cranes.

Third-party crane rope inspections are a fairly new concept in the lifting and rigging industry. It’s a streamlined process where you will get some extra documentation and protection before your crane is put into service.

The lifting and rigging industry is dynamic, and price increases continue impacting vendors and customers alike. Because of that, it’s important for you to be as precise with your expenditures as possible, while still making sure everything with your crane and its ropes are in working order before it actually goes to a jobsite.

When the crane returns from the field, the rope may no longer be in good working order and should be inspected before going back into service on another job. This would be the time to bring in a third-party inspector to examine your rope, especially if your operators are unable to determine whether the rope should stay in service or be discarded.

If this process isn’t completed, and there is enough damage to meet removal from service criteria, the ropes must be replaced in the field. Replacing crane ropes in the field is much more complicated and costly, especially if a hot shot is required. In the crane ropes industry, a “hot shot” is an expedited order that is needed because an inactive crane is costing the renter thousands of dollars an hour in downtime.

First, you must find a company that has the correct rope for your crane. Then, there’s the matter of shipping and delivery, as well as finding an experienced technician who can remove the old crane rope and install new ones.

The moment a technician arrives on location, they’re going to set up the equipment. Then, they’re going to conduct and discuss the Job Safety Analysis (JSA) with everyone involved in the inspection.

Mazzella technicians will dictate how the inspection is going to occur, and explain whether we need access to the equipment all day, as well as provide a rough timeframe for completion of the process.

We require each technician to take between 20 and 50 pictures per inspection for documentation purposes. Everything we do in the field is going to be documented on a piece of paper and photographically. The report and photos will be given to you at the end of the inspection.

During the inspection, the technicians are tasked with conducting specific measurements. If they find damage, they’re noting damage in their report. They count the number of wire breaks and note other potential damage that was found. When they pull off the rope, they take rope diameter measurements every 500’ to make sure there is not less visible damage to the rope.

You do need to have a crane operator on site to help with the inspection. Also, if the crane requires a mechanic to reset some of the codes and indicators, then they need to be on location, too.

A properly trained inspection technician should be able to handle the majority of the inspection himself. However, with certain cranes, you really need to be on-site to support the technician. Additionally, you should designate an on-site person to handle the paperwork.

During a rope inspection, our technicians will communicate with the decision-maker throughout the entire process so there are no surprises at the end. If we do find broken wires, we let you know right away. If in the middle of a rope inspection, we find broken wires, we’re going to let you know we found damage.

A lot of the cost will be dependent on the location of the crane versus where our technician(s) and equipment are located at the time you need the inspection. When you consider the price of the rope, investing in an inspection could save you a significant amount of money from potential downtime after the crane is in the field.

The hourly rate for Mazzella crane ropes inspectors is between $195 and $250. That’s our technician’s rate from the time they leave the shop until they get back after the inspection is complete.

The overall length and time of the inspection also affects the cost. Weekends and holidays will come with higher rates for the technician’s services. Also, if multiple technicians are needed to service multiple cranes, that will add to the overall cost of an inspection.

Mazzella is a one-stop-shop for high-performance crane ropes, or any kind of specialty ropes. Also, we have fittings and sockets that we can install, and a large inventory of ropes in stock that allow us to help get you back up and running as quickly as possible.

We offer a new rope replacement off the same truck and trailer that we’re doing the inspection from. If it’s a rope replacement, that’s something we can typically get on a truck and on the way the same day if the order is placed by 2 p.m. EST. If that happens, we can get the rope on the road and conduct the install the next day.

We have one of the largest crane ropes inventories in the United States…ready for immediate delivery! We provide wire rope assemblies, and manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies:In sizes from ¼” to 3” diameter and 9mm to 52mm diameter

On top of all that, you’re probably also responsible for rigging inspectionsand maintenance of any overhead lifting slings, hardware, below-the-hook devices, and personal fall protection that your employees use on a daily basis.

As we all know, OSHA and ASME have some type of standard or regulation related to the usage and inspection of each piece of equipment in your shop or facility. It can make your head spin trying to make sure that your facility is in good standing with sanctioning bodies and that your employee’s equipment is compliant, in proper working condition, and safe for them to use.

At Mazzella, we have one of the few business units in the industry that is dedicated solely to the inspection of lifting and rigging equipment, below-the-hook lifting devices, and personal fall protection equipment. Our growing team of Rigging Inspectors are fully certified through an accredited training program to understand all of the related ASME standards and assist you in getting your company’s lifting and rigging inspection program in compliance.

There are two industry standards that exist to provide the end-user with guidelines for inspection and criteria that warrants removal from service: OSHA 1910.184 and ASME B30.9 Slings.

Best practice is to inspect all rigging equipment upon receiving it from your supplier. For lifting slings, double-check the sling tags to make sure it’s what you ordered and that the rated capacity meets all of your project specifications and lifting requirements.

Designate a Competent Person to perform a daily visual inspection of hardware, slings, and all fastenings and attachments for damage, defects, or deformities. The inspector should also make sure the rigging gear being used for the lift meets the specific job requirements it’s being used for.

Users can’t rely on a once-a-day inspection for slings, shackles, hoist rings, hooks, etc. if they’re being used multiple times throughout the day. Damage to rigging equipment can occur on one lift and best practice is to perform a visual inspection before any shift change or changes in lifting application. Because shock loads, severe angles, sharp edges, and excessive heat can quickly cause damage to a lifting sling, the user should inspect all slings prior to each lift.

A documented periodic inspection is performed by either a professional service provider, or a Qualified Person every 12 months (at a minimum) and monthly to quarterly in more severe service conditions. The following are all determining factors in scheduling the frequency of a periodic inspection:Frequency of use

Depending on the severity of the operating environment and frequency of use, your business may decide that a more thorough sling inspection should occur more often than the minimum yearly requirement.

As an employer, you are required to maintain a record of the most recent thorough inspection—however, individual records for each sling that was inspected are not required. Failure to maintain and retain inspection records is one of the most common issues we see that can prevent a company from reaching full OSHA compliance.

To get the process rolling, a customer reaches out to a company who performs rigging inspections because they know they need some sort of documented third-party inspection of their rigging equipment. Oftentimes, we hear, “I know I need my slings inspected…tell me what I need to do and where I need to start.”

Typically, all you need is a phone call to give the inspection provider an idea of what type of inspection you’re looking for. Are you looking for an inspection that satisfies OSHA 1910.184?

Do you have lifting slings, below-the-hook devices, rigging hardware, or personal fall protection and need an inspection that covers all of the applicable ASME standards? Or, do you have a more stringent internal compliance program in place and you need an inspection to cover your stricter internal standards?

The brief consultation will give the service provider with an understanding of the types of rigging gear you have in your facility, how much of it needs to be inspected, and what your timeframe is to fulfill the mandated periodic inspection requirements.

Once the inspection is scheduled, the company will determine approximately how long the inspection should take place and how many inspectors will be required. For a smaller manufacturing or production facility, one inspector can typically handle a full inspection over the course of a 4-8 hour period.

Unlike overhead crane inspections, rigging inspectors prefer to perform their inspections when production is up and running. This way, all of the gear that they need to inspect is out and available to them. The inspectors can move quickly through rigging products without disrupting production—spending only a few minutes inspecting each piece, before moving on to the next.

After the inspection has been performed, the inspectors should provide you with some type of digital report that they review with you, and then, leave with you to keep for your records. This report can include:The total number of products inspected and the number of slings, hooks, shackles, etc. that passed or failed based on ASME inspection criteria

Over the course of an inspection, a rigging inspector can inspect any of the following product types:Lifting Slings: alloy chain slings, wire rope slings, synthetic roundslings, synthetic web slings, metal mesh chain slings, synthetic rope slings

At the end of the inspection, you should receive a comprehensive inspection report that will give you insight into the effectiveness of your internal compliance programs and the training of your riggers and crane operators.

Remember, OSHA won’t penalize you for having gear that failed inspection and was removed from service. If anything, you can look at the numbers from your inspection reports and determine if there should be a larger investment in training for your riggers and operators. These types of reports can help you understand:Are your employees inspecting their gear before each shift? Inspecting their gear before each lift?

There are a few other factors that can affect the cost of a rigging inspection. All of the factors listed below can affect the overall cost of a rigging inspection in one way or another:

Will the inspector need to provide any type of special equipment for magnetic particle testing, or on-site proof testing? Will the inspector need to apply inspection tags to all material that was looked at during the course of the inspection?

If an inspector has to travel to a location outside of their normal territory, or an inspection will last more than one day, then the customer may be required to pay for travel / lodging / meal costs.

Is additional safety training required for an inspector to come on your job site or access your facility? Additional training will add on to the number of hours required for the inspection and increase costs. It’s best to let your rigging inspection provider know about this upfront so they can build it into their quote.

Every company that offers rigging inspection services has its own business model or set pricing. You may have even been offered a “free” rigging inspection in the past, and you’re confused about why you should pay for services that you can have performed at no cost from another provider. That’s a topic we’ve already covered in depth, but just understand that a company who performs free inspections of your rigging gear may not have your best interests in mind, and may not be able to provide you with:Digital reporting outputs for ASME records retention requirements

When you contact a rigging inspection provider, make sure you ask for their hourly rate, plus an estimate of the total number of hours required to complete the inspection process at your facility.At a minimum, a four-hour rigging inspection could cost around $480. For a full-day, eight-hour rigging inspection, you could expect to pay around $960. Mazzella’s rate for a rigging inspection is around $120 / hour.

Anything longer than eight hours in a single day would add overtime pay to the total cost. A multi-day inspection would obviously cost more based on the total number of days (or hours) required, and the total number of inspectors required to complete the inspection in a timely manner.

Also, be prepared to replace or repair some of the rigging equipment that is found to be unfit for continued use during the course of an inspection. You may need to allocate additional funds to cover the cost of purchasing replacement slings, hooks, personal fall protection gear, etc.

Remember, bringing a third-party rigging inspector into your facility shouldn’t be considered an added expense, but instead, an investment in the safety of your employees. If you have the proper compliance processes in place, and your employees are properly trained, then a rigging inspection should really just be a validation of how well those programs are working.

If an inspector comes in and verifies that your rigging gear is in proper working condition—that shows your employees have been trained to identify damaged or failed products and they know what to do with that damaged product once it’s been identified.

On the reverse side, if you end up with a large amount of damaged rigging gear at the end of an inspection, use that as an opportunity to improve your internal processes. You may learn that this is an opportunity to provide more training for your employees.

Also, lean on the inspectors to help identify products that your employees may not be using properly or may not be the most practical for your lifting application. They can make recommendations based on best practices they’ve seen across all industries, and also, make recommendations for improvement based on their knowledge of the applicable ASME standards.

At Mazzella, we have a dedicated team of Rigging Inspectors that are independently trained and certified. Their only responsibility is to come on-site and perform a thorough inspection of your rigging gear, address solutions as required, and complete the service in a timely manner.

OSHA 1910.184, ASME B30.9, B30.20, B30.26, & ANSI Z359 Require … Periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions.

Any wire rope in use should be inspected on a regular basis. You have too much at stake in lives and equipment to ignore thorough examination of the rope at prescribed intervals.

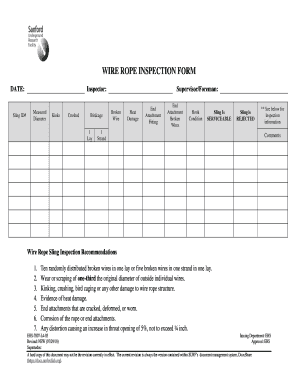

The purpose of inspection is to accurately estimate the service life and strength remaining in a rope so that maximum service can be had within the limits of safety. Results of the inspection should be recorded to provide a history of rope performance on a particular job.

On most jobs wire rope must be replaced before there is any risk of failure. A rope broken in service can destroy machinery and curtail production. It can also kill.

Because of the great responsibility involved in ensuring safe rigging on equipment, the person assigned to inspect should know wire rope and its operation thoroughly. Inspections should be made periodically and before each use, and the results recorded.

When inspecting the rope, the condition of the drum, sheaves, guards, cable clamps and other end fittings should be noted. The condition of these parts affects rope wear: any defects detected should be repaired.

To ensure rope soundness between inspections, all workers should participate. The operator can be most helpful by watching the ropes under his control. If any accident involving the ropes occurs, the operator should immediately shut down his equipment and report the accident to his supervisor. The equipment should be inspected before resuming operation.

The Occupational Safety and Health Act has made periodic inspection mandatory for most wire rope applications. If you need help locating the regulations that apply to your application, please give our rigging experts a call.

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

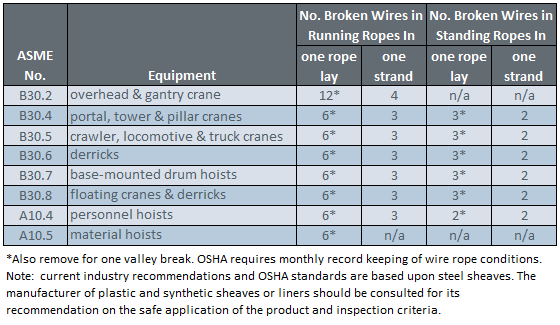

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

This 12-page brochure presents important guidelines for inspecting wire rope systems or installations. It provides a clear and concise approach to assisting wire rope users" needs to comply with industry and governmental regulations that require inspections of individual ropes, fittings and attachments, as well as entire operating systems at regularly scheduled intervals. It is very useful for conducting safety meetings and training sessions. In addition to information and criteria, the brochure includes a blank Inspection Form, which may be easily copied for recording results of regular inspections for the permanent, written files required by many regulations.

Wire ropes are largely used in marine environment or for rigging purposes. They receive considerable loads and thus suffer a great deal of mechanical damage throughout their service life. Moreover, research has shown that the major cause of wire rope failure is excessive deterioration and corrosion, lack of maintenance and inspection, and wrong usage resulting in early discarding, reduced safety and replacement cost increase.

Sometimes damage can be easily detected, while in other cases fractured wires may occur on the inside. Hence, wire ropes should be inspected and maintained by the right person (competent person assigned by the company), to assure they’re in perfect condition. Regular inspectionsensure high rope performance, long service lifetime , safety of personnel and equipment, and reduced operating costs.

All ropes (synthetic, high modulus and wire ropes) should be inspected before and after an operation. This guideline ensures maximum safety for both a ship’s personnel and equipment. Even though it’s difficult to determine the exact service life span of ropes, there is a way to have a more precise estimation about their efficient lifecycle. Calculating the exact time ropes have been in use (e.g mooring time, mooring conditions, weather and tidal conditions) is the answer. All in all, rope inspections should occur at least once a year.

Inspecting wire ropes in particular, comes with great responsibility. Inspection results should be recorded, and any defects noticed have to be reported and addressed properly. Some defects can be repaired, while in some cases replacing a wire rope is inevitable.

Periodical inspections ofvessel deck equipment is also crucial for maintaining the good condition of wire ropes. The condition of the drum, chocks, bitts, rollers, sheaves, cable clamps and other end fittings, affect the rope’s performance, threads and cords. Make sure to mark these parts during your overall inspection.

In order to help marine officers and staff conduct successful wire rope inspections – and keep an up-to-date record of them – we have created an inspection solution that helps in maintaining and monitoring a ship’s ropes and deck equipment.

When calculating mass using F = Minimum Breaking Force, according to the wire rope’s diameter, you can determine the Minimum Breaking Massand therefore the wire’s max strength. When calculating mass using F = Safe Load according to the wire rope’s diameter, you can determine the Safe Load Mass,which is the advised load for this rope diameter.

The strands of a wire rope absorb the majority of the tensile force applied on the rope. Their design and manufacturing standards affect the level of fatigue resistance and resistance to abrasion. An easy way to understand which rope design is suitable for each purpose, is the wire rope classification.

Wire ropes are classified according to the number of strands in each construction and the number of wires in each strand. For example, a classification of 6X19 means that a wire rope of this type always has six strands, but its wires could be 15-26 per strand. This is because 19 is not the exact number of wires, but the classification of a wire number range.

Visual inspections are a common and fast way to assess wire rope condition. Both the standard and rotation resistant wire rope inspectionprocesscomply with the same four steps of examination. A ship’s crew can perform them as follows:

Steel wire rope distortion is obvious in most cases and can easily be identified by the inspector or the ship‘s crew. It usually occurs if load is suddenly applied or abruptly released (shock loading), or even if swift torque is forcefully induced.

Although not all of these deformations make the rope absolutely dangerous to use, they all may cause ropes to wear unevenly in time. This means inspections should take place more often, and distorted ropes should be handled with caution.

The rag and visual inspection is a good method for regular inspection intervals. The inspector pulls a rag along the rope trying to find broken wire cords. If the rug gets snagged by the rope, the inspector has to stop and assess the wire rope’s condition. Extreme caution should be exercised during the visual inspection, and under no circumstances should this method be the only one used to inspect wire ropes.

Tip: When you encounter a protruding wire end, bend it back and forth manually, until it separates from the wire. This will protect neighboring wires from wearing out.

Diameter reduction is a critical factor in steel wire rope wear and if not properly taken care of, it can result in rope breakage. Excessive abrasion, loss of core mass, corrosion or inner wire failure are all factors that contribute to diameter reduction.

To get an accurate measurement of the rope’s diameter, measure the rope at three different points at least 5 feet apart. Take the average of these three measurements to determine the true diameter.

Any measurements showing a reduction of ⅓ or more, indicate that a replacement should follow without delay. A diameter reduction of less than 1/3 still requires attention, and the inspector or the ship’s crew should be on guard in the next scheduled wire rope inspection.

Failure from abrasion or corrosion is a result of deficient deck equipment inspection or insufficient wire rope lubrication respectively. Internal corrosive damage is more difficult to identify than any other types of degradation. In most cases, the damage has progressed more than the external signs suggest.

Wire rope storage plays a significant role in the rope’s operation life.Wire rope corrosion and pitting can be avoided if ropes are safely stored in a clean, cool, dry and well-ventilated place. Steel wire ropes should not by any means rest on the floor, and should be protected from water, dust or any chemical fumes. Long term storage requires periodic greasing, turning the reel upside down for preventing grease dripping and possibly re-winding to another reel with larger inner tube diameter.

Wire ropes should be maintained with periodical lubrication. In order to prevent internal corrosion, a pressure lubricator is suggested to be used. In this case, a small amount of grease is used to lubricate the rope internally, while the deck stays grease-clean. Pressure lubricators clean the rope before they grease it so that the new grease enters a clean rope. The type of grease used is very important for maximum protection and greasing efficiency.

Steel wire ropes exposed to dirt, grime and other contaminants, have to be cleaned with a wire brush and petroleum (unless a pressure lubricator is used). Optimal cleaning of wire ropes can extend their service life and guarantee safe operations.

The reeling process is of high importance for the longevity of wire ropes. To protect them from being damaged, it is important that the surface of the drum is clean, smooth and dry. Improper reeling may cause wire-rope strands to spread or get flattened, when in contact with one another, as successive layers are being spooled and upper layers apply pressure on the lower ones.

Katradis S.A. offers a wide range of top quality wire ropes for shipping (mooring and hoisting operations), fishing and construction purposes. Our wire ropes have greater resistance to fatigue, and they distribute tension force equally among the rope strands. They are less likely to kink, providing higher staff safety and assuring operation success.

The MOL, CSA, OHSA and ANSI, AMSE and OSHA are North American governing bodies which legislate that inspections be performed at regular service intervals.

Immediately after the inspections are complete you will receive your certifications and will be in compliance with the Ministry of Labor and Government Law & Regulations

All running ropes in service should be visually inspected, at least, once each working day. A visual inspection shall consist of observation of all rope which can reasonably be expected to be in use during the day’s operations.

A – Distortion of the rope such as kinking, crushing, unstranding, birdcaging, main strand displacement, or core protrusion. Loss of rope diameter in a short rope length or unevenness of outer strands should provide evidence that the rope must be replaced.

Inspect the entire length of the rope. Some areas of the wire rope such as around the core are more difficult to inspect. To inspect the core, examine the rope as it passes over the sheaves. The strands have a tendency to open up slightly which will give the inspector a better view of the core. Also regularly inspect for any reduction in diameter and lengthening of rope lay as both conditions indicate core damage.

Wire ropes undergo constant stress and wear through daily use. So, wire rope requires monthly inspection in accordance with this section to reduce the risk of failure and potential resulting injury or property damage. In addition, this section covers criteria to use in determining when to replace rope, and requires inspection of rope on equipment that has been idle for a month or more, before the rope and equipment can be returned to service.

A thorough inspection of all ropes shall be made at least once a month and a certification record which included the date of inspection, the signature of the person who performed the inspection and an identifier for the ropes which were inspected shall be kept on file where readily available to appointed personnel. Any deterioration, resulting in appreciable loss of original strength, shall be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard. Some of the conditions that could result in an appreciable loss of strength are the following:

All rope which has been idle for a period of a month or more due to shutdown or storage of a crane on which it is installed shall be given a thorough inspection before it is used. This inspection shall be for all types of deterioration and shall be performed by an appointed person whose approval shall be required for further use of the rope. A certification record shall be available for inspection which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the rope which was inspected.

Wear and damage to wire rope can’t always be seen on the surface. Konecranes RopeQ Magnetic Rope Inspection pairs visual inspection with non-destructive testing to detect internal broken wires that may escape detection through traditional inspection methods.

Wire rope isa type of cablewhich is made up of several strands of metal wirelaid or twisted into a braid or helix.Do you know how often your wire rope needs to be inspected? Wire rope inspections are vital to industries that use wire rope.

One of the most important purposes of carrying out wire rope inspections or testing is to oversee the process of depreciation in the wire rope. When any depreciation or deterioration is identified these wire ropes can cease to be used immediatelybefore it becomes a hazard. A great advantage of conducting these examinations is to analyse and identify if there is unexpected corrosion and destruction.

Commonly, there is a constant increase rate in the amount of wire rope breaks, during the lifespan of that wire rope. Wire ropes need to be inspected and tested as they have a limited life, like all consumable products. Early in the life of the wire rope (when it is starting to be used), the wires and strands of the rope settle into position and the breaking strength increases. Once it has hit its maximum, the breaking strength then decreases rapidly.

Wire rope inspections should only be carried out by highly trained professionals. There are 2 ways that these inspections are carried out on crane wire rope: Visual and Non-Destructive. Visual and no-destructive examinations are equally as important but a non-destructive wire rope test is a lot less frequent than a visual wire rope inspection. Destructive testing only takes place when specifically required by a company to find out what type of wire rope something is that has not been labelled and is not common practice in the general testing/inspections.

Visual inspection of wire ropeThe visual method is a simple yet effective method to check for external damage to a crane wire rope. Visually inspecting the entire length of rope is very important. The rope should be inspected 2 to 3 feet at a time and examined carefully at each stop. Whilst inspecting the wire rope it also cleaned with Lanotec and a wire brush.

Although tedious, it can determine many visual signs of wire rope damage, such as; kinks, bird caging, cutting, knots, flattening, crushing & heat damage (burn marks, discolouration of the metal). Wearing heavy duty gloves, an inspector will grab the rope and lightly move a rag slowly along the length of rope. Broken wires will often stick out (porcupine) and will therefore snag on the rag. Should the rag snag on a wire, the inspector should the stop and visually assess the rope condition. Broken wires do not always ‘porcupine’. Visual inspections should not be the only method relied on for inspecting crane wire ropes.

Due to the composition of a wire rope, the outer layer only represents approximately 40% of the metallic cross section of the rope and only approximately half of this is visible due to the strand twisting inside and out. That means you are only able to visually examine approximately 20% of the entire rope composition. You can only assume that the other 80% is in good condition.

Although the external 20% may look in good condition it may be concealing a great number of wire breaks and internal damage. Wire ropes with internal damage that have no signs of external damage can be extremely dangerous. This is why an internal wire rope inspection should also be completed. Internal deterioration is the primary cause of many rope failures, mainly due to corrosion and the normal progress of fatigue. Single-layer stranded ropes may be opened up slightly to allow an assessment of their internal condition, provided that they are at zero tension; though, some restrictions occur with large rope sizes. Permanent damage can be caused to multi-layer wire ropes if they are opened.

Internal inspection should always be carried out by a capable person. The method of inspection consists of firmly attaching two clamping jaws of appropriate size at a suitable distance apart to the rope. During the inspection of sections of rope adjacent to terminations, it is adequate to use a single clamping jaw, since the end anchorage system, or a bar suitably located through the end portion of the termination, may be used as the second clamp.

By the application of a force to the clamping jaws in the opposite direction to the rope lay, the outer strands separate and move away from the core. Care should be taken during the opening process to ensure that the clamping jaws do not slip about the outside of the rope. The strands should not be displaced excessively. When a limited opening is achieved, a small probe, such as a screwdriver, may be used to remove grease or debris that could obstruct observation of the interior of the rope. The crucial points that should be observed are as follows:

After inspection, a service dressing should be introduced into the opened part and the clamping jaws rotated with moderate force to ensure correct replacement of the strands around the core. After removal of the jaws, the outer surface of the rope should be greased. Since it is impossible to inspect the interior of the wire rope over the whole of its length, suitable sections shall be selected.

For wire ropes that wind onto a drum, or pass over pulleys or rollers, it is recommended that the lengths that engage the pulley grooves when the appliance is in a loaded condition be inspected. Those localised lengths in which shock forces are arrested (i.e., adjacent to drum and jib head pulleys) and those lengths that are particularly exposed to the weather for long periods should be inspected. Attention should be given to the length of rope close to its termination, and this is particularly important for fixed ropes, such as stays or pendants. This is where a visual inspection is complimented by a non-destructive test. .

Wire rope slings have played a critical role in applications like lifting, rigging, and hoisting. They are usually made from galvanized or un-galvanized steel wire strands, which are woven into ropes with end terminations. The end terminations can be loops or hooks.

Several industries, such as mining, manufacturing, shipping, and power generation, use wire rope slings because they are easy-to-use, cost effective, and reliable. Depending on the type of load and crane, you can use an assembly of wire rope slings for lifting, rigging, and hoisting.

Although they are extremely strong and durable, wire rope slings require regular maintenance and inspection. They must be inspected to ensure safety and prevent economic losses. In this short guide, we will take a look at wire rope sling inspection, maintenance, and replacement.

As mentioned before, the purpose of wire rope sling inspection is to identify any damage or excessive wear before it leads to a disaster. Two leading organizations in the US, OSHA, and ASME have published inspection and maintenance guidelines to ensure wire rope slings safety and functionality.

The two standards governing the criteria and guidelines of wire rope sling inspection are OSHA 1910.184 and ASME B30.9. As per these guidelines, there are three types of inspections.

This inspection should be carried out immediately after receiving the wire rope slings. During this inspection, make sure to check the sling identification tags. These tags will bear the product information, its rated load capacity, and other specifications. Check if they are what you ordered and what you need.

The second type of wire rope sling inspection is to be carried out daily or prior to use. As wire rope slings are used in a wide range of applications, it is always better to inspect them before each use. In other words, if you are going to use a sling three times a day, you should inspect it three times.

As wire rope slings can get damaged during a loading or rigging application, this inspection is extremely critical. You can have designated personnel, usually a competent crew member, to inspect wire rope slings before each use.

Only a certified professional or service provider can carry out periodic inspections. You also need to document each periodic inspection and maintain records, as per the ASME B30.9 guidelines. The schedule of periodic wire rope sling inspection depends on factors like frequency of use, the severity of work conditions, type of lifting or rigging, and experience gained on the service life of wire rope slings used in similar applications.

Even though it’s usually a visual inspection, you have to be thorough with it. Neither OSHA nor ASME has specified any fixed sling inspection process. You need to set up a process of your own based on your requirements, rope sling usage, and other factors.

Usually, a proper wire rope sling inspection process should include the following steps:Make sure to lay down the sling on a flat surface in such a way that all its areas are visible and easily accessible.

If possible, maintain a detailed record of all your sling inspections. Well-kept records make it easier to identify slings that are nearing the end of their service life or are damaged.

Sling tag identification is the most critical step in sling inspection. These tags help you identify the usage specifications of the slings. So, make sure to maintain the tags in excellent condition throughout the lifespan of the slings. If the tag is damaged or illegible, remove the sling from use immediately.

If you come across any of the following scenarios during your sling inspection, you will need to remove the slings immediately. Furthermore, if you are unsure of the potential damage, discontinue the use of slings.

While the structure and specifications of wires vary greatly, wire rope slings often have the following four key components:Core: The core is made from steel, synthetic, or natural fibers. The function of the core is to provide strength and support to the wires.

Wires: Wires are made from materials like steel, iron, bronze, and stainless steel. Wires surround the core, and they come in different sizes and strengths.

The guidelines for allowable broken wires are as follows:Single Part Body Slings and Strand Laid Grommets:5 broken wires in one strand in one rope lay

Distortion constitutes damages like kinking, crushing, and birdcaging, among others. If you see any such damage or wires and strands pushed out of their original positions, you need to replace the wire rope sling immediately.

Wire rope damage due to heat results in metallic discoloration, fusing of wires, or loss of lubricant. Make sure to replace the sling if there is heat damage.

While light surface rust will not affect the strength of wire rope slings, you will need a replacement if the corrosion has caused pitting or binding of wires.

When using wire rope slings, pulling through a loop can push out wires and strands from their original positions, pushing the slings out of balance. If you see this damage, replace the slings immediately.

Kinks are nothing but loops with permanent wire and strand distortions. As this type of damage is irreparable, you need to replace the slings right away.

Improper use of wire rope slings can cause doglegs, which are permanent bends. If the slings have minor doglegs with no strand distortion or if you can’t see them when the sling is under tension, you can continue using the sling. However, replacement is necessary if the doglegs are severe.

Make sure to discard the damaged wire rope slings in an eco-friendly manner. You should label the slings “Do Not Use” to avoid accidental use. Then, you should cut the eye and fittings from the rope, cut the rope into 3’ to 4’ sections, and send them for recycling.

The third most important step is wire rope sling maintenance. You should keep the following points in mind to ensure regular and comprehensive maintenance:Always keep the slings off the ground, in hanging position, and in a dry and cool environment.

Wire rope slings play a critical role in a wide range of industries such as mining, manufacturing, and shipping, among others. Although they are strong and have a long lifespan, rope slings do need regular inspection and maintenance to ensure safety and longevity. Hopefully, this guide will help clear all your doubts regarding wire rope sling inspection, replacement, and maintenance. If you need help with any rigging equipment inspection, maintenance, and replacement, feel free to reach out to our team at Holloway Houston Inc.

A thorough inspection of all ropes shall be made at least once a month and a certification record which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the ropes which were inspected shall be kept on file where readily available to appointed personnel. Any deterioration, resulting in appreciable loss of original strength, shall be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard. Some of the conditions that could result in an appreciable loss of strength are the following:

All rope which has been idle for a period of a month or more due to shutdown or storage of a crane on which it is installed shall be given a thorough inspection before it is used. This inspection shall be for all types of deterioration and shall be performed by an appointed person whose approval shall be required for further use of the rope. A certification record shall be available for inspection which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the rope which was inspected.

Get a range of wholesale wire rope inspection designed for different testing needs. For those involved in the field of digital electronics and who need to work with digital circuits and systems regularly, consider the wide range of logic analyzers that are available. Quality testing equipment will be able to help verify and debug your digital designs efficiently when required.

For owners of electronic tools and equipment supply stores, there is also a large variety of testing equipment that you might want to consider purchasing. Products that are available include vector network analyzers, circuit breaker testers, megohmmeters and even tube testers. Get wire rope inspection from several popular and leading brands here.

8613371530291

8613371530291