wire rope inspection requirements pricelist

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

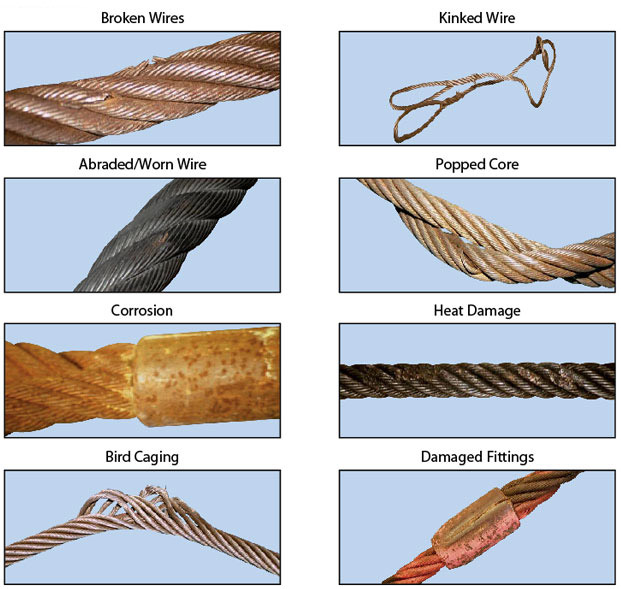

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

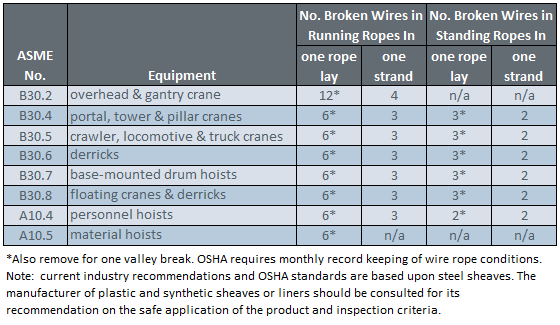

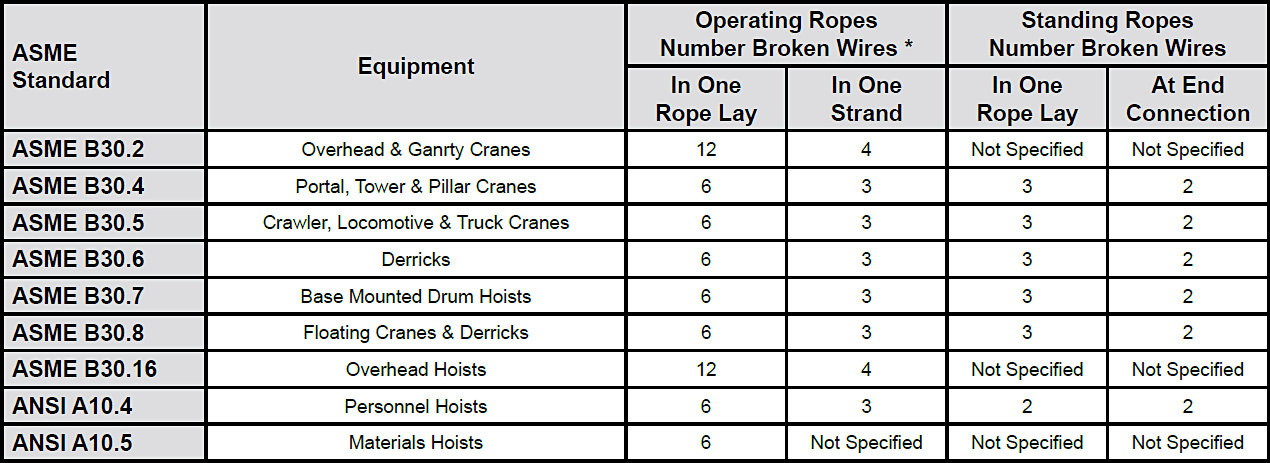

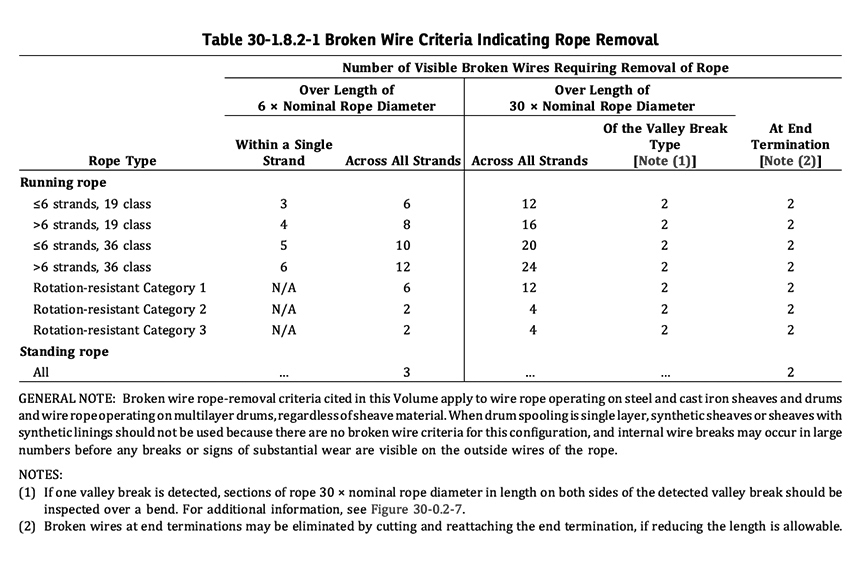

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

Wire rope isa type of cablewhich is made up of several strands of metal wirelaid or twisted into a braid or helix.Do you know how often your wire rope needs to be inspected? Wire rope inspections are vital to industries that use wire rope.

One of the most important purposes of carrying out wire rope inspections or testing is to oversee the process of depreciation in the wire rope. When any depreciation or deterioration is identified these wire ropes can cease to be used immediatelybefore it becomes a hazard. A great advantage of conducting these examinations is to analyse and identify if there is unexpected corrosion and destruction.

Commonly, there is a constant increase rate in the amount of wire rope breaks, during the lifespan of that wire rope. Wire ropes need to be inspected and tested as they have a limited life, like all consumable products. Early in the life of the wire rope (when it is starting to be used), the wires and strands of the rope settle into position and the breaking strength increases. Once it has hit its maximum, the breaking strength then decreases rapidly.

Wire rope inspections should only be carried out by highly trained professionals. There are 2 ways that these inspections are carried out on crane wire rope: Visual and Non-Destructive. Visual and no-destructive examinations are equally as important but a non-destructive wire rope test is a lot less frequent than a visual wire rope inspection. Destructive testing only takes place when specifically required by a company to find out what type of wire rope something is that has not been labelled and is not common practice in the general testing/inspections.

Visual inspection of wire ropeThe visual method is a simple yet effective method to check for external damage to a crane wire rope. Visually inspecting the entire length of rope is very important. The rope should be inspected 2 to 3 feet at a time and examined carefully at each stop. Whilst inspecting the wire rope it also cleaned with Lanotec and a wire brush.

Although tedious, it can determine many visual signs of wire rope damage, such as; kinks, bird caging, cutting, knots, flattening, crushing & heat damage (burn marks, discolouration of the metal). Wearing heavy duty gloves, an inspector will grab the rope and lightly move a rag slowly along the length of rope. Broken wires will often stick out (porcupine) and will therefore snag on the rag. Should the rag snag on a wire, the inspector should the stop and visually assess the rope condition. Broken wires do not always ‘porcupine’. Visual inspections should not be the only method relied on for inspecting crane wire ropes.

Due to the composition of a wire rope, the outer layer only represents approximately 40% of the metallic cross section of the rope and only approximately half of this is visible due to the strand twisting inside and out. That means you are only able to visually examine approximately 20% of the entire rope composition. You can only assume that the other 80% is in good condition.

Although the external 20% may look in good condition it may be concealing a great number of wire breaks and internal damage. Wire ropes with internal damage that have no signs of external damage can be extremely dangerous. This is why an internal wire rope inspection should also be completed. Internal deterioration is the primary cause of many rope failures, mainly due to corrosion and the normal progress of fatigue. Single-layer stranded ropes may be opened up slightly to allow an assessment of their internal condition, provided that they are at zero tension; though, some restrictions occur with large rope sizes. Permanent damage can be caused to multi-layer wire ropes if they are opened.

Internal inspection should always be carried out by a capable person. The method of inspection consists of firmly attaching two clamping jaws of appropriate size at a suitable distance apart to the rope. During the inspection of sections of rope adjacent to terminations, it is adequate to use a single clamping jaw, since the end anchorage system, or a bar suitably located through the end portion of the termination, may be used as the second clamp.

By the application of a force to the clamping jaws in the opposite direction to the rope lay, the outer strands separate and move away from the core. Care should be taken during the opening process to ensure that the clamping jaws do not slip about the outside of the rope. The strands should not be displaced excessively. When a limited opening is achieved, a small probe, such as a screwdriver, may be used to remove grease or debris that could obstruct observation of the interior of the rope. The crucial points that should be observed are as follows:

After inspection, a service dressing should be introduced into the opened part and the clamping jaws rotated with moderate force to ensure correct replacement of the strands around the core. After removal of the jaws, the outer surface of the rope should be greased. Since it is impossible to inspect the interior of the wire rope over the whole of its length, suitable sections shall be selected.

For wire ropes that wind onto a drum, or pass over pulleys or rollers, it is recommended that the lengths that engage the pulley grooves when the appliance is in a loaded condition be inspected. Those localised lengths in which shock forces are arrested (i.e., adjacent to drum and jib head pulleys) and those lengths that are particularly exposed to the weather for long periods should be inspected. Attention should be given to the length of rope close to its termination, and this is particularly important for fixed ropes, such as stays or pendants. This is where a visual inspection is complimented by a non-destructive test. .

There is no denying that wire ropes are one of the most used materials in the industrial landscape. According to Statista, in 2020 itself, the production volume of steel wire ropes in Japan amounted to approximately 240.32 thousand tons. Their necessity is evident, and the wire rope sling manufacturers are increasingly deploying their solutions in marine environments or for rigging purposes. However, as wire ropes face considerable loads, they suffer massive mechanical damage.

As suggested by the leading steel wire rope manufacturers, some well-known reasons for wire rope failure are corrosion, excess deterioration, improper usage, and lack of maintenance resulting in reduced safety, increased replacement costs, and early discard. Do you want to know the professional ways steel wire rope manufacturers inspect wire ropes? Then here"s a guide for you!

All wire ropes must be inspected visually on daily basis before starting the operation. This safety guideline can ensure maximum security. Although it"s daunting to determine the exact service span of the ropes, close analysis on a more frequent basis can help get a more precise estimation of their predictive life cycle. Also, note that calculating the precise times when the ropes have been in use during the mooring/tidal conditions, load pressures, etc., can be the answer. A competent person shall carry out an overall, thorough periodical inspection of the wire rope.

You can use the rag-and-visual process to check for any external damage. All you need to do is grab the rope lightly with a rag or cotton cloth. Then move the rag along the wire, and if there are any broken wires, they will stick out and snag on the rag. If the cloth catches broken wires, you can stop and assess the rope visually. Also, make sure to visually inspect the wire without any rag because some wire breaks don"t stick out.

Measure the diameter of the rope and compare the diameter with the original values. When the measurements are different, the change implies internal or external rope conditions.

When a steel wire rope passes over the drum and sheaves or any other metallic equipment component, abrasion takes place. Hence, it is important that all components must be in proper working order and of the appropriate diameter for the rope. A badly corrugated or worn-out sheave or drum will significantly damage a new rope, resulting in premature rope replacement.

In addition, try to look for corrosion, pitting, abrasions, end fitting conditions, wire breakage (if any), and lubrication inside the rope. Wire rope should be inspected to check for any abnormality like External damage, Kink, Strand looseness, Core protrusion, or Bird-caging.

While sometimes the damage can be easily identified on the surface, in other cases, the fracture might occur inside the wires. Therefore, ensure that the ropes are maintained, manufactured, and inspected by competent professionals. Searching for the best wire rope sling manufacturers and inspecting company that focuses stringently on quality checks? Usha Martin can be your one-stop solution!

(a) Breaking Strength. All hoisting wire rope shall be of such breaking strength as to provide a minimum factor of safety of seven. The factor of safety (F) shall be calculated by the following formula:SN

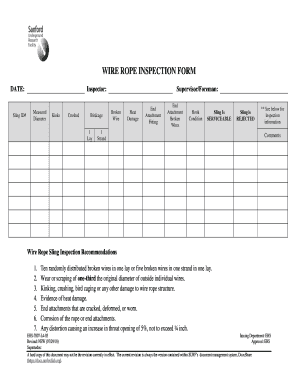

A representative of the user of the material hoist shall be appointed and this representative shall keep written reports of the rope condition on file at the work site. The representative shall have the authority to order wire rope replacements and keep unsafe wire rope from being used.

Inspection periods shall be set-up for each material-hoist wire rope. The frequency of inspection shall be determined by consideration of environment, degree of hazard to materials, frequency of operation, and the frequency with which the rope is subjected to its capacity limits. Inspections shall be made not less often than once each 30 days.

The working length of the wire rope shall be unwound from the hoist drum. Thorough inspection shall be made of the rope sections that pass over sheaves, drums, or contact saddles, or which make opposing turns. The rope close to end attachments shall be carefully inspected.

Sheaves, guards, guides, drums, flanges, and other surfaces contacted by wire rope during operation should be examined at the time of inspection. Any condition harmful to the rope in use at the time should be corrected.

(2) Broken Wires. One or more valley breaks shall be cause for replacement. (A valley break is a wire break occurring in the valley between two adjacent strands.)

Six randomly distributed broken wires in one rope lay, or three broken wires in one strand in one rope lay, shall be cause for replacement. (A rope lay is the length along the rope in which one strand makes a complete revolution around the rope.)

(3) End Attachments. Development of broken wires in the vicinity of attachments shall be cause for replacement. If this condition is localized in an operating rope and the section in question can be eliminated by making a new attachment, this can be done rather than replacing the entire rope.

(4) Abrasion. Abrasion, scrubbing, flattening, or peening causing loss of more than one-third of the original diameter of the outside wires shall be cause for replacement.

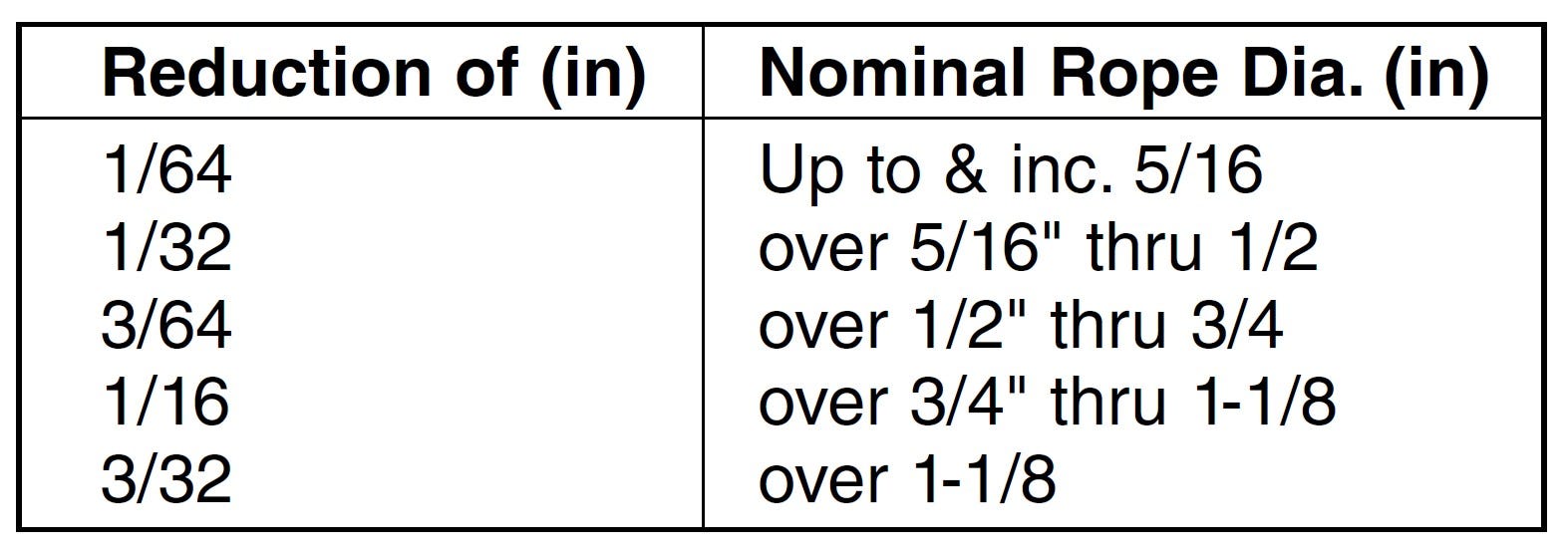

(7) Reduction of Rope Diameter. Reduction from nominal diameter of more than 3/64-inch for diameters up to and including 3/4-inch; 1/16-inch for diameters 7/8 to 1 1/8 inches; and 3/22-inch for diameter 1 1/4 to 1 1/2 inches shall be causes for replacement. Marked reduction in diameter indicates deterioration of the core.

(d) Wire Rope Installation. Hoisting ropes shall be installed in accordance with the wire rope manufacturer"s recommendations. The hoisting ropes shall be secured to the drum by clamps or by an approved equivalent means.

(1) Pitch diameters of drums shall be a minimum of 24 times the nominal rope diameter. The drum flange shall extend at least 2 inches radially beyond the last layer of rope when all rope is coiled on the drum.

(3) All hoisting wire rope shall be improved plow steel grade or stronger, and equal in flexibility to 6 x 19 classification wire rope. The joining of hoisting ropes by splicing is prohibited.

(4) There shall be at least 4 feet of clearance between the cathead sheave and the hoisting-rope fastening on the platform, cage, or bucket when either is at the uppermost terminal or landing.

(7) Load-bearing sheaves for wire rope shall be grooved to accommodate the rope and shall have a diameter at least 20 times that of the wire rope. For minimum tread diameter of sheaves see Table 2. (The diameter of a sheave is measured at the bottom of the grooves.)

(9) Defective and worn sheaves that may cause equipment failure or damage to the wire rope shall be replaced. If pillow blocks are used, they shall be mounted on top of beams and securely bolted. Open bearings shall not be used.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. Wire rope comes in a variety of strand patterns including single layer, filler wire, seale, warrington, and combination. Wire rope strands can be laid around the core in different configurations including regular lay wire rope, lang lay wire rope, and alternate lay wire rope. There also many types of grades of wire rope, including: improved plow steel (IPS), extra improved plow steel (EIPS), and extra extra improved plow steel (EEIPS). Some types of wire rope is preferred over others due to the unique properties, including: rotation resistant wire rope, compacted strand wire rope, swaged wire rope, plastic coated wire rope, plastic impregnated (PI) wire rope.

Any wire rope in use should be inspected on a regular basis. You have too much at stake in lives and equipment to ignore thorough examination of the rope at prescribed intervals.

The purpose of inspection is to accurately estimate the service life and strength remaining in a rope so that maximum service can be had within the limits of safety. Results of the inspection should be recorded to provide a history of rope performance on a particular job.

On most jobs wire rope must be replaced before there is any risk of failure. A rope broken in service can destroy machinery and curtail production. It can also kill.

Because of the great responsibility involved in ensuring safe rigging on equipment, the person assigned to inspect should know wire rope and its operation thoroughly. Inspections should be made periodically and before each use, and the results recorded.

When inspecting the rope, the condition of the drum, sheaves, guards, cable clamps and other end fittings should be noted. The condition of these parts affects rope wear: any defects detected should be repaired.

To ensure rope soundness between inspections, all workers should participate. The operator can be most helpful by watching the ropes under his control. If any accident involving the ropes occurs, the operator should immediately shut down his equipment and report the accident to his supervisor. The equipment should be inspected before resuming operation.

The Occupational Safety and Health Act has made periodic inspection mandatory for most wire rope applications. If you need help locating the regulations that apply to your application, please give our rigging experts a call.

We stock a large variety of rigging gear and hardware. Our in-house services include inspection, test, and certifying of slings and rigging gear. We also offer on-site inspection of rigging, of rolex replica slings and rigging gear, on-site inspection of rigging, and pickup and delivery. We can have any of our experienced sales staff go on-site and assist with determining the best way to handle your lifting needs. We also offer an on site class on proper rigging gear inspection.

The following is a fairly comprehensive listing of critical inspection factors. It is not, however, presented as a substitute for an experienced inspector. It is rather a user’s guide to the accepted standards by which wire ropes must be judged. Use the outline to skip to specific sections:

Rope abrades when it moves through an abrasive medium or over drums and sheaves. Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. This is not easy to determine, and discovery relies upon the experience gained by the inspector in measuring wire diameters of discarded ropes.

All ropes will stretch when loads are initially applied. As a rope degrades from wear, fatigue, etc. (excluding accidental damage), continued application of a load of constant magnitude will produce incorrect varying amounts of rope stretch.

Initial stretch, during the early (beginning) period of rope service, caused by the rope adjustments to operating conditions (constructional stretch).

Following break-in, there is a long period—the greatest part of the rope’s service life—during which a slight increase in stretch takes place over an extended time. This results from normal wear, fatigue, etc.

Thereafter, the stretch occurs at a quicker rate. This means that the rope has reached the point of rapid degradation: a result of prolonged subjection to abrasive wear, fatigue, etc. This second upturn of the curve is a warning indicating that the rope should soon be removed.

In the past, whether or not a rope was allowed to remain in service depended to a great extent on the rope’s diameter at the time of inspection. Currently, this practice has undergone significant modification.

Previously, a decrease in the rope’s diameter was compared with published standards of minimum diameters. The amount of change in diameter is, of course, useful in assessing a rope’s condition. But, comparing this figure with a fixed set of values can be misleading.

As a matter of fact, all ropes will show a significant reduction in diameter when a load is applied. Therefore, a rope manufactured close to its nominal size may, when it is subjected to loading, be reduced to a smaller diameter than that stipulated in the minimum diameter table. Yet under these circumstances, the rope would be declared unsafe although it may, in actuality, be safe.

As an example of the possible error at the other extreme, we can take the case of a rope manufactured near the upper limits of allowable size. If the diameter has reached a reduction to nominal or slightly below that, the tables would show this rope to be safe. But it should, perhaps, be removed.

Today, evaluations of the rope diameter are first predicated on a comparison of the original diameter—when new and subjected to a known load—with the current reading under like circumstances. Periodically, throughout the life of the rope, the actual diameter should be recorded when the rope is under equivalent loading and in the same operating section. This procedure, if followed carefully, reveals a common rope characteristic: after an initial reduction, the diameter soon stabilizes. Later, there will be a continuous, albeit small, decrease in diameter throughout its life.

Deciding whether or not a rope is safe is not always a simple matter. A number of different but interrelated conditions must be evaluated. It would be dangerously unwise for an inspector to declare a rope safe for continued service simply because its diameter had not reached the minimum arbitrarily established in a table if, at the same time, other observations lead to an opposite conclusion.

Corrosion, while difficult to evaluate, is a more serious cause of degradation than abrasion. Usually, it signifies a lack of lubrication. Corrosion will often occur internally before there is any visible external evidence on the rope surface.

Pitting of wires is a cause for immediate rope removal. Not only does it attack the metal wires, but it also prevents the rope’s component parts from moving smoothly as it is flexed. Usually, a slight discoloration because of rusting merely indicates a need for lubrication.

Severe rusting, on the other hand, leads to premature fatigue failures in the wires necessitating the rope’s immediate removal from service. When a rope shows more than one wire failure adjacent to a terminal fitting, it should be removed immediately. To retard corrosive deterioration, the rope should be kept well lubricated with a clear wire rope lube that can penetrate between strands. In situations where extreme corrosive action can occur, it may be necessary to use galvanized wire rope.

Kinks are tightened loops with permanent strand distortion that result from improper handling when a rope is being installed or while in service. A kink happens when a loop is permitted to form and then is pulled down tight, causing permanent distortion of the strands. The damage is irreparable and the sling must be taken out of service.

Doglegs are permanent bends caused by improper use or handling. If the dogleg is severe, the sling must be removed from service. If the dogleg is minor, exhibiting no strand distortion and cannot be observed when the sling is under tension, the area of the minor dogleg should be marked for observation and the sling can remain in service.

Bird caging results from torsional imbalance that comes about because of mistreatment, such as sudden stops, the rope being pulled through tight sheaves, or wound on too small a drum. This is cause for rope replacement unless the affected section can be removed.

Particular attention must be paid to wear at the equalizing sheaves. During normal operations, this wear is not visible. Excessive vibration or whip can cause abrasion and/or fatigue. Drum cross-over and flange point areas must be carefully evaluated. All end fittings, including splices, should be examined for worn or broken wires, loose or damaged strands, cracked fittings, worn or distorted thimbles and tucks of strands.

After a fire or the presence of elevated temperatures, there may be metal discoloration or an apparent loss of internal lubrication. Fiber core ropes are particularly vulnerable. Under these circumstances the rope should be replaced.

Continuous pounding is one of the causes of peening. This can happen when the rope strikes against an object, such as some structural part of the machine, or it beats against a roller or it hits itself. Often, this can be avoided by placing protectors between the rope and the object it is striking.

Another common cause of peening is continuous working-under high loads—over a sheave or drum. Where peening action cannot be controlled, it is necessary to have more frequent inspections and to be ready for earlier rope replacement.

Below are plain views and cross-sections show effects of abrasion and peening on wire rope. Note that a crack has formed as a result of heavy peening.

Scrubbing refers to the displacement of wires and strands as a result of rubbing against itself or another object. This, in turn, causes wear and displacement of wires and strands along one side of the rope. Corrective measures should be taken as soon as this condition is observed.

Wires that break with square ends and show little surface wear have usually failed as a result of fatigue. Such fractures can occur on the crown of the strands or in the valleys between the strands where adjacent strand contact exists. In almost all cases, these failures are related to bending stresses or vibration.

If diameter of the sheaves, rollers or drum cannot be increased, a more flexible rope should be used. But, if the rope in use is already of maximum flexibility, the only remaining course that will help prolong its service life is to move the rope through the system by cutting off the dead end. By moving the rope through the system, the fatigued sections are moved to less fatiguing areas of the reeving.

The number of broken wires on the outside of a wire rope are an index of its general condition, and whether or not it must be considered for replacement. Frequent inspection will help determine the elapsed time between breaks. Ropes should be replaced as soon as the wire breakage reaches the numbers given in the chart below. Such action must be taken without regard to the type of fracture.

* All ropes in the above applications—one outer wire broken at the point of contact with the core that has worked its way out of the rope structure and protrudes or loops out of the rope structure. Additional inspection of this section is required.

Rope that has either been in contact with a live power line or been used as “ground” in an electric welding circuit, will have wires that are fused, discolored and/or annealed and must be removed.

On occasion, a single wire will break shortly after installation. However, if no other wires break at that time, there is no need for concern. On the other hand, should more wires break, the cause should be carefully investigated.

On any application, valley breaks—where the wire fractures between strands—should be given serious attention. When two or more such fractures are found, the rope should be replaced immediately. (Note, however, that no valley breaks are permitted in elevator ropes.)

It is good to remember that once broken wires appear—in a rope operating under normal conditions—a good many more will show up within a relatively short period. Attempting to squeeze the last measure of service from a rope beyond the allowable number of broken wires (refer to table on the next page) will create an intolerably hazardous situation.

Recommended retirement criteria for all Rotation Resistant Ropes are 2 broken wires in 6 rope diameters or 4 broken wires in 30 rope diameters (i.e. 6 rope diameters for a 1″ diameter rope = 6″).

Distortion of Rotation Resistant Ropes, as shown below, can be caused by shock load / sudden load release and/or induced torque, and is the reason for immediate removal from service.

PFEIFER Wire Rope & Lifting Technology Inc. is wholly owned by the family run PFEIFER group, Germany. The administration and sales headquarter is located in Hampton, Virginia. Hampton has a warehouse specialized in the complete range of crane and industrial ropes and the full range of machines for handling wire ropes and terminations. All wire rope terminations, the tools and relevant dies are made in Germany by PFEIFER and guarantee a perfect match and the highest performance and safety. PFEIFERs rope competence team members are working to solve customer problems through inspection of wire ropes and analysis of spooling systems.

The new service center in the north of Houston, Texas provides sales and service to customers in the Gulf Coast Area. The warehouse reflects the needs of the area and stocks, besides the standard range of mobile crane replacement ropes and the terminations, bigger diameter ropes for the offshore instustry. It is also equipped with the necessary machines and tools for fabrication and provides service to the regional customers.

PFEIFER Wire Rope & Lifting Technology Inc. can offer competitive prices through direct purchase under groupwide conditions and the selection of the perfect rope for every application through strict benchmark testing.

The CSIR is the recognised custodian of in-service mine rope technology, and performs the bulk of the statutory tests required for hoist ropes in the mining industry.As a National Key Point, the Wire Rope Testing Laboratory also maintains the largest historical database of rope tests in Africa.

Access to rope test data and certificates are provided via a user-friendly web-based system. Through this facility clients can get direct access to their test results, and the Department of Minerals and Energy can draw lists of tests performed by the various mines. Registered users can follow the link below to access the rope test database. (Rope Certificates) The rope test prices are also provided.

Safety is a crucial factor in the profitability of the mining industry. With thousands of workers transported up and down mine shafts each day, measuring the safety of hoisting ropes form an integral part of mine management.Strict laws cover the maintenance and testing of steel wire ropes.The Wire Rope Testing Laboratory focuses mainly on the destructive testing of these ropes.

For each hoist rope tested, the customer is provided with a detailed report that includes the breaking force, absorbed strain energy, force vs. elongation curve and an assessment of the condition of individual strands and wires at the point of failure.The report also alerts the customer to rope characteristics that breach, or are approaching, accepted performance standards. For example, a breaking force that is 90% or less than the new rope-breaking force. An assessment of corrosion and general rope lubrication is also provided.

The Laboratory is an advanced technology facility housing state of the art wire rope testing equipment.The machines used in the destructive testing of steel wire ropes have capacities ranging from 1 MN for small diameter ropes, to 15 MN for ropes up to 160 mm in diameter.

A 15 MN MFL tensile test machine which is able to accommodate large-diameter ropes as used in the oil drilling, bridge and shipping industries.It also caters for tensile tests on conveyor belts up to 1.2m wide and large-link chains as used on coal mine draglines and;

The CSIR Wire Rope Testing Laboratory is the government approved facility for statuary testing of winding ropes. Because of the CSIRs impartiality, professionalism and technical expertise, rope manufacturers locally and abroad also choose to have their wire rope samples tested by the CSIR. Existing clients include, but are not limited to, the following:

Yes, it is absolutely safe to buy Wire Rope Inspection Guidelines (25/pack) from desertcart, which is a 100% legitimate site operating in 164 countries. Since 2014, desertcart has been delivering a wide range of products to customers and fulfilling their desires. You will find several positive reviews by desertcart customers on portals like Trustpilot, etc. The website uses an HTTPS system to safeguard all customers and protect financial details and transactions done online. The company uses the latest upgraded technologies and software systems to ensure a fair and safe shopping experience for all customers. Your details are highly secure and guarded by the company using encryption and other latest softwares and technologies.

8613371530291

8613371530291