wire rope inspection standards made in china

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

Steel wire rope sleeve ring, which can also be called the heart ring, it is a kind of lifting machinery. Therefore, it is widely used in the field of heavy industry hoisting. Then the following is a brief introduction of its inspection standards by Piner superior industrial equipment, so that we can understand, and at the same time, but also can increase their own knowledge of steel wire rope.

(1) steel wire rope sleeve ring, the first inspection before leaving the factory, inspection qualified to leave the factory, otherwise can not. In addition, for the inspection of qualified products, also should be attached to the product quality certificate.

Any wire rope in use should be inspected on a regular basis. You have too much at stake in lives and equipment to ignore thorough examination of the rope at prescribed intervals.

The purpose of inspection is to accurately estimate the service life and strength remaining in a rope so that maximum service can be had within the limits of safety. Results of the inspection should be recorded to provide a history of rope performance on a particular job.

On most jobs wire rope must be replaced before there is any risk of failure. A rope broken in service can destroy machinery and curtail production. It can also kill.

Because of the great responsibility involved in ensuring safe rigging on equipment, the person assigned to inspect should know wire rope and its operation thoroughly. Inspections should be made periodically and before each use, and the results recorded.

When inspecting the rope, the condition of the drum, sheaves, guards, cable clamps and other end fittings should be noted. The condition of these parts affects rope wear: any defects detected should be repaired.

To ensure rope soundness between inspections, all workers should participate. The operator can be most helpful by watching the ropes under his control. If any accident involving the ropes occurs, the operator should immediately shut down his equipment and report the accident to his supervisor. The equipment should be inspected before resuming operation.

The Occupational Safety and Health Act has made periodic inspection mandatory for most wire rope applications. If you need help locating the regulations that apply to your application, please give our rigging experts a call.

Crane inspection protocols that are clear, systematic, and precise ensure not just the quality of the equipment, but worker safety as well. It is also essential that only highly qualified inspectors should carry out the inspection processes to maintain integrity and accuracy of the results.

InTouch thoroughly considers every detail of your requirement in drawing up the right protocols. It uses the most updated international standards and practices in all of its inspection checklists. Here are some of the crane inspection protocols that InTouch uses:

Hook Materials – Verify that metals used for the manufacture of hooks have the required ductility. This test shall ensure that crane hook does not break midair that could lead to fatalities or damage of property.

Coating Materials - Verify that the types and grades of coating materials such as paints, fiberglass, and carbon fibers are the same with those on contract. This ensures that the equipment is properly protected from corrosion.

Reeving Accessories – Check that wire rope clips, eye splices, and socket fittings are constructed and installed in accordance with standard practices or contract specifications.

Sheaves Inspection – Check that sheaves are free from any form of damage that in turn may cause damage to ropes, and verify that sheave bearings are properly lubricated to negate the damaging effects of friction. Verify that sheave sizes do not fall below standard specifications in relation to the nominal sizes of ropes used.

These are just some of the crane inspection protocols applicable to limited types of cranes. To know more about the protocols suitable to your crane equipment, send InTouch the details of your inspection needs.

Wire ropes are largely used in marine environment or for rigging purposes. They receive considerable loads and thus suffer a great deal of mechanical damage throughout their service life. Moreover, research has shown that the major cause of wire rope failure is excessive deterioration and corrosion, lack of maintenance and inspection, and wrong usage resulting in early discarding, reduced safety and replacement cost increase.

Sometimes damage can be easily detected, while in other cases fractured wires may occur on the inside. Hence, wire ropes should be inspected and maintained by the right person (competent person assigned by the company), to assure they’re in perfect condition. Regular inspectionsensure high rope performance, long service lifetime , safety of personnel and equipment, and reduced operating costs.

All ropes (synthetic, high modulus and wire ropes) should be inspected before and after an operation. This guideline ensures maximum safety for both a ship’s personnel and equipment. Even though it’s difficult to determine the exact service life span of ropes, there is a way to have a more precise estimation about their efficient lifecycle. Calculating the exact time ropes have been in use (e.g mooring time, mooring conditions, weather and tidal conditions) is the answer. All in all, rope inspections should occur at least once a year.

Inspecting wire ropes in particular, comes with great responsibility. Inspection results should be recorded, and any defects noticed have to be reported and addressed properly. Some defects can be repaired, while in some cases replacing a wire rope is inevitable.

Periodical inspections ofvessel deck equipment is also crucial for maintaining the good condition of wire ropes. The condition of the drum, chocks, bitts, rollers, sheaves, cable clamps and other end fittings, affect the rope’s performance, threads and cords. Make sure to mark these parts during your overall inspection.

In order to help marine officers and staff conduct successful wire rope inspections – and keep an up-to-date record of them – we have created an inspection solution that helps in maintaining and monitoring a ship’s ropes and deck equipment.

When calculating mass using F = Minimum Breaking Force, according to the wire rope’s diameter, you can determine the Minimum Breaking Massand therefore the wire’s max strength. When calculating mass using F = Safe Load according to the wire rope’s diameter, you can determine the Safe Load Mass,which is the advised load for this rope diameter.

The strands of a wire rope absorb the majority of the tensile force applied on the rope. Their design and manufacturing standards affect the level of fatigue resistance and resistance to abrasion. An easy way to understand which rope design is suitable for each purpose, is the wire rope classification.

Wire ropes are classified according to the number of strands in each construction and the number of wires in each strand. For example, a classification of 6X19 means that a wire rope of this type always has six strands, but its wires could be 15-26 per strand. This is because 19 is not the exact number of wires, but the classification of a wire number range.

Visual inspections are a common and fast way to assess wire rope condition. Both the standard and rotation resistant wire rope inspectionprocesscomply with the same four steps of examination. A ship’s crew can perform them as follows:

Steel wire rope distortion is obvious in most cases and can easily be identified by the inspector or the ship‘s crew. It usually occurs if load is suddenly applied or abruptly released (shock loading), or even if swift torque is forcefully induced.

Although not all of these deformations make the rope absolutely dangerous to use, they all may cause ropes to wear unevenly in time. This means inspections should take place more often, and distorted ropes should be handled with caution.

The rag and visual inspection is a good method for regular inspection intervals. The inspector pulls a rag along the rope trying to find broken wire cords. If the rug gets snagged by the rope, the inspector has to stop and assess the wire rope’s condition. Extreme caution should be exercised during the visual inspection, and under no circumstances should this method be the only one used to inspect wire ropes.

Tip: When you encounter a protruding wire end, bend it back and forth manually, until it separates from the wire. This will protect neighboring wires from wearing out.

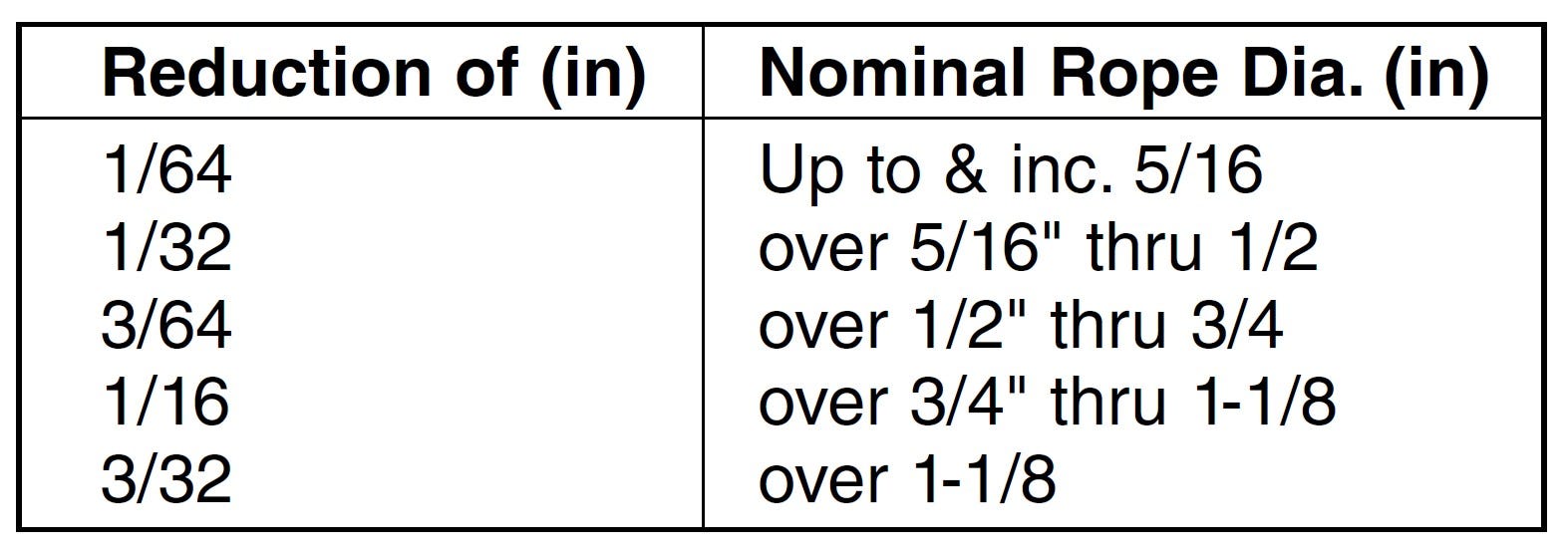

Diameter reduction is a critical factor in steel wire rope wear and if not properly taken care of, it can result in rope breakage. Excessive abrasion, loss of core mass, corrosion or inner wire failure are all factors that contribute to diameter reduction.

To get an accurate measurement of the rope’s diameter, measure the rope at three different points at least 5 feet apart. Take the average of these three measurements to determine the true diameter.

Any measurements showing a reduction of ⅓ or more, indicate that a replacement should follow without delay. A diameter reduction of less than 1/3 still requires attention, and the inspector or the ship’s crew should be on guard in the next scheduled wire rope inspection.

Failure from abrasion or corrosion is a result of deficient deck equipment inspection or insufficient wire rope lubrication respectively. Internal corrosive damage is more difficult to identify than any other types of degradation. In most cases, the damage has progressed more than the external signs suggest.

Wire rope storage plays a significant role in the rope’s operation life.Wire rope corrosion and pitting can be avoided if ropes are safely stored in a clean, cool, dry and well-ventilated place. Steel wire ropes should not by any means rest on the floor, and should be protected from water, dust or any chemical fumes. Long term storage requires periodic greasing, turning the reel upside down for preventing grease dripping and possibly re-winding to another reel with larger inner tube diameter.

Wire ropes should be maintained with periodical lubrication. In order to prevent internal corrosion, a pressure lubricator is suggested to be used. In this case, a small amount of grease is used to lubricate the rope internally, while the deck stays grease-clean. Pressure lubricators clean the rope before they grease it so that the new grease enters a clean rope. The type of grease used is very important for maximum protection and greasing efficiency.

Steel wire ropes exposed to dirt, grime and other contaminants, have to be cleaned with a wire brush and petroleum (unless a pressure lubricator is used). Optimal cleaning of wire ropes can extend their service life and guarantee safe operations.

The reeling process is of high importance for the longevity of wire ropes. To protect them from being damaged, it is important that the surface of the drum is clean, smooth and dry. Improper reeling may cause wire-rope strands to spread or get flattened, when in contact with one another, as successive layers are being spooled and upper layers apply pressure on the lower ones.

Katradis S.A. offers a wide range of top quality wire ropes for shipping (mooring and hoisting operations), fishing and construction purposes. Our wire ropes have greater resistance to fatigue, and they distribute tension force equally among the rope strands. They are less likely to kink, providing higher staff safety and assuring operation success.

(a) Wire rope slings must be made from new or unused regular lay wire rope. The wire rope must be manufactured and tested in accordance with ASTM A 1023-02 and ASTM A 586.

(f) Wire rope clips, if used, must be installed and maintained in accordance with the recommendations of the clip manufacturer or a qualified person, or in accordance with the provisions of ASME B30.26-2010.

(g) You must not use slings made with wire rope clips as a choker hitch.Note:If using wire rope clips under these conditions, follow the guidance given in Table 5.

Number, Torque Values, and Turn Back Requirements for U-Bolt Wire Rope ClipsNumber, Torque Values, and Turn Back Requirements for Double Saddle (Fist Grip) Wire Rope Clips

•Slings made of rope with 6x19 and 6x36 classification.A minimum clear length of rope 10 times the rope diameter between splices, sleeves, or end fittings (see Figure 4, Minimum Sling Length) unless approved by a qualified person.

•Braided slings.A minimum clear length of rope 40 times the component rope diameter between the loops or end fittings (see Figure 5, Minimum Braided Sling Length) unless approved by a qualified person.

(3) Identification information. All wire rope slings must have legible identification information attached to the sling which includes the information below, see sample tag in Figure 6. For slings in use that are manufactured before the effective date of this rule, the information below must be added before use or at the time the periodic inspection is completed.

Sample Wire Rope Sling ID TagNote:Sample tag for a 1/2" single-leg sling 6x19 or 6x36 classification, extra improved plow steel (EIPS) grade fiber core (FC) wire rope with a mechanical splice (ton = 2,000 lb).

(c) For single- or multiple-leg slings and endless slings, each leg must be proof loaded according to the requirements listed in Table 8 based on fabrication method. The proof load test must not exceed 50% of the component ropes" or structural strands" minimum breaking strength;

Note: For mechanical splice, swaged socket and poured socket slings follow the rope manufacturer"s recommendations for proof load testing provided that it is within the above-specified proof load range, including (c) of this subsection.

(a) You must use wire rope slings within the rated loads shown in Tables 7 through 15 in ASME B30.9-2010. For angles that are not shown in these tables, either use the rated load for the next lower angle or have a qualified person calculate the rated load.

(iii) You must keep a record of the most recent periodic inspection available, including the condition of the sling.Note:An external code mark on the sling is an acceptable means of recording the inspection as long as the code can be traced back to a record.

(e) You must decrease the rated load of the sling when D/d ratios (Figure 8) smaller than 25 to one. Consult the sling manufacturer for specific data or refer to the Wire Rope Sling User"s Manual (wire rope technical board).

Wire ropes undergo constant stress and wear through daily use. So, wire rope requires monthly inspection in accordance with this section to reduce the risk of failure and potential resulting injury or property damage. In addition, this section covers criteria to use in determining when to replace rope, and requires inspection of rope on equipment that has been idle for a month or more, before the rope and equipment can be returned to service.

A thorough inspection of all ropes shall be made at least once a month and a certification record which included the date of inspection, the signature of the person who performed the inspection and an identifier for the ropes which were inspected shall be kept on file where readily available to appointed personnel. Any deterioration, resulting in appreciable loss of original strength, shall be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard. Some of the conditions that could result in an appreciable loss of strength are the following:

All rope which has been idle for a period of a month or more due to shutdown or storage of a crane on which it is installed shall be given a thorough inspection before it is used. This inspection shall be for all types of deterioration and shall be performed by an appointed person whose approval shall be required for further use of the rope. A certification record shall be available for inspection which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the rope which was inspected.

Wear and damage to wire rope can’t always be seen on the surface. Konecranes RopeQ Magnetic Rope Inspection pairs visual inspection with non-destructive testing to detect internal broken wires that may escape detection through traditional inspection methods.

*The foregoing OSHA regulations are not intended to be a comprehensive overview of all applicable regulations pertaining to the designated topic. State laws may mandate different safety and maintenance standards. Accordingly, please consult applicable state laws as well as original equipment manufacturer specifications for further guidance. The statements and descriptions contained herein constitute the opinion/recommendation of the seller and are not intended to create any express warranties.

Wire ropes are widely used in industrial production, tourist cable cars, bridges, metallurgy, mining, and informal elevators. Therefore, it is important to ensure the safety of the wire ropes being used. The study of the residual strength of wire ropes is significant for developing advanced instruments that can quantitatively detect wire-rope defects [1]. Currently, the stable and safe working performance of wire ropes is of interest to more and more scholars who are interested in checking the remaining longevity of wire ropes by using online inspection devices.

Jomdecha [2] improved on equipment that was magnetized by electric current. The equipment was designed to control the strength of magnetization by adjusting the magnetized power supply or engaged loops. One special type of testing coil was designed to capture the MFL signals. An eddy current testing method [3] that used an alternating current to generate eddy current in the wire rope was proposed. A function model, which explained the relationship among defects, characteristic vectors, sensor parameters and wire ropes was established by relying on the testing data features. Raišutis [4] studied the dispersion curves of ultrasonic guided-wave spread inside wire ropes. On the basis of this research, the best and most promising receiving positions for ultrasonic guided-waves were calculated. In [5] Peng and Wang designed a visual system on the basis of gamma rays. This system focused on thick ropes used in a suspension bridge. Li et al. [6], used X-ray to detect defects in the steel core of transmission belts. They also proposed a modified threshold rules method, which captured the approximate shape of defects in the steel core.

For the detection of wire rope gaps, Wang and Tian [7] applied the analysis method of finite element to the MFL of wire ropes, and proposed an excitation method that adopted magnetic cores into a magnetic column to improve the magnetic leakage strength of gaps. A system of strong magnetic detection was designed using Hall sensors. During detection of the magnetic leakage signals of wire ropes, the air gap affected the testing accuracy, therefore, Wang et al. [8] studied the influence of different lift-off distances and different air gaps on detection accuracy and improved the structural designs of the detector and the exciter. This device inhibited the influence of lift-off variation. Li et al. [9] investigated the excitation model, established a design standard for the magnetizing structure whose theoretical size was solved through numerical solution, and used finite-element analysis to verify the theoretical size so that the final size was adjusted and determined. Some researchers adopt digital-image processing (DIP) for the MFL signals, Cao et al. [10] unrolled the MFL signals to grayscale, applied the DIP to extract the characteristics of the grayscale image, and identified the different defects. Zhang et al. [11] discussed the limits of lift-off with the digital signal processing method and designed a digital band trap to inhibit the strand waves of wire ropes. The sizes of different defects, which were processed and recognized with statistics, were described as binary images. Furthermore, Zhang et al. [12] designed a spatial filter to inhibit the strand texture of defects of grayscale image and extracted textural features of filtered defects. Finally, a BP neural network was designed and used for the quantitative identification of defects. Recently, most nondestructive testing (NDT) devices were designed using a permanent magnet as an excitation component, which excited wire rope to saturation magnetization. The MFL signals were captured by Hall sensors [10,11,12,13].

The most important aspect of a quantitative detection system is noise filtering of MFL signals. To some degree, the selected filtering algorithm would have a major effect on the quantitative inspection results. Taking into account the previously mentioned algorithm, Cao et al. [14] discussed the relationship between the temporal domain and spatial domain of electromagnetic testing signals of wire ropes, proposing a sampling theorem of the space-time signals, and the collection and processing of the space-time signals was described in detail. Tian et al. [15] combined wavelet transform (WT) and morphological transformation, and presented a morphological filtering algorithm used to inhibit the baseline drift of MFL signals. For the quantitative inspection method, Zhang and Xu [16] discussed the wavelet neural network model and weight-learning algorithm.

In this paper, GMR sensors were distributed uniformly on the circumference of the wire rope to capture the three-dimensional radial direction MFL signal of wire ropes’ residual magnetism. Compressed sensing (CS) and wavelet filtering algorithms were used to eliminate noise signals. The defect signal was translated into a two-dimensional image. For the image, the features that served as inputs for damage inspection were extracted. Experimental results show that this method can better distinguish the amount and width of broken wires and depict circumferential distribution of the defects. The device has the advantages of high detection speed, high precision, structural simplicity, as well as being lightweight, small in size, and low cost.

The paper is organized as follows: the remanence detection head device, data acquisition board and MFL imaging approach are introduced in Section 2. Section 3 focuses on noise elimination, which includes reprocessing the MFL signal and using the CSWF algorithm. The filtered MFL signal was grayed into an image that was interpolated circumferentially. Next, positioning detects and dividing negative axle waveform of defects, extracting morphological eigenvalues and invariant moments as identification vector. Section 4 presents a BP neutral network design that uses the extracted vector as inputs. Finally, the quantitative inspection of broken wires was completed. Section 5 includes comments and the discussion of this paper. Section 6 concludes the paper indicating major achievements and future scope of this work.

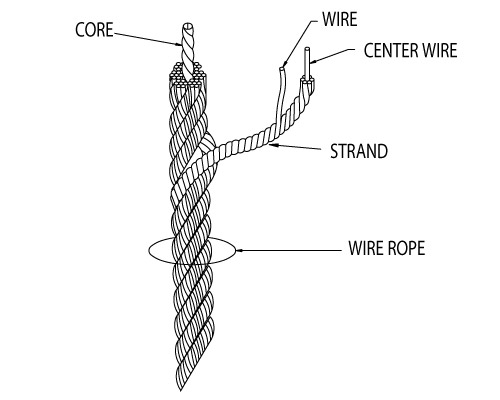

By definition, wire rope is a twisted bundle of drawn steel wires. It is usually composed of wires, strands, and a core. The wires are drawn to a pre-determined size and laid together in various arrangements having a definite pitch (or lay) to form a strand. The required number of strands are helically laid or formed around the core, which may be a core of synthetic or natural fiber, a metallic strand, or an independent wire rope core.

The size, number, and arrangement of wires, the number of strands, the lay, and the type of core in a rope are determined largely by the service for which the rope is to be used. Flexibility and abrasion are the most important considerations; other factors, such as load conditions, rope speeds, vibration, crushing, and equipment design also must be considered.

Wires are the basic building blocks of a wire rope. They lay around a “center” in a specified pattern in one or more layers to form a strand. The strands are helically laid together around a center, typically some type of core, to form a wire rope.

The strands provide all the tensile strength of a fiber core rope and over 90% of the strength of a typical 6-strand wire rope with an independent wire rope core.

Wire rope consists of multi-strand metal wires wrapped around a suitable core material. Wire-rope cores are carefully designed and must be precisely manufactured to close tolerances to ensure a perfect fit in the rope. The most common types of cores include the following:

2. INDEPENDENT WIRE ROPE CORE( IWRC):Literally an independent wire rope with strands and a core, called IWRC. Most wire ropes made with steel core use an IWRC. The primary function of the core is to provide adequate support for the strands. As the name implies, an IWRC is a separate small-diameter wire rope that is used as the core for a larger wire rope. When severe crushing or flattening of the rope is encountered, an IWRC is usually specified.

3. STRAND COREA strand made of wires. Typically, strand cores are used in utility cables only. This type of core has a single strand used as the core. This type is generally confined to the smaller ropes as a substitute for IWRC. The strand core may or may not have the same cross-section as the surrounding strands.

The first two meanings of “lay” are descriptive of the wire and strand positions in the rope. The third meaning is a length measurement used in manufacturing and inspection.

1. The direction strands lay in the rope – right or left. When you look down a rope, strands of a right lay rope go away from you to the right. Left lay is the opposite. (It doesn’t matter which direction you look.)

2. The relationship between the direction strands lay in the rope and the direction wires lay in the strands. In appearance, wires in regular lay appear to run straight down the length of the rope, and in Lang lay, they appear to angle across the rope. In regular lay, wires are laid in the strand opposite the direction the strands lay in the rope. In Lang lay, the wires are laid the same direction in the strand as the strands lay in the rope.

3. The length along the rope that a strand makes one complete spiral around the rope core. This is a measurement frequently used in wire rope inspection. Standards and regulations require removal when a certain number of broken wires per rope lay are found.

All ropes of the same size, grade, and core in each classification have the same minimum breaking force and weight per foot. Different constructions within each classification differ in working properties. Consider these features whenever you’re selecting a rope for a specific application.

The 6 x 19 classification of wire ropes includes standard 6 strands, round strand ropes with 16 through 26 wires per strand. The 6 x 36 classification of wire ropes includes standard 6 strands, round strand ropes with 27 through 49 wires per strand. Although their operating properties vary, all have the same weight per foot and the same minimum breaking force, size for size.

While the 6 x 19 ropes give primary emphasis to abrasion resistance in varying degrees, the 6 x 36 ropes are important for their fatigue resistance. This fatigue resistance is made possible by the greater number of small wires per strand.

Although there are exceptions for special applications, the constructions in the 6 x 36 classification are primarily designed to be the most efficient for each rope diameter. As the rope size increases, for instance, a large number of wires can be used to achieve the required fatigue resistance, and still those wires will be large enough to offer adequate resistance to abrasion.

The actual diameter of a wire rope is the diameter of a circumscribed circle that will enclose all the strands. It’s the largest cross-sectional measurement as shown here. You should make the measurement carefully with calipers.

The rope diameter should be measured on receipt for conformity with the specification. British Standard (B.S. 302:1987, standard steel wire rope, Part 1. Clause 5.1) allows for a tolerance of - 1% to 4 % of the nominal rope diameter.

The generally accepted method of measuring rope diameter for compliance with the standard is to use a caliper with jaws broad enough to cover not less than two adjacent stands. The measurement must be taken on a straight portion of rope at two points at least 1 meter apart. At each point, two diameters at right angles should be measured. The average of the four measurements is the actual diameter.

After the rope has made the first few cycles under low load, the rope diameter should be measured at several points. The average value of all the measurements at each point must be recorded and will form the basis of comparison for all future measurements.

The measurements of the rope diameter are an essential part of all inspections and examinations. It ensures the maximum diameter reduction does not exceed the recommended figure. As stated in 5.2 British standards 6570 recommends that a wire rope should be discarded when the diameter of the rope is reduced to 90% of the nominal diameter.

A comparison of the measured data with the recorded previous values can detect an abnormal rate of reduction in diameter. Coupled with an assessment of previous rope examination data, the probable date of rope renewal can be predicted.

If we examine the cross-section of a six-stand wire rope, we will find that measuring the thickness of the rope over the crowns (Fig-a) will produce a higher value than measuring it over the valleys (Fig-b). The actual diameter of the rope is defined as the diameter of the circumscribing circle.

PREPARATION FOR INSTALLATION Most ropes is shipped with the ends seized as they are prepared for cutting. You can usually install seized ropes without further preparation. In some cases, though, tight openings in drums and wedge sockets – or even complicated reeving systems – require special end preparation. Then, the strands must be tightly held without increasing the rope diameter. In such cases, the ends are tapered and welded, or the ends fused. It’s sometimes necessary to provide a loop or link to which a lighter line is fastened to pull the rope into place or around sheaves.

Some of these special end preparations are shown here. With the exception of category 1 rotation-resistant ropes, any end preparation that results in welding or fusing of the rope must be cut off in a manner that leaves the strands and wires free to adjust before you clamp or seat it in an end termination. Welded ends must remain on category 1 rotation resistant ropes and XLT4. If a situation arises in the field that requires the cutting of a category 1 rotation-resistant rope, we have special preparation and cutting instructions available.

A hoist wire rope is a machine in and of itself that requires proper selection, installation, and maintenance. As a wire rope is used in a hoisting application, the individual wires move and allow the rope to bend around the drum and sheaves. This movement causes friction and abrasive forces that require proper lubrication. If selection, installation, operation, or maintenance is improper, the rope life will be shortened dramatically. Even under the optimum conditions and usage, every wire rope used in a hoisting application will eventually fail. Therefore, routine periodic inspections, by a trained and qualified inspector must be employed to determine the condition of the wire rope so that replacement is made before the rope fails.

Click the below link to know more in detail about Wire ropes classes, damages, and inspection guidelines, PowerPoint presentation on wire rope examination, classification, damages, and a wire rope sling safety guidelines, etc. in one page.

Xinghua City Guangtong Metal Products Factory is a stainless steel wire rope and stainless steel cable supporting rigging products and other professional production and research and development of high-quality manufacturers. The company was founded in 2005,has advanced production equipment,complete testing equipment and strong technical force. The company mainly produces high-quality stainless steel wire rope,coated steel wire rope(PVC,TPU,PP),stainless steel wire rope,jump rope,climbing steel wire rope,new invisible protection mesh steel wire rope,water proof corro

8613371530291

8613371530291