wire rope isolator price quotation

About products and suppliers:Alibaba.com offers 312 wire rope isolators products. About 20% % of these are shock absorber, 7%% are other fabrication services, and 1%% are other rubber products.

A wide variety of wire rope isolators options are available to you, You can also choose from cross razor, wire rope isolators,As well as from energy & mining, manufacturing plant, and construction works . And whether wire rope isolators is online technical support, {2}, or {3}.

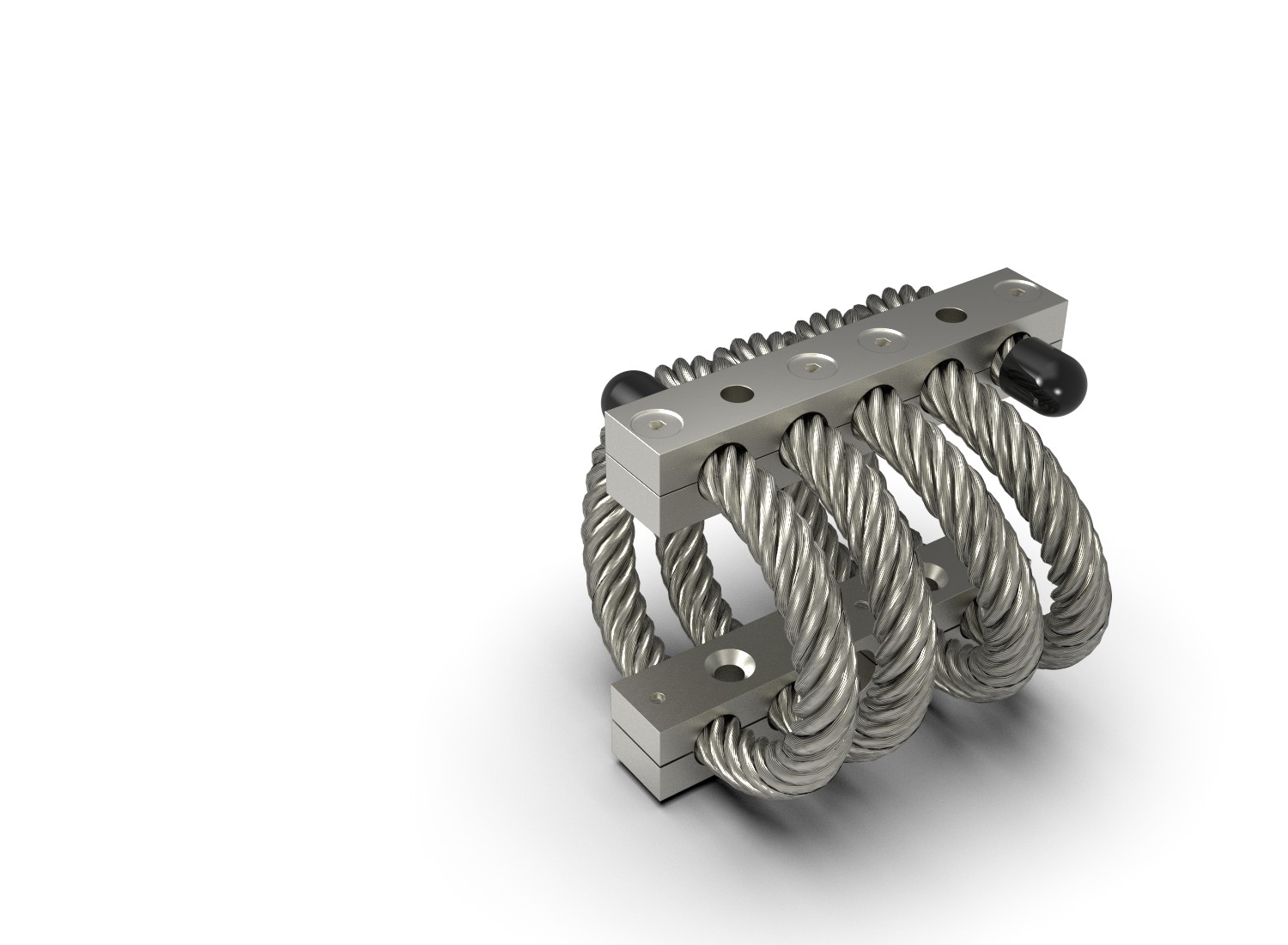

Wire rope isolators are passive isolation equipment’s that help in the isolation of vibration and shock from industrial machines and equipment’s. These isolation equipment’s come in varying forms and sizes depending on its requirement in the industry. Designed for heavy duty industrial applications, these wire rope isolates any form of vibration arising from machines and protects them from all sorts of damage. Made of stainless steel cables or wire strands and stainless steel retaining screws makes them an ideal maintenance-free, corrosion-resistant isolation equipment that protects products in all directions. Wire rope isolators are mainly used in applications or equipment where they need to be mounted against shock or vibration and where sound isolation is of minor importance.

Andre HVAC offers a wide range of vibration wire rope isolators for equipment’s that require vibration and shock dampening. We provide you a wide variety of these equipment’s made from different materials and of varying sizes. Made of high quality materials, these wire rope isolators are highly corrosion resistant making it the right choice for corrosive environment. Not just that our products have high dampening capabilities which makes it an efficient yet effective equipment for isolation.

Wire rope isolators are perfect for isolation & absorption of shock & vibration. These are systems that require no special attention or any sort of maintenance. They are functional even under adverse environmental conditions. These wire rope isolators dampening systems are mainly used in HVAC equipment’s, motor generators & compressors, shipping containers and in a number of medical & electronic equipment’s for effective vibration isolation. These one of a kind equipment’s that feature crimping pattern and come along with a variety of mounting options that are available in varied sizes. The vibration Wire rope isolators ensure efficient performance in terms of high frequency vibration dampening that arise in various commercial, industrial, and defence industrial application.

Equipment’s like these wire rope isolators are comparatively better and much more efficient than the conventional steel mounts or other elastic dampers in terms of performance and absorption of shock and vibration damping. While vibration wire rope isolators offer high level shock and vibration isolation, they are also beneficial in terms of supporting the structing in which they are installed. Customized and designed for easy use and installation the wire rope isolators can be easily loaded in any direction without the risk of malfunctioning of the application in which they are installed.

Using of equipment’s like the wire rope isolators increases the potential durability of all the equipment in which they are installed. Not just that they also increase its reliability, and overall productivity in the industry by enhancing the operation speed & improving the production quality of the machine. Further these wirerope isolators are known to reduce the potential damage caused due to high frequency shock & vibration by the machines. although small in size these equipment’s require minimum space for installation and deliver maximum isolation efficiency for a given equipment in the industry.

What really makes these cables or is wire rope isolators so effective is that they are made of high quality stainless steel cable woven in metal retaining bars that offers perfect surface mounting for the application in which they are installed. Further the configuration of the wire rope isolator provides resilience and good cushioning to the fragile load that helps in absorption of vibration with its wide frequency spectrum. Moreover, the cable or wire rope isolators are operational in any position be it compression, extension, shear, or even roll. What makes these equipment’s even more special is that it provides protection to the machines in all axes simultaneously during operation.

So, be it domestic appliances or any heavy duty industrial machineries, these equipment’s will surely be the best option for quality shock & vibration absorption from the applications. Vibration isolation wire ropes are generally used in various types of military applications, rough terrain vehicles, industrial and medical equipment, shipping containers. At Andre HVAC Inc we help our clients meet all the system requirements for domestic, industrial, commercial, and defence applications by catering a wide assortment of wire rope isolators at a very reasonable price. The products offered here are not just of the highest quality but also reasonably priced for our clients, making it the best choice in the industry for vibration isolation. Here different types of wire rope isolators are available including helical wire rope, circular wire rope, and even square wire rope isolators for various application.

The wire rope isolators offered by Andre HVAC are ingenious. These equipment’s can also be customized to suit specific requirements. The vibration wire rope isolators are basically stainless-steel wires that are twisted into a cable and is mounted between two bars. We can customize this equipment by simply changing the thickness of the cable, the number of loops and the angle of mounting which would provide specific behaviour or results under a given shock and/or vibration load. In short, these wire rope isolators can be constructed and easily fine-tune to specific customer requirements, or as per industry needs. This applicable in case of both bulk orders as well as for small quantities. All the products that we offer here are of the highest quality and comply to both national and international standards making them the most reliable equipment for any industry.

C/CB Helical Wire Rope Isolators are available in a wide range of sizes to permit attachment to almost any machinery or enclosure regardless of weight

Wire rope isolators comprise helical steel cables threaded through high-strength retaining bars. These cable isolators deliver superior shock and vibration protection for sensitive equipment and products. With their durable construction, corrosion resistance and high-temperature tolerance, these isolation solutions are ideal for many applications across a broad industry range.

WE ARE INTO MANUFACTURING OF WIRE ROPE ISOLATORS, SHOCK MOUNTS,ANTI VIBRATION MOUNTS, SPRING ISOLATORS,SPRING HANGARS, VISCOUS DAMPERS, SEISMIC DAMPERS & SPECIFIED RUBBER MOUNTS (ACCORDING TO CLIENTS REQUIREMENTS).

WE ARE INTO MANUFACTURING OF WIRE ROPE ISOLATORS, SHOCK MOUNTS,ANTI VIBRATION MOUNTS, SPRING ISOLATORS,SPRING HANGARS, VISCOUS DAMPERS, SEISMIC DAMPERS & SPECIFIED RUBBER MOUNTS (ACCORDING TO CLIENTS REQUIREMENTS).

At Socitec. We provide all-metal, multi-directional Helical wire rope isolators with exceptional endurance and reliability, high adaptability, excellent resistance, and other great features. It comes in standard models of 6, 8, or 10 cable loops, and you can always request a special model.

Socitec took care of everything you need in your anti-vibration helical wire rope isolator to secure protection for your equipment, So, we encourage you to order your isolator Now!

Socitec offers multi-directional isolators, with many remarkable features such as exceptional endurance and reliability, high adaptability, excellent corrosion resistance, and much more. These isolators come in standard models of four cable loops, and you can always request a special model.

We offer these all-metal, multi-directional polycal wire rope isolators which have some unique features such as high endurance and reliability, excellent corrosion resistance, and no aging. You can get them at a great price now from Socitec, keep reading more specifications and information, then order your polycal wire rope isolator that will solve your problem.

At Socitec, we help you protect your equipment from shock and absorption of vibration. You can find these unique all-metal multi-directional Axycal shock and vibration wire rope isolators. We provide these isolators with high endurance, no aging, excellent resistance to corrosion, a wide usage temperature range, and a lot more.

Axycal shock and vibration wire rope isolators will serve you exactly as you need. Before ordering one, read more specifications so you can find the perfect Axycal Wire Rope Isolators for you.

At Socitec, as a leader in shock and vibration control solutions, we offer you, different models of Naval Wire Rope Isolators. These isolators typically use on naval vessels for the protection of non-deck mounted shipboard equipment against underwater shock and ship. Naval Wire Rope Isolators are excellent for any application that requires water flow whereby they include many remarkable features such as, exceptional reliability, long life, high damping, corrosion resistance, and more. Get your Isolator quickly now!

Socitec provides you with Polycal Spring shock and vibration isolators. These isolators contain some noteworthy features such as exceptional reliability, long life, high damping, corrosion resistance, no aging, and much more. Polycal Springs are suitable for direct isolation of rotating and vibrating machinery or passive isolation of sensitive equipment. Keep reading for more information and qualities, then contact us to book your order now.

This Tuned Mass Damper is an excellent isolator used to reduce the vibration on tubes and pipes that equips motors, pumps, or other equipment which may generate vibrations. Tuned Mass Damper has a wide array of remarkable features, such as high lifetime, smooth to install, and much more. Contact us to provide you with the best isolator for your application

We offer these all-metal, multi-directional polycal wire rope isolators which have some unique features such as high endurance and reliability, excellent corrosion resistance, and no aging. You can get them at a great price now from Socitec, keep reading more specifications and information, then order your polycal wire rope isolator that will solve your problem.

VMC Group offers a variety of wire rope isolators that resolve shock and vibration issues in virtually any application. By selecting wire rope with the proper characteristics - wire diameter, number of strands, cable length, cable twist or lay, and the number of cables per section, we have created isolators that provide superior equipment protection. Ideally, passive isolation systems require no maintenance, use little space and keep functioning under varying temperatures and in corrosive environments.

As an elastic element, wire rope isolators will afford attenuation of vibration disturbances in much the same manner as they attenuate shock inputs. Wire rope isolators provide inherent damping by virtue of relative motion between wire strands. This damping limits vibration response peaks and limits responses to start-up and shut-down transients.

Isolators must also attenuate shock with minimum dynamic travel. A design that buckles under heavy shock loads without bottoming or permanent deformation provides the large deflection needed to bring the impacts within acceptable limits. When shock load is applied, the isolators soften and deform. This displacement reduces the acceleration level, through the controlled buckling of the wire rope loops.

This wire rope design handles both shock and vibration. In addition, three-plane, all-axes isolation permits installation in any attitude - vertically, horizontally or laterally.

Welcome to Vibro/Dynamics, where we will find effective and excellent solutions for shock and vibration problems. We offer you a great collection of wire rope isolators, constructed of stranded steel cable and contained between metal bars. The isolators’ design is chosen carefully to maximize the quality performance starting with the flexing of the cable loops that function as a spring, and the friction between the cable wires and strands that provides damping. Wire rope isolates are ideal for combined shock and vibration thanks to their large multidirectional deflection capabilities and high non-linear damping ratios. Moreover, our products can last a lifetime with quality performance and mechanism protection.

By their nature, wire rope isolators are self-snubbing, fail-safe, and captive to the ultimate limits of the metals. They are insensitive to temperature from cryogenic up to near anneal. They resist most industrial and natural environments. The VMC Group’s manufacturing process is set up to create special winding configurations to customize spring rate and deflection.

VMC Group presents tables of isolator recommendations based on the type of application and applied static weight per isolator. The indicated isolator is a convenient starting point when performing selection analysis.

The tables referenced are not a substitute for proper analysis of system requirements. The key elements to performing a meaningful selection and analysis are:Payload weight, geometry, center of gravity, isolator location

Quite often, we size the isolation system to do the best job within reasonable size constraints. Any theoretical isolator selection must be reconsidered in light of real-world limitations on equipment sway space and the isolator’s physical size and stability. Some very simple equations are used in selecting wire rope isolators. When considering shock, we use an energy method. We reduce a shock pulse to an equivalent velocity step. For a few typical shock inputs, the velocity steps are as follows:

With the spring rate (K) and dynamic displacement (Dd) established, we can now select an isolator. However, designers should take caution: The spring rates published are average. The placement of the static load on the load-deflection curve modifies the spring rate, available dynamic deflection capability, and cross-axes stability. The load-deflection curves for the principal and cross axes should be requested and considered when making any selection. VMC Group’s modeling software takes both the full third-order curve and damping into account.

Particularly with wire rope isolators, a robust system should be designed such that variances in the effective natural frequency due to dynamic damping do not significantly alter performance in the desired band.

VMC Group pioneered the wire rope isolator more than fifty years ago. Steel wire rope is strong, flexible, and fatigue-resistant because it is made up of many individual strands of high-tensile strength drawn wire. When bent or buckled, it is as much an elastic element as any tempered coil spring or elastomeric mount. Due to frictional forces between the individual strands, wire rope can provide a significant level of dynamic damping — typically 15% to 20% of critical damping. This level of damping makes wire rope isolators attractive for applications that involve sweeps through resonance and transients such as shock.

To create a shock and vibration isolator from wire rope, VMC Group creates buckling elements either in the form of helical loops (Helical Series isolators), or individual arcs (Arch and Circular Arch Series). Like any buckling element, a third-order force-deflection curve results. This can also be called a “softening curve.” Graphically, the curve starts from zero and is nearly linear. As load and deflection increase, the curve eventually begins to flatten. At some further point along the load-deflection curve, it becomes steeper, creating an inherent snubbing effect.

Shock is attenuated by spreading the input energy over time and distance. The flattened section of the curve is excellent for this. The load-deflection curve of a wire rope is very long given the isolator’s physical size. The isolator is a hollow, slender device capable of collapsing in on itself. For its size, it can deflect far more than elastomer and more than a coil spring. This is not to say that wire rope isolators are strictly shock attenuators and not vibration isolators. As an elastic element in a spring-mass system, it will exhibit a natural frequency and thereby form a low-pass filter for vibration energy in the same manner as any coil spring or elastomeric isolator. VMC Group does not list load ratings for individual wire rope isolators and we publish two different average spring rates. We have average static load-deflection curves available in both hard copy and electronic form for the principal isolator directions. They are always available on request. We have also chosen not to include load-deflection curves for wire rope isolators and encourage you to obtain assistance from VMC Group’s Engineering Services Division at 1-800- 569-8423. In almost all cases, application assistance, including analysis and modeling, is performed free of charge and without obligation to the customer.

To determine how much load can be placed on a wire rope isolator, we must first ask what the customer intends to do with the isolator. If small amplitude vibration is the input, we can place the static load along much of the lower two- thirds of a typical load-deflection curve. The effective static spring rate is the tangent of the curve at that load point. If large amplitudes, particularly deep shocks, are to be the input, we place the static load down in the linear first third of the curve. This allows the load to ride high up onto the curve in response to the shock. In this case, the effective average spring rate is a global straight-line, end-to-end slope of the curve over the excursion. To provide average values in the catalog for design purposes, we take the vibration spring rate as the tangent slope near zero and the shock spring rate as the overall end-to-end straight-line slope over the curve. VMC Group’s modeling software takes the entire third-order curve into account. The non-linear nature of the response curve and the presence of input-dependent damping are good reasons to work with our engineering department when selecting an isolator.

Another reason to consult with VMC Group before selecting your wire rope isolators is the interrelationship between the axes of the isolator. Wire rope isolators are elastic elements in all directions simultaneously. This makes them suited for all-attitude and mobile applications and applications that involve complex, off-axis inputs. The physics of the isolator is such that most inputs produce a response with components in more than one direction.

We can manage this characteristic using properly engineered solutions that take all axes into account. It should be noted that use of the tension direction for primary shock attenuation is not recommended. This is due to the predominance of tensile loading within the cable that results in a stiffening curve.

As the world leader in wire rope technology, our custom plate assemblies, and custom-designed isolators have been used in various applications for over 50 years. Whether for avionics and aerospace equipment, electronics apparatus, engine gensets, auxiliary power supplies, or other sensitive equipment requiring isolation, our engineering group will work with you throughout the entire design process to provide the custom solution you require. Our modeling software has an excellent reputation in the industry for its accuracy and will ensure your project is designed correctly from the beginning. Our plate assemblies and custom isolators have been designed to support weights from just a few pounds to over 100,000 pounds and take the form of special length bars, differing diameter wire, and winds, custom rail systems, plate assemblies, trays, and skids. Our helical wire rope isolators have been qualified on numerous military projects requiring the following typical specifications for shock and vibration:

8613371530291

8613371530291