wire rope lifting capacity chart for sale

This ratchet tie down is made of imported strap, processed of dye and iron and steps of delicate finish. It is made from Heavy Dacron and polypropylene, with all species of tie-down ranging from width 1-4" and break strength 1100lbs-20000lbs . You can choose and customize the fittest hook on Tie-down. Ratchet Straps are used for tying down loads whilst transporting , shifting or moving them. They have replaced traditional jute ropes, chains and wires used for transportation and for a variety of other applications.

The end point in a wire rope sling’s useful service life is prior to the failure of the sling. It must be removed from service when normal wear or accidental damage weakens the sling to the degree that an adequate factor of safety no longer exists.

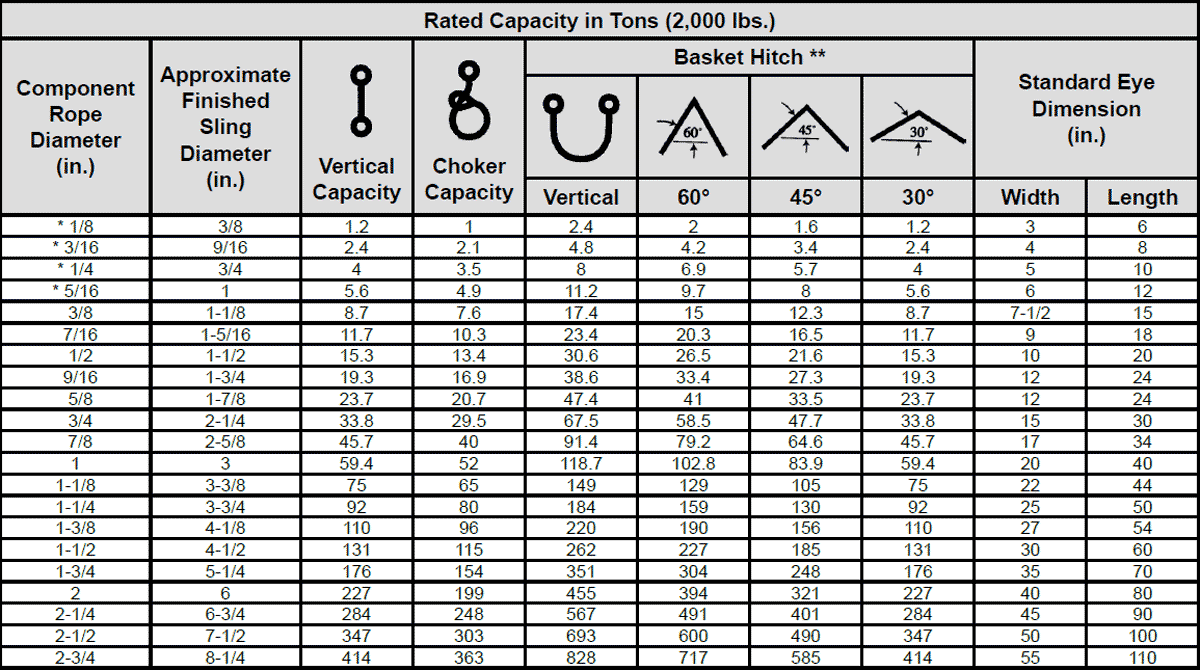

The term “Breaking Strength” is never used with reference to slings. Slings have a “Rated Capacity” that is determined by the manufacturer. A sling should never be used to lift a load that is greater than the published “Rated Capacity” for the particular sling and for the type of hitch being used. The design factor used in the calculation of a sling’s Rated Capacity compensates for normal dynamic loading and builds useful life into the sling.

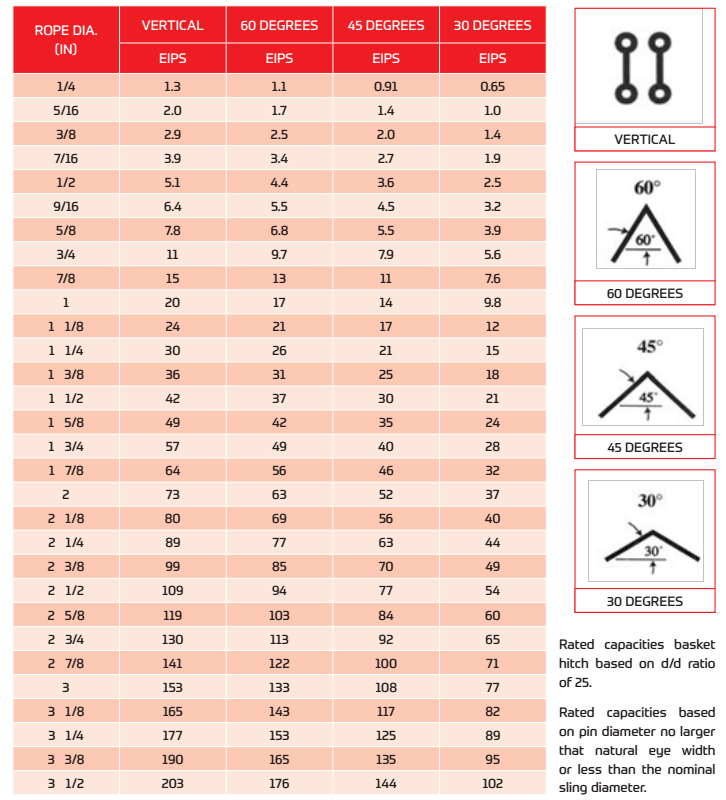

Selection of a sling to lift a load is based on selecting a sling with a Rated Capacity at least equal to the weight of the load. The sling must also be proper to allow the user to select a hitch that will conform to the shape of the load and keep it under control during the lift, The use of multiple leg slings is not recommended when the angle between any leg and the vertical is greater than 450• In any case when lifting headroom is restricted and a larger leg angle is necessary, care must be exercised in selecting a sling with a proper Rated Capacity at the leg angle which will be used. A visual inspection of the sling must be conducted before each lift to make sure the sling is in new or near new condition. A manufacturer’s Rated Capacity applies only to an undamaged sling.

Delta Rigging and Tools is a proud distributor of Slingmax® Rigging Solutions and their Gator-Laid®, Gator-Flex®, and Tri-Flex® braided wire rope slings. Multi-part braided wire rope slings allow you to get a great deal of flexibility and high capacity from a wire rope sling. With traditional wire rope slings as the capacity of the sling increases the diameter of the wire rope gets thicker and the flexibility of the sling decreases. This makes it difficult to manipulate and maneuver the slings in the field. By using multiple wire ropes braided together instead of one thicker wire rope the Slingmax® slings give you the flexibility of the small diameter wire ropes used in their construction, and a high capacity created by the multiple parts of line working together.

When a wire rope is bent around any sheave or other object there is a loss of strength due to this bending action. As the D/d ratio becomes smaller this loss of strength becomes greater and the rope becomes less efficient. This curve relates the efficiency of a rope diameter to different D/d ratios. This curve is based on static loads and applies to 6-strand class 6×19 and 6×37 wire rope.

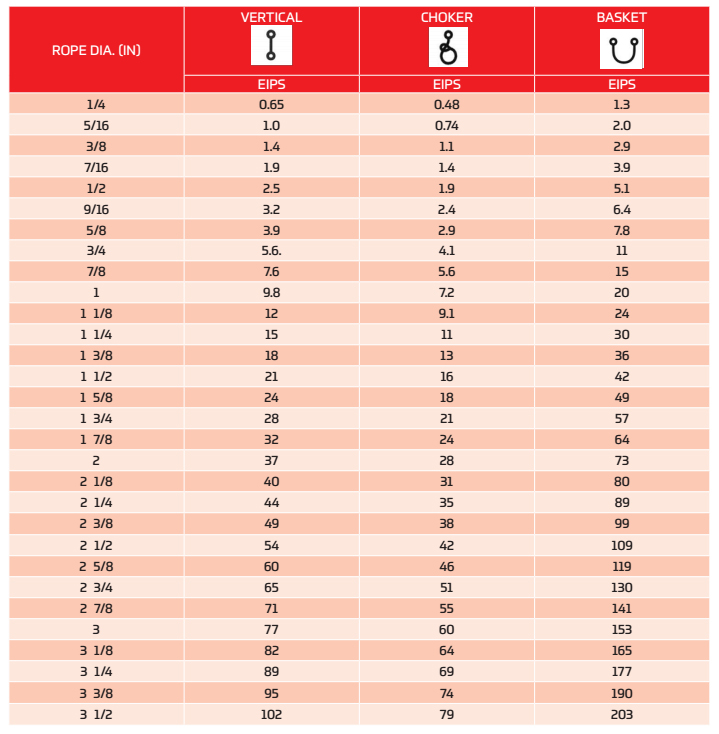

When a sling is used in a BASKET- or CHOKER HITCH with D/d ratios smaller than listed in the capacity tables, the rated capacities (or WLLs) must be decreased.

For example: The BASKET and CHOKER hitch capacities listed (in all Standards and Regulations) for 6-strand ropes are based on a minimum D/d ratio of 25:1.

An object you place into a 1" diameter 6-strand wire rope sling using a basket- or choker hitch must have a minimum diameter of 25". If the object is smaller than the listed 25:1 D/d ratio the capacity (or WLL) must be decreased. Table A) illustrates the percentage of decrease to be expected.

If the object lifted with a 6-strand wire rope sling in a basket hitch is at least 25 x larger than the sling diameter (D/d 25:1) the basket capacity need not to be adjusted.

It is better to use a larger shackle or a Wide Body shackle type. If the shackle or object has at least 5x the sling diameter (D/d 5:1) the basket sling capacity must still be reduced by about 25%.

Load Hooks must have sufficient thickness to ensure proper sling D/d ratio, particularly when using slings in an inverted basket hitch; that is the sling BODY is placed into the hook and the sling EYES are facing downwards.

Endless (or Grommet) slings DO NOT HAVE A LOOP which has double the strength of the sling body. Prior to EVERY lift, YOU, the user, has to determine if the D/d ratio is equal or higher than the ones listed in the capacity tables.

6x36 is a flexible general engineering wire rope readily available in galvanised, ungalvanised and marine grade stainless steel. The wire rope has an equal lay construction (warrington seale) and achieves a superior breaking load to the 6x19 construction range. The construction has been designed to give a flexible rope with a good fatigue life. A 6x36 wire rope is available with either FC (fibre core) or IWRC (independent wire rope core) and is used for a wide range of applications, examples of which are shown below:

Rope strength is a misunderstood metric. One boater will talk about tensile strength, while the other will talk about working load. Both of these are important measurements, and it’s worth learning how to measure and understand them. Each of these measurements has different uses, and here we’re going to give a brief overview of what’s what. Here’s all you need to know about rope strength.

Each type of line, natural fiber, synthetic and wire rope, have different breaking strengths and safe working loads. Natural breaking strength of manila line is the standard against which other lines are compared. Synthetic lines have been assigned “comparison factors” against which they are compared to manila line. The basic breaking strength factor for manila line is found by multiplying the square of the circumference of the line by 900 lbs.

Just being able to calculate breaking strength doesn’t give one a safety margin. The breaking strength formula was developed on the average breaking strength of a new line under laboratory conditions. Without straining the line until it parts, you don’t know if that particular piece of line was above average or below average. For more information, we have discussed the safe working load of ropes made of different materials in this article here.

It’s very important to understand the fundamental differences between the tensile strength of a rope, and a rope’s working load. Both terms refer to rope strength but they’re not the same measurement.

A rope’s tensile strength is the measure of a brand-new rope’s breaking point tested under strict laboratory-controlled conditions. These tests are done by incrementally increasing the load that a rope is expected to carry, until the rope breaks. Rather than adding weight to a line, the test is performed by wrapping the rope around two capstans that slowly turn the rope, adding increasing tension until the rope fails. This test will be repeated on numerous ropes, and an average will be taken. Note that all of these tests will use the ASTM test method D-6268.

The average number will be quoted as the rope’s tensile strength. However, a manufacturer may also test a rope’s minimum tensile strength. This number is often used instead. A rope’s minimum tensile strength is calculated in the same way, but it takes the average strength rating and reduces it by 20%.

A rope’s working load is a different measurement altogether. It’s determined by taking the tensile strength rating and dividing it accordingly, making a figure that’s more in-line with an appropriate maximum load, taking factors such as construction, weave, and rope longevity into the mix as well. A large number of variables will determine the maximum working load of a rope, including the age and condition of the rope too. It’s a complicated equation (as demonstrated above) and if math isn’t your strong point, it’s best left to professionals.

However, if you want to make an educated guess at the recommended working load of a rope, it usually falls between 15% and 25% of the line’s tensile strength rating. It’s a lotlower than you’d think. There are some exceptions, and different construction methods yield different results. For example, a Nylon rope braided with certain fibers may have a stronger working load than a rope twisted out of natural fibers.

For safety purposes, always refer to the information issued by your rope’s manufacturer, and pay close attention to the working load and don’t exceed it. Safety first! Always.

If you’re a regular sailor, climber, or arborist, or just have a keen interest in knot-tying, be warned! Every knot that you tie will reduce your rope’s overall tensile strength. Some knots aren’t particularly damaging, while others can be devastating. A good rule of thumb is to accept the fact that a tied knot will reduce your rope’s tensile strength by around 50%. That’s an extreme figure, sure, but when it comes to hauling critical loads, why take chances?

Knots are unavoidable: they’re useful, practical, and strong. Splices are the same. They both degrade a rope’s strength. They do this because a slight distortion of a rope will cause certain parts of the rope (namely the outer strands) to carry more weight than others (the inner strand). In some cases, the outer strands end up carrying all the weight while the inner strands carry none of it! This isn’t ideal, as you can imagine.

Some knots cause certain fibers to become compressed, and others stretched. When combined together, all of these issues can have a substantial effect on a rope’s ability to carry loads.

Naturally, it’s not always as drastic as strength loss of 50% or more. Some knots aren’t that damaging, some loads aren’t significant enough to cause stress, and some rope materials, such as polypropylene, Dyneema, and other modern fibers, are more resilient than others. Just keep in mind that any knots or splices will reduce your rope’s operations life span. And that’s before we talk about other factors such as the weather or your rope care regime…

BC Wire Rope & Rigging is a full service provider of wire rope, slings, chain, hoists, and rigging equipment. BC Wire Rope has served the heavy lifting needs of customers throughout Los Angeles, San Diego, Las Vegas, Tucson and the Western United States since 1974. Specializing in lifting products ranging from fall protection to synthetic slings, BC Wire Rope & Rigging carries products from the industry’s most reputable vendors including Crosby, Slingmax, Campbell, and Bridon American. With ample testing and manufacturing capabilities, BC Wire Rope is also the manufacturer of KWIK synthetic slings.

Crosby has determined that 7/8″ shackles with the Product Numbers below that also contain the Production Identification Code (PIC) 5YH may have a reduced capacity and should be removed from service and replaced. 1019542 7/8” 6.50t S-2130 Shackle1019533 7/8” 6.50t G-2130 Shackle1018151 7/8” 6.50t G-213 Shackle1018160 7/8” 6.50t S-213 Shackle1018516 […]

Crosby has determined that some 1″ G-209/S-209 Shackles with product codes 1018534 and 1018543 may have a condition that reduces the load capacity. The impacted shackles were shipped from Crosby between November 23, 2021, and January 28, 2022. These shackles should be removed from service and returned for replacement. Please […]

BC Wire Rope was onsite as the last steel beam was raised by Schuff Steel at the new, future home of the Los Angeles Rams and LA Chargers at SofFi Stadium in Inglewood, California. The raising of the last beam is marked by the raising of a ceremonial Christmas Tree, […]

Established nearly 40 years ago in Southern California, BC Wire Rope now manufacturers and distributes wire rope from 5 locations to strategically serve customers across the West Coast. Headquartered in a 35,000 square foot warehouse and manufacturing facility in Anaheim, BC Wire Rope is the premier provider of rigging throughout the greater Orange County and Los Angeles area and also has branches in Tucson, Las Vegas, San Diego, and Elko. These locations allows BC to stock a full inventory of specialty lifting products and enables BC to efficiently meet a wide range of manufacturing needs.

Full in-house testing and wire rope manufacturing capabilities help ensure that BC Wire Rope can meet or exceed its customers’ needs. BC Wire Rope can press wire rope slings and swaged boom pendants, splice slings and soft rope, and can fabricate special end fittings. BC also manufacturers its own line of synthetic slings through its KWIK Products division. KWIK Products include nylon eye & eye endless flat slings, high performance fiber slings, polyester round slings, and choker and basket hardware slings. BC Wire Rope also provides customers with proof testing through use of its 4 test beds that can test slings, blocks, and hardware with up to 1 million pounds of force.

BC Wire Rope & Rigging’s unrelenting focus on customer service and industry leading products is evidenced by its ‘Quality – No Compromise’ motto. BC Wire Rope has been a proud member of the wire rope industry’s trade association—Associated Wire Rope Fabricators (AWRF)—for over 35 years. The commitment to longstanding industry relationships is also demonstrated by the fact the more than half of BC Wire Rope’s employees have remained with the company for over 18 years.

With years of industry knowledge and a full product inventory, chances are that BC Wire can meet your lifting needs. Contact the specialists at BC Wire Rope today to find out more about what BC Wire Rope can do for you.

8613371530291

8613371530291