wire rope lifting sling free sample

Wire rope slings are extremely strong and an excellent choice for heavy duty jobs involving not only lifting, but also hoisting, towing, or anchoring loads. The fabrication of wire slings also offers excellent abrasion-resistance and heat resistance so it can be used in extreme conditions and temperatures. Its pliable design can conform to the shape of a load for a more secure application.

Wire rope slings are manufactured in a variety of configurations, with 6x19 and 6x36, being two of the most common. The numbers represent the number of wires making up the strand and the number of strands wrapped around the core. For example, a 6x19 indicates that there are 19 wires making up a strand, and 6 strands are wrapped around the core.

Each steel wire rope configuration will offer different benefits and will be better suited to certain applications. In general, a smaller number of large outer wires offers better wear and corrosion resistance, while a larger number of small wires provides a better level of flexibility and fatigue resistance.

We offer steel wire rope slings in both 6x19 and 6x36 configurations, depending on the diameter of the wire rope. All are in a bright (unfinished) wire rope, but other configurations are available by request. Our cable laid slings are manufactured in a 7x7x7 galvanized wire rope (composed of 7 strands of 7x7 cables), which make them extremely flexible and useful for more specialized applications.

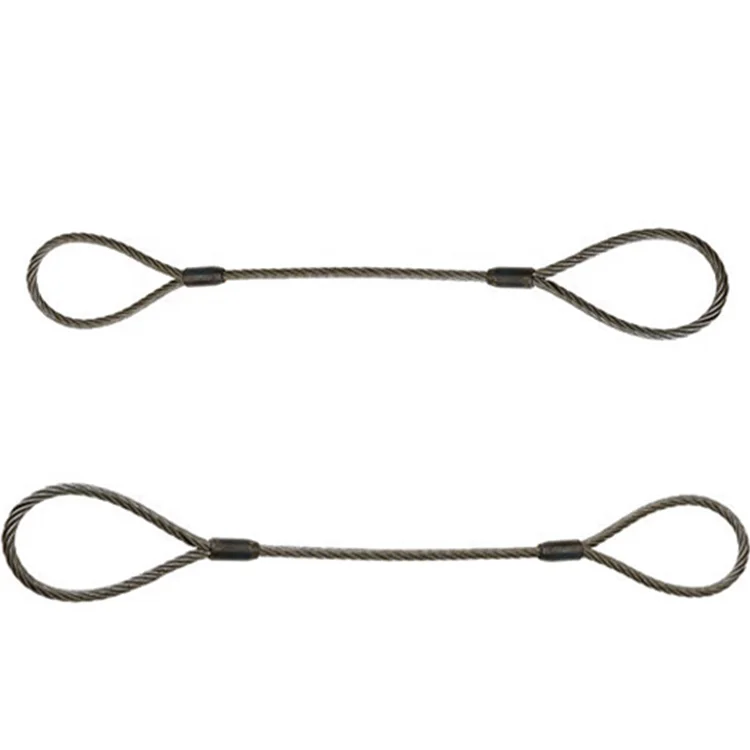

The eye loops on our sling cable are created with a Flemish splice, which is a mechanical splice where the rope cable is separated into two parts (one part has three strands, the other part has the remaining three strands plus the core), then re-laid back in the opposite direction to form the loop. The ends are then secured with a carbon steel sleeve around the entire area. Flemish splices offer the most efficient use of capacity.

The core of the wire rope used in cable slings can be made of several different materials, including steel or natural fibers. Our steel wire rope slings are made with Extra Improved Plowed Steel (EIPS) around an Independent Wire Rope Core (IWRC) for the ultimate in strength and durability.

Our categories of wire rope slings are broken down by number of legs, hardware, and the diameter of the wire rope. Each wire sling is made to order, so custom slings are also always an option if you don"t see what you"re looking for here.

We offer a wide selection of both domestic wire rope slings and import wire rope slings online, with additional options and customization available by calling our sales team.

Import slings are a more cost-effective choice yet offer the same wire rope strength and working load limits as our domestic slings. Our imported slings also feature sleeve components from Crosby. Wire rope slings we import are also available in custom configurations.

Sometimes called eye & eye slings because of an oval "eye" at each end, these 1 leg cable slings are rugged and reliable and a very popular choice among wire slings. The eyes are formed using a Flemish eye splice and secured with a carbon steel sleeve.

Single leg cable slings are available in a variety of styles: Eye & Thimble, Thimble & Thimble, Eye & Hook, Eye & Eye, Sliding Choker, and Cable Laid.

Also known as a 2 leg bridle sling, this sling offers increased versatility over a sling with just a single leg. Manufactured with a Flemish eye that"s spliced with a carbon steel sleeve; end options range from a latched eye hook to a simple eye design. Our 2 leg wire rope slings are available in seven different diameters of rope. Custom options are also an option.

Our 3 leg wire rope slings are also known in the industry as a 3 leg bridle sling. Each is manufactured with a Flemish eye that"s spliced with a carbon steel sleeve for the ultimate in safety and strength. End options include latched eye hooks, eyes equipped with thimbles, and more, as customized options are always available. Our 3 leg wire rope slings are available in seven different diameters of rope.

A 4 leg bridle sling offers the ultimate in versatility. Also known in the industry as wire rope 4 leg bridle slings, ours are manufactured with a Flemish eye that"s spliced with a carbon steel sleeve for an extra measure of security. And because legs can be fitted with hardware of your choosing, from simple eye formations to heavy duty hooks, it results in a sling customized to your exact application needs. Our 4 leg wire rope slings are available in six different diameters of rope.

Braided wire rope slings are formed when multiple wire ropes are braided continuously to form the body of the sling and the eye/eyes into a single fabricated sling. Braided wire slings are excellent for higher capacity lifts and can be either round or flat. One benefit of a braided sling is its ability to conform snugly to a load that"s in a choker hitch. Because of the braided design, they also are better resistant to kinking.

Our braided wire rope slings are made in the USA and available in a variety of configurations, including a 3-part braid, 6-part braid, 8-part braid, and 9-part braid. Several style options are also available, including standard eyes, thimble eyes, and more, to create a customized braided wire rope sling to your specifications.

Wire rope bridles are measured by the length of the sling leg plus the end hook. The length of the oblong master should not be included in the overall measurement.

Our slings are available in a variety of lengths, but can also be customized to any length you need. Give our sales team a call for more information or to place a custom order.

"Slings in contact with edges, corners, protrusions, or abrasive surfaces shall be protected with a material of sufficient strength, thickness, and construction to prevent damage."- ASME B30.9 (2021) 9-5.10.4(d)

All of our slings are inspected, certified and tagged with metal tags displaying rated capacities by hitch types and angles; diameter or size; and name/trademark of the manufacturer.

Proof testing certificates can be supplied with your order for a nominal fee and must be requested at the time of order. Proof tests are performed in the factory where the sling is pull tested to 2x the vertical rating and officially recorded as proof for governing bodies. During the standard manufacturing process, only random slings during a production run are tested for compliance; in order to provide proof testing certificates with your order, every sling must be pull tested at the time of manufacture.

If steel wire rope slings are not the best choice for your application, we also offer chain slings, nylon lifting slings, and polyester round slings in a wide range of styles and capacities. As with all of our lifting slings, customization is always an option.

If you need help selecting a sling, check out our How to Choose a Lifting Sling page or call our product specialists . They"ll be happy to any answer questions you may have and can even place a custom order if needed.

Domestic steel slings are available in two main configurations, 6x19 and 6x36, depending on the diameter of the wire rope. The numbers represent the number of wires making up the strand and the number of strands wrapped around the core. For example, a 6x19 indicates that there are 19 wires making up a strand, and 6 strands are wrapped around the core.

When choosing domestic cable slings, keep in mind that a smaller number of large outer wires will offer excellent resistance to general wear and corrosion; whereas a larger number of small wires will provide better flexibility and resistance to fatigue.

The core of the wire rope used in cable slings can be made of several different materials, including steel or natural fibers. Our domestic wire rope slings are made with Extra Improved Plowed Steel (EIPS) around an Independent Wire Rope Core (IWRC) for the ultimate in strength and durability.

All of our steel wire rope slings are inspected, certified, and marked with metal tags with the wire rope diameter or size and the name / trademark of the manufacturer. The tags also display rated capacities by hitch types and angles.

All of our made-in-the-USA wire rope slings are manufactured with a Flemish splice to create the eye loops. A Flemish splice is a mechanical splice where the wire rope is separated into two parts (one part has three strands, the other part has the remaining three strands plus the core), then re-laid back in the opposite direction to form an open loop (“eye”). The ends are then secured with a carbon steel sleeve around the entire area. Flemish splices offer the most efficient use of capacity.

Also known as a 2 leg bridle sling, this lift sling offers more versatility than a single leg sling, as well as increased load balance. Ours are manufactured with a latched eye hook on each end and are available in several different diameters of rope.

A sliding choker sling features a hook between the two eyes that slides from one end to the other for easy hook-up. Sliding choker slings are manufactured with a regular eye on one end and a thimble eye on the end of the sling that loops back to attach to the sliding hook.

When measuring a domestic wire rope sling with multiple legs, do not include the oblong master - instead, measure the length of the sling leg to the loadbearing point of the hook or eye.

If you need proof testing certificates for your wire rope slings, please request them at the time of order. Available for a nominal fee, these tests are performed in the factory for reliable results. Each sling is pull-tested to 2x the vertical rating, then the results are officially recorded as proof for governing bodies.

This differs from the standard manufacturing process in that every sling is pull-tested at the time of manufacture. Normally, only random slings during a production run are tested for compliance.

If domestic wire rope lifting slings are not the best choice for your job, we also offer chain slings, nylon lifting slings, high performance round slings, plasma slings, and polyester round slings in a wide range of styles and capacities.

Not sure what sling is right for you? Check out our How to Choose a Lifting Sling page or get in touch with one of our lifting sling specialists. They have the knowledge and experience to help you create the ideal lifting setup.

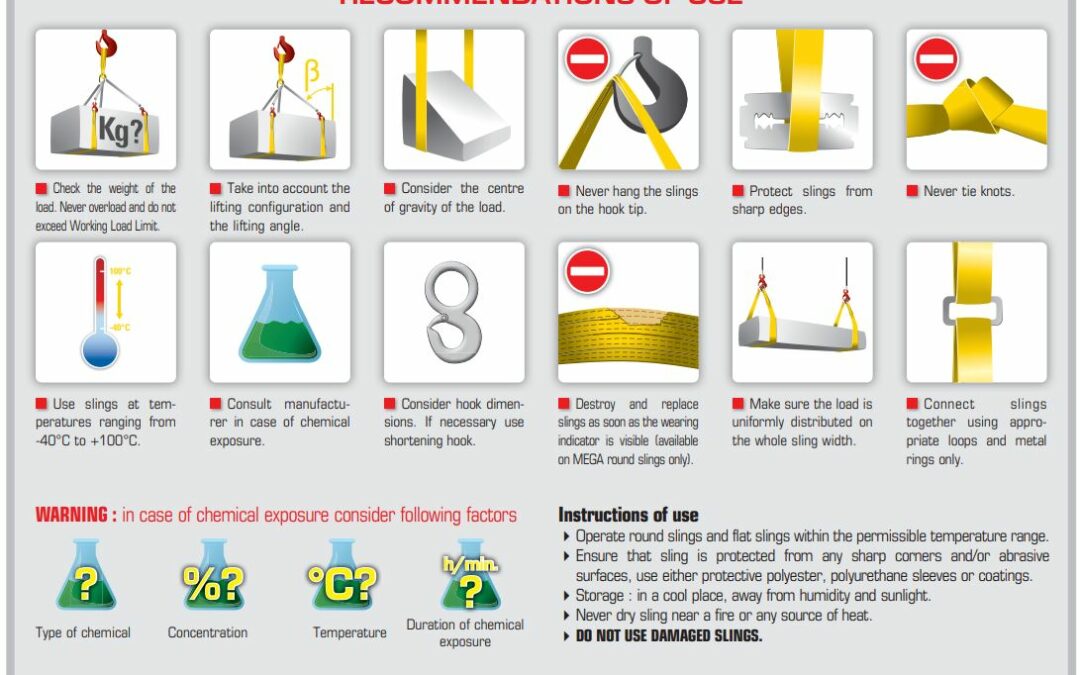

Before lifting with slings, it is important to ensure that the load will be stable when it is raised clear of the ground. It is dangerous if a load can tilt or swing in an uncontrolled manner, or if it can topple over.

A load will not tilt, if, before lifting, the sling(s) i"s (are) arranged so that the load is suspended with its centre of gravity aligned directly below the main point of attachment of the hook (see figure 1). (The centre of gravity is the point about which the parts of a body, when left free, exactly balance each other.I

Yes. We are a professional manufacturer of wire assemblies with 40 years producing experience in China .We have always been cooperating with domestic and overseas customers and partners with the first- class quality and service to make great achievements. If this is your first time to contact us, please trust us, we’ll not let you down.

Before lifting with slings, it is important to ensure that the load will be stable when it is raised clear of the ground. It is dangerous if a load can tilt or swing in an uncontrolled manner, or if it can topple over.

A load will not tilt, if, before lifting, the sling(s) i"s (are) arranged so that the load is suspended with its centre of gravity aligned directly below the main point of attachment of the hook (see figure 1). (The centre of gravity is the point about which the parts of a body, when left free, exactly balance each other.I

1.Pressed Steel Wire Rope Sling is made by using the best high quality steel wire rope and produced with the most professional equipment and technique 2.Make the easy lifting come true. It is a safe and applied lifting tools. With its characteristics: Resist against the,high,temperature and the abrasion; Easy to use and with big working load

4.Our company edited and draft the national standard. The Pressed Wire Rope sling with the produce range 6mm-190mm. 5.And we also can make the special standard pressed sling according with the requirements from the customers.

The Mazzella name is synonymous with quality slings—from the customer preferred Mazzella 7-Part™wire rope sling to one of the world’s largest synthetic Twin-Path®high-performance slings, we can manufacture the right sling to meet your needs.

At Cortland, success isn’t marked by sales, but rather the success of our customers. At the same size and strength of steel sling options, synthetic solutions can be up to 86% lighter, significantly improving the safety or your workforce. Synthetic slings are easier to move and control, gentle on the hands, and maintain lifting capacity even when wet. What’s more, our synthetic rope slings are incredibly strong and flexible, so they won’t mar the surfaces of the objects they lift. And since they’re about half the size of standard round slings, they only require about half the hardware width of most high-performance round slings.

Cognitive Market Research has published a detailed market analysis report of Wire Rope Sling Industry titled, "Global Wire Rope Sling Market Report 2022". Question such as what is the Wire Rope Sling Market Size, Trends, Growth and Competitors Analysis (2016-2028)". The research study is an outcome of extensive primary and secondary research conducted by our highly experienced analyst team located across the globe. The market study focuses on industry dynamics including driving factors to provide the key elements fueling the current market growth. The report also identifies restraints and opportunities to provide high growth segments involved in this industry. Key industrial factors such as macroeconomic and microeconomic factors are studied in details with the help of PESTEL analysis in order to have a holistic view of factors impacting Wire Rope Sling market growth across the globe. Market growth is forecasted with the help of complex algorithms such as regression analysis, sentiment analysis of end users, etc.

The global Wire Rope Sling market has been segmented based on various factors. All segments have been analyzed and forecast based on Revenue and Volume from 2016 to 2028.

All the type segments have been analyzed based on present and future trends and the market size is estimated from 2020 to 2028. Moreover, study also provides quantitative and qualitative analysis of each type to understand the driving factors for the fastest growing type segment for Wire Rope Sling market.

Figures are for representative purpose only. Market share not depicted as per actual scale. To understand the trends and dominating segment of Wire Rope Sling market. Request for your Free Sample Pages.Click Here

This report forecasts revenue growth at the global, regional, and country levels and provides an analysis of the latest industry trends and opportunities for each application of Wire Rope Sling from 2016 to 2029. This will help to analyze the demand for Wire Rope Sling across different end-use industries. Our research team will also help aquire addtional dta such as Value Chain, Patent analysis, Company Evaluation Quadrant (Matrix), much more confidential analysis and data insights.

Figures are for representative purpose only. Market share not depicted as per actual scale. To understand the trends and dominating segment of Wire Rope Sling market. Request for your Free Sample Pages. Click Here

All type and application segments have been analyzed based on current trends at the global, regional as well as country level. The Wire Rope Sling market research report provides in-depth information about the data analyzed and interpreted during the course of this research by using the figures, graphs, pie charts, tables and bar graphs. The key regions are analyzed by considering various factors such as the profit, product price, capacity, production, supply, demand, market growth rate and many more.

Following regions and respective countries data is covered by the scope Wire Rope Sling market research report: (In case you wish to aquire a region specific or any country specific data then please contact us)North America (U.S., Canada and Mexico)

Jiangsu Safety Steel Wire RopeIf any Company(ies) of your intrest has/have not been disclosed in the above list then please let us know the same so that we will check the data availibility in our database and provide you the confirmation or iclusion in the final deliverables.

8613371530291

8613371530291