wire rope load calculation manufacturer

Wire rope is also known by many other names, such as: wire, multi-strand wire, flexible wire, cable, cord, steelcord, etc. but it is essentially a collection of small filaments wound around each other in a manner that largely retains its shape when bent, crushed and/or tensioned.

It is a system for significantly increasing the strength and flexibility of steel wire and is used in almost every important application we see around us. For example: suspension bridges, tyres, brake and accelerator cables (in cars), high-pressure flexible pipes, lifting and rigging cables, electrical conductors, etc. and it comes in many different forms. Fig 2 shows just a very small sample of available designs.

With minor variations, the generally accepted method for designating a wire rope construction in the industry is by describing it numerically. For example:

Whilst "IWRC" wire ropes offer a slightly greater tensile capacity (≈7%) than those with fabric or polymer fillers, the additional strength does not come from the tensile capacity of the core filaments but from improved dimensional stability under load. And whilst they are also much more resistant to crushing, they are stiffer than fibre core ropes and therefore not recommended for applications where tension occurs under bending.

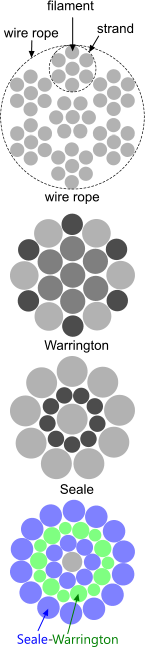

Warrington (Fig 1) is a parallel lay construction with an outer layer comprising wires of alternating large and small diameters, each outer layer having twice the number of wires as the layer immediately beneath. The benefit of this design is to increase packing and therefore strength density, however, unless the different diameter filaments are of the same strength (unlikely), this construction is limited by the strength of the weakest filaments.

Seale (Figs 1 & 2 6x36) is also a parallel lay construction but with the same number of wires in each wire layer. All the wires in any layer are the same diameter. This is an alternative to the Warrington construction, with similar benefits and disadvantages.

Regular lay constructions are used much more widely (than Lang lay) because they have excellent structural stability and less tendency to unwrap under tension (see Rotating vs Non-Rotating below). However, because it has a knobbly (undulating) surface it will wear both itself and any surface over which it is run much more quickly than Lang lay wire rope.

Lang lay constructions have a flatter surface than regular lay constructions giving them better resistance to wear and bending fatigue, especially when made from flattened (elliptical) filaments. They are, however, much less structurally stable and subject to birdcaging if the wire rope is over-bent or twisted against its wrapped direction.

"Regular Lay", multi-strand constructions are normally subject to slightly less rotation under tension (than Lang lay) due to the opposite helical direction of the filaments (within the strands) and the strands (within the rope), however, you can improve their rotation characteristics still further by;

Fillers (Fig 2) may be fabric, polymer or even smaller diameter filaments (e.g. 6x36). Whilst they contribute little to the tensile strength of wire rope, they can significantly; improve performance under bending (fabric and polymer cores only), reduce axial growth, reduce rotation in rotation-resistant constructions, improve structural stability and increase fatigue life.

This filler material should not be included in strength (tensile capacity) calculations, but must be included in those for axial stiffness (extension). If it is ignored, your calculations will reveal excessive extension as the wire rope collapses.

Suspension bridges tend to be constructed from densely packed, single strand plain "Wire Rope" constructions using large diameter galvanised filaments. Little heed is paid to rotational resistance as strength is paramount and once tensioned, they should remain in that loading condition for their design life.

Lifting & winching normally require wire ropes of good flexibility and fatigue resistance. Therefore they tend to be similar to 6x36 but with fibre core instead of the IWRC in Fig 2

Remote operating cables such as hand-brakes and accelerators on cars normally only work in tension so they need to be strong but not necessarily stiff (as they are fully contained in reinforced outer sheaths). These tend to be manufactured from large diameter "TyreCord" or small diameter single-strand "Wire Rope".

Wire rope does not obey Hooke"s law. Therefore, you cannot accurately predict how much it will stretch for any specified force. This unpredictability applies to any section removed from the same manufactured length of cord and even between cords produced to the same specification but by different manufacturers.

CalQlata has decided that the accuracy of axial stiffness (EA) of wire rope falls outside its own levels of acceptability and therefore does not include it in the wire rope calculator. The extension calculated in the Wire Rope calculator (δLᵀ) is based upon the effect of axial tension on packing density. It is therefore important that core material is not ignored when using the calculator to evaluate this characteristic.

Wire rope does not obey Hooke"s law. Therefore, you cannot accurately predict how much it will twist for any specified torque. This unpredictability applies to any section removed from the same manufactured length of cord and even between cords produced to the same specification but by different manufacturers.

CalQlata has decided that the accuracy of torsional stiffness (GJ) of wire rope falls outside its own levels of acceptability and therefore does not include it in the wire rope calculator.

1) No wire rope calculator, whether dedicated or generic, will accurately predict the properties of any single construction under a wide range of loading conditions

2) No wire rope calculator, whether dedicated or generic, will accurately predict any single property for a range of constructions under a wide range of loading conditions

The only wire rope that can be reliably analysed is that which is used for suspension bridges, because; it comprises a single strand, is very densely packed, has negligible twist, contains filaments of only one diameter, is never subjected to minimum bending and every filament is individually tensioned.

There is a very good reason why manufacturers do not present calculated performance data for construction or design proposals, because even they cannot accurately predict such properties and quite rightly rely on, and publish, test data.

During his time working in the industry, the wire rope calculator"s creator has seen, created and abandoned numerous mathematical models both simple and complex. He has gradually developed his own simplified calculation principle based upon his own experience that still provides him with consistently reliable results of reasonable accuracy.

The purpose of CalQlata"s wire rope calculator is to provide its user with the ability to obtain a reasonable approximation for a generic construction, after which, accurate test data should be sought from the manufacturer for the user"s preferred construction.

The calculation principle in the wire rope calculator is based upon changes in the properties of the wire rope that occur with variations in packing density under tension

Bearing in mind the above limitations CalQlata can provide the following assistance when generating (manipulating) the wire rope calculator"s input data and interpreting its output

Alternatively, for wire rope with multiple filament diameters, you need to find an equivalent diameter with the following proviso; you must enter the minimum filament yield stress (SMYS)

It is expected that apart from fillers, all the material in the wire rope will be identical and therefore have the same density, i.e. using different materials will result in less than "best" performance. However, if such a construction is proposed, you can calculate an equivalent density as follows:

It is expected that apart from fillers, all the material in the wire rope will be identical and therefore have the same tensile modulus, i.e. using different materials will result in less than "best" performance. However, if such a construction is proposed, you should enter the highest tensile modulus.

The wire rope calculator simply adds together the total area of all the filaments and multiplies them by the SMYS entered, which represents a theoretical maximum breaking load that would exist if this load is equally shared across all of the filaments and the lay angles have been arranged to eliminate localised (point) loads between adjacent filaments.

If the wire rope has been properly constructed it is likely that its actual break load will be greater than 80% of this theoretical value. However, given the vagaries of wire rope construction, the actual break load can vary considerably dependent upon a number of factors. CalQlata suggest that the following factors may be used to define the anticipated break load of any given construction:

The axial stiffness and strain under load will be affected by this value, hence the reason why the most reliable (predictable) constructions tend to be minimum [number of] strands and single filament diameter. The Warrington and Seale constructions and combinations thereof tend to provide the highest packing density (but lowest flexibility) and there is little to be gained from using these constructions in more than single stranded wire rope as the benefit of high-packing density will be lost with no gain in flexibility.

The anticipated second moment of area of the wire rope at tension "T" due to deformation but insignificant flattening as it is assumed the wire rope will be bent over a formed (shaped) sheave or roller.

The anticipated tensile modulus of the wire rope at tension "T" due to deformation but insignificant flattening as it is assumed the wire rope will be bent over a formed (shaped) sheave or roller.

It is not advisable to induce this bend radius in operation due to uncertainties associated with wire rope construction, especially for dynamic applications. CalQlata suggests that a similar approach to that used for the break load (Fb) above also be applied here, i.e.:

A change in diameter will occur in all wire rope, irrespective of construction, until packing density has reached a limiting value. The value provided in the wire rope calculator is that which would be expected if the construction remains intact at the applied tension "T"

Unreliability of this value increases with complexity in wire rope due to its longitudinal variability and the increased likelihood of premature failure.

The accuracy of this data will range from about ±1% for wire rope with a single strand and a single filament diameter, up to about ±15% for constructions of similar complexity to OTR cord

A change in length of any wire rope will occur due to the fact that the packing density increases with tension. This is not, however, a linear relationship.

This can be an unreliable value as illustrated by tests carried out (by the author) on two pieces of wire rope supplied by the same well-known manufacturer both of which were cut from the same length, varied in tensile capacity by only 1.5%, but the tensile modulus (and strain at break) varied by 34%. Whilst this was an extreme case, significant variations have been seen in wire rope manufactured by a number of manufacturers.

Whilst the wire rope calculator does not calculate axial stiffness (see Calculation Limitations 9) above), CalQlata can suggest the following rule-of-thumb that will provide reasonable results for most constructions at the applied tension "T":

Where: θ = the "absolute" sum of the average filament lay angle and the average strand lay angle⁽²⁾. Note; the angle of twist (θ) will reduce as tension approaches break load.

Whilst the wire rope calculator does not calculate bending stiffness (see Calculation Limitations 8) above), CalQlata can suggest the following rule-of-thumb that will provide reasonable results for most constructions at the applied tension "T":

Low complexity means single strand and single wire diameter. Medium complexity means multi-strand and single wire diameter. High complexity means multi-strand and multiple wire diameters.

Enter the diameter of the wire rope, in mm, into the calculator to determine the safe working load (SWL). This calculator is for education purposes only, follow manufacturing guidelines for true SWL values.

A safe working load of a wire rope is a measure of the total load or weight that a wire rope can safely support during operation. Values greater than the SWL could result in a failure of the rope.

Wire ropes are essential for safety purposes on construction sites and industrial workplaces. They are used to secure and transport extremely heavy pieces of equipment – so they must be strong enough to withstand substantial loads. This is why the wire rope safety factor is crucial.

You may have heard that it is always recommended to use wire ropes or slings with a higher breaking strength than the actual load. For instance, say that you need to move 50,000 lbs. with an overhead crane. You should generally use equipment with a working load limit that is rated for weight at least five times higher – or 250,000 lbs. in this case.

This recommendation is all thanks to the wire rope safety factor. This calculation is designed to help you determine important numbers, such as the minimum breaking strength and the working load limit of a wire rope.

The safety factor is a measurement of how strong of a force a wire rope can withstand before it breaks. It is commonly stated as a ratio, such as 5:1. This means that the wire rope can hold five times their Safe Work Load (SWL) before it will break.

So, if a 5:1 wire rope’s SWL is 10,000 lbs., the safety factor is 50,000 lbs. However, you would never want to place a load near 50,000 lbs. for wire rope safety reasons.

The safety factor rating of a wire rope is the calculation of the Minimum Break Strength (MBS) or the Minimum Breaking Load (MBL) compared to the highest absolute maximum load limit. It is crucial to use a wire rope with a high ratio to account for factors that could influence the weight of the load.

The Safe Working Load (SWL) is a measurement that is required by law to be clearly marked on all lifting devices – including hoists, lifting machines, and tackles. However, this is not visibly listed on wire ropes, so it is important to understand what this term means and how to calculate it.

The safe working load will change depending on the diameter of the wire rope and its weight per foot. Of course, the smaller the wire rope is, the lower its SWL will be. The SWL also changes depending on the safety factor ratio.

The margin of safety for wire ropes accounts for any unexpected extra loads to ensure the utmost safety for everyone involved. Every year there aredue to overhead crane accidents. Many of these deaths occur when a heavy load is dropped because the weight load limit was not properly calculated and the wire rope broke or slipped.

The margin of safety is a hazard control calculation that essentially accounts for worst-case scenarios. For instance, what if a strong gust of wind were to blow while a crane was lifting a load? Or what if the brakes slipped and the load dropped several feet unexpectedly? This is certainly a wire rope safety factor that must be considered.

Themargin of safety(also referred to as the factor of safety) measures the ultimate load or stress divided by theallowablestress. This helps to account for the applied tensile forces and stress thatcouldbe applied to the rope, causing it to inch closer to the breaking strength limit.

A proof test must be conducted on a wire rope or any other piece of rigging equipment before it is used for the first time.that a sample of a wire rope must be tested to ensure that it can safely hold one-fifth of the breaking load limit. The proof test ensures that the wire rope is not defective and can withstand the minimum weight load limit.

First, the wire rope and other lifting accessories (such as hooks or slings) are set up as needed for the particular task. Then weight or force is slowly added until it reaches the maximum allowable working load limit.

Some wire rope distributors will conduct proof loading tests before you purchase them. Be sure to investigate the criteria of these tests before purchasing, as some testing factors may need to be changed depending on your requirements.

When purchasing wire ropes for overhead lifting or other heavy-duty applications, understanding the safety dynamics and limits is critical. These terms can get confusing, but all of thesefactors serve an important purpose.

Our company has served as a wire rope distributor and industrial hardware supplier for many years. We know all there is to know about safety factors. We will help you find the exact wire ropes that will meet your requirements, no matter what project you have in mind.

Structural Stretch is the lengthening of the lay in the construction of cable and wire rope as the individual wires adjust under load. Structural Stretch in Loos & Co., Inc. products is less than 1% of the total cable length. This form of stretch can be completely removed by applying a cable or wire rope prestretching operation prior to shipment.

Elastic Stretch is the actual physical elongation of the individual wires under load. The elastic stretch can be calculated by using the following formula*:

SWL, NWL, MBS — all of the acronyms can get very confusing. Don’t fret – we’re here to clear things up when it comes to safe working load limits and the terms associated with it.

Safe Working Load (SWL) sometimes stated as the Normal Working Load (NWL) is the mass or force that a piece of lifting equipment, lifting device or accessory can safely utilize to lift, suspend, or lower a mass without fear of breaking. Usually marked on the equipment by the manufacturer and is often 1/5 of the Minimum Breaking Strength (MBS) although other fractions may be used such as 1/4, 1/6 and 1/10.[1][2][3]

Other synonyms include Working Load Limit (WLL), which is the maximum working load designed by the manufacturer. This load represents a force that is much less than that required to make the lifting equipment fail or yield, also known as the Minimum Breaking Load (MBL). SWL or WLL are calculated by dividing MBL by a safety factor (SF). An example of this would be a chain that has a MBL of 2000 lbf (8.89 kN) would have a SWL or WLL of 400 lbf (1.78 kN) if a safety factor of 5 (5:1, 5 to 1, or 1/5) is used.

Here at Industrial Rope Supply, we are not only committed to providing you with a quality product, but also with all the information needed to insure safety comes first on every job. Have safety questions on a product purchased from us? Contact us today and we’ll be happy to talk you through and/or provide you with the safety materials needed.

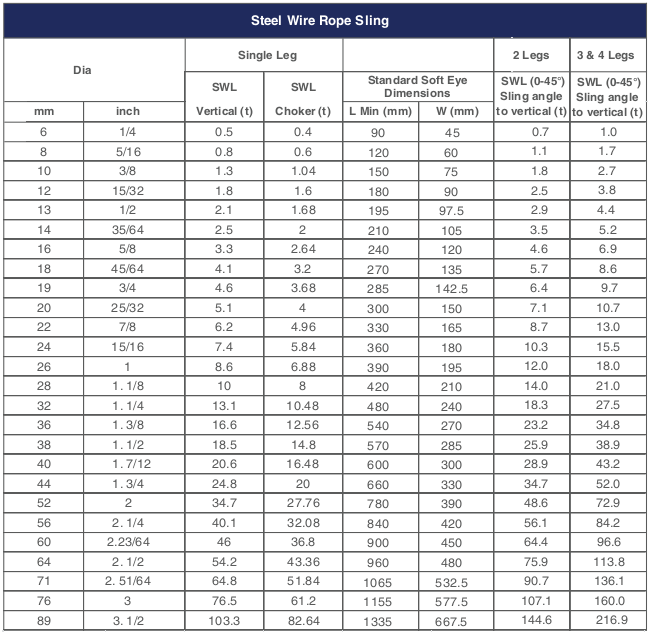

While wire rope is a relatively simple piece of equipment, there are several terms and factors that you must be aware of before you, or any of your staff, operate this gear. Below you will find a handy all-in-one wire rope weight guide.

One of the most important pieces of information, and this applies to any piece of lifting gear that lifts loads, are the safe working load and minimum breaking limit. These are two separate limits, but both apply to the same piece.

The safe working load (SWL), also referred to as the working load limit (WLL) or the normal working load (NWL), is the figure that you should be operating at whenever using it. It will change depending on the strength of your rope, and is the figure that the manufacturer has deemed safe to work at. You may also see this being referred to as simply the safe load.

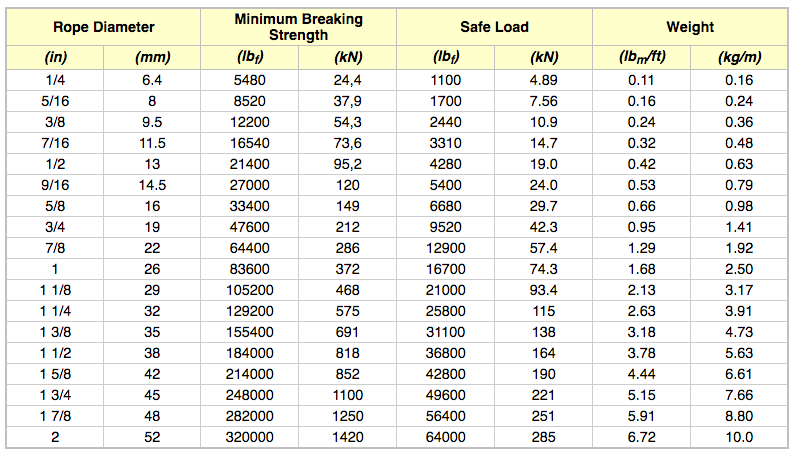

To help demonstrate the breaking limit of wire rope, The Engineering Toolbox have put together this handy table. It lists the strength of improved plow steel (IPS) wire rope that is uncoated and has a fibre core.

They have also offered an example of the strength of 3/8” wire rope that has a safe working load of 10.9 kN. To determine the strength, the calculation m = F / g is used, where:

These calculations will have been worked out by your clever manufacturers beforehand using this equation. So, whatever safe working load is provided to you, it’s absolutely crucial that you stick to it. It isn’t just a random figure!

To ensure that all of the guidelines and limits are followed, it’s essential that you train your staff properly. Having the right awareness with a piece of equipment is actually part of the law, as it requires competent people to be planning and operating all lifting equipment.

This training must include proper training with how to use the equipment, sufficient knowledge of weight limits, and what signs of damage to look out for in gear. Should you, or any of your staff, exceed the SWL or notice any damages at any time, please contact one of us immediately.

Alongside these wire rope weight guides, it’s also important that you familiarise yourself with the relevant laws too. We have detailed all ISO standards that relate to wire rope here, and you can read more on the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) here.

If you would like to discuss anything that you’ve read above about the wire rope weight guides in more detail, then please feel free to contact us here.

Have you ever wondered how much weight a wire cable can safely hold? It’s surprising how strong wire cables are. Although wire cables often have small diameters and look flimsy, their strength is impressive. Calculating how much weight a wire cable can hold is called a Safe Working Load (SWL), and involves a mathematical formula. The SWL is usually calculated by the manufacturer of the cable and is marked on the packaging to inform consumers. To ensure your safety, always take note of the SWL the manufacturer provides.

SWL can also apply to other lifting devices or components of lifting devices, such as a line, rope or crane. The SWL is also sometimes referred to as Normal Working Load or Working Load Limit. It is the mass that lifting equipment can safely hold without fear of breaking. The SWL or NWL is often a fifth of the Minimum Breaking Strength of the cable, although sometimes other fractions are used, depending on the manufacturer.

To calculate the SWL, you need to know the diameter of the cable or rope. While you may find this on the packaging, you can also calculate it manually by measuring it yourself. Ensure that you enclose all of the strands of rope when measuring the diameter, and measure from the top of one strand to the top of the strand which is directly opposite. If you’re worried about the accuracy of your measurements, conduct your measurements three times at different places on the cable, and use the average of your three measurements as the diameter of the rope.

Once you know the diameter of the rope, you can apply it to the formula, which is SWL = D2 x 8. D represents the diameter of the rope in inches. If you’re working with a 1.5-inch diameter cable, for example, then the formula would be SWL = 1.52 x 8 or SWL = 2.25 x 8. This calculation means the SWL of a 1.5-inch diameter rope is 18 tons.

Take note that most manufacturers will provide you with the SWL for their rope or cable under specific conditions. It’s important to use the SWL the manufacturer gives you. If you’re working with old rope or rope that is worn down, you may want to reduce the SWL of the rope by as much as half, based on the condition of the rope. You can also use the manufacturer’s Breaking Strength of the rope if it is available.

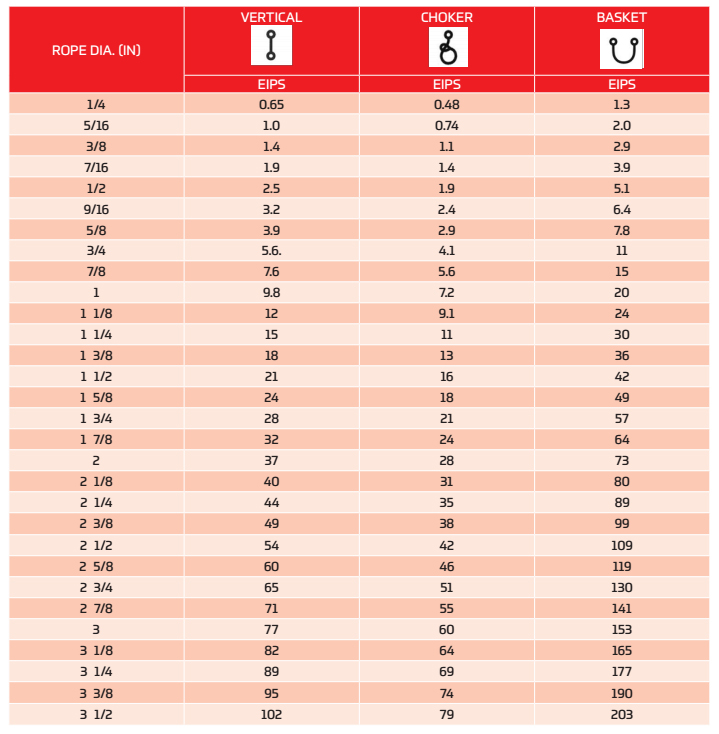

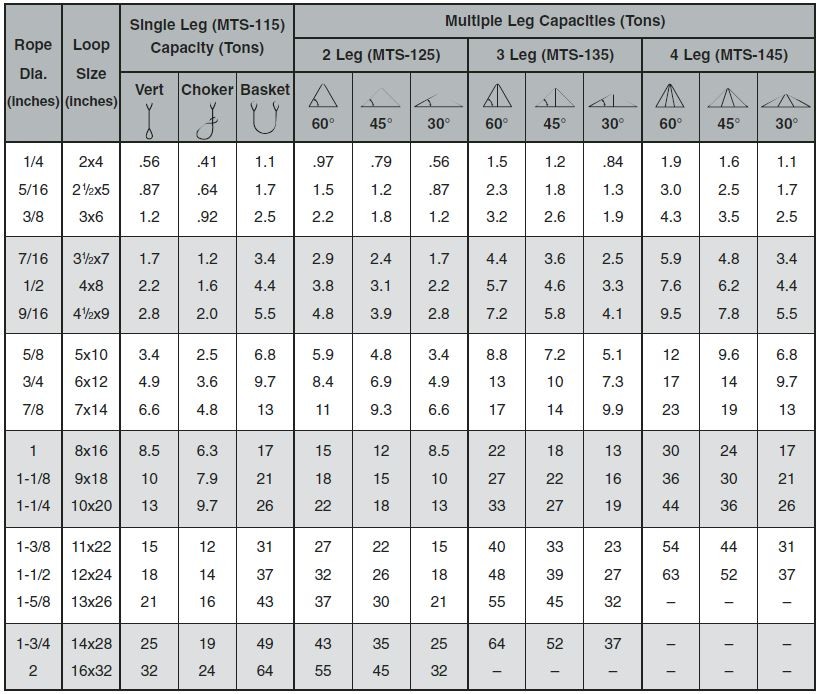

VERTICAL, or straight, attachment is simply using a sling to connect a lifting hook to a load. Full rated lifting capacity of the sling may be utilized, but must not be exceeded. A tagline should be used to prevent load rotation, which may damage a sling.

When two or more slings are attached to the same lifting hook, the total hitch becomes, in effect, a lifting bridle, and the load is distributed equally among the individual slings.

CHOKERhitches reduce lifting capability of a sling since this method of rigging affects ability of the wire rope components to adjust during the lift. A choker is used when the load will not be seriously damaged by the sling body — or the sling damaged by the load, and when the lift requires the sling to snug up against the load.

The diameter of the bend where the sling contacts the load should keep the point of choke against the sling BODY — never against a splice or the base of the eye. When a choke is used at an angle of less than 120 degrees (see next page), the sling-rated capacity must be adjusted downward.

A choker hitch should be pulled tight before a lift is made — NOT PULLED DOWN DURING THE LIFT. It is also dangerous to use only one choker hitch to lift a load which might shift or slide out of the choke.

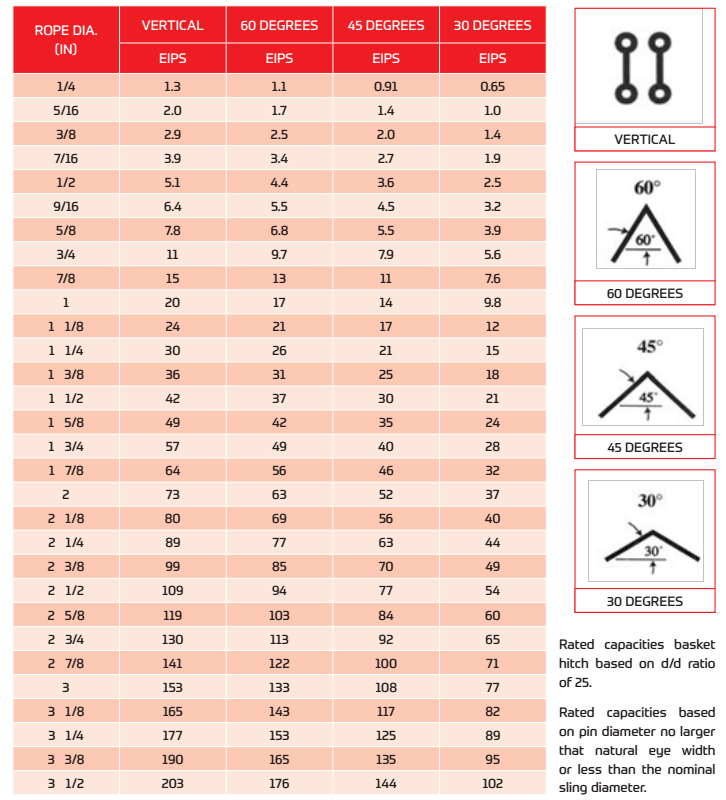

As the included angle between the legs of a sling decreases, the load on each leg increases. The effect is the same whether a single sling is used as a basket or two slings are used with each in a straight pull, as with a 2-legged bridle.

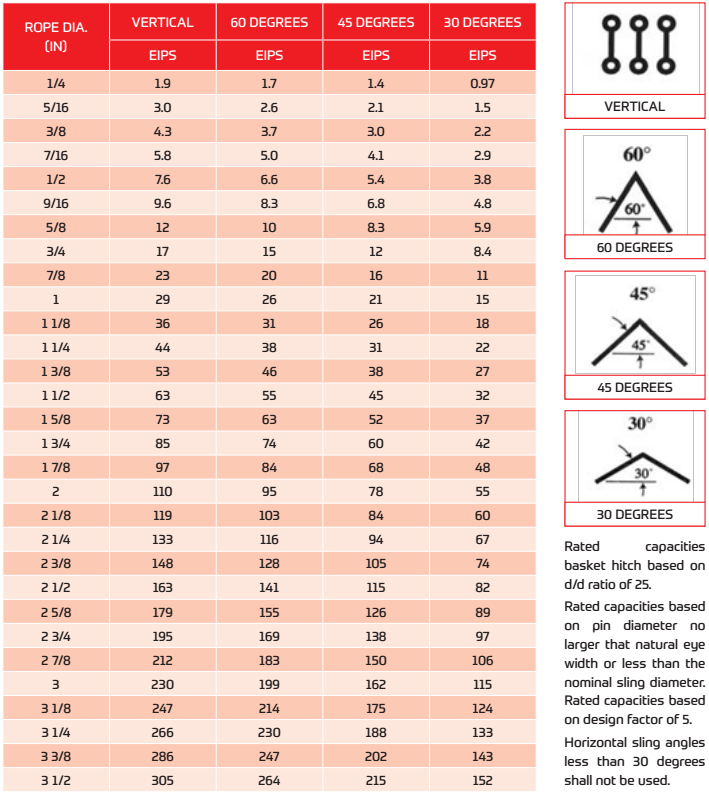

Anytime pull is exerted at an angle on a leg—or legs—of a sling, the load per leg can be determined by using the data in the table above. Proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift.First, divide the total load to be lifted by the number of legs to be used. This provides the load per leg if the lift were being made with all legs being vertically.

Then MULTIPLY the load per leg (as computed above) by the Load Factor for the leg angle being used (from the table at the bottom) – to compute the ACTUAL LOAD on each leg for this lift and angle. THE ACTUAL LOAD MUST NOT EXCEED THE RATED SLING CAPACITY.

Thus, in the above drawing (sling angle at 60°): 1000 ÷ 2 = 500 (Load Per Leg if a vertical lift) 500 x 1.154 = 577 lbs. – ACTUAL LOAD on each leg at the 60° included angle being used.

In the above drawing (sling angle of 45°): 1000 ÷ 2 = 500 (Load Per Leg if a vertical lift) 500 x 1.414 = 707 lbs. = ACTUAL LOAD on each leg at the 45° horizontal angle being used.

The horizontal angle of bridles with 3 or more legs is measured the same as the horizontal sling angle of 2-legged hitches. In this case, where a bridle designed with different leg lengths results in horizontal angles, the leg with the smallest horizontal angle will carry the greatest load. Therefore, the smallest horizontal angle is used in calculating actual leg load and evaluating the rated capacity of the sling proposed.

On the other hand, the eye should always be used on a hook or pin with at least the nominal diameter of the rope—since applying the D/d Ratio shows an efficiency loss of approximately 50% when the relationship is less than 1/1.

When rigged as a basket, DIAMETER of the bend where a sling contacts the load can be a limiting factor on sling capacity. Standard D/d ratios— where “D” is the diameter of bend, and “d” the diameter of the rope—are applied to determine efficiency of various sling constructions, as indicated below:Mechanically Spliced, Single-Part Slings: 25 times rope diameter

Whether to use a single-part sling (one made of a single wire rope in the sling body) or a multi-part sling (several ropes in the body) is usually the first decision to make after determining the sling length and capacity for a lift.

The starting point for this decision involves the handling characteristics of the sling more than any other factor. Based on capacity alone, multi-part slings will be more flexible…more easily handled…than single-part slings. The larger the capacity of a sling, the more important this becomes…to the point, it becomes unrealistic to build big capacity slings from single, very large wire ropes.

In the design of the sling, rope engineers must seek a balance between strength-handling characteristics and number of parts…since there is a tendency to lose strength as core parts are added to increase flexibility.

If a load is hanging free, the normal choke angle is approximately 135 degrees. When the angle is less than 135 degrees, an adjustment in the sling-rated capacity must be made. Choker hitches at angles greater than 135 degrees are not recommended since they are unstable.

Extreme care should be taken to determine the angle of choke as accurately as possible. In controlled tests, where the angle was less than 120 degrees, the sling body always failed at the point of choke when pulled to destruction. Allowance for this phenomenon must be made anytime a choker hitch is used to shift, turn or control a load, or when the pull is against the choke in a multi-leg lift.

This is the length of wire rope between splices, sleeves or fittings. Generally, the minimum body length is equal to ten (10) times the sling body diameter. This allows approximately one and one half (1-1/2) rope lays between splices. For Multi-part slings, the minimum body length between splices is equal to forty (40) times the component rope diameter.

Original equipment wire rope and replacement wire rope must be selected and installed in accordance with the requirements of this section. Selection of replacement wire rope must be in accordance with the recommendations of the wire rope manufacturer, the equipment manufacturer, or a qualified person.

Wire rope design criteria: Wire rope (other than rotation resistant rope) must comply with either Option (1) or Option (2) of this section, as follows:

Option (1). Wire rope must comply with section 5-1.7.1 of ASME B30.5-2004 (incorporated by reference, see § 1926.6) except that section"s paragraph (c) must not apply.

Option (2). Wire rope must be designed to have, in relation to the equipment"s rated capacity, a sufficient minimum breaking force and design factor so that compliance with the applicable inspection provisions in § 1926.1413 will be an effective means of preventing sudden rope failure.

Type I rotation resistant wire rope ("Type I"). Type I rotation resistant rope is stranded rope constructed to have little or no tendency to rotate or, if guided, transmits little or no torque. It has at least 15 outer strands and comprises an assembly of at least three layers of strands laid helically over a center in two operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type II rotation resistant wire rope ("Type II"). Type II rotation resistant rope is stranded rope constructed to have significant resistance to rotation. It has at least 10 outer strands and comprises an assembly of two or more layers of strands laid helically over a center in two or three operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type III rotation resistant wire rope ("Type III"). Type III rotation resistant rope is stranded rope constructed to have limited resistance to rotation. It has no more than nine outer strands, and comprises an assembly of two layers of strands laid helically over a center in two operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type I must have an operating design factor of no less than 5, except where the wire rope manufacturer and the equipment manufacturer approves the design factor, in writing.

A qualified person must inspect the rope in accordance with § 1926.1413(a). The rope must be used only if the qualified person determines that there are no deficiencies constituting a hazard. In making this determination, more than one broken wire in any one rope lay must be considered a hazard.

Each lift made under § 1926.1414(e)(3) must be recorded in the monthly and annual inspection documents. Such prior uses must be considered by the qualified person in determining whether to use the rope again.

Rotation resistant ropes may be used as boom hoist reeving when load hoists are used as boom hoists for attachments such as luffing attachments or boom and mast attachment systems. Under these conditions, all of the following requirements must be met:

The requirements in ASME B30.5-2004 sections 5-1.3.2(a), (a)(2) through (a)(4), (b) and (d) (incorporated by reference, see § 1926.6) except that the minimum pitch diameter for sheaves used in multiple rope reeving is 18 times the nominal diameter of the rope used (instead of the value of 16 specified in section 5-1.3.2(d)).

The operating design factor for these ropes must be the total minimum breaking force of all parts of rope in the system divided by the load imposed on the rope system when supporting the static weights of the structure and the load within the equipment"s rated capacity.

Wire rope clips used in conjunction with wedge sockets must be attached to the unloaded dead end of the rope only, except that the use of devices specifically designed for dead-ending rope in a wedge socket is permitted.

Prior to cutting a wire rope, seizings must be placed on each side of the point to be cut. The length and number of seizings must be in accordance with the wire rope manufacturer"s instructions.

The end point in a wire rope sling’s useful service life is prior to the failure of the sling. It must be removed from service when normal wear or accidental damage weakens the sling to the degree that an adequate factor of safety no longer exists.

The term “Breaking Strength” is never used with reference to slings. Slings have a “Rated Capacity” that is determined by the manufacturer. A sling should never be used to lift a load that is greater than the published “Rated Capacity” for the particular sling and for the type of hitch being used. The design factor used in the calculation of a sling’s Rated Capacity compensates for normal dynamic loading and builds useful life into the sling.

Selection of a sling to lift a load is based on selecting a sling with a Rated Capacity at least equal to the weight of the load. The sling must also be proper to allow the user to select a hitch that will conform to the shape of the load and keep it under control during the lift, The use of multiple leg slings is not recommended when the angle between any leg and the vertical is greater than 450• In any case when lifting headroom is restricted and a larger leg angle is necessary, care must be exercised in selecting a sling with a proper Rated Capacity at the leg angle which will be used. A visual inspection of the sling must be conducted before each lift to make sure the sling is in new or near new condition. A manufacturer’s Rated Capacity applies only to an undamaged sling.

Our responsibility is limited to the sling as purchased new; and the responsibility for safe operation, maintenance and use rest with the purchaser.Whenever a sling is being rigged, tensioned or used to lift a load, a potentially hazardous condition exists and extreme caution should be used by riggers and personnel in the area. In all cases, safe rigging practices must be employed.

Rope strength is a misunderstood metric. One boater will talk about tensile strength, while the other will talk about working load. Both of these are important measurements, and it’s worth learning how to measure and understand them. Each of these measurements has different uses, and here we’re going to give a brief overview of what’s what. Here’s all you need to know about rope strength.

Each type of line, natural fiber, synthetic and wire rope, have different breaking strengths and safe working loads. Natural breaking strength of manila line is the standard against which other lines are compared. Synthetic lines have been assigned “comparison factors” against which they are compared to manila line. The basic breaking strength factor for manila line is found by multiplying the square of the circumference of the line by 900 lbs.

Just being able to calculate breaking strength doesn’t give one a safety margin. The breaking strength formula was developed on the average breaking strength of a new line under laboratory conditions. Without straining the line until it parts, you don’t know if that particular piece of line was above average or below average. For more information, we have discussed the safe working load of ropes made of different materials in this article here.

It’s very important to understand the fundamental differences between the tensile strength of a rope, and a rope’s working load. Both terms refer to rope strength but they’re not the same measurement.

A rope’s tensile strength is the measure of a brand-new rope’s breaking point tested under strict laboratory-controlled conditions. These tests are done by incrementally increasing the load that a rope is expected to carry, until the rope breaks. Rather than adding weight to a line, the test is performed by wrapping the rope around two capstans that slowly turn the rope, adding increasing tension until the rope fails. This test will be repeated on numerous ropes, and an average will be taken. Note that all of these tests will use the ASTM test method D-6268.

The average number will be quoted as the rope’s tensile strength. However, a manufacturer may also test a rope’s minimum tensile strength. This number is often used instead. A rope’s minimum tensile strength is calculated in the same way, but it takes the average strength rating and reduces it by 20%.

A rope’s working load is a different measurement altogether. It’s determined by taking the tensile strength rating and dividing it accordingly, making a figure that’s more in-line with an appropriate maximum load, taking factors such as construction, weave, and rope longevity into the mix as well. A large number of variables will determine the maximum working load of a rope, including the age and condition of the rope too. It’s a complicated equation (as demonstrated above) and if math isn’t your strong point, it’s best left to professionals.

However, if you want to make an educated guess at the recommended working load of a rope, it usually falls between 15% and 25% of the line’s tensile strength rating. It’s a lotlower than you’d think. There are some exceptions, and different construction methods yield different results. For example, a Nylon rope braided with certain fibers may have a stronger working load than a rope twisted out of natural fibers.

For safety purposes, always refer to the information issued by your rope’s manufacturer, and pay close attention to the working load and don’t exceed it. Safety first! Always.

If you’re a regular sailor, climber, or arborist, or just have a keen interest in knot-tying, be warned! Every knot that you tie will reduce your rope’s overall tensile strength. Some knots aren’t particularly damaging, while others can be devastating. A good rule of thumb is to accept the fact that a tied knot will reduce your rope’s tensile strength by around 50%. That’s an extreme figure, sure, but when it comes to hauling critical loads, why take chances?

Knots are unavoidable: they’re useful, practical, and strong. Splices are the same. They both degrade a rope’s strength. They do this because a slight distortion of a rope will cause certain parts of the rope (namely the outer strands) to carry more weight than others (the inner strand). In some cases, the outer strands end up carrying all the weight while the inner strands carry none of it! This isn’t ideal, as you can imagine.

Some knots cause certain fibers to become compressed, and others stretched. When combined together, all of these issues can have a substantial effect on a rope’s ability to carry loads.

Naturally, it’s not always as drastic as strength loss of 50% or more. Some knots aren’t that damaging, some loads aren’t significant enough to cause stress, and some rope materials, such as polypropylene, Dyneema, and other modern fibers, are more resilient than others. Just keep in mind that any knots or splices will reduce your rope’s operations life span. And that’s before we talk about other factors such as the weather or your rope care regime…

Hoisting crane has steel rope 2 and has twined load drum 1 above that.The two ends of steel rope 2 all are fixed near the two ends of this load drum 1.When load drum 1 rotates forward, from load drum 1, extract steel rope 2 out.When load drum 1 contrarotation, steel rope 2 is recoiled on the load drum 1.The axle of load drum 1 is connected on lifting/recoil driving engine 2.Rotate this axle of driving through lifting/recoil driving engine 2, forward direction and rotary lifting cylinder 1 oppositely.The driving of lifting/recoil driving engine 2 (control of hand of rotation, rotation begin and stop control from reaching this rotative speed of control or the like) is realized by the craneman.

The a plurality of pulleys that below load drum 1, provide steel rope 2 to twine above that.In hoisting crane shown in Figure 1, placed equalizer pulley 3 in winding (loopback) position of steel rope 2.On each side of equalizer pulley 3, to have placed dead sheave 4 and two removable pulleys (lifting hook pulley) 5,6 around the mode of left and right symmetry of equalizer pulley 3.The suspension hook 7 of Suspended Cargo is connected to removable pulley 5,6.

Because steel rope 2 is extracted out from load drum 1 when load drum 1 forward direction rotates, so the removable pulley 5,6 that steel rope 2 twines above that moves down.Because steel rope 2 is wound on the load drum 1 when load drum 1 contrarotation, therefore removable pulley 5,6 moves up.Along with the rising of removable pulley 5,6 or descend, be suspended on goods on the suspension hook 7 and be raised or reduce.

To be used to detect the load sensor 8 that is applied to the load on the equalizer pulley 3 and be installed in equalizer pulley 3.Load sensor 8 can have desktop type, extruding type, tension force type, amplifier type, bearing type or follow closely type or the like.From load sensor 8 outputs and the corresponding voltage of load.The voltage of exporting from load sensor 8 is applied to rope service-life management devices 10.

Fig. 2 is to draw the time and along the form of the figure of plotted load (with this corresponding voltage of loading) along horizontal shaft; Show during being lifted to it and putting down subsequently of goods, from load sensor 8 data output and that be applied to rope service-life management devices 10.Details about term shown in this Fig will be described after a while.

As stated, hoisting crane will be suspended on goods on the suspension hook 7 and mention, moves and put down subsequently.After mentioning the goods that remains static, very big load just acts on equalizer pulley 3.Himself compare with goods, the load that after mentioning this goods, acts on equalizer pulley 3 is just bigger.Hereinafter will temporarily act on equalizer pulley 3 after mentioning goods bigger load is called " impact load ".The size of this impact load depends primarily on craneman"s operation skill.

When mentioning goods, steel rope 2 is in its state of from load drum 1, having extracted out.Therefore, because impact load has very strong influence to steel rope 2.If impact load is bigger, then to compare with the less situation of impact load, its degree to the damage that steel rope 2 causes is bigger.Compare with the steel rope 2 that does not receive greater impact load continuously, fast more to the damage development ground of the steel rope 2 that receives the greater impact load continuously.

Rope service-life management devices 10 passes through not only to consider to use the number of times of steel rope 2, but also considers the influence of impact load, predicts the replacement time (calculating its life-span) of the steel rope 2 that is using in the hoisting crane.

Fig. 3 shows the transparent view of the outward appearance of rope service-life management devices 10, and Fig. 4 shows the block diagram of the electrical arrangement of rope service-life management devices 10.

The front elevation of rope service-life management devices 10 is provided, and is the display unit 12 with display panel that can videotex at it than top, is the input block 13 with the TIP that comprises numerical key than the lower part at it.Show that on the display panel of display unit 12 screen (being used to import the screen that data are set) is set shields (screen that is used to show the serviceability etc. of hoisting crane) with operating.

With reference to Fig. 5, what on the display panel of display unit 12, shown is provided with on the screen title that shows a plurality of projects that will import (setting).Use input block 13 to import the character that perhaps is used to specify this digital value with the corresponding digital value of items displayed title.With reference to Fig. 6; Operating period of hoisting crane or after, attend display operation state on institute"s operation displayed screen [number of times (remaining operable number of times) (description after a while) that the number of times that the actual payload of the goods of mentioning, steel rope have used (access times of accumulation) and residue are used or the like] at the display panel of display unit 12.

Once more with reference to Fig. 3 and Fig. 4, the input/output end port 14 (invisible Fig. 3) of the voltage that provides from aforesaid load sensor 8 to its input is provided on the back side of rope service-life management devices 10.The input/output end port 14 of load sensor 8 and rope service-life management devices 10 is electrically connected by signal wire (SW) (coaxial cable etc.).

Rope service-life management devices 10 comprises and is used for CPU 11 that the operation of rope service-life management devices 10 is managed as a whole.Above mentioned display unit 12, input block 13 and input/output end port 14 be connected to CPU 11.Be connected to the RAM 15 that also is useful on temporarily stored programme and data of CPU 11 and be used to store ROM 16 that data and program are set or the like.

Fig. 7 and Fig. 8 show to use the data that are provided with of shielding among the ROM 16 that imports and be stored in rope service-life management devices 10 are set.

This is provided with data and comprises the data relevant with hoisting crane and steel rope 2, and with the relevant data of evaluation criteria (for example, being used for confirming the standard of executed load/unload).The data that are provided with shown in Fig. 7 are be provided with data relevant with hoisting crane and steel rope 2.The data that are provided with shown in Fig. 8 are be provided with data relevant with evaluation criteria.

Workload W: it is the maxim (rated value) of the load of the steel rope 2 that is applied in fact to use in the hoisting crane.Under the situation of the hoisting crane shown in Fig. 1, because steel rope 2 is wrapped in the fact on equalizer pulley 3, dead sheave 4 and the removable pulley 5,6, so steel rope 2 has eight drop wires (fall) (load is treated to and is distributed among eight steel ropes 2).If the lifting load (rated load) of supposition hoisting crane is 40 tons, suppose that then the 40/8=5 ton is the workload W relevant with steel rope 2.

The quantity X that rope is sagging: the quantity of its steel rope that comes down to use in the hoisting crane 2, this quantity that is based on the pulley that hoisting crane has obtains, as stated.

1: it is that the point (zone of regulation) on the steel rope 2 is crossed the number of times of pulley during the mentioning and put down (circulation) of goods.Under the situation of the hoisting crane shown in Fig. 1, on each side of equalizer pulley 3, arrange three pulleys (dead sheave 4 and two removable pulleys 5,6).Therefore, when promoting goods, steel rope 2 is crossed pulley three times, and steel rope 2 is crossed pulley three times (six times altogether) when putting down goods.Therefore, to cross the number of times of the pulley (bending) of the hoisting crane shown in Fig. 1 be six times to steel rope.

2: it is that the point (zone of regulation) on the steel rope 2 is crossed the number of times of load drum 1 during the mentioning and put down (circulation) of goods.Under the situation of the hoisting crane shown in Fig. 1, there is a load drum 1, therefore in a circulation, steel rope 2 is crossed this cylinder once.Therefore, to cross the number of times of the cylinder (bending) of the hoisting crane shown in Fig. 1 be once to steel rope.

aBe used to through Niemann formula calculating steel rope 2 operable residue degrees (life-span of estimation) that use description after a while and the number of times (life-span minimizing value) that steel rope 2 has used.Usually, the pulley that has a U-lag generally is used for the pulley that hoisting crane uses.

Steel rope coefficient b: it is through using the Niemann formula to calculate the employed value of number of times (coefficient) that steel rope 2 operable residue degrees and steel rope 2 have used.Structure according to the steel rope 2 that uses is come regulation steel rope coefficient b (for example, this steel cord structure is " ordinary lay " or " afterturn in the same way ").

3: they are to be used for being similar to the mode of top mentioned rope coefficient b, proofread and correct the value (coefficient) of the number of times that steel rope 2 operable residue degrees and steel rope 2 used according to the structure of steel rope 2.The correct-by-construction coefficient k

3It is another value (coefficient) (shape of cross section [no matter cross-sectional plane is circle or non-circular (line of peculiar shape)] of forming the rope of steel rope 2 is no matter whether the surface of steel rope 2 is smeared or the like) that meets the structure of steel rope 2.

Load detection load: it is the load of the lifting of goods (loading) that has been used for having confirmed the hoisting crane executed.If detect the load that is equal to, or greater than this loading detection load, then definite hoisting crane has been mentioned goods.

The unloading detection load: it is to be used to confirm that after hoisting crane was mentioned goods, this goods was put down the load of (unloading).If detect load, confirm that then this goods is put down less than this unloading detection load.

Load obtains time gap: the specified time section that the time of mentioned loading detection load begins above obtaining is that load obtains time gap, and is as shown in Figure 2.Be equal to, or greater than the load that loads detection load if detect; Detect load, in addition, comparing the longer time with load acquisition time gap less than the unloading detection load; Detect continuously and be equal to, or greater than the load that loads detection load and be equal to, or greater than the unloading detection load; Then definite hoisting crane has been carried out individual task, promptly by promoting, transport and put down subsequently the sequence of operations (circulation) (that is, having satisfied the loading and unloading standard) that goods constitutes.

Load reads type: use load in the average computation time gap to calculate the load (actual payload) of the goods that hoisting crane promotes.With reference to Fig. 2, the average computation time gap is from the acquisition time passage specific time that loads detection load (average delay time at interval) time of obtaining afterwards at interval, and obtains the period that time that time gap finishes finishes at load.Can select " instantaneous " perhaps " on average " read type as load.If selected " instantaneous ", time that then will be when the average computation time gap finishes (its with load obtain time that time gap finishes identical) detected load, the load (actual payload) of the goods of mentioning as hoisting crane is handled.If selected " on average ", the load (actual payload) of the goods that then will mention as hoisting crane at the aviation value of the load of the detection in the average computation time gap is handled.

Average delay time is at interval: as stated, it is from loading the acquisition time of detection load, and obtains the time gap (with reference to Fig. 2) that time that time gap finishes finishes at load.Above mentioned impact load (peak value) drop on average delay time at interval within.

End-of-life preparation warning condition: whether it is provided with and when the steel rope 2 operable residue degrees of predicting (residual life of estimation) reach certain percentum of new steel rope 2 operable residue degrees (initial lifetime), gives a warning.For example, 20% end-of-life preparation warning condition means, when the residual life of steel rope 2 reach initial lifetime 80% the time, give a warning.Can send this warning through warning tones or the demonstration that on display unit 12, appears with coming sense of hearing ground or vision.

Loading above normal capacity 1-3: when the actual payload of detected goods surpasses the lifting load (rated load) of hoisting crane, also can give a warning.Loading above normal capacity 1-3 is the load when sending this warning.Can send the warning relevant in a plurality of stages (rank) with loading above normal capacity.For example, be under 40 tons the situation,, then to give a warning at the lifting of hoisting crane load if the actual payload of detected goods is equal to, or greater than 45 tons.Through the actual payload according to detected goods be equal to, or greater than 45 tons and less than 50 tons, be equal to, or greater than 50 tons and less than 55 tons and be equal to, or greater than 55 tons various situation and change the demonstration on warning tones (perhaps volume) or the display unit 12; Which come to have used level other loading above normal capacity (that is the concrete load class of the goods of crane) to operator"s untill further notice.

Coefficient of correction: its be used to proofread and correct according to above the value (coefficient) of size (that is, impact load surpasses the percentum of the actual payload of goods) number of times definition, that steel rope 2 has used of mentioned impact load.In this embodiment, be equal to, or greater than under 110% the situation of actual payload sensing impact load, carry out the processing of using this coefficient of correction to proofread and correct the number of times that uses steel rope.To describe after a while and use this coefficient of correction to proofread and correct the details of the processing of the number of times that uses steel rope.

Before being placed on steel rope 2 in the hoisting crane and hoisting crane operate; Relevant with hoisting crane and steel rope 2 data (Fig. 7) that are provided with that rope service-life management devices 10 uses storage among the ROM 16 are calculated steel rope 2 operable residue degrees (life-span of estimation) under the initial condition.

In this embodiment, described and used Niemann (G.Niemann) formula in known up to now a plurality of computing formula, calculated the operable residue degree of steel rope (life-span of estimation).Through the mode of example, at " Wire Rope Handbook " (steel rope handbook editorial board, Nikkan Kogyo Shimbunsha; Publish March 30 nineteen ninety-five; The 352-352 page or leaf) and " All About Wire Rope (Last Volume)-The Road to Safety " (association of industry and commerce of shell mound, the iron and steel manufacturing activates research association, association of industry and commerce of shell mound; Publish the 153-158 page or leaf July 25 nineteen ninety-five) in the details about the Niemann formula has been described.

The Niemann formula is suc as formula shown in (1).Based on the Niemann formula, calculate steel rope 2 and cross the times N of pulley up to its fracture

Next, calculating steel rope based on following formula (2) coefficient safe in utilization crosses pulley and bears the times N of 10% breakage up to it

2Should be noted in the discussion above that " 10% breakage " is the notion of using when considering safety.When steel rope ruptures fully, think that breakage is 100% breakage, and with " 10% breakage " be assumed to complete breakage 1/10 damage state based.

Next, consider tired differential based on the steel rope formation, and based on following formula (3), utilization structure coefficient of correction K

2It is the coefficient that rope structure determined according to the steel rope 2 that uses; It is scheduled in accordance with rope structure.With the correct-by-construction coefficient k that is stored in advance among the ROM 16

Remove this limit number of bends N through using to each hoisting crane circulation (mention, move and put down subsequently goods) steel rope 2 crooked number of times

1The number of times of these pulleys is crossed in expression to each circulation steel rope 2.Use the numerical value of before having imported (setting), as shown in Figure 7 based on crane structure (quantity of pulley).

Bending based on each place of supposition steel rope in these pulleys and cylinder is compound and fatigue accumulation, calculates this steel rope 2 operable residue degrees.According to following formula, pulley mentioned above the use can use cycle number N

As next will describe, according to the crane operation situation (the existence of considering aforesaid impact load or do not exist with and size after), reduce the 2 operable residue degree N of steel rope under initial condition that obtained

Fig. 9 shows the diagram of circuit of flow process of the operation of rope service-life management devices 10.Figure with reference to the load data shown in Fig. 2 describes this diagram of circuit.

When manipulating crane, follow the voltage of the load of goods from load sensor 8 output, and it is offered rope service-life management devices 10.The load data (magnitude of voltage) (with reference to Fig. 2) that load sensor 8 is provided is stored among the RAM 15 of rope service-life management devices 10 (step 31).

At first, judge whether to satisfy load/unload standard (step 32).This is the purpose that is used for the life-span management of (operation cycle is to constitute by mentioning, moving and put down goods) execution steel rope 2 under the situation that hoisting crane is finished the work basically.

Use the normal data (data are set) shown in Fig. 8 to judge whether to satisfy the load/unload standard.With reference to Fig. 2; If detect the load that is equal to, or greater than said loading detection load, detect load, in addition less than said unloading detection load; Comparing the longer time with load acquisition time gap; Detect the load that is equal to, or greater than this loading detection load and is equal to, or greater than this unloading detection load continuously, then confirmed hoisting crane executed individual task, i.e. sequence of operations (circulation) (step 32 " being ").

For example, though even cause under the situation that suspension hook 7 waves in the influence owing to wind, load sensor 8 is output voltage also, in this case, does not satisfy the load/unload standard.If the load data from load sensor 8 does not satisfy the load/unload standard, then rope service-life management devices 10 is not carried out any specific processing (step 32 " denying ").

If load sensor 8 provides the load data that satisfies the load/unload standard, judge then whether the maxim (peak value) (impact load) that comprises in this load data surpasses 110% (step 33) of actual payload.As stated, read the type place at load and select under the situation of " instantaneous ", actual payload is the ubiquitous load that detects when the average computation time gap finishes.If selected " on average ", then actual payload is the aviation value of detected load during the average computation time gap.

If impact load is equal to or less than 110% of actual payload, think that then impact load does not influence (that is, not having impact load) (step 33 " denying ") to steel rope 2.

In this case, control advances to the general processing (being used to calculate the processing of operable residue degree) (step 35) that is used to deduct the number of times that this rope uses.

At first,, use and calculate steel rope 2 operable residue degree N to (5) according to formula (1) based on the actual payload that load data obtained from load sensor 8

(for example, having the structure shown in Fig. 1 if the lifting of hoisting crane load is 40 tons and this hoisting crane, then workload W=5 ton) (it is based on the drawing stress σ that uses in the supposition Niemann formula (with reference to Fig. 7)

tUnder the situation of (=W/A), lifting that hoisting crane can be sling load (rated load)), mentioned 2 operable residue degree N of steel rope under initial condition above calculating

xOn the other hand, exist with promoting load and compare, the load of the actual goods that promotes is the situation of light (perhaps heavier) more.For example, if 40 tons of hoisting cranes are handled 40 tons of goods, then this is the disposable use of supposition steel rope 2.But if handle compare lighter goods (for example, 30 tons) with 40 tons, then this is that supposition is compared use still less with the disposable use of steel rope 2.

RemainWith load (actual payload) that promotes and access times (as long as the basic work of hoisting crane execution up to now; Just calculate the accumulated value of the number of times that this steel rope uses) or the like, be presented at (step 36 on the display panel of display unit 12 of rope service-life management devices 10 together; With reference to Fig. 6).

On the other hand, if impact load surpasses 110% of actual payload, then steel rope 2 is treated to the damage (step 33 " being ") that receives the conflict load.

1The value that multiplies each other and obtained with the coefficient of

8613371530291

8613371530291