wire rope load cell free sample

Tension load cells are not new, however traditionally they have either been heavy steam-gauge style machines or complex combinations of electrical components that seem more at home in a science lab than out on a roping job.

This all changed in 2014 when Rock Exotica brought out their enForcer Load Cell. Suddenly we had a user-friendly, stand-alone unit that was small and light enough to ‘throw in the bag’ and use on any job. We could get all of this for under $1,000.

At RopeLab we have been using both the Delphi 100T-5 Tension Load Cell and the Rock Exotica enForcer Load Cell. Below, I will present some of the key considerations when looking at tension load cells. First, we need to define a few key terms.

The following graphs present the data recorded for an actual test where a 75kg steel mass was dropped 1m onto a 1m rope with figure-of-8 knots at each end. The second graph is simply a zoomed in section of the first graph and details the event between 0.5 and 0.6 seconds. There are four plots each corresponding to sampling the same event at 500, 100, 20, and 5 samples per second. This is typically measured in Hertz (Hz), or cycles/second.

If we want to observe dynamic events such as drop tests of rope based systems then we must use a sampling rate of at least 100 samples per second. For relatively slow movements and lifting/lowering systems much lower sampling rates are fine.

The specifications for tension load cells normally state an accuracy value as a percentage of the full scale measurement. This is analogous to the spacing between the ticks on a ruler. So, in theory, a 50kN load cell with an accuracy of +/- 0.5% should be interpreted as accurate to +/- 0.5% of 50kN (+/-0.25kN) for any reading. 0.25kN equates to approximately 25kg.

An appropriate device should be chosen for each particular use. For example, I would not use this 50kN load cell to check the weight of my luggage before heading to the airport, as the weight of my luggage may be insignificant compared to the accuracy of the device. The check-in counter at the airport probably has scales with a full-scale of 0.5kN. Even with the same accuracy (+/- 0.5%) they will determine the weight of my baggage to +/- 0.0025kN (or +/- 250grams).

Thus, it is important to select a load cell with the minimum possible full scale without risk of overload or damage. This selection will maximise the accuracy you can achieve with readings.

This system cost over $5,000 Australian Dollars (without the laptop). It is ideal for the testing I do with RopeLab, however it has taken a while to become comfortable with its use. I also had to write the software to provide real-time readings on the laptop. Even though this system has a 200m wireless range, it is really only for use indoors as it is heavy, bulky, and dependent on powering a laptop computer.

The Rock Exotica enForcer retails for under $US1,000. It is self-contained in a small unit and is excellent for use in the field and monitoring real loads in rope based systems. The Bluetooth functionality is useful but limited by a range of 10m or less. I have certainly found that the accuracy is “better than +/-2%” but users must keep this value in mind. This +/-2% corresponds to +/-40kg (or +/- 88lbs) so it is not really appropriate for “experiments” measuring hand-held tensions. Stick with minimum tensions of 1kN for robust results.

Users need to be aware of the testing capacity of this device. The technical notice for the enForcer states: “The Enforcer will measure up to 20kN. If you exceed 20kN it will permanently say “Overloaded” on the display. You can still use it for testing, but not for life safety. You should establish your own Working Load Limit depending on use. For example a 6:1 safety factor from the 36kN breaking strength would be a WLL of 6kN.”

Tension Load Cells come in many shapes and sizes and it has not been easy to understand their specifications and how these potentially limit practical use. Hopefully, I have made this a little clearer. In short, the Rock Exoctica enForcer has revolutionised the accessibility of these devices, however we still need to be attentive in the way it is used.

A wide variety of wire rope tension load cell options are available to you, such as resistance sensor, optical sensor.You can also choose from pressure sensor, wire rope tension load cell,As well as from standard, {2}, and {3}. And whether wire rope tension load cell is industrial automation, {2}, or {3}.

CableSafe Running Line Tensiometer is designed to measure the tension on running leader ropes or fiber ropes that are used to pull fiber optic cables and other conductors thru conduit and cable troughs. When used in the field, it will allow the user to monitor tension with exceedingly high levels of accuracy, which ensures that rope/cables do not become overstretched or break.

Another example of best use is during the installation of cell phone towers or similar delicate structures. You will be able to use the product to help ensure structure-to-ground ropes, connected to a gin pole and pully system, do not exceed maximum tension whilst lifting sections of the tower to the top. There can be the possibility of the rope becoming snagged and cause greater tension to be loaded upon the system. With heavy materials being lifted to great heights; this would create a major safety hazard leading to a catastrophic failure with the endangerment of lives. Avoid the unknown through accurate monitoring, especially when risks are high.

The five wheel design and gravity catches with top sheave pins allows for fast and simple rope attachment setup that also eliminates errors normally caused by changes in the same diameter and sample rigidity. The accuracy is also improved over three wheel alternatives.

When used with a cable/rope pulling device you can remotely monitor the tension on the line using your smart handheld device via a Bluetooth connection*. You will be able to locate yourself up to 50m/164ft away from the Cable Safe to allow you to survey job progress from a distance.

The ENFORCER App for iPhone greatly expands the capabilities of Rock Exotica"s ENFORCER Load Cell. With this combination you can accurately monitor static forces remotely and record dynamic events with up to 500 samples per second. A graph of the force can be viewed directly on the iPhone but also sent as an email attachment for further analysis. Additionally it can be saved to cloud services such as Dropbox and Google Drive. App sold seperately.

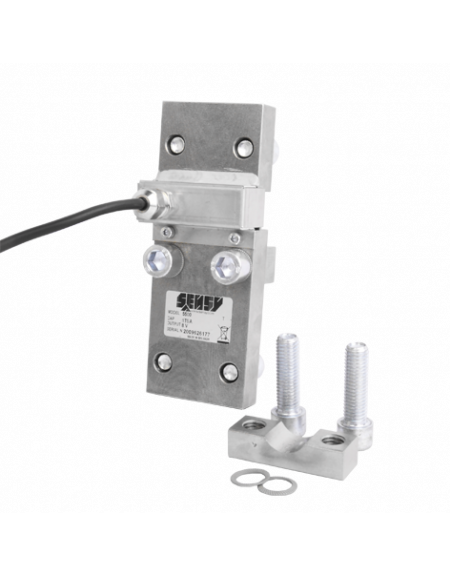

Designed to measure tension force in crane and hoist applications, our IP67 alloy steel wire rope load cell is an accurate and effective force measurement solution, even in harsh conditions.

The G1092 high capacity wire/ rope grip is designed for high capacity wire and rope pull testing applications. Secures the free end of the sample via a bollard and vise. Includes an integrated eye end, and can attach to Mark-10 force gauges, load cells, and test stands.

Mark-10 defines accuracy as a percentage of full scale of the instrument. To determine the measurement error as an actual load value, multiply the accuracy percentage by the instrument’s capacity.

Further using the example of an M5-50 force gauge, a fixed error of ±0.05 lbF represents a higher error as a percentage of reading for a load of 1.00 lbF than 30.00 lbF.

To calculate the error as a percentage of reading, divide the fixed error by the measured value. For a 1.00 lbF load, the fixed error equals ±0.05 ÷ 1.00 lbF = ±5% of reading. For a 30.00 lbF load, the fixed error equals ±0.05 ÷ 30.00 lbF = ±0.17% of reading.

Because of the relationship between load and accuracy, we recommend selecting an instrument capacity as close as possible to the maximum measured load.

One of the first questions riggers need to know to insure proper rigging is the weight of the load. Although there are many useful methods to estimate and assist determining the weight, a load cell is a great device to have in your inventory.

Loadlinks, load shackles, and load cylinders are now readily available and affordable. Data is immediately transmitted wirelessly or through a cable and is extremely accurate (< +/- 1%).

8613371530291

8613371530291