wire rope locking mechanism quotation

Versatile – you can use the same wire suspension kit with a wide range of fixtures, base materials and Hilti MT strut and MVA ventilation hardware, simplifying inventory management

Easier to adjust – self-locking wire lock can be adjusted tool-free, making levelling, retrofitting and long drop lengths much simpler. Pre-mounted safety nuts on the locks can then be tightened to help fix the wire rope securely in place

Versatile – you can use the same wire suspension kit with a wide range of fixtures, base materials and Hilti MT strut and MVA ventilation hardware, simplifying inventory management

Easier to adjust – self-locking wire lock can be adjusted tool-free, making levelling, retrofitting and long drop lengths much simpler. Pre-mounted safety nuts on the locks can then be tightened to help fix the wire rope securely in place

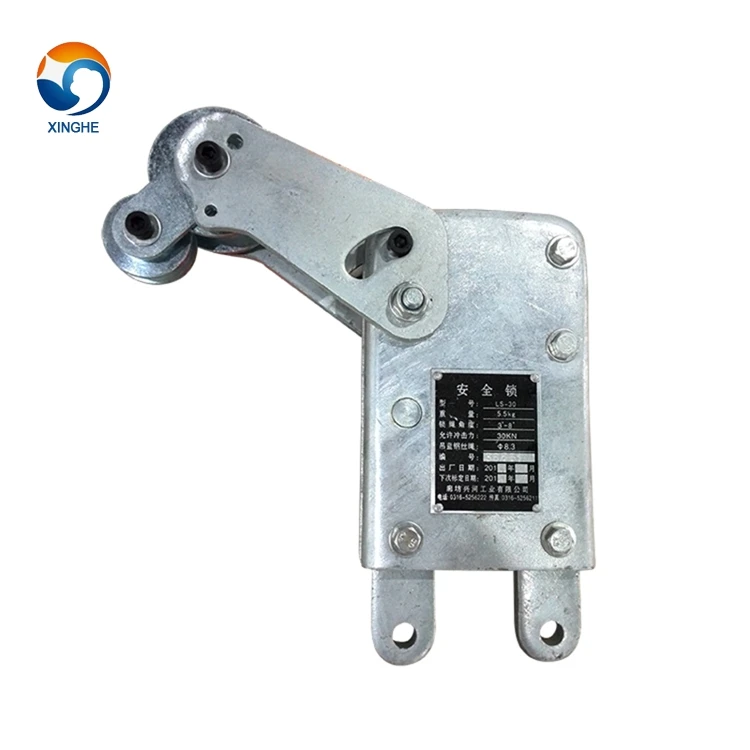

An oil impregnated sintered steel locking wedge is seated in each of two channels. Both wedges incorporate a release pin for easy adjustment. Each wedge makes contact with the wire rope using serrated teeth. These teeth press onto the wire rope and spread the load across the length of the wedge, maximizing grip strength.

Access Doors – The "Sandwich" for Round and Rectangular DuctAccessoriesClutcher SystemClutcher ToolsDuctmate Rectangular Duct Connector SystemsIsolation Hanger Type SIMoisture Drains and CapsPROguard – Protective Duct CoveringQuick Sleeve Round Duct Connector – Galvanized – with FDA GasketRound Duct Strap Bracket Type BASpiralmate® – Round Duct Connector SystemTrapeze Duct Hanger, Isolation Pads, and Trapeze Beam ClampsUltimate Access Doors – Black IronWire Rope

With its unique locking system, the ASAP sets the standard in fall protection for workers at height. For normal use, the device moves freely along the rope without any manual intervention and accompanies the user in all his movements. In case of shock or sudden acceleration, the ASAP locks on the rope and stops the user. The ASAP may also be combined with an ASAP’SORBER or ABSORBICA energy absorbing lanyard to work at a distance from the rope.

Polar Focus Wire Rope Clutch Lock with Eye for 1/8″ wire rope with a galvanized eye nut, secured with Loctite. WLL is 220 pounds with 5:1 design factor.

A Wire Rope Clutch Lock is used to position a rigging point along the length of 7×19 wire rope. This device is an industrial fitting, not rated for critical overhead lifting. It is used in Tilt Cable Kits to control tilt on a loudspeaker otherwise safely suspended with a 10:1 design factor. Speaker rigging tilt control is extremely easy using these devices.

nVent products shall be installed and used only as indicated in nVent"s product instruction sheets and training materials. Instruction sheets are available at www.nvent.com and from your nVent customer service representative. Improper installation, misuse, misapplication or other failure to completely follow nVent"s instructions and warnings may cause product malfunction, property damage, serious bodily injury and death and/or void your warranty.

nVent products shall be installed and used only as indicated in nVent"s product instruction sheets and training materials. Instruction sheets are available at www.nvent.com and from your nVent customer service representative. Improper installation, misuse, misapplication or other failure to completely follow nVent"s instructions and warnings may cause product malfunction, property damage, serious bodily injury and death and/or void your warranty.

At Carl Stahl Sava Industries, manufacturing a comprehensive family of cable, stainless steel wire rope fittings and tools only explain a portion of what makes us so special as a cable assembly manufacturer. In addition to possessing an ISO 9001:2015 certification, Sava is also FDA and ITAR registered, as well as RoHS and REACH certified. Our wire rope manufacturing process leverages almost 50 years of engineering and manufacturing expertise that customers around the world have grown to depend upon every single day. Additionally, Sava’s sales professionals boast over 100 years of combined technical experience helping organizations just like yours meet the most complex and sophisticated application requirements.

Strand Products began by supplying precision mechanical cable assemblies to the Class 8 Truck Markets. Since the 1970s, Strand has built a reputation as a high quality, dependable, and low cost supplier of mechanical wire and cable assemblies. Today we supply to many OEM’s and aftermarket parts distributors.

Like other wire ropes, cables are made up of strands, and each strand is made up of smaller metal wires. Each cable can be customized to fit the needs of a given application by using a different number of wires, a different number of strands, and different materials.

Strands are usually made from wire bundles with seven, thirteen, and nineteen wires because a circular configuration can be achieved easily with these bundle sizes. For example, a strand of seven wires is made from a single central wire surrounded by six wires.

In the same way, cables are also commonly made with seven, thirteen, and nineteen strands. Other configurations are possible, and many cables will use other materials within the cable, such as a fiber core instead of a central wire strand.

The number of wires and strands has a significant impact on the strength and durability of the cable. Typically, a larger number of wires will help increase the cable"s resistance to fatigue, allowing the cable to hold heavier loads for prolonged periods of time. A larger number of wires also improves the flexibility of the cable.

Additionally, larger wire diameter increases the cable"s resistance to abrasion and crushing, making it more durable and less likely to break due to wear. However, thicker wires will also reduce the flexibility of the cable.

In order for a cable to be coiled, it must be fairly flexible, so most coiled cables are constructed from thinner wires. This means that coiled cables are often more susceptible to wear and tear from heavy use or exposure to larger forces. For this reason, coiled cables are more frequently utilized in commercial and personal applications as opposed to heavy duty industrial applications.

Security applications are possibly the most common uses for coiled cables. Wire ropes can be equipped with a variety of end fittings, including locking mechanisms. Bicycle locks are a common example of coiled cable use. The cable can be wrapped around the bicycle and a large permanent structure, such as a bike rack, with the ends of the cable locked together. They also coil up into a relatively small size, which makes them easy to transport as you move from place to place.

8613371530291

8613371530291