wire rope lubricant specification in stock

![]()

This product is a semi-fluid wire rope lubricant designed to meet the lubrication and corrosion prevention requirements of wire ropes working under all conditions. Typical application areas are dockside and ship crane ropes, drag lines, hoists and mobile cranes.

Wire Rope Lube will penetrate between the rope strands to provide integral lubrication and to provide both internal and external protection against corrosion caused by wet, adverse weather conditions and sea water.

Castrol Molub-Alloy 902 SF Wire Rope Lubricant may be applied manually. However, application by automatic spray equipment is recommended. For best coverage and penetration, wire rope should be sprayed on all sides, which requires a minimum of two nozzles opposing each other.

Castrol Molub-Alloy 902 SF Wire Rope Lubricant is intended to provide safe operation through longer service life of wire ropes while reducing total lubrication and maintenance costs. The naturally flexible and adhesive film provides the required persistence to assure also protection of sheaves and drums without excessive application.

Dynagard™ Blue has outstanding structural and chemical stability. An unleaded extreme pressure additive provides exceptional protection against wear and shock loads. Additional additives enhance resistance to water wash-off, protection against fling-off at high Wire Rope travel speeds, and long service in a high- temperature environment.

Recent LC-50 Bio-Aquatic toxicity tests using sensitive marine organisms performed by independent test laboratories have shown it to have over 250,000 PPM LC-50 rating making it possibly the best LC-50 value of any Wire Rope Lubricant marketed in the world today.

Crown® by Aervoe® Open Gear and Wire Rope Lubricant, High Grade, Aerosol Can Container, 16 oz Container, 12 oz Net Weight, Aliphatic Petroleum Distillates Base, Composition: Aliphatic Petroleum Distillates, Aliphatic Petroleum, Hydrocarbon Propellant, Black, Hydrocarbon Odor/Scent, 40 to 110 deg F, 0.8 Specific Gravity, 0.44 VOC, Flammability: 0.9% LEL, 13% UEL

LUBEGARD Wire Rope Lubricants are patented, aquatically non-toxic & biodegradable. They contain a unique blend of corrosion inhibitors, thickeners and wear reducers. Both are ideal for all types of wire ropes and chains in a variety of services and environments.

The Chain and Wire Rope Lubricant is a heavy duty high temperature and pressure lubricant that penetrates chains, cables, and wire rope to deposit a wear resistant coating. The foam spray clings to the surface penetrates and coats leaving a Molybdenum and extreme pressure lubricant on the inner surfaces. This two in one lubricant both penetrates into the core of the wire rope , evaporates and leaves behind a heavy lubricating film to protect and lubricate each strand and with a second coating penetrates slightly and seals the outside from moisture reducing wear and corrosion.

The Chain and Wire Rope Lubricant can be used on conveyors, hoist chains, link and roller assemblies, rail equipment, mining equipment, road and construction machinery, cutter bars, material handling equipment, chain saws, etc.

Proper lubrication of your wire rope, chain and cable can safely extend its operational life regardless of application. Cranes, elevators, shovels, drilling rigs, suspension bridges and draglines are some of the many applications that use wire rope, chain or cable to perform work such as pulling, dragging or hoisting. These applications often are exposed to harsh environmental conditions, including extreme weather. Lubrication Engineers can help your wire rope, chain and cable last longer and operate safely by implementing a lubricant reliability program and recommending the right lubricants for the job.

Most wire ropes are lubricated during the manufacturing process, but this lubricant will not last the entire life of the rope. When looking for a lubricant to relubricate your wire rope, choose one that contains no acids or alkalis, possesses the adhesive strength to stay on the rope, can penetrate between wires and strands, has high fluid film strength, resists oxidation and remains pliable. It is important to remember that most wire ropes fail from the inside out. Corroded rope can be a safety hazard, as there is no way to determine its remaining strength and life. Proper lubrication will help prevent deterioration of wire rope due to rust and corrosion.

Because most wire ropes fail from the inside, it is critical to ensure the center core receives sufficient lubricant. LE recommends a combined regimen in which a penetrating lubricant is used to saturate the core, followed by a coating lubricant to seal and protect the outer surface. LE offers several penetrating and coating type wire rope lubricants to suit your specific needs.

Penetrating lubricants contain an evaporative solvent that facilitates migration of the lubricant into the core of the wire rope, then evaporates, leaving behind a heavy lubricating film that protects and lubricates each strand.

Wirelife Almasol Coating Grease (451-453) is a soft, semifluid calcium-based grease designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its tacky, water-resistant characteristics enable it to adhere strongly to rapidly moving parts, seal out damaging moisture, protect against premature wear and shield metal against corrosive attack.

Typical Applications: Wire rope, chain links, pins, bushings, cable sheave bushings, cables, open and closed silent and roller chains, and small, slow-turning gearboxes that require a semifluid lubricant

Wirelife Almasol Coating Lubricant (2002) is a fluid wire rope lubricant that provides a tough outer coating to seal and protect against fretting corrosion, wear and rust – even under extreme load and moisture. It seals and protects better than any product available. When used in conjunction with Wirelife Monolec Penetrating Lubricant, maximum protection and wear reduction is achieved.

Wirelife Almasol Syn Coating Lubricant (2022) is an extremely tacky, nonasphaltic synthetic lubricant with exceptionally high film strength. Perfect for extreme environments and conditions, it is the ultimate outer surface protector for wire rope and cable and comes from the same advanced technology that LE developed to protect large open gears in the mining and quarry industries. It derives its high load-carrying capacity from its synergistic blend of an extreme pressure additive and Almasol, LE’s exclusive wear-reducing additive.

Wirelife Monolec Penetrating Lubricant (2001) has excellent corrosion resistance and high load-carrying (EP) properties. It penetrates to the core of wire ropes, whether they are running or stationary. It is also excellent as a penetrating lubricant for chains of all sizes and works well in a variety of other industrial applications. When used in conjunction with Wirelife Almasol Coating Lubricant, maximum protection and wear reduction is achieved.

It contains a petroleum solvent to enhance its ability to penetrate. The solvent evaporates, leaving behind a film of heavy-bodied lubricant that protects and lubricates each strand and resists leakage from the wire rope core. Available in bulk sizes or in an aerosol version.

Typical Applications: All stationary or moving wire ropes or cables under heavy loads; chains of all sizes; mining and construction applications such as standing and running lines, draglines, cranes and derricks; marine applications such as cranes, hoists and drilling rigs; any other application that requires excellent rust protection for steel parts.

Designed for marine environments and other applications where environmental concerns require the use of a very low toxicity wire rope and chain lubricant, LE’s Wirelife Low Tox Penetrating Lubricant (2011) has excellent load-carrying capability and provides outstanding protection against rust, while having the lowest possible toxic effect on the environment.

Earthwise EAL Wire Rope Grease (3353) is recommended for use in applications on or near the waterways. It is an EAL and meets the specifications required by the EPA’s Vessel General Permit (VGP). It is readily biodegradable, exhibits minimal aquatic toxicity and will not accumulate in the cells of fish and other aquatic life forms. It is a soft, semifluid formulation designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its semi-tacky, water-resistant characteristics enable it to adhere to the application and seal out damaging moisture and protect against rust formation.

Typical Applications: Applications near or around waterways including: Wire rope; chain links, pins and bushings; cable sheave bushings, bearings and strands; open and closed silent and roller chains. Ideal for use in automatic lubrication systems.

LE is happy to offer industrial lubricant and reliability recommendations for a variety of applications, and to provide product-specific data on all of our items to help you make the right decision. To learn more about our wire rope lubricants, wire rope lubricators as well as our other enhanced lubricants and lubricant reliability products, please

Do your wire ropes, cables and draglines become rusted, corroded or frayed? You can protect your wire rope and cable from high stress loading, shock loading, jerking and heavy loads with LE"s full line of penetrating and coating wire rope lubricants. Whether you want lubricant to penetrate to the core or to coat and seal, LE has a full range of protective lubricant solutions, including wire rope lubricant applicators to reduce labor costs and ensure safe, reliable operation.

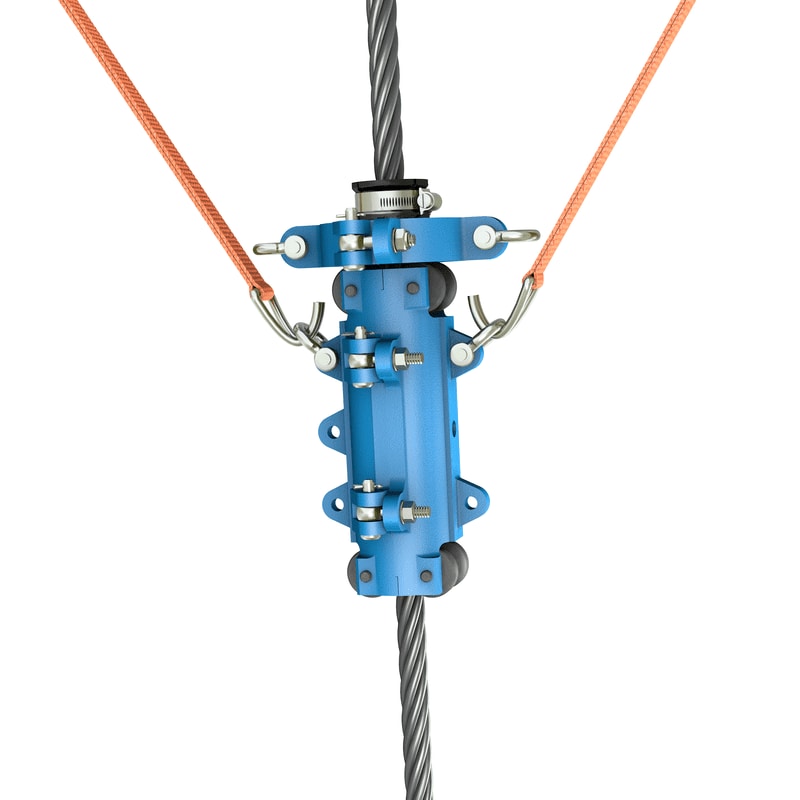

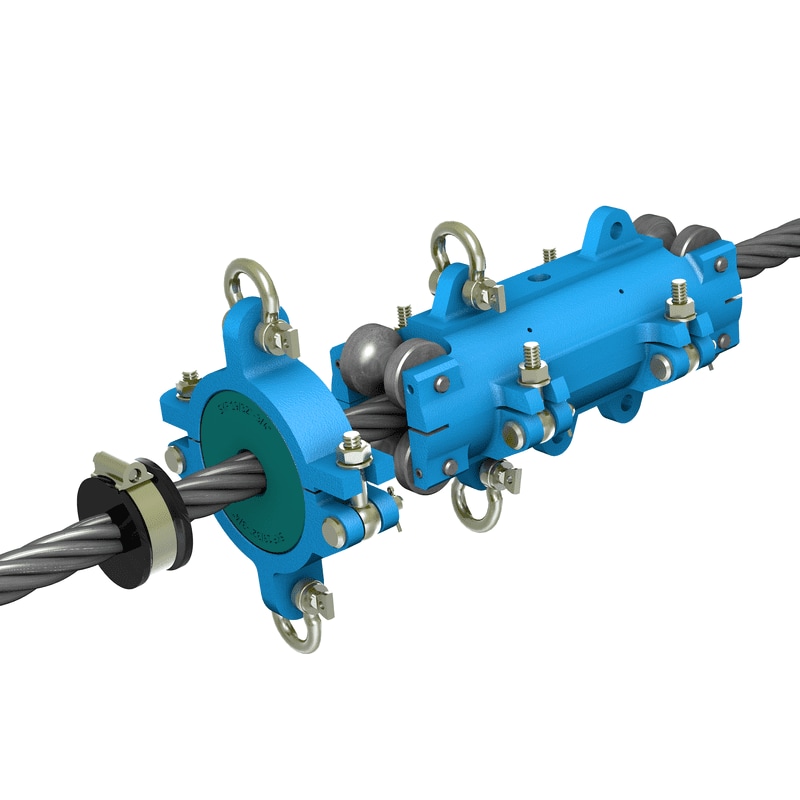

New Extended Warranty: Documented use of LE452, LE453 Wirelife™ Almasol Wire Rope Lubricant or Earthwise™ EAL Wire Rope Lubricant will double the Viper warranty period to 24 months.

Prolongs the life of wire rope, sheaves, pulleys, drums, guides, pins and rollers in a variety of applications, including cranes, hoists, marine tow and mooring lines, dockside cables, aerial tramways, dredges, draglines, mining, elevators and many other applications in construction, mining, transportation and manufacturing

Wire Rope Dressing is manufactured from high quality petroleum base stocks, carefully blended with selected soaps and additives. It is designed as a field dressing for drum hoist ropes and is equally recommended for rope lubrication on shovels and drag lines.

At ambient temperatures between -40 °C and +50 °C, wire ropes are protected by a tenacious film that adheres firmly to the rope. Fling-off and sling-off are virtually eliminated so lubricant consumption and housekeeping concerns are minimized. Wire Rope Dressing is formulated using non-asphaltic base stocks which minimize peeling, cracking and flaking off in cold weather. The formulation is also designed to ensure complete coverage of the rope while preventing excessive lubricant buildup.

Wire Rope Dressing is formulated using mineral base oils blended with molybdenum disulfide and solid graphite lubricant. Crown wires retain a tough, cohesive lubricant film even after passing over the sheave and idler wheels or the hoist drum. The cohesive nature of Wire Rope Dressing also contributes to reduced fling off and sling off while in service.

Wire Rope Dressing offers exceptional water resistance. Moderate amounts of water can be absorbed by the grease with little or no change in NLGI penetration. In field tests, the majority of shaft water seen was in the form of beads on the surface of the lubricant.

Wire Rope Dressing is recommended for application either by split-box, pressurized canister or spray method onto hoist drum wire ropes in underground mining, dragline or electro-mechanical shovel operations. Always protect Wire Rope Dressing from contamination with dust.

The values shown above are representative of current production. Some are controlled by manufacturing and performance specifications while others are not. All may vary within modest ranges

8613371530291

8613371530291