difference between drilling rig and workover rig made in china

Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs.

Belonging to the same family, Sovonex™ service rigs comprise many of the technological advantages that result in smooth operation and make the life of our customers’ easier:

Wide selection: At our production facility in China we design and develop workover rigs for service depths ranging from 1,600 m to 8,500 m (5,250 ft-27,900 ft), and workover depths from 2,000 m to 9,000 m (6,600 ft-30,000 ft) for 2 7/8” DP.

Full API coverage: The different components of our well-servicing rigs are manufactured to the following API standards:Steel structures, such as the mast: API Spec 4F

Highly maneuverable : Sovonex™ mobile drilling rigs and self-propelled workover rigs possess excellent driving properties in the desert, mountain, and other impassable terrains.

Powerful CAT engines and a custom-made chassis that can be equipped with single wheel full suspension enable well service operations in even the most remote areas.

Reduced NPT: The mast is erected hydraulically to reduce time for rig up and increase safety. Likewise, all rig components have been designed to allow for fast assembly and disassembly.

With every service rig, we send technical staff to our customer to provide first-hand technical support. The engineer responsible for the rig design is always part of the service crew.

Based on our extensive experience in the design of land rigs and special vehicles, Sovonex™ truck-mounted drilling rigs are a prime example of advanced engineering.

When drilling on impassable terrain or in remote areas, our truck-mounted drilling rigs’ excellent off-road capability and mobility can make the difference between a drilling operation being commercially feasible or not.

With our extensive experience in the manufacturing of skid-mounted rigs and oilfield vehicles, we are able to design each Sovonex™ mobile rig to individual customer requirements.

Your mobile drilling rig can be 100% made in China, or you can choose rig components from distinguished international suppliers as you like. By default, the following rig components are imported:Main diesel engines: Caterpillar

A key advantage of our truck-mounted rigs is their uniquely constructed chassis. Designed for extreme stability and with a small turn cycle, they give the rigs the power and mobility required for driving on impassable terrains.

Customers can choose between different types of suspensions, including single wheel independent suspension. A mobile rig with independent suspension is especially advantageous when driving in inaccessible mountain regions.

At our production facility in China we manufacture the complete range truck-mounted and trailer mounted drilling rigs capable of drilling wells from 1000m to 4000m. Below you will find a detailed description for each of these rigs.

This 4000m truck-mounted rig with a power of 1000 hp is the most powerful among our mobile rig and often employed in geothermal drilling operations in remote mountain regions.

The specially designed chassis is optionally available with independent suspension on every wheel, giving it superior driving characteristics on rough and extremely muddy terrain.Drilling depth (4-1/2” DP): 4,000 m (13,000 ft)

We do manufacture both truck-mounted and trailer-mounted drilling rigs. While truck-mounted rigs are more compact and easier to handle in rough terrain, the truck of a trailer-mounted rig can be used for other purposes during drilling operations.

The 4000 m mobile rig can optionally be equipped with a top drive system. We provide repair and maintenance services for all major top drive manufacturers like Varco, Canrig, Tesco, BPM, MH, and Bomco

With every drilling rig we send technical staff to the drill site to provide first hand technical support. The engineer responsible for the design of the rig is always part of the service crew.

For your convenience, here is a summary of the benefits of our truck-mounted drilling rigs we consider the most important:Production quality standard API Q1 and ISO 9001

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This article is about the onshore oil rig. For offshore oil rig, see Oil platform. For drilling tunnels, see Tunnel boring machine. For handheld drilling tool, see Drill.

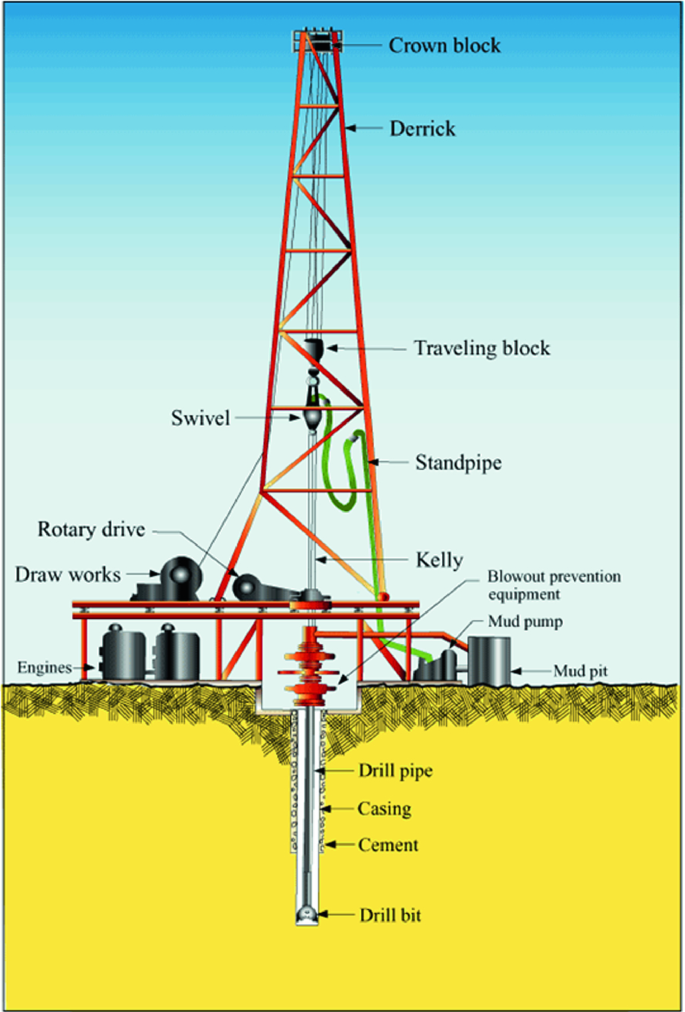

A drilling rig is an integrated system that drills wells, such as oil or water wells, in the earth"s subsurface. Drilling rigs can be massive structures housing equipment used to drill water wells, oil wells, or natural gas extraction wells, or they can be small enough to be moved manually by one person and such are called augers. Drilling rigs can sample subsurface mineral deposits, test rock, soil and groundwater physical properties, and also can be used to install sub-surface fabrications, such as underground utilities, instrumentation, tunnels or wells. Drilling rigs can be mobile equipment mounted on trucks, tracks or trailers, or more permanent land or marine-based structures (such as oil platforms, commonly called "offshore oil rigs" even if they don"t contain a drilling rig). The term "rig" therefore generally refers to the complex equipment that is used to penetrate the surface of the Earth"s crust.

Small to medium-sized drilling rigs are mobile, such as those used in mineral exploration drilling, blast-hole, water wells and environmental investigations. Larger rigs are capable of drilling through thousands of metres of the Earth"s crust, using large "mud pumps" to circulate drilling mud (slurry) through the drill bit and up the casing annulus, for cooling and removing the "cuttings" while a well is drilled. Hoists in the rig can lift hundreds of tons of pipe. Other equipment can force acid or sand into reservoirs to facilitate extraction of the oil or natural gas; and in remote locations there can be permanent living accommodation and catering for crews (which may be more than a hundred). Marine rigs may operate thousands of miles distant from the supply base with infrequent crew rotation or cycle.

Antique drilling rig now on display at Western History Museum in Lingle, Wyoming. It was used to drill many water wells in that area—many of those wells are still in use.

Until internal combustion engines were developed in the late 19th century, the main method for drilling rock was muscle power of man or animal. The technique of oil drilling through percussion or rotary drilling has its origins dating back to the ancient Chinese Han Dynasty in 100 BC, where percussion drilling was used to extract natural gas in the Sichuan province.Edwin Drake to drill Pennsylvania"s first oil well in 1859 using small steam engines to power the drilling process rather than by human muscle.Cable tool drilling was developed in ancient China and was used for drilling brine wells. The salt domes also held natural gas, which some wells produced and which was used for evaporation of the brine.

In the 1970s, outside of the oil and gas industry, roller bits using mud circulation were replaced by the first pneumatic reciprocating piston Reverse Circulation (RC) drills, and became essentially obsolete for most shallow drilling, and are now only used in certain situations where rocks preclude other methods. RC drilling proved much faster and more efficient, and continues to improve with better metallurgy, deriving harder, more durable bits, and compressors delivering higher air pressures at higher volumes, enabling deeper and faster penetration. Diamond drilling has remained essentially unchanged since its inception.

Oil and natural gas drilling rigs are used not only to identify geologic reservoirs, but also used to create holes that allow the extraction of oil or natural gas from those reservoirs. Primarily in onshore oil and gas fields once a well has been drilled, the drilling rig will be moved off of the well and a service rig (a smaller rig) that is purpose-built for completions will be moved on to the well to get the well on line.

Mining drilling rigs are used for two main purposes, exploration drilling which aims to identify the location and quality of a mineral, and production drilling, used in the production-cycle for mining. Drilling rigs used for rock blasting for surface mines vary in size dependent on the size of the hole desired, and is typically classified into smaller pre-split and larger production holes. Underground mining (hard rock) uses a variety of drill rigs dependent on the desired purpose, such as production, bolting, cabling, and tunnelling.

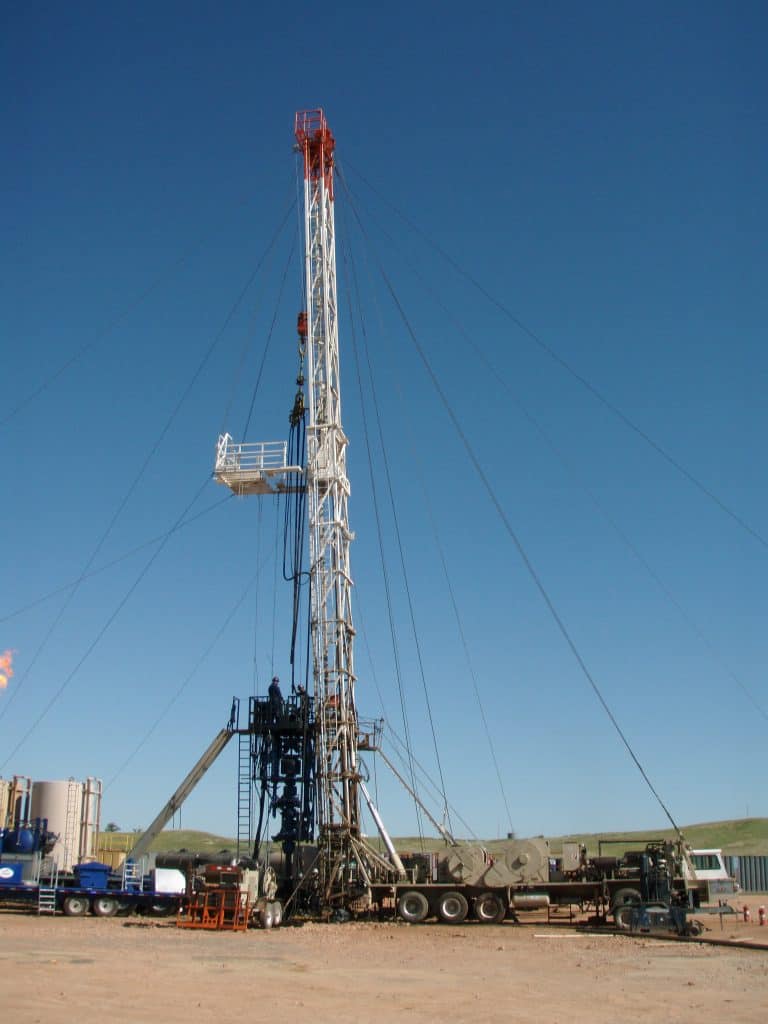

In early oil exploration, drilling rigs were semi-permanent in nature and the derricks were often built on site and left in place after the completion of the well. In more recent times drilling rigs are expensive custom-built machines that can be moved from well to well. Some light duty drilling rigs are like a mobile crane and are more usually used to drill water wells. Larger land rigs must be broken apart into sections and loads to move to a new place, a process which can often take weeks.

Small mobile drilling rigs are also used to drill or bore piles. Rigs can range from 100 short tons (91,000 kg) continuous flight auger (CFA) rigs to small air powered rigs used to drill holes in quarries, etc. These rigs use the same technology and equipment as the oil drilling rigs, just on a smaller scale.

The drilling mechanisms outlined below differ mechanically in terms of the machinery used, but also in terms of the method by which drill cuttings are removed from the cutting face of the drill and returned to surface.

An automated drill rig (ADR) is an automated full-sized walking land-based drill rig that drills long lateral sections in horizontal wells for the oil and gas industry.Athabasca oil sands. According to the "Oil Patch Daily News", "Each rig will generate 50,000 man-hours of work during the construction phase and upon completion, each operating rig will directly and indirectly employ more than 100 workers." Compared to conventional drilling rigs", Ensign, an international oilfield services contractor based in Calgary, Alberta, that makes ADRs claims that they are "safer to operate, have "enhanced controls intelligence," "reduced environmental footprint, quick mobility and advanced communications between field and office."steam assisted gravity drainage (SAGD) applications was mobilized by Deer Creek Energy Limited, a Calgary-based oilsands company.

Temple, Robert; Joseph Needham (1986). The Genius of China: 3000 years of science, discovery and invention. New York: Simon and Schuster. pp. 52–4

Baars, D.L.; Watney, W.L.; Steeples, D.W.; Brostuen, E.A (1989). Petroleum; a primer for Kansas (Educational Series, no. 7 ed.). Kansas Geological Survey. p. 40. Archived from the original on 8 November 2020. Retrieved 18 April 2011. After the cementing of the casing has been completed, the drilling rig, equipment, and materials are removed from the drill site. A smaller rig, known as a workover rig or completion rig, is moved over the well bore. The smaller rig is used for the remaining completion operations.

"Ensign Launches Newest And Most Powerful Automated ADR 1500S Pad Drill Rigs In Montney Play", New Tech Magazine, Calgary, Alberta, 21 November 2014, archived from the original on 10 December 2014, retrieved 6 December 2014

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

/cloudfront-us-east-2.images.arcpublishing.com/reuters/XMYRPMRVYVIVFDQ3B63SKJODDY.jpg)

Main Features Name: traveling hook Brand: KH Original: China Domestic famous fluid end, strong driving force, low fuel consumption, high economic benefits. Machine Parts Name: derrick platform Brand: KH Original: China Domestic famous, strong driving force, low fuel consumption, high economic benefits. After-Sales Service * Training how to instal the machine, training how to use the machine.

Enjoy the best returns on your investment with these supreme workover rig price ranges at Alibaba.com. Their efficacy and reliability will prove that they’re worth their price tags. They will empower you to attain your mining and drilling goals and definitely surpass your expectations.

workover rig price options also include an air compressor, a mud pump, drilling rods of various sizes, connectors, and a drilling tower. Drilling is done using drill bits of various shapes, sizes, and compositions. You can choose between diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits. Each drill bit uses different drilling methods, including rotary, percussion, blast hole, and core drilling.

Are you looking for a wholesale workover rig price? Look no more as Alibaba.com has all sorts of pile drivers that will ease your next pile driving process. A pile-driving machine is critical equipment in constructing structures and buildings as it helps in driving piles into the soil. These piles help in providing foundation support for a structure or building under construction. In that way, you can comfortably move a load of the structure to a difficult depth without a machine. Regarding your liking workovers rig price, visit Alibcom.com as they have unlimited pile available at wholesale prices. Inther you are looking for pneumatic tools or hydraulic pipes, you will find them type at affordable prices. If you need a drill, it can advisable to have a workover r price.

The following is a list of seasonal work gear worn by drilling rig workers. Savanna supplies rig employees with coveralls, hard hat, safety glasses & impact gloves (1 pair).

Drilling rig crews are generally made up of six (6) people: Rig Manager, Driller, Derrickhand, Motorhand, Floorhand, and Leasehand. Each crew works 12 hours shifts as the rig operates 24 hours per day, and each position is vital to the operation of the rig.

Work in the oil and gas services industry is seasonal. Because of the weight of rigs and their equipment, and the remote location of wells, these locations are often only accessible when the ground conditions can tolerate heavy loads. Therefore, wells are typically drilled and serviced in the winter when the ground is frozen solid, or in the summer, when the ground has thawed and dried sufficiently. During the spring and fall, when the ground is in a transitional state, it is too soft to move equipment on and easily damaged. For this reason, provincial governments implement “road bans” prohibiting heavy loads from operating in certain areas. During this time, rig work is slower, and many rigs are shut down and their crews sent home. Be prepared to be off for anywhere from 6 to 12 weeks without pay during this time. However, rigs that are shut down are usually in need of maintenance, and there may be opportunities for employees who would like to help in this regard. Employees may be eligible for Employment Insurance benefits during seasonal shutdowns.

To work on a drilling rig, you must be able to get to and from all of your work locations. As drilling often occurs in remote areas, having reliable transportation is considered mandatory for non-camp locations. Drilling rigs commonly operate 24 hours per day, 7 days per week with either three crews working 8 hour shifts or two crews working 12-hour shifts. Most often day crews and night crews will alternate weekly, so each crew has a chance to work during both the day and night. Most crews will work 14 days straight with 7 days off in-between. The typical living situation while working falls into three categories: Non-Camp, Full Camp and Texas Camp.

Non-Camp: When the rig site is near a town, non-camp conditions normally apply. Crews will stay in hotel rooms and receive a per day living allowance for food and accommodation. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and accommodation out of your own pocket.

Full-Camp: When a rig site is in a remote location, crews may stay in a full camp. In a full-camp all food and full accommodation is provided. Once at the camp, the crew travels to and from the rig in the crew truck. Almost all camp work is available in the winter only.

Texas Camp: These camps are typically located nearby the rig location. Crews are responsible for supplying their own bedding, cooking supplies, groceries and toiletries. While staying at a texas camp, a daily allowance is provided for food and toiletries. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and toiletries out of your own pocket.

Savanna employees are paid every two weeks via direct bank deposit. Savanna’s compensation package includes company group health, dental and disability coverage including paramedical coverage (acupuncturist, chiropractor, massage therapist, naturopath physiotherapist and much more). Savanna also offers a competitive and rewarding retirement savings plan.

Once you have completed your orientation, you will immediately receive any other necessary training. This involves Workplace Hazardous Materials Information System (WHMIS) and Transportation of Dangerous Goods (TDG), along with an in-depth General Safety Orientation. This training is mandatory and provided by Savanna at no cost to the employee. Job-related, hands on training is conducted in the field through Savanna’s Rig Mentoring Program.

Some well locations have sour gas (Hydrogen Sulfide or H2S) present which is extremely dangerous. All employees are required to possess a valid H2S Alive certificate regardless of whether they are working on a sour gas well. This can be obtained by signing up for and completing a one-day (8 hour) course.

Courses are available at various locations across the province. For more information, contact Energy Safety (formerly Enform) at (780) 955-7770 or visit www.enform.ca or Leduc Safety Service at (780) 955 3300 or visit www.leducsafety.com. The cost of the course is usually between $130 and $150 plus tax, and the certification is valid for three years.

While it is not mandatory to have this certification, each service rig crew is required to have two members who are certified in Standard First Aid with CPR level C. Therefore, obtaining a certification beforehand is a great way to improve your chances of being hired.

Savanna is committed to providing a safe, productive and respectful work environment. As such, Savanna has Policies in place to ensure the protection of our employees, contractors, the pubic and the environment. All Savanna employees are required to acknowledge and follow the policies at all times.

As a China top oil drilling rig solids control system manufacturer: GN Solids Control now list the top 10 oil drilling rig manufacturers for your reference.

equipment in China, is the earliest established, largest and most powerful oil drilling rig and production equipment developer and manufacturer under CNPC, the largest research and production base of land rigs and series mud pumps in the world, and also the largest and most powerful base for R&D and production of wire ropes for special purposes in China.

Lanzhou LS-National Oilwell Petroleum Engineering Co. Ltd. (LS-NOW for short) is a Sino-American Joint Venture established between Lanzhou Petrochemical Machinery Equipment and Engineering Group Corporation (LS Group) and National Oilwell International, Inc. (NOI). Scope of business: design, develop and manufacture complete land and offshore drilling rigs and workover rigs, and provide equipment package, components, fittings, parts and full services.

Main products: serial drilling rigs that are electrical or mechanical or electrical-mechanical compounded driven and suitable for different applications such as land, shallow, offshore and desert and meet the requirements of drilling and workover services. The drilling depth ranged from 1000 to 9000 meters.

Sichuan Honghua Petroleum Equipment Co., Ltd., established in 1997, is a subsidiary of Honghua Group which has been listed successfully in the Stock Exchange of Hong Kong. The company has been engaged in research, design, manufacturing and general assembly of oil drilling rig and equipments for oil exploration and development. Now it is the world’s second land drilling rig manufacturer, and China ‘s largest exporter of drilling rigs.

The company owns five subsidiaries totally in home and abroad, with 3600 employees. Company headquarter is located in Deyang City, Sichuan, a heavy-duty equipment base in China, which covers an area of about 1,000 mus, and with more than 2,200 employees, annual output of 150 drilling rigs and 600 mud pumps etc. Its production capacity is up to 8 billion RMB production scale.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electric rig, mechanical drilling rig, composite drive rig, trailer mounted rig and independent RT electric drive drilling rig, as well as their matched equipments, i.e. drilling pumps, traveling block system, solid control system, electric control system etc.

RG PETRO-MACHINERY (GROUP) CO. LTD is one of the largest manufacturers for petroleum drilling rig equipment in China. It is a stock company, reorganized from Nanyang petroleum machinery plant (former No.2 Petroleum Machinery Manufacturing Plant of National Petroleum Industrial Ministry of China). As a former national technical equipment production base, authorized by former national economic and commercial committee of China, RG PETRO-MACHINERY (GROUP) CO. LTD has become a company for national new product trial production of China, light-duty drilling rigs production base of SINOPEC and a high-tech enterprise in Henan Province.

RG PETRO-MACHINERY (GROUP) CO. LTD, with its technical center, information center and quality inspection center at provincial level, has possessed 16 production plants for forging, metal machining, heat treatment, steel-structure manufacturing, general assembly, painting and new product trial production, and 3 comprehensive testing sites for drilling rigs as well as 2 Sino-American joint ventures and 2 share-holding joint ventures.

SJ Petroleum Machinery Co. , one of petroleum drilling rig and production equipment backbone manufacturers and Manufacturing Base for National Key Equipment (Workover, Cementing and Fracturing Equipment) recognized by National Economy and Trade Commission, has provided lots of advanced equipment to domestic customers in lieu of expensive imported equipment, and played an important role in increasing profits of petroleum industry and decreasing domestic oilfield development cost.

Our company Shandong Kerui Holding Group is located in Shengli Oilfield the second largest oilfield in China. Our company arranges a wide range of businesses covering the scientific research and manufacture of the petroleum drilling equipment and oilfield engineering technical service. The main products manufactured and supplied include drilling equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China.

The main products manufactured and supplied include oil drilling rig equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China

(shanghai) petroleum equipment co., ltd. is established on august 2001. the 3h is the first rig manufacturer that introduces ship-building technology to the fabrication of petroleum equipment.

Shengli Oilfield Highland Petroleum Equipment Co., Ltd Established in 1992 was a private incorporated manufacturer of petroleum equipments located in Dongying city, Shandong province, the PRC. Through many years development, the company had been recognized and become well-known in petroleum industry achieved the superior position in the field of scale, product quality, technology ensuring and selling service and so on in petroleum equipment manufacturing in China. It possesses 3.5 billion RMB of total assets, owns more than 1,980 thousand square meters of plant area, China’s state-approved high-tech enterprise, China’s patent star enterprise, Shandong Province top 100 and excellent enterprise, Shandong Province unique petroleum equipment R & D center and over 370 engineers and technicians and 150 contracted noted specialists in ceeusro field.

Drilling Rig: Highland Company Drilling Rig Plant has advanced key facilities and assembly workshops for manufacturing rigs and it has enough test sites for assembling 12 sets of large scale drilling rigs at the same time,5 series (ZJ20~ZJ70, including 18 types) of drilling rigs have been developed and manufactured. These developed and manufactured products consist of mechanical drive, DC driven, AC VF drive and Electromechnical drilling rigs, which can handle the well with depth of 1500- 7000m in most of the large oilfields both at home and overseas.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 406b4f95116c28dca247da206ca234ea 63.210.148.230 10/28/2022 01:41 AM UTC

Super capacitor energy storing dual—power workover rig mainly consists of Diesel engine power unit which is made up of Diesel engine and Hydraulic transmission box, Electric power unit which is made up of Frequency conversion motor and Mechanical transmission box, Transfer case, Angle gear box, Drawworks, Mast assembly, Super capacitor energy storing and control system, Hydraulic and Pneumatic control system, Voltage transformer, Power connection box, MCC control cabinet, Frequency conversion cabinet, Electric air compressor, Electric hydraulic pump station etc.

The power of Diesel engine is used for the heavy load workover job of workover rig, such as running and jam release etc. The power of Frequency conversion motor is used for the normal trip—up and down operation

Activities associated with drilling include initial site visit, clearing, and site preparations, installation of the drill rig, drilling, containment and removal of any waste product, stabilization of the site, installation of the pump check, installation of the gathering and transmission line and tank battery installation, as well as restoring disturbed vegetation, and installation of a fence and a containment berm around the well site or its facilities.

Drilling is an industrial activity and may result in noise, odors or dust. Accordingly, standards have been established by the Oil and Gas Commission for drilling and ongoing operations including noise levels. State regulations also require gas companies to mitigate dust and air pollution during construction and operations. Dust and air pollution regulated by the State Health Department and various permits are required for these emissions. In addition, any contaminated soils are required to be removed and disposed of in accordance with Federal regulations. If you are concerned about the sound or other emissions generated by drilling operation or an existing well, please contact the COGCC field inspector to take sound measurements and coordinate with the rig operator (303.894.2100) and the owner of the well may make any necessary corrections. You may also contact the rig or well operator or the Town’s designated representative for assistance.

Installing a well from start to finish will take as long as five or six weeks. However, if there are multiple well sites to be drilled, then the length of time the rig is on-site may be longer. In addition:Depending on the location, an access road may be constructed.

Drilling rig and equipment are moved off location, and the completion operation begins. This requires a smaller rig used to fracture or “frack” the well, temporary water tanks, and pump equipment. This operation is usually completed within 24– 48 hours, per well.

With the increase in world energy needs for fossil fuels, exploration and production of hydrocarbons have been extended to remote areas such as offshore locations. Although the main intended purpose of a drilling rig and its main systems may not be influenced by well location, the water depth requires modification of land rigs. Consequently, mobile offshore drilling units (MODUs or rigs) or marine rigs were developed and introduced. The main design features for offshore rigs are portability and maximum water depth of operation. Offshore rigs are classified broadly as floating or bottom support. The floating rigs are categorized as semisubmersible, and drillship. Bottom supported rigs are categorized as barge, jackup, and platform rigs [3].

These types of rigs are used for drilling at shallow water depths. The operational water depth of these submersible barge rigs is less than 40 (ft) and where there is no severe wave action. The rig is installed on a barge, large pontoon-like structure, and towed to the location. When on location, the pontoons are filled with water, the platform sinks partly or fully, and rests on its anchors. When the drilling operation is completed, water is pumped out and the platform is ready to move to a new location. If the barge rests on the seafloor, then it is counted as a bottom supported drilling rig.

Semisubmersible (see Fig. 5.3) rigs are capable of performing drilling operations while resting on the seafloor as well as being in a floating position. In other words, the drilling rig is on a barge similar to submersible rigs. Compared to submersible rigs (known also as bottle-type semisubmersible rig), the semisubmersible rigs (known as column-stabilized semisubmersible rigs) are designed with good stability and seakeeping characteristics. These types of rigs are usually used at larger water depths where a rig cannot rest on the seafloor. When the semisubmersible rig cannot rest on the seafloor, the unit is either anchored onto the position or kept on location with dynamic positioning systems. The construction and operational cost of semisubmersible rigs are higher than for submersible rigs.

A drillship is a type of floating vessel where the drilling rig is mounted on a merchant ship (see Fig. 5.4). The drillship is usually used for offshore exploration and equipped with advanced dynamic positioning systems. As drillships benefit from the dynamic positioning systems, they are usually much more costly compared to semisubmersible rigs. In recent years, drillships have been used for operation in deepwater and ultra-deepwater areas. There are some generations of drillships, which are equipped with only mooring systems or general dynamic positioning systems that have lower cost compared to semisubmersible rigs. Another challenge for using a drillship is its susceptibility to severe waves, wind and currents. A benefit of using drillships is their efficient mobilization and high speed between drilling locations.

Recently, riserless well intervention vessels have been used for small activities such as coring [4]. These types of vessels are small sized drillships which have the capability to be equipped with well intervention equipment such as coiled tubing units. The cost of these vessels is much lower than cost of other types of rigs; however, time spent waiting on weather is higher compared to other types of drilling rigs. The vessels will be reviewed later in this chapter.

Jackups are the most common bottom-supported rigs. The rig consists of a barge-type hull (triangular barge form) and three legs, Fig. 5.5. When the rig is in place, legs are lowered to adjust to a given clearance. Jackups are self-contained rigs that can be mobilized and demobilized easily. Depending on their size, they can operate in water depths up to 500 (ft) [5].

Platform rigs are usually employed during development phase where an economically viable offshore field is exploited. Many directional wells can be drilled from a platform. Large platforms are capable of accommodating drilling rigs or modular rigs and therefore are known as self-contained (see Fig. 5.6). Rig-up time of platform rigs are usually less compared to most of the MODUs as no mooring system nor dynamic positioning system is required. But there are some circumstances when the rig-up time can increase due to waiting on weather.

There are circumstances where the platform is small and not capable of accommodating all the components of a drilling rig or storage facilities. In this situation, a floating vessel is anchored next to the platform (see Fig. 5.7). The floating vessel is known as the rig tender. The rig tender can contain storage facilities, many of the rig components and the living quarters.

Vessels are small sized merchant ships which offer some basic operations such as well intervention activities and anchor handling. Compared to drillships, the day rate of vessels are much lower. These types of vessels are categorized as light well intervention vessel and anchor handing vessels.

Light Well Intervention Vessels (LWIVs) have been used for over 25 years in the North Sea. LWIVs are typically monohull, flexible and extremely cost efficient and can be used for a single or multi-well (a campaign) of subsea wells. They can accommodate a wireline unit and coiled tubing unit, Fig. 5.8.

Well integrity and suspension operations including mechanical plug setting, mechanical repair or well maintenance, perforating and setting cement plugs, wellhead cutting and removal, logging, Remotely Operating Vehicle (ROV) services, and pumping operations are typical activities which are conducted by use of LWIVs [6]. The future approach for the use of LWIVs is to perform the complete permanent P&A operations. However, there are some limitations to be solved before reaching to the goal, see Table 5.1.

Anchor handling operations may contribute 10–20% of the total well costs of offshore exploration drilling [8]. In a conventional anchor handling operation, the rig’s winches are used to tension the anchors. AHV transports and deploys the anchors, connects the required chains, wires and polyester ropes. AHV can pre-lay the anchors before the rig arrives, and more time can be dedicated to drilling or P&A operations.

The land drilling market worldwide is structured primarily as a rental market, not a sales market, where land drilling companies lease their rigs to E&P companies for an agreed period of time – weeks, months, or years – at a day-rate. The rigs are then used to drill wells and execute the E&P’s drilling programs.

Drilling opportunities are analysed and explored in order, leaving a series of dry holes, until a discovery is made. It is rare for an E&P company to actually own the rigs which they operate, but there are some exceptions such as Chesapeake, who will purchase their own fleet of rigs.

Under these rental contracts, a turnkey cost is paid by an E&P business to a middleman. This includes an insurance premium, which is returned if nothing goes wrong, but may be lost if there are difficulties. Higher specification equipment commands a larger premium.

Investors require a minimum level of return for their investment dollars in drilling operations, and typically equate cost with risk. These turnkey drilling contracts may limit risk by guaranteeing a minimum number of wells that can be drilled with the rig. The contract will also outline how the rig can be used – including the pieces of equipment, when to change pieces, temperature and pressure tolerances and the weight of mud.

The International Association of Drilling Contractors (IADC) lists 547 members in the category of Land Drilling Contractors. According to Statista, the key US land drilling contractors are: Nabors Industries Ltd, Helmerich & Payne Inc, Patterson-UTI Energy Inc, Precision Drilling Corporation and Pioneer Energy Services Corp.

Nabors operates the world’s largest land drilling rig fleet, with around 500 rigs operating in over 25 countries – in almost every significant O&G basin on the planet. It also has the largest number of high-specification rigs (including new AC rigs and refurbished SCR rigs) and custom rigs, built to withstand challenging conditions such as extreme cold, desert and many complex shale plays.

Headquartered in Tulsa, Oklahoma, H&P is a global business with land operations across the US, as well as offshore operations in the Gulf of Mexico. It is engaged primarily in the drilling of O&G wells for E&P companies, and recognised for its innovative FlexRig technology.

Patterson-UTI operates land based drilling rigs, primarily in O&G producing regions of the continental US, and western Canada. The company also provides pressure pumping services to US E&P companies and specialist technology, notably pipe handling components, to drilling contractors globally.

Precision is an oilfield services company and Canada’s largest drilling rig contractor, with over 240 rigs in operation worldwide. The Company has two segments. The Contract Drilling Services segment operates its rigs in Canada, the United States and internationally. The Completion and Production Services segment provides completion and workover services and ancillary services to O&G E&P companies in Canada and the US.

Pioneer operates a modern fleet of more than 24 top performing drilling rigs throughout onshore O&G producing regions of the US and Colombia. The company also offers production services include well servicing, wireline, and coiled tubing services – supported by 100 well-servicing rigs, and more than 100 cased-hole, open-hole and offshore wireline units.

Together these five companies dominate the US rental market. Other smaller but prominent contractors include: Parker Drilling, Unit Corp, Independence Contract Drilling, Seventy Seven Energy, Schramm and Ensign Drilling. Beyond these players, the market is highly fractured, with many “mom & pop” style drillers.

In Texas, generally considered to be the centre of US land drilling, RigData reports that there are currently 678 active rigs – split between Helmerich & Payne (160), Patterson-UTI (85), Nabors (64), Precision Drilling (39) and 77 other drillers (330).

Most new onshore rigs, both drilling and work over rigs, are built by OEMs in China. In the US, the larger vertically integrated land drillers have in-house manufacturing operations, so they will outsource some equipment construction, but assemble the new rigs at their own facilities. The leading provider of US newbuild rigs is National Oilwell Varco.

The secondary market, where existing rigs are sold, is largely auction dominated with mostly older rigs changing hands. As a rule, the big land drillers do not sell their newbuild rigs, as each has their own flagship designs.

8613371530291

8613371530291