parts of a workover rig made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs.

Belonging to the same family, Sovonex™ service rigs comprise many of the technological advantages that result in smooth operation and make the life of our customers’ easier:

Wide selection: At our production facility in China we design and develop workover rigs for service depths ranging from 1,600 m to 8,500 m (5,250 ft-27,900 ft), and workover depths from 2,000 m to 9,000 m (6,600 ft-30,000 ft) for 2 7/8” DP.

Full API coverage: The different components of our well-servicing rigs are manufactured to the following API standards:Steel structures, such as the mast: API Spec 4F

Highly maneuverable : Sovonex™ mobile drilling rigs and self-propelled workover rigs possess excellent driving properties in the desert, mountain, and other impassable terrains.

Powerful CAT engines and a custom-made chassis that can be equipped with single wheel full suspension enable well service operations in even the most remote areas.

Suited for corrosive environments: All steel parts are specially protected against corrosion through the application of multiple layers of ship paint. The same coating process is used in marine shipbuilding.

Reduced NPT: The mast is erected hydraulically to reduce time for rig up and increase safety. Likewise, all rig components have been designed to allow for fast assembly and disassembly.

With every service rig, we send technical staff to our customer to provide first-hand technical support. The engineer responsible for the rig design is always part of the service crew.

Main Features Name: traveling hook Brand: KH Original: China Domestic famous fluid end, strong driving force, low fuel consumption, high economic benefits. Machine Parts Name: derrick platform Brand: KH Original: China Domestic famous, strong driving force, low fuel consumption, high economic benefits. After-Sales Service * Training how to instal the machine, training how to use the machine.

Our company founded in the Yellow River delta (Shengli Oil Field, the second large oil field in China)--- Dongying City, Shandong Province. It engages into the designing, developing, testing, manufacturing, repairing, and drilling service. Its business covers drilling rig, workover rig, solids control equipment, drilling rig supporting and drilling strings and other equipments related with petroleum.

As a China top oil drilling rig solids control system manufacturer: GN Solids Control now list the top 10 oil drilling rig manufacturers for your reference.

equipment in China, is the earliest established, largest and most powerful oil drilling rig and production equipment developer and manufacturer under CNPC, the largest research and production base of land rigs and series mud pumps in the world, and also the largest and most powerful base for R&D and production of wire ropes for special purposes in China.

Lanzhou LS-National Oilwell Petroleum Engineering Co. Ltd. (LS-NOW for short) is a Sino-American Joint Venture established between Lanzhou Petrochemical Machinery Equipment and Engineering Group Corporation (LS Group) and National Oilwell International, Inc. (NOI). Scope of business: design, develop and manufacture complete land and offshore drilling rigs and workover rigs, and provide equipment package, components, fittings, parts and full services.

Main products: serial drilling rigs that are electrical or mechanical or electrical-mechanical compounded driven and suitable for different applications such as land, shallow, offshore and desert and meet the requirements of drilling and workover services. The drilling depth ranged from 1000 to 9000 meters.

Sichuan Honghua Petroleum Equipment Co., Ltd., established in 1997, is a subsidiary of Honghua Group which has been listed successfully in the Stock Exchange of Hong Kong. The company has been engaged in research, design, manufacturing and general assembly of oil drilling rig and equipments for oil exploration and development. Now it is the world’s second land drilling rig manufacturer, and China ‘s largest exporter of drilling rigs.

The company owns five subsidiaries totally in home and abroad, with 3600 employees. Company headquarter is located in Deyang City, Sichuan, a heavy-duty equipment base in China, which covers an area of about 1,000 mus, and with more than 2,200 employees, annual output of 150 drilling rigs and 600 mud pumps etc. Its production capacity is up to 8 billion RMB production scale.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electric rig, mechanical drilling rig, composite drive rig, trailer mounted rig and independent RT electric drive drilling rig, as well as their matched equipments, i.e. drilling pumps, traveling block system, solid control system, electric control system etc.

RG PETRO-MACHINERY (GROUP) CO. LTD is one of the largest manufacturers for petroleum drilling rig equipment in China. It is a stock company, reorganized from Nanyang petroleum machinery plant (former No.2 Petroleum Machinery Manufacturing Plant of National Petroleum Industrial Ministry of China). As a former national technical equipment production base, authorized by former national economic and commercial committee of China, RG PETRO-MACHINERY (GROUP) CO. LTD has become a company for national new product trial production of China, light-duty drilling rigs production base of SINOPEC and a high-tech enterprise in Henan Province.

RG PETRO-MACHINERY (GROUP) CO. LTD, with its technical center, information center and quality inspection center at provincial level, has possessed 16 production plants for forging, metal machining, heat treatment, steel-structure manufacturing, general assembly, painting and new product trial production, and 3 comprehensive testing sites for drilling rigs as well as 2 Sino-American joint ventures and 2 share-holding joint ventures.

SJ Petroleum Machinery Co. , one of petroleum drilling rig and production equipment backbone manufacturers and Manufacturing Base for National Key Equipment (Workover, Cementing and Fracturing Equipment) recognized by National Economy and Trade Commission, has provided lots of advanced equipment to domestic customers in lieu of expensive imported equipment, and played an important role in increasing profits of petroleum industry and decreasing domestic oilfield development cost.

Our company Shandong Kerui Holding Group is located in Shengli Oilfield the second largest oilfield in China. Our company arranges a wide range of businesses covering the scientific research and manufacture of the petroleum drilling equipment and oilfield engineering technical service. The main products manufactured and supplied include drilling equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China.

The main products manufactured and supplied include oil drilling rig equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China

(shanghai) petroleum equipment co., ltd. is established on august 2001. the 3h is the first rig manufacturer that introduces ship-building technology to the fabrication of petroleum equipment.

Shengli Oilfield Highland Petroleum Equipment Co., Ltd Established in 1992 was a private incorporated manufacturer of petroleum equipments located in Dongying city, Shandong province, the PRC. Through many years development, the company had been recognized and become well-known in petroleum industry achieved the superior position in the field of scale, product quality, technology ensuring and selling service and so on in petroleum equipment manufacturing in China. It possesses 3.5 billion RMB of total assets, owns more than 1,980 thousand square meters of plant area, China’s state-approved high-tech enterprise, China’s patent star enterprise, Shandong Province top 100 and excellent enterprise, Shandong Province unique petroleum equipment R & D center and over 370 engineers and technicians and 150 contracted noted specialists in ceeusro field.

Drilling Rig: Highland Company Drilling Rig Plant has advanced key facilities and assembly workshops for manufacturing rigs and it has enough test sites for assembling 12 sets of large scale drilling rigs at the same time,5 series (ZJ20~ZJ70, including 18 types) of drilling rigs have been developed and manufactured. These developed and manufactured products consist of mechanical drive, DC driven, AC VF drive and Electromechnical drilling rigs, which can handle the well with depth of 1500- 7000m in most of the large oilfields both at home and overseas.

The automatic workover rig is a new type of wellhead operation automation equipment developed for the lifting and lowering of oil pipes (sucker rods) in small oil and water well repair operations.

The equipment refers to the basic actions of “lifting, turning, and throwing” in manual pipe and rod operations, and applies robot automation technology to realize automatic lifting and lowering of pipes (rods), automatic buckling (unloading), automatic pipe throwing, and self-loading and unloading of the whole machine.

The equipment is driven by an AC variable frequency motor, which has the advantages of low cost, easy management, and reduced environmental pollution compared with traditional diesel engine drive; using automated technical means, the operator in the control room can control all the actions of starting and lowering operations, which is truly realized The unmanned operation of the wellhead frees the operators from the traditional high-intensity, high-risk collaborative operation, and achieves the purpose of effectively reducing labor intensity, improving intrinsic safety and reducing construction costs.

The automatic workover rig has made major breakthroughs in key technologies such as unmanned automatic operation at the wellhead, automatic pipe and rod transfer, electro-hydraulic servo control, and man-machine synchronization control. Various performance indicators have been verified by a large number of field tests.

The new device has great advantages with its simple design, small volume and stable performance, do not occupy the wellhead artificial operation space, do not affect the artificial well control emergency, do not interfere with the wellhead evacuation and do not increase the moving vehicles and operation cost. Its operation speed is controllable and as nearly as manual operation. It is popular with the oilfield workers.

At present, although some oilfield workover operations have adopted some automatic equipment, the unmanned operation of the wellhead has been realized, which has greatly reduced the labor intensity of workers, improved the operating environment, and improved the safety factor. But the tubing cannot swing with the pipe pusher when working in windy weather, the pipe pusher cannot accurately align the tubing with the coupling, which affects the reliability and stability of the automated operation. At the same time, there are many equipment movement mechanisms, which are distributed around the wellhead, resulting in manual intervention in the operation space, especially in the wellhead emergency rescue process, which will affect the efficiency of emergency rescue.

For the above disadvantages, Sanjack Company provides an automatic wellhead operation device for oilfield workover operations, which mainly realizes the accurate alignment of tubing couplings, improves the reliability and stability of automated operations, and secondly, through innovative design and reasonable layout of the components of the workover platform, the platform operation space is increased, which is convenient for manual operation and wellhead rescue operations.

Fuselage, 2. Safety slips, 3. Tubing pusher, 4. Splash-proof coupler, 5. Hydraulic clamp, 6. Floating platform, 7. Coupling locator, 8. Pallet wheel mechanism, 9. Connection flange;

The automatic wellhead operation device for automatic workover operation adopts the principle of electro-permanent magnet suction pipe, and design a set of mechanism that can swing freely under its own gravity to achieve accurate alignment of the tubing.

This automatic wellhead operation device improves the reliability and stability of automated operations. At the same time, through the innovative design and reasonable layout of the components of the workover platform, the structure is compact and simple, which increases the platform operation space and facilitates manual operation and wellhead rescue operations. Accurate movement positioning achieves precise and reliable workover.

(1) This device is based on the power and lifting conditions of the existing workover rigs. Through the hydraulic control transformation of elevators and hydraulic clamps, the development of automatic positioning manipulators and manipulators, and the selection of pneumatic chucks, the workover workers can be far away from the wellhead. The completion of the lifting and lowering of the tubing operation, the construction speed is artificially controllable and can reach the level of manual operation, which greatly reduces the labor intensity of the workers, and reduces the various injuries faced by the workers at the wellhead of the station, which is generally welcomed by the workers on the spot.

(2) This device realizes the dual functions of unmanned operation or manned operation at the wellhead without occupying the manual operation space at the wellhead. Normally, the wellhead is not operated by the wellhead. When disassembling and assembling the Christmas tree and the blowout preventer, raising and lowering the sucker rod, loading and unloading downhole tools, performing blowout rescue, and carrying out well control exercises, it does not affect the cooperation of the wellhead.

(3) This device transforms the work of lifting and lowering the tubing from labor-intensive to knowledge-intensive, but the high degree of automation of all processes is not pursued in the research and development, because that will increase a lot of auxiliary equipment and investment, and the workload of operation and maintenance is large, and it is not suitable. The need for frequent moving and low-cost operation for minor repairs.

(4) After the two-person operation of the oil pipe is realized, the original wellhead personnel is trained as the driver, and the vehicle is operated in turn, which can further improve the work efficiency.

(5) After unmanned operation at the wellhead, the manipulator of the workover rig moves more. Therefore, simplifying operations and improving work efficiency through automation and intelligence is the next development direction of this device.

BEIJING, China, June 2021 – Sinopec SJ Petroleum Machinery Co. (SJP), a leading Chinese oil field equipment maker, has selected Allison Transmission’s 4500 Oil Field Series™ (OFS) for its new light workover rig.

During oil and gas recovery operations from underground reservoirs, chemical and mechanical processes can affect the wellbore, negatively affecting production and causing surface and downhole equipment to fail. Light workover rigs, which can reach remote oil fields swiftly and handle production emergencies efficiently, are always in high demand.

SJP’s latest light workover rig model (GVW at 46 ton) adopts a truck-mounted CNHTC chassis and is equipped with an MC11.40-60 diesel engine rated at 297 kW, coupled to a light and compact Allison Transmission 4500 OFS, which can deliver maximum torque of 1900Nm. The new light workover rig model also carries hydraulic lifting derricks, winches and drilling rigs.

“Our latest model, a light truck-mounted drilling and workover rig, has two main duty cycles: driving the rig to the work site (road mode) to running a second function (work mode), specifically in oil wells that require consistent, durable power and high reliability,” said Zhang Bin, Vice President of SJP Drilling & Repair R&D Center. “Allison has a wide range of oil field transmissions for different work conditions. The Allison 4500 OFS model can be matched with the biggest engines where it can deliver maximum output torque up to 2237 Nm, while being light and compact. It meets the needs of both duty cycles very well.”

Allison’s 4500 transmission is specifically designed for the toughest applications. Allison Transmission’s Continuous Power Technology™ smoothly multiplies engine torque and transmits without any power interruption. Allison Automatics accelerate with a 14% higher average speed than a manual or automated manual transmission (AMT). They also offer vehicles better control, traction and maneuverability on loose terrain. The dual mode operations allow one vehicle to be used for multiple operations. Users simply activate a switch to transfer the function of the transmission. Whether driving to the location or working on-site, Allison transmissions improve productivity and deliver the quality, reliability and durability needed in the toughest situations.

“Allison products are highly regarded by end-users in the oil field industry in China due to extraordinary quality and superior advantages. The Allison 4500 OFS offers highly rated input power, a wide gear ratio, efficient power transmission, proven reliability and excellent aftersales service,” said Zhang Bin. “Our new model equipped with the Allison 4500 OFS has another big advantage compared to competitive products: it enables lower whole life cost without losing out on performance parameters or reliability.”

With an Allison transmission, there are no clutches to replace. Operating and maintenance costs are further reduced thanks to Allison Prognostics, which results in less downtime and lower life-cycle costs by predicting oil and filter life. The transmission requires only periodic oil and filter changes, thus achieving greater vehicle reliability with more operating time.

Allison has a global network of authorized distributors and dealers who, in addition to providing service parts, are ready to offer complete service support, technical assistance and training. Many Allison Authorized Distributors and Dealers offer an emergency service.

For more information on Allison Transmission technologies and its innovative products, visit the Allison booth in hall W1, Booth 410 at CIPPE Beijing 2021.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

SHANGHAI/HANOI (Reuters) - A Chinese oil rig has finished drilling near the disputed Paracel islands in the South China Sea after finding signs of oil and gas and is being moved away from the area, more than two months after its deployment damaged relations with Hanoi.Chinese ships are seen on the horizon guarding the Haiyang Shiyou 981, known in Vietnam as HD-981, oil rig (2nd R) in the South China Sea, July 15, 2014. REUTERS/Martin Petty

The Vietnamese coastguard said the $1-billion rig had been towed from contested waters. China’s official Xinhua news agency said the rig would be relocated off the southernmost island province of Hainan. It gave no timeframe.

The rig’s relocation could reduce tensions between the two neighbours after one of the worst breakdowns in ties since they fought a brief war in 1979.

Its movement toward Hainan is also likely to be welcomed by Washington, which had criticised China’s decision to put the rig in waters disputed with Vietnam, calling it a “provocative” act.

Hanoi had said the rig was in its 200-nautical-mile exclusive economic zone and on its continental shelf. Beijing had said it was operating completely within its waters around the Paracel islands, which China occupies.

China National Petroleum Corporation (CNPC), the country’s dominant oil and gas producer, said in a statement the rig “smoothly completed” its drilling on Tuesday and found signs of oil and gas. The next step would be to analyse the geological data and evaluate the layers of oil and gas, it said.

CNPC’s preliminary analysis showed “the area has the basic conditions and potential for oil exploration, but extraction testing cannot begin before a comprehensive assessment of the data”, Xinhua quoted Wang Zhen, deputy director of the CNPC Policy Research Office, as saying.

China had previously said the rig was scheduled to explore the waters around the Paracels until mid-August. It was not clear why it had finished one month ahead of schedule, although Xinhua said July was the beginning of the typhoon season.

China’s popular Twitter-like microblogging service Weibo lit up with criticism of the move. Many people said the government had bowed to the United States, underscoring the domestic pressure Beijing faces to be tough in its territorial disputes.

Wu Shicun, president of the National Institute for South China Sea Studies, a Chinese government think tank on Hainan, said he believed the rig completed its work ahead of schedule because of good weather before the typhoon season began. “The place has fairly good oil and gas potential. It looks promising,” said Wu, an expert on China’s energy ambitions in the South China Sea.

The rig was towed from its original position overnight to beyond what Hanoi considers its exclusive economic zone, Lieutenant-Colonel Ngo Minh Tung of the Vietnamese coastguard told a small group of reporters on one of the maritime agency’s ships in the area.

On Tuesday, the same coastguard vessel was chased off by a group of Chinese ships in what had been a near daily cat-and-mouse routine between boats from both sides since the rig was deployed on May 2. Vietnamese Prime Minister Nguyen Tan Dung demanded that China not send any more rigs into Vietnamese waters.

The deployment was a major test for Dung, especially when deadly anti-Chinese riots broke out in Vietnam in May, triggering protests from China. Several people were killed.

It is China’s newest and most advanced rig, and can drill in waters up to 3,000 m (9,840 ft) deep, about double that of the other two rigs China uses for deep sea work, industry sources say.

China claims 90 percent of the South China Sea. Vietnam, the Philippines, Malaysia, Brunei and Taiwan also claim parts of the waters, whose estimated energy potential varies widely.

Discoveries near the coasts of Southeast Asian countries in recent years have been mostly natural gas, reinforcing the belief among geologists and explorers that there is more gas than oil in the South China Sea.

Chinese industry experts have said the rig had a good chance of finding enough gas to put the area into production. That would give China its first viable energy field in the disputed South China Sea, but make it a source of friction with Hanoi for years to come.

In a 2013 report, the U.S. Energy Information Administration, a government agency, said geological evidence suggested the Paracel islands themselves did not have significant potential in terms of conventional hydrocarbons.

However, the chance of making a major gas discovery near the islands was high because there had been several gas finds already in the area, experts have said.

Vietnam has two fields to the left of where the rig had been stationed, much closer to its coast, where U.S. giant Exxon Mobil Corp discovered oil and gas in 2011 and 2012.

Additional reporting by Michael Martina, Ben Blanchard and Chen Aizhu in BEIJING, Charlie Zhu in HONG KONG, Ho Binh Minh in HANOI and Martin Petty aboard Vietnamese Coastguard Ship 8003; Writing by Dean Yates; Editing by Paul Tait and Clarence Fernandez

/cloudfront-us-east-2.images.arcpublishing.com/reuters/XMYRPMRVYVIVFDQ3B63SKJODDY.jpg)

This article is about the onshore oil rig. For offshore oil rig, see Oil platform. For drilling tunnels, see Tunnel boring machine. For handheld drilling tool, see Drill.

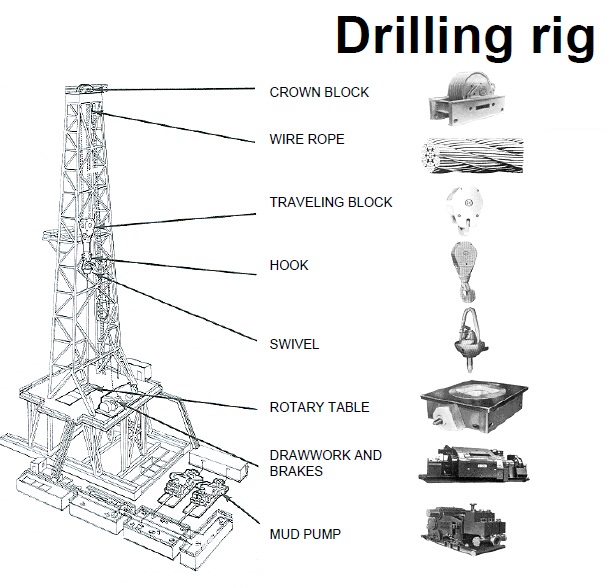

A drilling rig is an integrated system that drills wells, such as oil or water wells, in the earth"s subsurface. Drilling rigs can be massive structures housing equipment used to drill water wells, oil wells, or natural gas extraction wells, or they can be small enough to be moved manually by one person and such are called augers. Drilling rigs can sample subsurface mineral deposits, test rock, soil and groundwater physical properties, and also can be used to install sub-surface fabrications, such as underground utilities, instrumentation, tunnels or wells. Drilling rigs can be mobile equipment mounted on trucks, tracks or trailers, or more permanent land or marine-based structures (such as oil platforms, commonly called "offshore oil rigs" even if they don"t contain a drilling rig). The term "rig" therefore generally refers to the complex equipment that is used to penetrate the surface of the Earth"s crust.

Small to medium-sized drilling rigs are mobile, such as those used in mineral exploration drilling, blast-hole, water wells and environmental investigations. Larger rigs are capable of drilling through thousands of metres of the Earth"s crust, using large "mud pumps" to circulate drilling mud (slurry) through the drill bit and up the casing annulus, for cooling and removing the "cuttings" while a well is drilled. Hoists in the rig can lift hundreds of tons of pipe. Other equipment can force acid or sand into reservoirs to facilitate extraction of the oil or natural gas; and in remote locations there can be permanent living accommodation and catering for crews (which may be more than a hundred). Marine rigs may operate thousands of miles distant from the supply base with infrequent crew rotation or cycle.

Antique drilling rig now on display at Western History Museum in Lingle, Wyoming. It was used to drill many water wells in that area—many of those wells are still in use.

Until internal combustion engines were developed in the late 19th century, the main method for drilling rock was muscle power of man or animal. The technique of oil drilling through percussion or rotary drilling has its origins dating back to the ancient Chinese Han Dynasty in 100 BC, where percussion drilling was used to extract natural gas in the Sichuan province.Edwin Drake to drill Pennsylvania"s first oil well in 1859 using small steam engines to power the drilling process rather than by human muscle.Cable tool drilling was developed in ancient China and was used for drilling brine wells. The salt domes also held natural gas, which some wells produced and which was used for evaporation of the brine.

In the 1970s, outside of the oil and gas industry, roller bits using mud circulation were replaced by the first pneumatic reciprocating piston Reverse Circulation (RC) drills, and became essentially obsolete for most shallow drilling, and are now only used in certain situations where rocks preclude other methods. RC drilling proved much faster and more efficient, and continues to improve with better metallurgy, deriving harder, more durable bits, and compressors delivering higher air pressures at higher volumes, enabling deeper and faster penetration. Diamond drilling has remained essentially unchanged since its inception.

Oil and natural gas drilling rigs are used not only to identify geologic reservoirs, but also used to create holes that allow the extraction of oil or natural gas from those reservoirs. Primarily in onshore oil and gas fields once a well has been drilled, the drilling rig will be moved off of the well and a service rig (a smaller rig) that is purpose-built for completions will be moved on to the well to get the well on line.

Mining drilling rigs are used for two main purposes, exploration drilling which aims to identify the location and quality of a mineral, and production drilling, used in the production-cycle for mining. Drilling rigs used for rock blasting for surface mines vary in size dependent on the size of the hole desired, and is typically classified into smaller pre-split and larger production holes. Underground mining (hard rock) uses a variety of drill rigs dependent on the desired purpose, such as production, bolting, cabling, and tunnelling.

In early oil exploration, drilling rigs were semi-permanent in nature and the derricks were often built on site and left in place after the completion of the well. In more recent times drilling rigs are expensive custom-built machines that can be moved from well to well. Some light duty drilling rigs are like a mobile crane and are more usually used to drill water wells. Larger land rigs must be broken apart into sections and loads to move to a new place, a process which can often take weeks.

Small mobile drilling rigs are also used to drill or bore piles. Rigs can range from 100 short tons (91,000 kg) continuous flight auger (CFA) rigs to small air powered rigs used to drill holes in quarries, etc. These rigs use the same technology and equipment as the oil drilling rigs, just on a smaller scale.

The drilling mechanisms outlined below differ mechanically in terms of the machinery used, but also in terms of the method by which drill cuttings are removed from the cutting face of the drill and returned to surface.

An automated drill rig (ADR) is an automated full-sized walking land-based drill rig that drills long lateral sections in horizontal wells for the oil and gas industry.Athabasca oil sands. According to the "Oil Patch Daily News", "Each rig will generate 50,000 man-hours of work during the construction phase and upon completion, each operating rig will directly and indirectly employ more than 100 workers." Compared to conventional drilling rigs", Ensign, an international oilfield services contractor based in Calgary, Alberta, that makes ADRs claims that they are "safer to operate, have "enhanced controls intelligence," "reduced environmental footprint, quick mobility and advanced communications between field and office."steam assisted gravity drainage (SAGD) applications was mobilized by Deer Creek Energy Limited, a Calgary-based oilsands company.

Temple, Robert; Joseph Needham (1986). The Genius of China: 3000 years of science, discovery and invention. New York: Simon and Schuster. pp. 52–4

Baars, D.L.; Watney, W.L.; Steeples, D.W.; Brostuen, E.A (1989). Petroleum; a primer for Kansas (Educational Series, no. 7 ed.). Kansas Geological Survey. p. 40. Archived from the original on 8 November 2020. Retrieved 18 April 2011. After the cementing of the casing has been completed, the drilling rig, equipment, and materials are removed from the drill site. A smaller rig, known as a workover rig or completion rig, is moved over the well bore. The smaller rig is used for the remaining completion operations.

"Ensign Launches Newest And Most Powerful Automated ADR 1500S Pad Drill Rigs In Montney Play", New Tech Magazine, Calgary, Alberta, 21 November 2014, archived from the original on 10 December 2014, retrieved 6 December 2014

Subsequent to writing that article I happened to read an excellent book with the title Salt: A World History, written by Mark Kurlansky. I highly recommend it to anyone with an interest in history and human affairs, along with Kurlansky’s other books, Cod: A Biography of the Fish that Changed the World, and The Basque History of the World. The three books’ themes are interrelated in a most entertaining way. But to get back to Salt, in one chapter an ancient salt producing industry involving sophisticated drilling techniques and coproduction of brine and natural gas in China’s Sichuan province, far pre-dating western efforts, is detailed. I was tremendously interested by this, and immediately felt that this topic would make a great follow up to my first one, as it involved hydrocarbon exploitation, and better still, was ideal nourishment for the bee in my bonnet – it involved another culture, from long ago, whose exploits and achievements are frequently overlooked by us in the west.

Through a little research I discovered the existence of a museum dedicated to Sichuan’s ancient brine / salt / gas industry. Called The Salt Museum, it is located in Zigong City, named after two of its famous salt wells, about three hours’ drive south of the provincial capital Chengdu (figure 1). I resigned myself to the fact that it was highly unlikely I’d be close to China in the near future, let alone Zigong. Then earlier this year, out of the blue, a business-related trip to Chengdu materialized, and I was determined to visit The Salt Museum while over there. It all worked out, and this article is the result. My aim is to provide interested readers with an understanding of the fascinating achievements of these people hundreds of years ago. As with my previous article this is not a scholarly analysis, but rather an amateur’s efforts to share his enthusiasm, and provide entertaining and stimulating reading.

When a break in our work responsibilities allowed it, I and my Geo-X colleagues, Bo Li and Andrew Royle, set off to Zigong, with our generous and gracious hosts from the Sichuan Geophysical Company (S.G.C.), Gang Lin and Zhirong Li. To drive through rural Sichuan is interesting, as one gets a sense of the intensity of human development in one of China’s richest regions. The heavily populated portion of Sichuan is a large basin, flanked by the Himalayan Plateau to the west, the Long Men Mountains to the north, and the Hua Ying Mountains to the south. The Yangtze River flows along the southern edge of the basin, and numerous tributaries drain south through the rich agricultural lands and into the Yangtze . With its fertile, well watered soil, and mild climate, Sichuan is one of China’s most productive farming regions. Since ancient times, Sichuan has been called “heaven country” within China. The most common crops include wheat, canola, rice, cotton, barley, corn, yams, tobacco, fruits and vegetables. On higher, less fertile ground, huge areas are devoted to the cultivation of mulberry bushes (figure 2), which feed one of the world’s oldest and biggest silk producing industries.

Naturally, with such attractive conditions for human habitation, Sichuan has been occupied by humans since the early dawn of our existence. The countryside has been worked by the human hand for so long, that it is hard to spot a single wild area in the basin proper. Even steep hillsides are terraced for farming, and ancient family crypts hewn into rock cliff outcrops can be spotted frequently from the highway. The contrast between the luxury cars speeding along the modern 6-lane highways, and the ancient terraces, tombs and irrigation systems is startling, but one can easily imagine one long continuous evolution of human technology here, from thousands and thousands of years ago, to the present. Many of China’s ancient technical accomplishments came from this region, including sophisticated irrigation techniques, and what I am particularly interested in, their drilling technology.

My reaction on arriving in Zigong was typical for a westerner first visiting China – yet another city of, what - half a million, one, two million people? - that I had never heard of, with big boulevards, high buildings, people everywhere, construction cranes sprouting willy-nilly. The scale of development in modern China is simply staggering.

After a visit to Zigong’s Dinosaur Museum, on par with our Tyrell Museum in Drumheller, and the requisite banquet of incredibly delicious Sichuan food, we arrived at the Salt Museum. The museum is housed in the former Shanxi Guildhall, built in 1736–1752 AD by salt merchants from Shanxi Province to the north (figure 3). The museum and the building housing it easily exceeded my expectations, as this is truly a world class exhibition. The fact that this historical building and the museum itself are still in existence today can be largely attributed to patriarchal leader Mr. Deng Xiaoping, who proposed and promoted this museum in the 1950s.

The earliest evidence of wells in China, in Zhejiang Province, comes from the era when humans were first turning to agriculture in this region, some 7,000 years ago. Approximately 5,000 years ago Chinese coastal people were boiling sea water to produce salt. As high density human settlement penetrated further and further inland and increasingly relied on farming, salt, critical to human survival as a vital food supplement and preservative, became a valuable commodity. The first recorded salt well in China was dug in Sichuan Province, around 2,250 years ago. This was the first time water well technology was applied successfully to the exploitation of salt, and marked the beginning of Sichuan’s salt drilling industry. From that point on, wells in Sichuan have penetrated the earth to tap into brine aquifers, essentially ground water with a salinity of over 50g/l. The water is then evaporated using a heat source, leaving the salt behind.

At some point around 2,000 years ago the leap from hand and shovel dug wells to percussively drilled ones was made (figure 4). By the beginning of the 3rd century AD, wells were being drilled up to 140m deep. The drilling technique used can still be seen in China today, when rural farmers drill water wells. The drill bit is made of iron, the pipe bamboo. The rig is constructed from bamboo; one or more men stands on a wooden plank lever, much like a seesaw, and this lifts up the drill stem a metre or so. The pipe is allowed to drop, and the drill bit crashes down into the rock, pulverizing it. Inch by inch, month by month, the drilling slowly progresses. It has been speculated that percussive drilling was derived from the pounding of rice into rice flour. When I read of this technique in Salt, I imagined a fairly crude technology. I had no idea how sophisticated these drilling methods became, to the point where these people really had developed most of the tools and techniques one might see on a modern drilling rig, albeit on a smaller scale and without the benefits of modern machining methods.

At regular intervals in the drilling, the crushed rock and mud at the bottom of the hole needed to be removed. The drill stem would be pulled from the hole using a large wheel, somewhat similar in appearance to that on a modern flexible cable down hole tool truck. A length of hollow bamboo with a leather foot valve would then be lowered to the bottom of the hole. When the tube was lifted, the weight of the mud inside would keep the valve closed, and the contents could be brought to the surface. Drilling would then recommence.

Figure 5. A series of diagrams showing the steps taken to repair a well bore cave in. The first four steps establish the top and bottom depths of the caved in zone; in the fifth step straw is inserted ~ 1m below the zone, where it expands as it soaks up water and plugs the hole; in step six a material is tamped down above the straw to plug the hole more securely; in step seven repair cement (tong oil + lime) is forced into the cave in zone; finally in step 8 a guided bit drills down through the centre of the repaired zone to reopen the well bore.

The drilling method on its own is impressive, especially when considering that the rest of the world had nothing comparable in the earlier centuries. But even more impressive are all the techniques the Sichuan drillers developed to overcome common drilling problems – cave ins, lost tools, deviated wells, and so on (figures 5 & 6). A huge variety of tools and techniques evolved to handle well repair issues (figure 7). Many different drill bits were also developed, with different sizes, shapes and compositions, to deal with the different rock types encountered, and the many different drilling requirements. For example, opening the hole at the wellhead required a large heavy bit (3m long, 150-250 Kg) called the “Fish Tail” (figure 8); the “Silver Ingot” drilled the well bore rapidly, but roughly; the “Horseshoe” bit drilled slowly, but achieved round, smooth, high quality well bores. Hollow logs were used in the near surface as casing.

Figure 7. A variety of down hole tools on display at the Salt Museum. Upper left a re tools designed to repair the surface of the well bore wall, by scraping off salt build up, reestablishing the correct diameter, etc. Bottom and middle left are lost tool retrieval tools. The rest are drill bits and miscellaneous tools.

A major breakthrough was achieved around 1050 AD, allowing deeper wells, when solid bamboo pipe was replaced by thin, light, flexible bamboo “cable” (figure 9). This dramatically lowered the weight that needed to be lifted from the surface, a weight that increased with the depth being drilled. By the 1700s Sichuan wells were typically in the range of 300 – 400m deep, and in 1835 the Shenghai Well was the first well in the world to exceed 1,000 metres of depth. In comparison, the deepest wells in the U.S. at that time were about 500m deep. The Sichuan salt producing industry was centred around Zigong, and early photographs show hundreds of producing derricks (“heaven carts”; figure 10), salt stove operations, and the Fuxi River jammed with salt trading boats (figure 11). Brine and natural gas were transported through 100s of kilometres of bamboo pipeline (figure 12).

Figure 9. Museum model of flexible down hole bamboo cable and the wheel from which it would be deployed. Deeper wells used a large cylinder with a vertical axis and driven by oxen to deploy cable.

Figure 10. A photo of Zigong early in the 20th century showing many of the derricks used to drill and produce brine and gas wells. Some of these "Heaven Carts" were over 100m tall!

The fuel used initially in the evaporation process was of course wood. Sources of wood became scarce due to the scale of the salt production industry. Some energy saving techniques were used during evaporation: spreading the brine on tree branches under the sun to increase the salt concentration before boiling, and putting several boiling pans on the same chimney path to use residual heat. There are instances of oil and gas production and use in China going back as far as 61 BC, but it appears as if the salt and hydrocarbon industries were separate for a long time. Fortuitously, at some point in the 16th century, techniques to harness the natural gas encountered during drilling for brine were developed, and this allowed natural gas to be burned beneath the big salt pans. It was the coexistence of brine and gas that pushed Zigong’s salt production into the industrial scale. Once wells were able to reach down to 700-800m, they were able to produce both brine and gas from the Jialingjiang group Triassic formations. Annual salt production in Zigong in the 1850s was about 150,000 tons. The Chinese population was about 0.45 billion at that time. The salt industry was a huge economic driver, and many large cities in Sichuan were established, and flourished, because of the lucrative salt trade.

A key technological advance was the introduction of the “Kang Pen” drum at the end of the 18th century (figure 13). This drum sat on top of the wellhead, and the pressure within the drum was controlled such that gas and brine could simultaneously be produced, and efficiently separated. One bamboo pipe line would take away the brine, and others the gas. The 2,000 year plus Sichuan salt industry has drilled approximately 130,000 brine and gas wells, and 10% of those were in the immediate Zigong area. Zigong has a cumulative gas production over this period of over 30 billion cubic metres. The area continues to be a major salt producer, and many of the historical wells are still in production.

One minor detail I found interesting. When I had first read of bamboo pipelines, I wondered how the barriers separating the segments within the bamboo were dealt with. Did they drill holes through these compartment walls with long augur bits to create pipe? My curiosity was satisfied by one of the displays depicting the process of turning bamboo into pipe. Each length of bamboo was cut in half, down its length. The segment walls were removed, and the insides of the bamboo further hollowed out to create a smooth inside surface of constant interior diameter. The two sections were then put back together and bonded with a glue made from a mixture of lime and tree seed oil. It was further bound together with twine inset into grooves in the outside surface of the bamboo, to prevent fraying, especially for down hole use where the hole’s rock walls would scrape against the exterior surface of the bamboo pipe as it was repeatedly lifted and lowered during drilling and production operations. Similar glue and twine techniques were used to link and splice pipe line sections together end-to-end in an airtight fashion. As recently as the 1950s there was still over 95km of bamboo pipeline in operation in the Zigong area.

Figure 13. An ancient sketch originally fro m "The Annals of Salt Law of Sichuan Province". A "Kang Pen" drum is seen in the centre foreground, with gas pipes directly feeding the salt stoves on the right. At the top, brine from a remote well is being carried in buckets by men, who feed it into a bamboo pipeline that runs down to the stoves. One of the carriers is being paid at top left, and it appears that a blow out is depicted on a new well being drilled in the left foreground; maybe the men operating the drill rig have run away, as tragically happened at a Chongqing, Sichuan sour gas well, late 2003.

Being earth scientists, Andrew, Bo and I were naturally curious about the geology of the region, and the knowledge the ancient drillers had of the subsurface. Did they practice geology, or geophysics, in some form? Did they draw diagrams of the sub-surface and choose new drilling locations based on geological models? This is one area the museum displays do not touch on. However, it is known that well locations were chosen based on the distribution of existing gas and brine wells, and on a variety of surface clues. Brine and gas seeps were obvious indicators of a good location. The salt drillers looked for a salt “frosting” on the surface rocks, or the smell of brine. Yellow brine wells (high in ferric chloride) were usually drilled into yellow sandstone outcrops, while black brine wells (containing hydrogen sulfide) were drilled into cracked sandstones with a black crust. Brine only wells were usually drilled on hillsides, while gas producing wells were usually drilled on hilltops, suggesting that the topography reflected the underlying geological structures. However, surface clues would not have revealed much about targets down towards 1000m depth, so we’re left to speculate on whether geological skills advanced along with the drilling technology.

My brief visit to Sichuan left me intrigued, fascinated, and eager to learn more about China’s ancient technical accomplishments. I can highly recommend the region as a place to visit, not only for its interesting historical sites, but also for its natural beauty (most of Sichuan is mountainous and unpopulated, especially the west, with bamboo forests, and panda bears), its rich culture with many interesting ethnic minorities, its delicious food, great shopping, and its wonderful, friendly people. However, the highlight of my trip was the visit to the Salt Museum, and I hope I have passed on my enthusiasm for this topic to readers.

The land drilling market worldwide is structured primarily as a rental market, not a sales market, where land drilling companies lease their rigs to E&P companies for an agreed period of time – weeks, months, or years – at a day-rate. The rigs are then used to drill wells and execute the E&P’s drilling programs.

Drilling opportunities are analysed and explored in order, leaving a series of dry holes, until a discovery is made. It is rare for an E&P company to actually own the rigs which they operate, but there are some exceptions such as Chesapeake, who will purchase their own fleet of rigs.

Under these rental contracts, a turnkey cost is paid by an E&P business to a middleman. This includes an insurance premium, which is returned if nothing goes wrong, but may be lost if there are difficulties. Higher specification equipment commands a larger premium.

Investors require a minimum level of return for their investment dollars in drilling operations, and typically equate cost with risk. These turnkey drilling contracts may limit risk by guaranteeing a minimum number of wells that can be drilled with the rig. The contract will also outline how the rig can be used – including the pieces of equipment, when to change pieces, temperature and pressure tolerances and the weight of mud.

The International Association of Drilling Contractors (IADC) lists 547 members in the category of Land Drilling Contractors. According to Statista, the key US land drilling contractors are: Nabors Industries Ltd, Helmerich & Payne Inc, Patterson-UTI Energy Inc, Precision Drilling Corporation and Pioneer Energy Services Corp.

Nabors operates the world’s largest land drilling rig fleet, with around 500 rigs operating in over 25 countries – in almost every significant O&G basin on the planet. It also has the largest number of high-specification rigs (including new AC rigs and refurbished SCR rigs) and custom rigs, built to withstand challenging conditions such as extreme cold, desert and many complex shale plays.

Headquartered in Tulsa, Oklahoma, H&P is a global business with land operations across the US, as well as offshore operations in the Gulf of Mexico. It is engaged primarily in the drilling of O&G wells for E&P companies, and recognised for its innovative FlexRig technology.

Patterson-UTI operates land based drilling rigs, primarily in O&G producing regions of the continental US, and western Canada. The company also provides pressure pumping services to US E&P companies and specialist technology, notably pipe handling components, to drilling contractors globally.

Precision is an oilfield services company and Canada’s largest drilling rig contractor, with over 240 rigs in operation worldwide. The Company has two segments. The Contract Drilling Services segment operates its rigs in Canada, the United States and internationally. The Completion and Production Services segment provides completion and workover services and ancillary services to O&G E&P companies in Canada and the US.

Pioneer operates a modern fleet of more than 24 top performing drilling rigs throughout onshore O&G producing regions of the US and Colombia. The company also offers production services include well servicing, wireline, and coiled tubing services – supported by 100 well-servicing rigs, and more than 100 cased-hole, open-hole and offshore wireline units.

Together these five companies dominate the US rental market. Other smaller but prominent contractors include: Parker Drilling, Unit Corp, Independence Contract Drilling, Seventy Seven Energy, Schramm and Ensign Drilling. Beyond these players, the market is highly fractured, with many “mom & pop” style drillers.

In Texas, generally considered to be the centre of US land drilling, RigData reports that there are currently 678 active rigs – split between Helmerich & Payne (160), Patterson-UTI (85), Nabors (64), Precision Drilling (39) and 77 other drillers (330).

Most new onshore rigs, both drilling and work over rigs, are built by OEMs in China. In the US, the larger vertically integrated land drillers have in-house manufacturing operations, so they will outsource some equipment construction, but assemble the new rigs at their own facilities. The leading provider of US newbuild rigs is National Oilwell Varco.

The secondary market, where existing rigs are sold, is largely auction dominated with mostly older rigs changing hands. As a rule, the big land drillers do not sell their newbuild rigs, as each has their own flagship designs.

Super capacitor energy storing dual—power workover rig mainly consists of Diesel engine power unit which is made up of Diesel engine and Hydraulic transmission box, Electric power unit which is made up of Frequency conversion motor and Mechanical transmission box, Transfer case, Angle gear box, Drawworks, Mast assembly, Super capacitor energy storing and control system, Hydraulic and Pneumatic control system, Voltage transformer, Power connection box, MCC control cabinet, Frequency conversion cabinet, Electric air compressor, Electric hydraulic pump station etc.

The power of Diesel engine is used for the heavy load workover job of workover rig, such as running and jam release etc. The power of Frequency conversion motor is used for the normal trip—up and down operation

Atlas Copco’s PowerROC T25 DC drill rig, made in Japan, is convincing Chinese customers of the wisdom of making the transition from pneumatic to hydraulically controlled equipment.

The city of Suizhou in China’s northern province of Hubei, is well known as the hometown of the ancient Chinese emperors Yandi-Shennong and Huangi. It is also the home of China’s famous chime bells which have been used as percussion instruments for thousands of years.

Nowadays, however, the city also functions as an important hub for East-West business development and a transition to more modern technology. A typical example is the current move by local contractors away from pneumatic towards hydraulically-driven drilling equipment.

One of these is the company now helping China Railway’s 12th Bureau Group to build a 665 km highway from Macheng to Zhuxi, using an Atlas Copco PowerROC T25 DC surface drill rig. This tophammer rig, manufactured at Atlas Copco’s plant in Yokohama, Japan, is used to drill holes of 89 mm in a quarry to provide aggregate for the new road. In these hard granite conditions, the penetration rate is 30 m/h. The contractor is small, cost conscious and used to operating locally made pneumatic drill rigs, but recently switched to the PowerROC T25 DC which gives a much lower fuel consumption of just 0.3–0.35 liters per minute. PowerROC T25 DC is equipped with the 12 kW COP 1240 rock drill and R32, T38 and T45 rods for drilling 58–89 mm holes to a maximum depth of 21 m. “It was not easy to persuade this company to buy the PowerROC T25 DC so they had extremely high expectations on the rig’s performance,” says Chi Zeng, Account Manager at the Atlas Copco dealer, Wuhan Zhongnan. “When introducing them to the rig, we provided them with a calculation showing how much they could save in relation to a pneumatic rig and how much more they would benefit from the PowerROC T25 DC. In the past few months, they have been running the rig with high frequency and the efficiency is so impressive that sometimes they have to stop drilling to wait for the downstream process to catch up.” The contractor says it is satisfied with the rig’s high reliability, performance, mobility and low fuel consumption. Concludes Zeng: “We are always very happy when a customer discovers the advantages of hydraulics, especially if the customer has been used to using the locally branded pneumatic machines.”

Very few things can bring chaos and mayhem to a country such as war. Kuwait, the small Middle East nation nestled in between Saudi Arabia, Iraq and the Gulf, have seen its fair share of destruction through the years. Since the mid 90’s however, the...

Atlas Copco’s PowerROC T25 DC drill rig, made in Japan, is convincing Chinese customers of the wisdom of making the transition from pneumatic to hydraulically controlled equipment.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 406b4f95116c28dca247da206ca234ea 63.210.148.230 10/26/2022 10:43 AM UTC

8613371530291

8613371530291