power swivel workover rig free sample

A wide variety of api drilling power swivel for workover rigs options are available to you, such as energy & mining, construction works and manufacturing plant.You can also choose from provided, api drilling power swivel for workover rigs,As well as from pump, motor api drilling power swivel for workover rigs.And whether api drilling power swivel for workover rigs is 1 year, {2}, or {3}.

After two years’ use of the swivel, remember to conduct crack detecting on bail, case, bail pin and central pipe. Use swivel only when confirming it meets requirements.

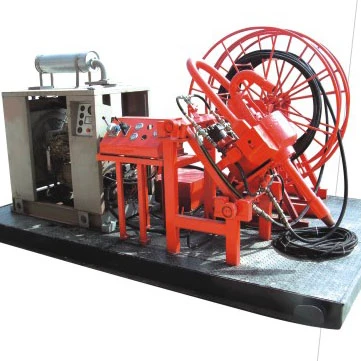

DSL-110 Power Swivel is hydraulic motor-driven swivel. It compact swivel-head design weighs 910kg. It is rated to support static load of 1100kN and dynamic load of 600kN at 100rpm.

DSL-110 Power Swivel is equipped with a hydraulic power unit with remote electric control system. All elements are set on a base seat, firm and convenient.

1. Fishing and workover operations:The power unit is ideal device to supply rotary power. It is ideally suited for use for internal or external cutting of casing or drill pipe; drilling out plugs, packers, or cement; milling operations; or scraping casing. Controlled torque is essential to eliminating the potential danger of twist-offs or damage or cutting tools.

2. Drilling applications:The compact, lightweight swivel is especially suited for drilling applications including oil and gas wells, water wells, pilings for piers and foundations. Suspending the swivel from a boom or crane eliminates a great deal of set-up time or shifts to additional locations.

3. Coring operations:When use power swivel for coring operation, any length or core may be taken. Accurate and smooth torque ensures against damage to core tools or strings.

Refer to Fig.2 and Fig.3, THT Power Swivel is powered by tow fixed displacement, piston-type, hydraulic motors. The motors are mounted on the underside of the swivel and is protected by a steel guard (11)

Two pressure hoses connect to the motor with swivel joints with quick disconnect couplers (18). The motor drain hose (14) is also fitted a self-sealing quick disconnect coupling.

The one-piece gooseneck (2) is constructed of cast steel. A 2-1/2” NPT access plug (Fig.1, 16) is located in the top. The plug may be removed to permit passage of tools with diameters smaller than 2-1/4”. The gooseneck and swivel packing are hydrostatically tested and rated at 35Mpa maximum circulating pressure.

A magnetic drain plug (65) is located on the lower cover plate (62) of the swivel assembly. A breather (47) is located on the upper cover plate. The gear housing is equipped a metal oil-leveler (46), so the operator may check oil level by watching the leveler.

Using a catline or derrick line, lift the swivel unit from the rack, and install torque rein assembly (67,Fig.2) on Swivel pinshaft. Then suspend the swivel over the wellhead. Attach one end of the safety rope of the torque rein near to pulley and the other end near to rig platform. Refer to Fig. 4. Turn the turnbuckle (7) and pull tight the rope. Secure rope in this place. Rope location should ensure the torque rein assembly geting at it at any level.

Note: If central pipe can’t be upright when lifting the power swivel, it is practicable to use a 1T hand chain hoist. Tie one end of the chain hoist in the bail and connect the other end with the rings on swivel gearbox cover. Adjust the hand chain hoist to ensure vertical location of the central pipe.

The following guidelines are intended to ensure maximum life of DSL-110 Power Swivel. These are recommendations only. Extreme peak load usage, temperature, and other variables will affect suggested service intervals.

During initial break-in, or after long period of idleness, run the Power Swivel with a reduced load at slower speed unit it reaches normal operating temperature ranging between 120o-200oF. a somewhat higher operating temperature is permissible in very hot climates, provided that it increase gradually.

6. It is practical to use thread gauge to check wearness or deformation of external and internal thread. Remaining thread top width should not be less than 3/4 of original, height not less than 4/5 of original, and worn thread number not over one and half round. If any, repair or replace right away.

If the Power swivel must be stored, it should be completely filled with gear lubricating oil to prevent oxidation. The stem should be installed with thread protector to prevent damage to the threads. Grease or dope the threads before installing the thread protector.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Drilling Swivel is one of the main components that make a Rotary System superior to the ones that don’t have one. The swivel is the most important part of the entire rotary drilling system. The swivel is supposed to transfer the water at very high speed through the stem of the drill all the way leading to the bit. This helps both in cooling and lubricating the bit while the drilling process continues through the flushing and forcing of the cuttings straight away out of the borehole.

Drilling a well that is more than twenty to thirty feet deep will be rather hard if not completely impossible, without a swivel that has a high volume and a huge capacity. Swivel of the smaller kind are generally fitted to the common drilling rigs available in the market. Swivel of this kind are intended for drilling short 6″ to 8″ deep holes in to the concrete surfaces aimed at fitting in anchor pods and bolts for grounding purposes. This won’t really render any valuable help if you are trying to dig deep water well.

But then the question is why are such petite and low-capacity swivels used on the water well drill-rigs? The answer is quite simple. Swivel of these types are not just inexpensive but easily accessible and available in plenty as well. Developing a swivel of a superior quality along with a high volume generally takes a lot of time. They are also expensive and need thorough labor while being used in drilling.

Drilling ventures of larger kind would need a high volume twirling pivot that is characterized with a weight bearing. Such swivels are generally four times larger than the commonly available ones and also have ten times more the capacity of the common imitation counterparts. Drilling with such a machine becomes a lot easier and takes lesser time as well. This is because the water ports are large and hence gush out more volume of water that helps keep the excess mud out of the borehole. Swivel of this type is outfitted with huge heavy duty that can be replaced without any real problems.

These have seals of the packing-type which are a further resistance to the abrasion caused by the sand and the mud cuttings that are persistently forced through the system while drilling. Swivel shaft is further supported by the roller bearings, making the rotation process smooth and straight. Yet another key feature of quality swivels is the built in weight-bearing support that plays a truly advantageous role. Swivel in this way is propped up to the frame rather than lynching straight from the gear box.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Blowout Preventers (BOPs) are a critical piece of safety equipment, as they protect rig crews, the rig, and the wellbore. Key maintains an inventory of

A pit in the ground to provide additional height between the rig floor and the well head to accommodate the installation of blowout preventers, ratholes, mouseholes, and so forth. It also collects drainage water and other fluids for disposal.†

A small enclosure on the rig floor used as an office for the driller or as a storehouse for small objects. Also, any small building used as an office or for storage.†

The hoisting mechanism on a drilling rig. It is essentially a large winch that spools off or takes in the drilling line and thus raises or lowers the drill stem and bit.†

On diesel electric rigs, powerful diesel engines drive large electric generators. The generators produce electricity that flows through cables to electric switches and control equipment enclosed in a control cabinet or panel. Electricity is fed to electric motors via the panel.†

A large, hook-shaped device from which the elevator bails or the swivel is suspended. It is designed to carry maximum loads ranging from 100 to 650 tons and turns on bearings in its supporting housing.†

The heavy square or hexagonal steel member suspended from the swivel through the rotary table. It is connected to the topmost joint of drill pipe to turn the drill stem as the rotary table turns.†

Shallow bores under the rig floor, usually lined with pipe, in which joints of drill pipe are temporarily suspended for later connection to the drill string.†

A diesel, Liquefied Petroleum Gas (LPG), natural gas, or gasoline engine, along with a mechanical transmission and generator for producing power for the drilling rig. Newer rigs use electric generators to power electric motors on the other parts of the rig.†

A hole in the rig floor 30 to 35 feet deep, lined with casing that projects above the floor. The kelly is placed in the rathole when hoisting operations are in progress.†

Shallow bores under the rig floor, usually lined with pipe, in which joints of drill pipe are temporarily suspended for later connection to the drill string.†

The hose on a rotary drilling rig that conducts the drilling fluid from the mud pump and standpipe to the swivel and kelly; also called the mud hose or the kelly hose.†

Wedge-shaped pieces of metal with teeth or other gripping elements that are used to prevent pipe from slipping down into the hole or to hold pipe in place. Rotary slips fit around the drill pipe and wedge against the master bushing to support the pipe. Power slips are pneumatically or hydraulically actuated devices that allow the crew to dispense with the manual handling of slips when making a connection. Packers and other down hole equipment are secured in position by slips that engage the pipe by action directed at the surface.†

The large wrenches used for turning when making up or breaking out drill pipe, casing, tubing, or other pipe; variously called casing tongs, rotary tongs, and so forth according to the specific use. Power tongs are pneumatically or hydraulically operated tools that spin the pipe up and, in some instances, apply the final makeup torque.†

The top drive rotates the drill string end bit without the use of a kelly and rotary table. The top drive is operated from a control console on the rig floor.†

8613371530291

8613371530291