tripping pipe on a workover rig manufacturer

The Attorneys at Spurgeon Law Firm know what it’s like to spend countless hours tripping pipe on a drilling rig. Stephen and Sam both have experience working on drilling rigs where they have roughnecked on Kelly and rotary drilling rigs.

Running in the hole or pulling out of the hole (aka tripping pipe) is one of the most labor intensive job tasks a worker will engage in while on a drilling rig. Long hours of throwing the slips in, breaking or making connections, and racking back stands of pipe in the derrick is mentally and physically exhausting whereby your brain will start to populate abnormal thoughts. Your mind will start to drift due to fatigue and exhaustion and thus cause you to lose focus on the job at hand. Because of this, people are more susceptible of making mistakes, which in turn will cause injury to themselves or someone else. This is why it is imperative that companies have adequate personnel on the job and to allow that personnel to take breaks as needed. Your safety should be priority and always put your health first and the company’s profit second.

All oilfield workers have the right to work in a safe environment. The oilfield is governed by rules, laws, and guidelines to keep workers safe. However, these rules and laws are not always followed and often lead to serious injury. If you have sustained injuries in the oilfield contact our experienced oilfield lawyers at 318-224-2222. Attorneys, Stephen and Sam, have both worked in the oilfield and know the ins and outs. Prior to becoming an attorney, Stephen worked offshore as a Petroleum Engineer gaining valuable experience which he uses to get his clients maximum compensation. Their experience can make the difference when it comes to getting the payment you deserve. Contact Spurgeon Law Firm today for a free consultation.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The act of pulling the drillstring out of the hole or replacing it in the hole. A pipe trip is usually done because the bit has dulled or has otherwise ceased to drill efficiently and must be replaced.

Working on monkey boards entails the risks of working at heights and working alone. Furthermore, the derrickman who works on the platform during trips, must carry out some of the most dangerous operations during drilling.

Monkey board is an elevated platform on a mast (rig’s derrick), located at a height equal to two, three, or four lengths of a drill pipe, based on how many lengths of pipe can stand in the rig’s derrick.

Monkey board is generally utilized for handling pipe, sucker rods, or other equipment stored in the derrick tower. It provides a small platform for the derrickman to stand and handle the pipes during tripping in/out when he/she should handle the top end of the pipe, which may be as high as 90 feet (27 m). Using this platform accelerates drilling operations since the entire “stands” of a drill pipe can be racked back in the monkey boards.

Monkey board is a lay term used in oilfield. However, the technical term used by various rig manufacturers is different. They call it diving/pipe racking board.

This operation is among the hardest physically intensive jobs and can be considered the most dangerous job in every drilling rig. The derrickman must do handling drill pipes at high speed, at a height all alone. During tripping out, he/she must guide the stand of drill pipe into the finger board, and inverse, during tripping in, he/she has to direct it into the elevator.

The following sections discussed some hazards and recommended safety measures to improve safety on the monkey board.Monkey board location and structure:

Monkey board structure must be designed and build in a way to avoid any excessive vibrations. It should be safely secured to the derrick with bolts or equivalent fasteners to prevent movement or dislodge during regular operation. The derrickman must check the bolts and fasteners regularly to avoid some loosened bolts lead to an accident. It is also his/her responsibility to secure all objects on the mast.

Another vital aspect to consider is the monkey board’s location. It is crucial that the driller always has a clear view of the monkey board, the crown block, and the traveling block at any point of its travel. Furthermore, during tripping-in operations, the driller, the driller’s assistant, or the person responsible for checking whether the latches on the fingerboards are open should stand in the proper position so they can clearly see the drill pipe stands and latches. This place must be determined and reminded to the crew during the pre-job safety meeting.Accident:

In 2015, a worker responsible for observing the latches wasstruck in the head by the bottom end of a drill pipe during tripping operations. One latch in the lower fingerboard didn’t open! The accident happened in the Drillship Pacific Santa Ana (PSA), operating approximately 250 miles south of Lake Charles, Louisiana, in the Gulf of Mexico. The PSA was under contract to Chevron USA. Inc.

In one related fatal accident, traveling blocks hit the stepping board while it was being lower into the mouse hole and caused the stepping board to detach from the monkey board and fell from a height of around 27 m onto the rig floor and hit a worker.

Working on monkey boards always needs essential fall protection. OSHA requires separate fall arrest systems to be used with Derrick Belts and Monkey Board Belts. As a rule, this type of safety harness also includes a self-retracting lifeline, energy-absorbing lanyard, or rope grab and lifeline.

The derrickman must also wear fall protection when climbing up from the ladder to reach the monkey board. There are many reasons to be cautious on the ladder, including being greasy, ice-covered, or using very narrow rungs, all of which can cause the derrickhand to slip.

After all, almost all safety professionals who work on oil rigs for several years consider using fall protection equipment one of the most critical safety issues that must be considered. In addition, the derrickman must conduct an inspection to ensure that all fall protection equipment is undamaged. The harnesses and lanyards must also be labeled carefully: available to use or unavailable to prevent accidents due to damaged or worn equipment.Accident:

In 2008, a derrickman checking the rear guardrail on the monkey board fell 25 feet (about 8 meters) and was killed. A slip or trip caused him to fall and failing to wear fall protection lead to his death.

Some derrickmans are careless about Body harnesses tie-off, or some forget to do it. It is better if Rig manufacturing companies install some system at monkey board that should be integrated with TDS. So, derrickman needs to tie off his harness since, without tie off, the system sends a signal to TDS to stop the operation until the derrickman hocked up his harness.Escape Equipment:

A monkey board must have an auxiliary escape route. Suppose an employee is unable to escape via the derrick ladder due to a blowout or other emergency in or around the derrick. In that case, an auxiliary means of escape shall be provided to allow them to reach the ground.

This emergency escape line is often called Geronimo Line. The derrickman is required to be attached to the escape device all the time. In an emergency, he can disconnect his safety belt from the rig, firmly grip the tee-bar handle and ride the trolley down the cable while holding on to the handle with his hands.

Escape lines must be equipped with a safety buggy or other approved device. It must also be fitted with a suitable brake and maintained in good condition. Besides, the derrickman should inspect the safety buggy or other approved deviceat least once a week and record unsafe conditions.Accident:

In the late 70s, Kevin Cooke worked on a rig when the lightning hit the crown block, and derrickman came down through the Geronimo Line as fast as possible.

As well as the monkey board safety issues mentioned previously, many other safety precautions should be taken. The following are a few of them:Risk assessment:The first step in eliminating hazards and reducing risks is identifying risks and determining what is of most importance. Thus, HSE managers in all workplaces, including oil rigs, must conduct risk assessments prior to implementing any operations. Risk assessments can inform managers about possible hazards and help them find suitable solutions to mitigate the risks.

Slips, trips, and falls caused by poor housekeeping are other hazards that must be considered. Thus, monkey boards must be kept clean and free of obstacles to mitigate the risk of slips, trips, and falls. It is recommended to cover monkey board surfaces with mats, grates, or cleats to provide good slip resistance.

People who work on oil rigs need to be well-trained and professional. Even if the company intends to hire a trainee, he/she must be well trained before operating in harsh environments like the monkey board. For example, on the rig floor, there are times when new forces are used to alert the driller when the fingerboard latches are opened. Still, as mentioned previously, this decision may easily result in an accident.

All equipment on the monkey board must be inspected to ensure that they are undamaged and safe to use, including slip-resistant mats on the surface, guardrails, an escape line, monitoring cameras, and other types of equipment. Furthermore, the monkey board structure, bolts, and joints must also be inspected annually.

Since the derrickman usually works alone on the platform, the only way the driller or other people can be aware of his/her condition is through the camera. The driller can see the camera’s output in the doghouse.

Poor lighting on the monkey board can also result in accidents. As a result, the platform lighting needs to be carefully checked, especially during night operations.In conclusion, despite all safety precautions, why are accidents and fatalities still occurring on monkey boards?

Despite all safety regulations, according to AIDC, in 2020, from 125 reported incidents in Middle East land oil rigs and 165 recordable incidents in US drilling rigs, respectively, about 7 percent and 17 percent happened to derrickmans.

An accident may have resulted from human error. Fatigue, overconfidence, and ignorance are also common reasons. Even experts mention that workers sometimes engage in unsafe behaviors and keep doing them because they have not been seriously injured yet.

Therefore safety managers and employers must find new solutions to improve safety on monkey boards. Digitalization and the use of new technologies are some of the solutions, in addition to establishing safety cultures among workers.Veunex AI-driven platform on monkey board

Do you want to see how we can improve safety on derrick boards? Click here, then join us to get into the new era of using AI for workplace safety.0 0 votes

I like the simplicity of the risk and hazards explained with the corrective measures to put in place while on monkey board and at the same time the accidents engaged with their root causes clearly explained from recent operations makes this article very effective and simple to understand issues concerning monkey boards. Well-done

It’s great that you found this article helpful. If you could also share your stories and experiences regarding safety issues and accidents on oil rigs, that would be fantastic. We strive to understand safety issues to offer proper safety solutions. Therefore, we will appreciate it if you could share your stories with us.

Normalisation of risk a human behaviour if a person completes a task with negative behaviour and no harm occurs or there is no negative outcome, even though it is a high hazard high risk task and despite the method used is known by the user to be unsafe they will continue to do it in that way. In this way working at height and in a high risk of harm environment can lead to unsafe behaviours and as long as the hazard potential is not realised it will lead to greater risk taking “it will never happen to me” ” I have done it that way for many years nothing bad has happened to me and I have not heard of anyone else being harmed doing it in the same way”. I personally witnessed a Derrickman fall because ” I forgot to tie off” however he candidly admitted later that he regularly did not clip on. in this incident he manged to get hold of a stand of pipe and self rescue.

Thank you so much for sharing your story with us. We hear similar complaints from many HSE officers as well. Our proposed solution to such cultural issues is to use AI. We work on a technology that can detect safety anomalies and risks in real-time; therefore, the story you told, hardly happens since you can prevent the incident by different scenarios; for instance, if the derrickman detaches from his rescue line, the TDS moving will stop, or a siren will be sounded besides warning HSE officers. We are developing this AI tech that combining with CCTV cameras to provide constant supervision to prevent deviation from safety regulations. Furthermore, our experience shows that this procedure can improve safety culture efficiently since you can also warn the worker in a meeting about the probable outcome of his behavior and make him aware of the importance of safety regulations. As a result, AI can avoid accidents in the workplace and alongside improve the safety culture. How does this technology sound to you?

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time d94a2288d76f819e65e1cc71545d07c7 63.210.148.230 10/25/2022 04:41 PM UTC

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Our client was a young man of slight build and the end of his foot was crushed when he was alone handling the slips on the drilling rig floor during a pipe-tripping

The driller, backed up by other company personnel, claimed that in-hole pipe tripping with one man handling of the slips — which weighed more than our client for the

5-inch drill pipe used — was routine. Though having a brake handle in one hand, the driller said that because he had to be looking up in the derrick at the block as the drill string was

The drilling company blamed the accident entirely on our client for falling as he navigated the rig floor, wet with drilling mud and dope (grease) as he tried to maneuver the slips to drop

During cross examination of the driller, it became clear to the driller that the attorney conducting the examination had himself worked as a driller, and it was made clear to the jury that

the driller routinely had both the ability to monitor floor activity while lowering the drill string as well as the duty to do so — particularly when he was working a two-man floor

Tripping refers to the process of removing and/or replacing pipes from the well when it is necessary to change the bit or other piece of the drill string, or when preparing to run certain tests in the well bore.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Most oil well interventions or Workover are done because the well is not performing up to expectations. Other reasons could be regulatory requirements, data gathering, supplemental recovery project requirements, etc. Wellbore workover might involve casing or equipment repair, maintenance and installation of new equipment. And some of the techniques are known as wireline, coiled tubing and snubbing.

The 2nd Stage Low Profile Load Rated Katch Kan will prevent wellbore fluid from spilling over B.O.P. due to tubing displacement as you run in / or incorrect hole fill volumes

The Mini Kelly Kan controls and redirects fluids being released from wet tubing or pipe. The fluids are captured in the 2nd Stage Low Profile Load Rated Katch Kan, and then can be drained through a two-inch discharge line to the containment area

The Low Profile Katch Kan will eliminate fluid from running down outside of the B.O.P.s when using a tubing stripper, keeping this area free of contaminants

When tripping out of the hole to service tools such as packers, swabbing effect may cause fluids to run over top of B.O.P. This problem is solved as these fluids are captured and redirected by the 2nd Stage Low Profile Load Rated Katch Kan

The Mini Kelly Kan / Katch Kan system will reduce the need for waiting on wire line trucks to perforate tubing thus reducing rig time by simply pulling wet

The Mini Kelly Kan/ Katch Kan system is designed for the dirtiest and messiest jobs in the oilfield. As well as keeping the worker safe and clean, use of the system lowers clean-up costs, minimizes vacuum truck work and reduces tripping time

The 2nd Stage Low Profile Load Rated Katch Kan and rod table adapter will attach to the bottom of all rod tables. Fluids released from the wellbore while pulling rods are captured and contained in the 2nd Stage Low Profile Load Rated Katch Kan. This fluid then can be redirected

The 2nd Stage Low Profile Load Rated Katch Kan will clamp on to most well heads, capturing leaking fluids from saver heads, when stripping the sand line while swabbing, also when changing the swab cups

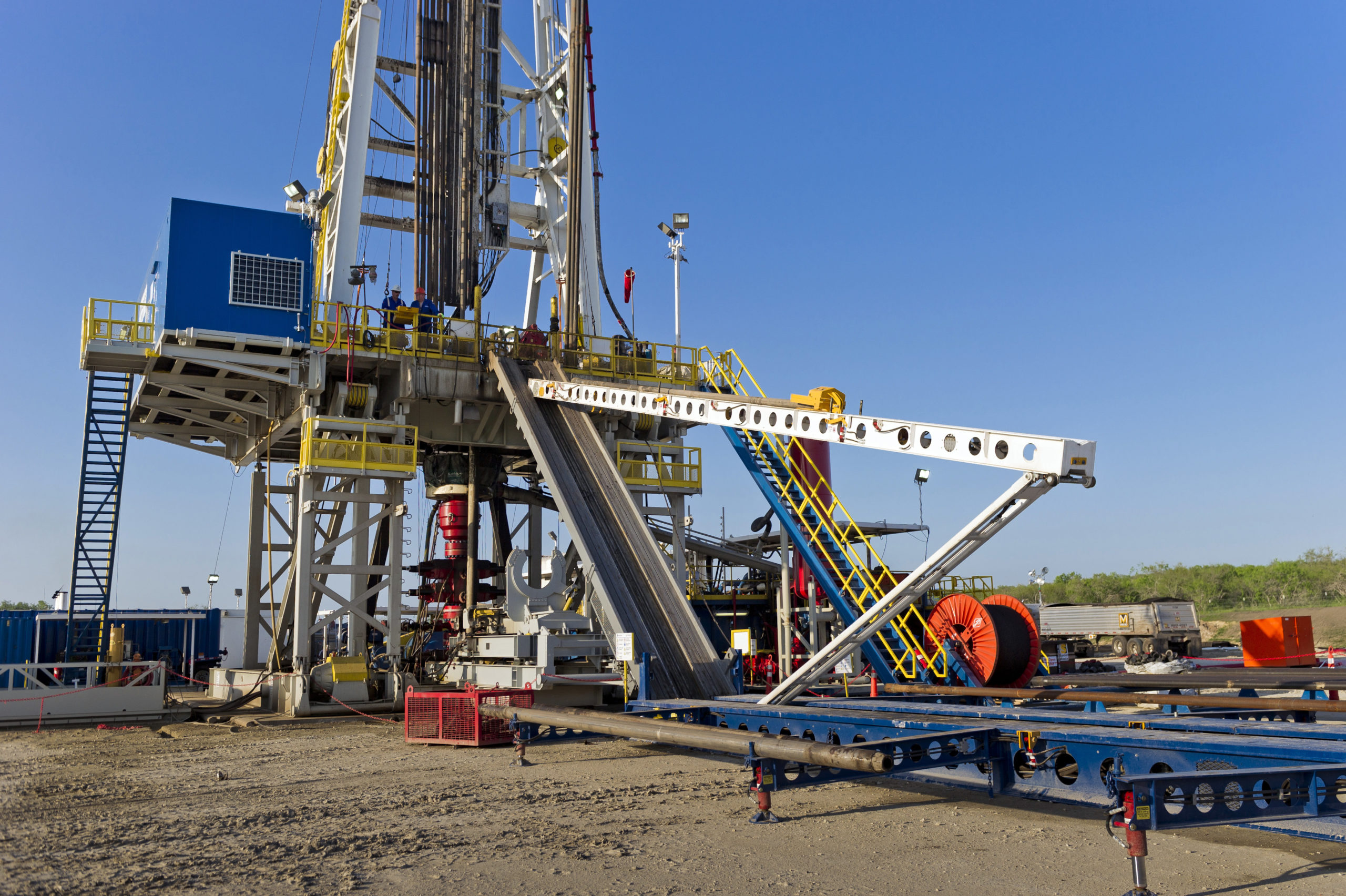

Workover rigs are specialized rigs designed for carrying out certain operations in a well. Drillmec is a leader in the production of specialized service rigs, we have rigs that cover a variety of workover operations in the oil and gas industry. Our service rigs have a wide range of applications and provide the best performance in different situations. Drillmec’s mobile drilling rigs are self-propelled, and trailer mounted for easy transportation for a variety of workover well services.

We manufacture a full range of workover rigs with capacities between 60 to 250 metric tons for a variety of well service applications. Our rigs are designed to be electrically or mechanically driven and are built to withstand varying extreme climatic conditions and a variety of terrains. Whether scorching heat of the desert or the bitter cold in the polar region or even the extreme elevation changes of Utica shale, our rigs are ready to deliver optimal performance always.

Operators working in shallow resource plays, such as shallow oil, unconventional shale gas and coalbed methane (CBM), just can’t get enough of a good thing. At their request, rig manufacturers are expanding the operating and mobility features of the industry’s rigs to a new level of sophistication – the highly or ultra-mobile rig. Highly mobile drilling rigs bring increased agility, automation, safety focus and cost savings, and are being used in deeper oil plays to perform top-hole work. Additionally, highly mobile rigs are carving niches for themselves in workover operations from offshore platforms, as well as geothermal applications.

Mobile and highly mobile rigs are different from their predecessor, the heliportable rig, which is used to access locations where no infrastructure exists, such as Siberia and the Amazon region. Heliportable rigs, which first appeared about 30 years ago, are capable of being broken down into a minimum number of loads, with each load weighing three tons, depending on the type of rig.

“Ironically, the helirig concept has not evolved very much, I suppose due to low-volume demand for these units. However, modular highly portable rigs have taken off, and the demand is very high for the foreseeable future,” Ray Pereira, vice president of North America sales for Drillmec, said.

For the purpose of this article, highly or ultra-mobile rigs are defined as small or medium-size self-driving rigs with wheels, mounted on either a substructure or trailer, and quite often their substructure and mast are self-erecting. How is this different from mobile rigs? According to rig manufacturers, features such as a heightened ability to be broken down and reassembled and still retain full functionality, increased use of automation for added safety and operational ability, and a reduction in crew size all set highly mobile rigs apart from mobile rigs.

“A fully engineered drilling system is even more important in highly mobile rigs given the trend toward more factory-styled well construction and automated drilling,” Eric Quinlan, LOC product manager for Huisman, commented. “The complete integration of third-party equipment into the rig design will further reduce the number of loads required, the rig-up and rig-down times, as well as improve on automation.”

“High mobility allows more wells to be drilled in a year,” he continued. Particularly for pad drilling in the shale plays, rigs must not only be able to skid or walk but also move quickly and safely to the next pad.

“There is a stronger focus on self-erecting components in highly mobile designs, for instance slingshot-type substructure and self-elevating or self-erecting masts,” Thomas Janowski, sales manager for Herrenknecht Vertical, said. The advent of portable top drives, iron roughnecks, as well as casing-running tools, have added to efficiencies of highly mobile rigs, he noted.

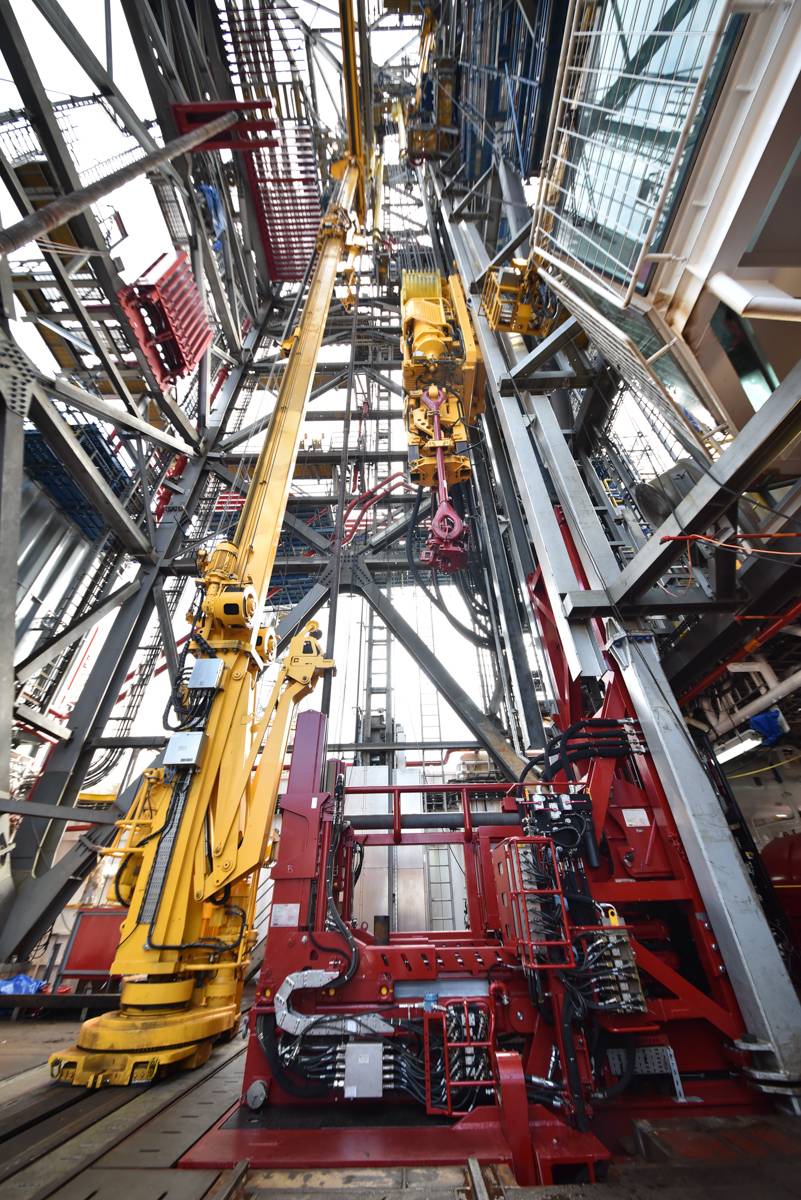

The design and construction of these highly mobile rigs have become very sophisticated, as with the case of the Drillmec HH Series rig, where the main rig components, such as the mast and part of the drill floor, are fused to the specially designed trailer. This allows the top drive and iron roughneck to be transported without being removed from the mast. The trailer concept has improved the mobility of mud pumps, mud tanks, variable frequency drive houses and pipe bins for the automatic racking system.

“A key limitation to current rigs is the available resources (people, trucks, etc) that enable the rig move. Location of the wells also plays a role and adds constraints, both geographic and regulatory,” Mr Quinlan said.

Therefore, there is a major push to reduce load weights and dimensions of all modules that are required to erect a highly mobile rig on location while at the same time reducing the number of loads required to fully assemble the rig on site, according to Mr Pereira.

It all comes down to the challenge of how to rethink components, such as a 40-ton mud pump, to make them more easily and economically transportable. “There is no standard solution at all,” Mr Janowski said. “How do you make 40 tons highly mobile? You can put wheels on it, but there are limits as to weight and size of components. It is challenging to design the components on the one hand lighter by using different compound materials like glass-reinforced plastic, and on the other hand, these heavy components like mud pumps, diesel generators and electrical cabinets and steel structures, such as the mast and substructure, have to be able to be broken down into smaller pieces but retain the same operational features.”

Equipment advances have brought challenges to highly mobile rig designs as well. “We are seeing a lot more wires and sensors being installed along with measurement equipment and video cameras,” Mr Quinlan remarked.

According to Atlas Copco, mobile rigs got their start in the energy industry when operators started using water-well rigs to drill for oil and gas. “The industry sort of evolved into using mobile rigs for oil and gas drilling rather than actually beginning at a definitive time. The Atlas Copco RD20 rig was borne out of the need for a mobile rig designed specifically for oil and gas drilling,” Alex Grant, well drilling product line manager for Atlas Copco, recalled. The rig was conceived from the T4 water-well rig and has received several technology upgrades since it was introduced in 1986.

The 120,000-lb hookload RD20 rig now has a sister rig, the highly mobile 200,000-lb hookload Predator, which took five years to develop and is just now finishing field trials. The first production unit is expected to begin work in September this year in a Texas shale play.

“We saw a definite need to get into the bigger fields with the bigger players. That’s where Predator came in. We took a clean sheet of paper and asked the question, ‘What does the oil and gas market need?’ ” Mr Grant said. “Because we desired to have an API 4F rating, we probably spent about two years getting our suppliers lined up…. Structures are designed to three times the loading capacity; that’s something you can’t just evolve from a rig that you already have. In 2010, we built two prototypes and put them in the field in an extensive testing program.”

Recognizing that more operators are performing directional drilling, Atlas Copco also added more pullback capacity to the Predator design. The RD20 rig had a pullback capacity of about 5,500 ft; the Predator has about 8,000 ft to 10,000 ft of pullback capacity.

For Drillmec, the Drillmec HH Series rig saw its evolution from a simple hydraulic rig for water wells upgraded to oil well standards in 1990. The first built-for-purpose HH rig was delivered to Eni in 1994. Since then, each generation of the rig has been improved to include enhanced automatic controls for the pipe handler using programmable logic controllers (PLCs) and advances to the hoisting and hydraulic systems. The latest generations include joystick controls and cyber control touchscreen features. The company offers up to 375-ton HH Series rigs for land applications and up to 600-ton rigs for offshore platforms.

Also on the HH Series rig, the vertical pipe-racking system is assembled in a semi-circular array around the rig floor to contribute to quick rig-up and rig-down. Further, containers can be transported and handled full of drill pipe to save time and to reduce risks associated with pipe handling.

“For us, the challenge in the beginning was to develop a rig that provided very safe working conditions for the crew, a small environmental footprint and a high level of operating efficiency,” Mr Pereira said. “Our extensive knowledge of hydraulics enabled us to effectively use a purpose-made cylinder for the hoisting aspect of the rig, thereby eliminating the need for mechanical drawworks and the operational and transport complexities that it brings. The rigs do not have a conventional mast structure nor drawworks and long wires or traveling equipment as the hydraulic cylinder replaces those items and is the main hoisting element of the rig.”

Safety has become a paramount driver alongside economics for highly mobile rigs. “Try to remove personnel from unsafe areas is what we’ve done,” Atlas Copco’s Mr Grant said.

“From a mechanical standpoint to achieve safety, we’re getting into more computer-controlled systems, such as a wireless pipe-handling system where the operator can stand away from the whole operation, observe from a distance and still control the unit. We’re bringing computers more into it. It’s the same with the driller; with the use of electronics, we’re able to stand away from the drill table, stand back in the doghouse even and operate the rig from back there, out of the area where injuries typically occur,” Mr Grant said.

“Drillmec uses single 45-ft joints of range 3 drill pipe that is transported in pipe bins and ready to be used,” Mr Pereira said. “There are no delays waiting to make up stands and set them in fingerboards. Stand-building operations can take days. With the HH Series rig, there is no need to touch the pipe, thereby increasing safety parameters.”

The LOC 250, Huisman’s first highly mobile rig, is a containerized rig, meaning that all elements of the rig fit into standard ISO containers, and has casing-while-drilling capabilities. Since introducing the LOC 250 in 2005, the company has upgraded its design to include AC drive, a higher hookload and an expanded mud system, and the LOC 400 was introduced in 2009. The next generation of the LOC 400, to be introduced in late 2012 or early 2013, will feature a higher level of automation, even quicker rig moves and enhanced skidding capabilities.

“We’re conducting a study on rig moves, finding the weak links and engineering the process to improve it, and preparing recommendations for field personnel to accomplish rig moves quicker,” Mr Quinlan said.

Increased rig safety features desired by operators have brought about another benefit – a reduction in the number of crews needed to run the rig. “The more features you have, such as self-erecting masts, self-erecting substructures and highly mobile components, the less the risk of accidents related to these activities. In Herrenknecht Vertical’s case, a high level of automation, together with the concept of mobility, eliminates almost all of the dangerous jobs on the rig,” Mr Janowski explained. “The number of people involved in tripping pipe in and out is limited to two persons.”

The Drillmec HH Series rig advanced automation concept requires few crew members as well. The concept “allows it to perform most of the routine drilling operations, including tripping in and out the drill string, with an almost unmanned drill floor where worker presence is basically limited to thread doping and handling the bottomhole assembly,” Mr Pereira said. “No one is exposed to direct contact with rotating tubulars, tongs and wrenches or to falling objects.”

“With the latest Atlas Copco rig, the Predator, we’ve got it down to the minimum amount where we can have three people operating a rig as opposed to the six or seven people that would be on a conventional rig,” Mr Grant said.

With Herrenknecht Vertical’s Terra Invader rig, only two people are involved in tripping pipe in and out. The rig came onto the work scene in a geothermal application in Germany in 2006, just one year after the company was established. This rig, which has a box-on-box substructure, is tailored to the Western European market, where cranes are readily available.

“The design criteria are different in that the situation regarding cranes and heavy trucks in Europe is slightly different from the rest of the world,” Mr Janowski noted. “It’s cheaper to install a crane because it’s available and you can rig-up in two days with a crane.”

“There has always been a demand for high mobility in this industry, but the higher the costs are for drilling and transportation, the higher the demand to make the equipment more mobile than before,” Mr Janowski noted. According to him, exploration drilling in remote places, on artificial islands, in the Brazilian Amazonas region and in Siberia has prompted the increased demand for highly mobile units. Crane and truck load capacities are limited. Cost levels are quite high, and the need to reduce crew cost is an issue.

An economic boost has been a huge plus for operators choosing highly mobile rigs. In addition to the shale plays in North America, key markets are North Africa and the Middle East. “In the Middle East, you have only to drill 700 to 900 meters (2,297 to 2,953 ft) to access resources. Drilling takes only five or six days,” Mr Janowski commented. “There must be a relation between the drilling time and the moving time. When you drill five days, no one would accept a rig move time of five days.”

“It is not just the rig design that enables high portability,” Mr Quinlan remarked. “The contractor must also have the right procedures and systems in place and have a dedicated rig-moving team that knows the rig and how to move it. It’s no use having a rig that can move in two days and be waiting for trucks for three days before it can move.”

“With the Huisman LOC rigs, we wanted a rig that could be moved anywhere on the planet with the same ease as moving a few miles on the road. In this regard, we have been very successful. To move the LOC rigs overseas is very cost effective and can be cheaper than rig moves over land.”

Also regarding improved economics, Mr Grant pointed out that “in addition to the rig’s ability to be broken down into manageable pieces that can be rolled down the road to the next site, the pieces are smaller and the capital outlay is a lot less to achieve the same result as that achieved by drilling with a conventional rig. We run less crew; staff overhead is a lot less. Ultimately, if you’re going for the shallower stuff, the overall cost of ownership is a lot less … roughly two-thirds of the cost of a big conventional rig.”

Rig manufacturers believe there is savings to be realized from use of a highly mobile rig to drill the top-hole section when an operator is targeting deeper reserves. The conventional rig doesn’t need to stay on-site as long. There’s also savings to be realized from reducing nonproductive time.

“It’s about decreasing nonproductive time and increasing safety,” Mr Pereira remarked. “The correct application of a fast-moving or portable rig can save the operator days in mobilization and demobilization between wells. Depending on the distance to the next well location, the Drillmec HH Series rig can be ready for drilling within 72 hours. A well-trained crew can do it in less than 48 hours.”

According to Drillmec, one of its expanded rig capabilities as a result of the design was for the rig to become an integral part of the substructure. “We figured, wouldn’t it be great if you could run the hydraulics of the substructure from the rig itself and offer connections on the substructure to quickly connect an air or mud pump system and reduce the downtime for setup,” Mr Grant said. “The other part was to have the pipe-handling on the back of that.” The Drillmec rigs have the main rig components fused to the specially designed trailer.

With Atlas Copco, Mr Grant said they’re expanding the operational ability of their highly mobile rigs by taking manual labor out of the scenario where possible. For example, “with the Predator rig, the driller has the more accurate ability to dial-in to a computer what he is trying to accomplish; for instance, establish weight on bit by dialing it in,” Mr Grant said. “Before, the driller had to watch the pressure gauge and dial-in weight-on-bit information as the formation changed.”

Highly mobile rigs are meeting diverse global drilling requirements as well. Drillmec’s HH Series rigs are currently operating in shale plays in North America, in the deserts of Egypt and the Middle East, in remote locations in Peru, Colombia, Venezuela and Australia, as well as in geothermal projects in Iceland and Chile. Further, the company recently announced the sale of 25 hydraulic rigs, with an option for an additional 125 rigs, to Chinese drilling company Greka Drilling. The units will work in CBM and shale-gas applications in China’s Shanxi Province.

Huisman’s LOC rigs have drilled oil, gas and geothermal wells in the US and Europe. Although the LOC rigs were designed for onshore drilling, the company has developed a concept and performed basic engineering on a LOC rig for offshore application.

“We have worked on a very interesting concept for using our LOC rig as a modular platform rig with a unique installation procedure onto the platform. This solution would see platform installation in a few days as compared with the several weeks required for similar modular rigs,” Mr Quinlan said.

In addition to shallow-resource development, Atlas Copco has found success using its highly mobile units to do top-hole drilling and set the casing so that conventional double or triple rigs can go in later to drill the deeper sections.

“We can use a top head drive to push the head down onto the drill bit to create weight on bit,” Mr Grant said. “The conventional rigs are not top head drive; they’re relying on collars and sticks of steel to give them weight on bit, making it harder there at the top of the hole.”

As operators expand their search for resources across the globe, rig manufacturers are keeping pace, delivering innovations in operation and transportability.

With more advances already on the drawing board, rig manufacturers are confident that the next generation of highly mobile rigs will continue to meet operator expectations.

Inserting and pulling up pipe tubing from oil wells is a precise and challenging job that not every rig is up for. That’s why you need a mobile workover rig from Dragon to get it done right every time. Our workover rigs are state-of-the-art and ready to tackle even the harshest conditions. A workover rig is perfect for site preparation while a standard mobile oil rig can handle a variety of piping tasks. Need workover rig parts, or service on another mobile rig? Dragon has that covered with our parts selection, too. View all of our workover rigs and other drilling rigs today.

8613371530291

8613371530291