workover rig base beam supplier

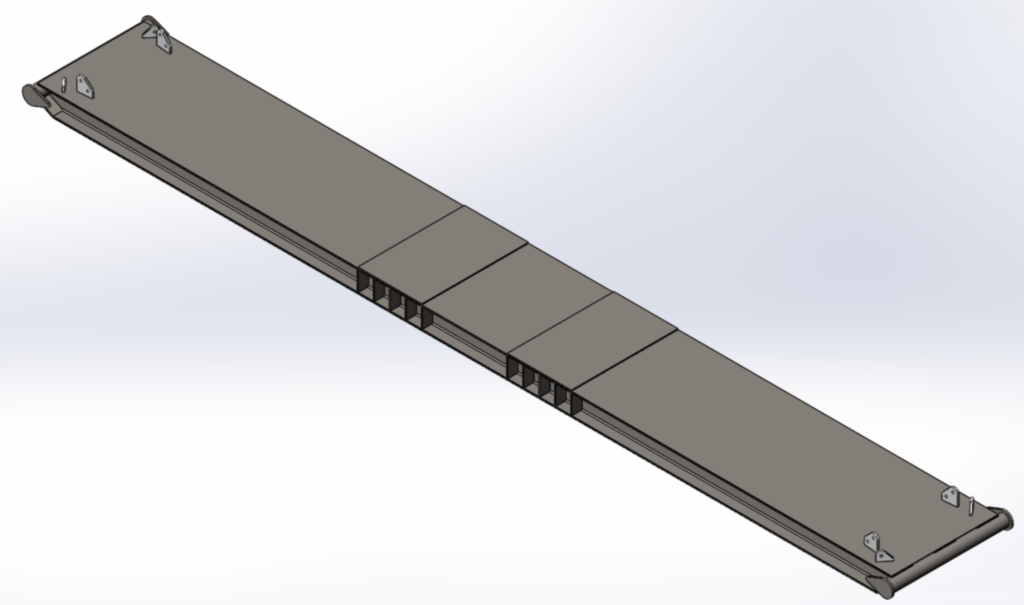

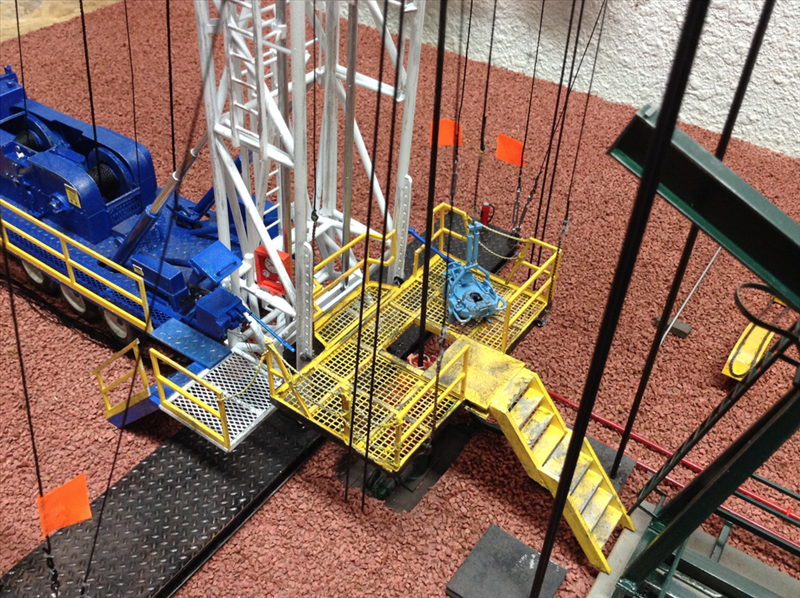

A Base Beam is used on a workover rig for stabilization. They are used in place of ground anchors. Guice Base Beams set the standard for internal guying solutions. They are designed to meet requirements of API RP 4G 14.3. Our beams are proven to decrease rig up and rig down times and will endure the rigorous stresses of the oilfield. We manufacture in-house at GEI Welding. Each beam comes with an assigned serial number to prove it’s a Guice Base Beam.

Guice Base Beams come in 3 standard widths, 2 different variations and can be customized and painted to your specific needs. Base Beam certification is free when manufactured by GEI Welding!

A Base Beam is used on a workover rig for stabilization. They are used in place of ground anchors. Guice Base Beams set the standard for internal guying solutions. They are designed to meet requirements of API RP 4G 14.3. They are proven to decrease rig up and rig down times and can endure the rigorous stresses of the oilfield. Guice Base Beams come in three standard widths: 4, 5, and 6 feet but can also be designed to meet your specific needs. We manufacture in-house at GEI Welding. Each beam also comes with an assigned serial number to prove it’s a Guice Base Beam.

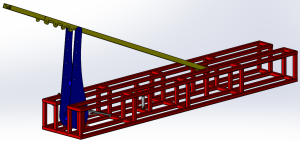

The President of Guice Oilfield: Dr. Lee Guice, PE invented the Guice SRL arm, a Fall Protection arm found on nearly all workover rigs in tight locations.

Our fall protection arm provides extra protection for your employees on the rig. With our staff of experienced licensed Professional Engineers (P.E.) we developed the Guice fall protection systems that meet OSHA, ANSI, ASME conformance.Guice Engineering is always innovating oilfield products with your safety in mind.

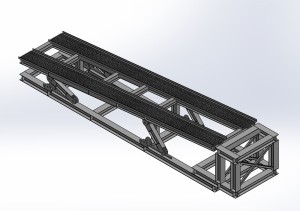

The Guice “Razor Ramp” is a short working area lift / ramp combo that ships in one single load. It raises workover rigs 4-8 ft, dependent on design, allowing use of your existing short rigs on most wellheads. With a net lifting load / capacity rated at 130K, the “Razor Ramp” allows 98′-104′ drilling rig to work on deeper holes with higher well head or BOP stacks.

The Guice Engineering cam design provides you multiple heights for multiple jobs. Easy rig up and rig down is achieved with the moving of a single pin. The Hydraulic Catwalk is a self-contained, hydraulic pipe assist machine. The lifting mechanism is designed to create opportunities where big hydraulic operations would otherwise be needed. The Hydraulic Catwalk picks up and lays down pipe rapidly, efficiently, and safely. It reduces personnel time and operation time on site and averts high-risk situations. The Hydraulic Catwalk eliminates costly man hours and strenuous effort by allowing employees to remain and work at a safe distance and avoiding the threat of “falling pipe” and personal harm. The Hydraulic Catwalk provides a safer way to handle pipe in high-risk situations, reducing insurance claims and saving your company money!

Manufacturer of standard & mobile rigs & carriers for oilfield applications. Includes well servicing from 14,000 ft. to 22,000 ft., workovers from 10,000 ft. to 16,000 ft. & drilling from 6000 ft. to 10,000 ft. Specifications include brakes range from 28 in. dia. x 8 in. wide to 42 in. dia. x 12 in. wide, barrels from 12 3/4 in. x 38 in. to 18 in. x 43 in., chains from 1 1/4 in. to 1 3/4 in., clutches of 24 in. with single & 2 plate air friction outboards, shafts of 5 in. dia. to 6 1/2 in. dia. & gross weights from 63,200 lbs. to 115,000 lbs. Also includes forged steel, demountable options, mufflers with spark arrestors, dry type air cleaners, transmissions with torque converters, water splash brake cooling & up to 6 axles.

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We are a parts supplier for all major brands of well servicing rigs and equipment. We are an authorized distributor of quality oilfield brands such as Crosby, WPT, Kobelt, Parker and Oil Country, to name a few. With a full machine shop and fabrication capabilities, we can make hard to find parts that keep older equipment in service.

WILSON WELL SERVICE RIG (Ref#3000Ta) 103’ x 248,000# derrick, Out of service since 2017, lot of rust, will start and run and/or drive down the road POR

Refurbished, 700 hp, Double drum 2042 drawwroks with Parmac 202 brake assist, (2) Caterpillar 3406 Engines, (2) rebuilt Allison 750 6 speed auto transmission with reverse. 112" x 300,000 # hook load capacity on 8 lines, clear height 97 feet, leg spread 7" 6-1/2", racking board, oil bath chain case, elevated rotary drive, all raising lines and guidelines. The Draw-works, hydro-mantic break, and crown assembly have been rebuilt. Heavy duty Draw works drive propeller shaft through right angle gear box, rotary drive propeller shaft, heavy duty reverse gear box and oil bath roller chain, and a self-locking handling winch. Mounted on triple front axle mechanical 6 axle carrier with 134,000# capacity designed to meet highway safety standards with necessary toughness for off road operations. Price: $265,000

Derrick fell onto rig when being raised, derrick would need to be replaced or repaired. Built 1981, double drum, 42 x 12, 42 x 8, swab drum removed from jack shaft, 5-axle back in carrier, 250,000# derrick with double racking board and triple rod basket, Cat 3408, CLT 5860 transmission, Cooper right angle box, 4 hydraulic leveling jacks, air rod transfer in derrick, hydraulic winch, Kerr 6 cyd 10000 psi Mustang pump powered from jack shaft, Kerr 3-valve release 10,000 psi, tong carrier f/Foster, steel work platform, Parmac 22 SR hydromatic brake. Extra rebuilt 3408 Cat engine. Price as is: $112,500

Manufactured 1981, mounted on 5 axle carrier, double triple service rig, 96’ x 250,000# derrick, Detroit Series 60 12.7 diesel engine, Allison transmission, 9/16” sandline, 1” drill line, hydraulic jacks, hydraulic catwalk, travelling block, tubing bard, rod basket and all necessary lines. Tooling not included. Price: $115,000

Manufactured 1983, double drum, 96’ x 180,000# derrick, mounted on 5 axle carrier with 92T engine, Allison transmission Price rig only: $300,000 Price with tooling:$340,000

WILSON 42 WELL SERVICE RIG(Ref#7562Ta) Manufactured 1975, 180,000# Pemco double/triple derrick, mounted on Wilson carrier with Detroit 8V71 engine, 4 hydraulic leveling jacks, ready to work Price rig only: $74,500 Price with tooling: $94,500

Manufactured 1983, 70" x 120,000# non telescoping stiff mast, double drum 26 x 8, Detroit 6V71 diesel engine, 740 Allison transmission with Spicer power divider, mounted on 4 axle carrier. Rig runs and truck drives, stacked for several years, good condition Price: $93,500 USD

FRANKS 500 WORKOVER RIG(Ref#7615Tc) Built 1980, refurbished 2018, 102’ derrick, 150 ton blocks, 15,000’ sandline, new engine and transmission, ready to work Price: $430,000

FRANKS 400 WORKOVER RIG(Ref#7615Ta) Built 1979, refurbished 2017, 102’ x 215,000# derrick, 100 ton blocks, 15,000’ sandline, 4 lines Price: $390,000

FRANKS 300 SERVICE RIG(Ref#1169Ta) 4-legged derrick, Series 60 Detroit engine, 6850 Allison transmission, blocks, Foster tongs, mounted on 4 axle carrier, working condition Price: $37,500

WILSON MOGUEL 42 WELL SERVICE RIG(Ref#3177Tb) Two available, 96" x 280,000# mast, Detroit Series 60 engine, 5860 Allison transmission, mounted on 5 axle Wilson carrier, handling tools Price: $315,000

WILSON SUPER 38(Ref#3307R) Double drum drawworks, friction clutches, Foster makeup and breakout catheads, Cummins 250 disel engine, Spicer 4 speed transmission, 70’ cantilever mast, 4-sheave crown block, racking board, mounted on 8’W x 22’L tandem axle trailer with folding walkways, mast base, 4 manual jacks, Budd wheels, National Ideal 75 ton 3-sheave block with hook, Price: $45,000

Workover rig with 83’ telescoping derrick, 10’ crown extension, 200,000# lift capacity, 100,000# snubbing capacity. Catwalk with 42’ reach, forward and revere motion, hydraulic pipe slide, six portable pipe racks, powered by workover rig. 5000 ft/lb hydraulic rotary, 15k psi working pressure capability kelly hose, 300 ton mast with 5 x 5 heavy wall box tubing and 2 x 2 heavy wall cross sections, (2) mast raising cylinders, 9-1/8 x 25’ telescoping cylinders/crown sheaves with cable guides, (2) winch sheaves/snubbing sheaves, SRS fall protection, retractable flow tube design, non-swivel boom pole on curb side winch, (2) mast supports, 1” lifting cables, mounted on 5 axle Crane Carrier (3rd axle drop), with 375k Volvo Penta engine, 150 gal fuel capacity, hydraulic self-leveling components, 6 speed Allison transmission, 1:1 gear box, (2) 65 gpm pumps, (2) 30 gpm pumps, (1) 28 gpm Commercial shearing pump, 40 gal accumulator storage, single man cab, hydraulic leveling jacks Price on Request

Manufactured 1960’s, double drum, single rig mast, 64’ x 250,000# (tubing and rod racks), 70 ton blocks, 2 lines, Detroit diesel 60 gpm @ 2000 psi, hydraulic system, air clutch. Rig was refurbished 2013/2014 at a cost of $130,000: repairs included used 65’ derrick installed, new 1” main line, repairs to air system, hydraulic system upgrade, leveling jacks, derrick ljghting, tires, 70 ton blocks installed. But the rig has been sitting since 2015 and now needs rebuilding. It doesn’t run. Price as is: $19,500

Manufactured 1980, completely refurbished 2004, 5 axle double drum well service unit, double 15 Parmac brake on main drum, 96" x 180,000# hydraulic raised mast, mast lighting, Detroit 60 Sereis engine, 5860 Allison 6 speed transmission, 4 hydraulic leveling jacks, dual manual outriggers, PD12 Braden utility winch, McKissick 100 ton tubing block 21-31 diving, 1000" of 1" tubing line, 13000" of 9/16" sandline Price: $225,000

CARDWELL KB200B SERVICE RIG(Ref#11674Ta) 72’ x 140,000# stiff mast, 40 x 10 double drum drawworks, 2 aux deck winches, tubing board, rod board, cat walks, railing, stairs, floor BOP controls and accumulator bottles, McKissick 75 ton tubing block and hook, mounted on 5 axle carrier, Detroit 8V71 diesel engine, Alliston CLBT4460 auto transmission PRICE: $127,500

Rig manufacture 1980, mounted on 1980 GMC Brigadier with Cat 3208 engine, includes elevators & misc tools, also includes 1996 1-ton Super Duty tool truck, tandem axle, Cat 3208 diesel, sitting 1-1/2 years Price: $92,500

1980, 475 hp, single drum (new), reworked, 96" x 205,000# hydraulically raised mast, 6 lines, crown block: 3 new sheaves blocks and bearings, racking board, guide wires, (2) hydraulic hoist, weight indicator, block, elevator links, fall safety device, work platform, mounted on 4 axle carrier with Detroit Series 60 diesel engine, Allison transmission, rig in excellent condition and has been well maintained, ready for use PRICE: $115,000

SKYTOP BREWSTER RR400(Ref#13190T) Mounted on 4 axle carrier, single drum drawworks, 8x7 disc assisted brakes, tubing board, Cat3406B engine, Allison 860DB transmission, 100 ton McKissick block, Foster 58-92R tongs, misc hand tools, approx 36" base beam for rig, ready to work Price: $110,000

Refurbished 2017, 4 lines, 96’ x 205,000# mast, 8V71 Detroit engine, mounted on CCC, 75 ton McKissick blocks, tubing board, rod basket, work platform, rigged up and working in field Price: $295,000

Manufactured 1977, 72’ x 125,000# derrick, 8V71 Detroit engine (rebuilt), Allison 750 transmission, 6500’ of new 5/8” sand line, tubing line new, drum brakes new, new style McKissick blocks, working daily Price rig only: $157,500

Double drum drawworks with hydromatic brake, 10" brakes, 96" x 180,000# derrick, mounted on 4-axle PEMCO carrier with hydraulic support legs, 8V71 Detroit, 4460 Allison transmission, Spicer 784 split shaft gearbox, 250 hp right angle drive, 650" of 7/8" tubing line, 8000" of 9/16" swab line, 100 ton Sowa block, hydraulic winch, hydraulic weight indicator, 84" links, 2-3/8" and 2-7/8" tubing elevators, BJ tubing slips, Foster 5893R power tongs with lift in derrick, rod hook, rod stripper, rod elevators, wrenches, transfers, rod fishing tools, misc hand tools and connections Price: $140,000

Manufactured 1974, double drum drawworks, double triple 96" x 180,000# derrick with a hydromatic. The rig has working line with heavy traveling block and approx. 12,000" 9/16 sand line. Mounted on Skytop carrier with tandem steering and rear ends 4 axles W/ tag axle, 4 leveling jacks, powered by an 8V-71 with a Allison 4460 transmission, (note transmission was overhauled in early 2000"s) and the engine has a new head on right bank. The rig has two leveling jacks on the rear and two leveling jacks on the front which are located right behind the steering axels. Tooled out with hydraulic rod and hydraulic tubing tongs, air slips, rod and tubing elevators, hand tools and misc over items. PRICE REDUCED: $115,000

10 x 13 pole, double Drum, Franks 33” air over grease, brakes in good shape, 7/8” tubing line, tubing blocks, tong pressure adjustment, hi/low on tubing, air slips control, master kill on drawworks, Foster 36 with 8’ lift ram, air backup, swing around tong rack, mounted on 2001 Freightliner F80 truck, Cat C12 Series 3125, Fuller 9-speed transmission, PTO, winch for pole scope Tulsa 48, blocks raise pole, dual fuel tank, dual battery, 50 gal hyd tank, toolboxes, hydraulic outriggers, BJ rod tongs, ¾” and 7/8” heads, tools, swabs, extra tongs, orbits, drilling head Price: $242,500

Double drum (second drum is removed, rig is running as single drum), hyd pole and down riggers, mounted on 1990 Crane Carrier, 9 sp Eaton Fuller transmission, 100,000 miles, 8 x 10 telescoping poles, 3/4” cable, no tooling Price: $52,500

10 x 13” pole, single drum, mounted on 1980 Brigadier 9500 Series truck with 671 inline Detroit, drop box, travelling blocks, tubing lines, hyd jacks, no tooling, sitting since 2000 PRICE: $49,500

Cable Tool Drilling and Completion Rig, 60" double poles rated to 150,000#, 5000" drill capacity, 10,000" pull capacity, propane Waukesha 145 engine, 500 gal propane tank, trailer moutned with International 4300 truck, last drilled 2012, 2300" drill line on drum, 3500" on spool casing drum, heavy block sandline drum, cat heads each side, tooling, spare engine Price: $72,500

400’ of 7/8” block line, 9/16” sandline drum (no cable), 2000’ of ¾” drilling drum, 3 McKissick sheaves, air clutches and controls, mounted on 1961 Mack truck with 250 hp Cummins engine, older rig but runs good. Includes elevators, oil saver pump, no BJ tongs, currently working. Price: $87,500 - Pennsylvania

Triple drum, friction clutch, cathead (sandline holds 2400’ of 5/8” line), mounted on tandem axle Chevy truck with 427 gasoline engine, 8-5/8” x 45’ single pole, new tires, power steering, wireline unit, good usable rig for shallow oil/gas lease, drills, workover, swab capabilities, no tools Price: $112,500 - Oklahoma

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Substructure type ZT90 with max capacity 202,000 lbs, 101 US ton (900KN) consisting of 6 x telescopic legs, box type, with rotary table base and setback base independent of each other

1 x generator Model: VOLVO 300KW, Voltage 130/400V, Frequency: 50HZ, Generator and MCC are housed in a single house. Lighting fixtures are rated for service in classified areas as per API RP 505 for rig system

11” 3K Annular BOP, 11” 3K Double Ram (2 sets of rams provided), Drilling Spool, BOP Test Pump, (air powered) with hoses and chart recorder. BOP Test Base. BOP Stack Lifting device. Transport Skid. BOP Control Unit. Choke and Kill Manifold 3-1/16” X 3K. 3-1/16” X 3K Manual valves. Non-return Valve on kill line. All high pressure fire proof hydraulic hoses, hand wheels etc.

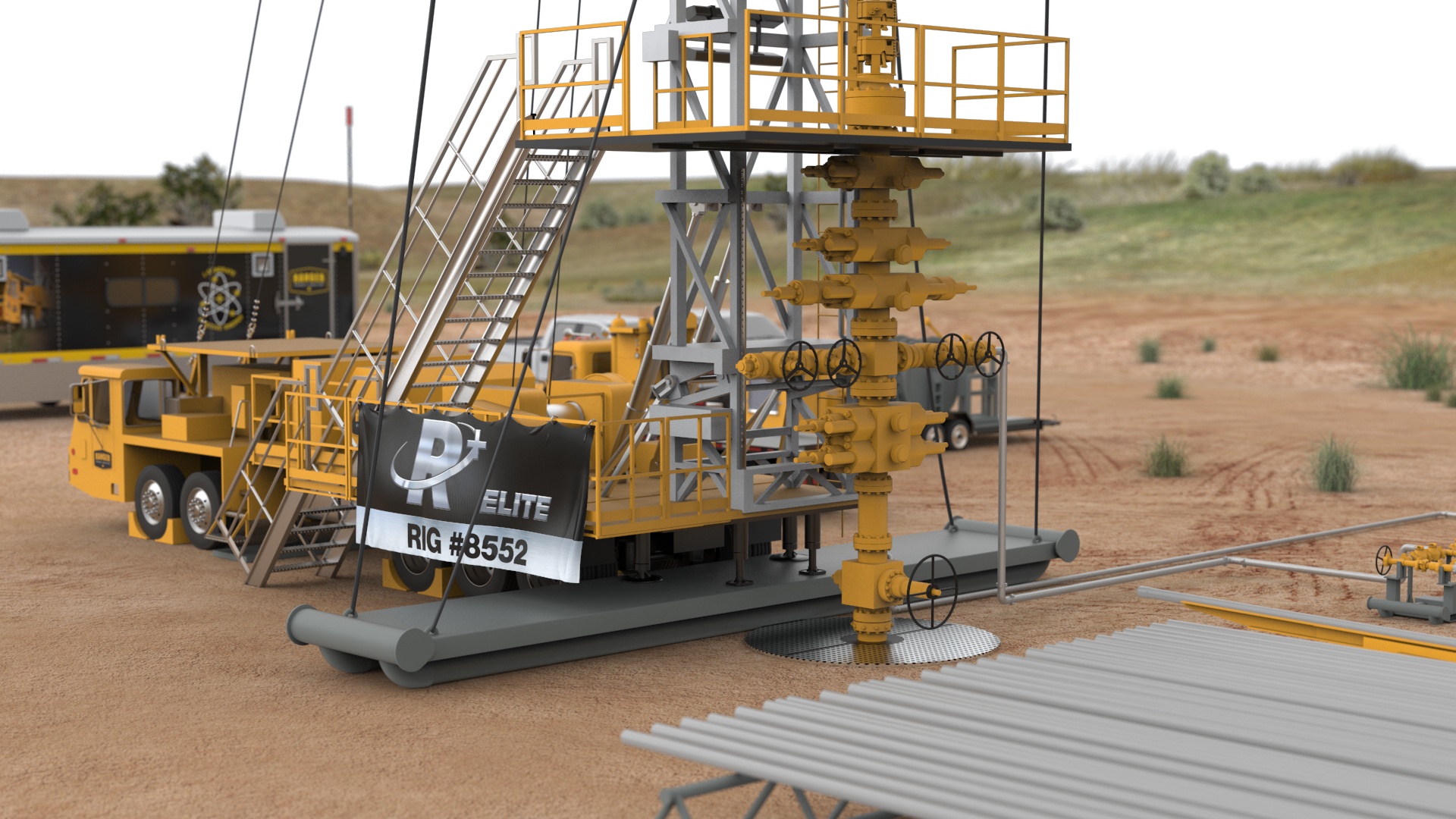

Axis Energy Services is proud to provide consistent production and workover services for a valued customer out of the Permian Basin with daylight Rig 35 in New Mexico. Our hardworking crews get the job done right and exhibit our culture of safety and excellence every day.

Our team solves customer challenges from routine to highly complex. Well servicing rig packages include rig base beams, power swivels, BOPs, closing units, pipe racks, hydraulic catwalks, and a broad range of pumps and tanks matched to each job.

To ensure our website performs well for all users, the SEC monitors the frequency of requests for SEC.gov content to ensure automated searches do not impact the ability of others to access SEC.gov content. We reserve the right to block IP addresses that submit excessive requests. Current guidelines limit users to a total of no more than 10 requests per second, regardless of the number of machines used to submit requests.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

SCOPE: To provide a representative basis for determining the availability, capability, dependability, reliability of Stability Systems on Land Based Work-Over Rigs and the recommended practices and procedures for their safe use.

The rig location area may grade away from the well bore along centerline II at a maximum drop of 1:20. The cross grades, parallel to centerline I, should be level. The area shall provide a minimum bearing capacity of 6000 psf.

The flat plate anchor is stamped from metal plate then folded into a reduced profile for insertion into the ground. The flukes are expanded into undisturbed soil, again by tamping or impact, to provide the holding power for this type of anchor. A base plate supports the extended flukes providing added strength and stability.

The "Well Head" is located at the center of the Chart. This will be considered the base reference point for positioning of the guy anchors. The holding capacity of the anchors will then be determined by the zone in which they are located. ie: A, B, C, or D.

The near parallel baseline of Zone "D" to the cross lines NS and EW is 25 feet. (see Northwest and Southeast Quadrants). The far baseline of Zone "D" to the cross lines is 35 feet. (see Northwest and Southeast Quadrants). The vertical distance from the cross lines to the end of the base line is 60 feet and 85 feet to the end of the far line. The area located within this geometrically angled rectangle, within each quadrant, is the area comprising Zone "D".

Using the chart: An anchor in Zone "A" located a horizontal distance of 70 feet from the "Well Head" would require an anchor of what minimum holding capacity? On the chart move along the horizontal legend from left to right until you reach 70 feet. At this juncture proceed vertical until you intersect the curved line for Zone "A", now follow the intersecting horizontal line, left toward the vertical legend. We have now determined that the minimum holding capacity for the anchor, at this precise location, is 20,000 pounds.

Standing at the "Well Head", with the well bore immediately to your back, proceed North (in direction monkey board is facing) 24 paces. (The pace length is not as important as the numerical relationship of the units and the consistency of the unit length. The method will work with any unit of length as long as the same unit is used throughout.) Place a stake or other marker at this location (Bench Reference). Turn West 90 degrees and proceed forward 10 paces. At this location turn your body so that the front portion of your anatomy is approximately parallel to the radial of the guy anchor. If the northwest guy anchor is forward of your right shoulder and the southeast guy anchor is aft to the rear of your left shoulder, it can then be presumed that the radial angles are within acceptable parameters. Repeat the procedure from the bench reference, this time to the east, proceed ten paces. In this orientation the northeast anchor should be forward of the left shoulder and the southwest anchor should be aft of the right shoulder.

In keeping with the concept, which embraces the acceptance of new and innovative approaches, that are based on sound engineering principals, the following alternative, recommended installation guideline, is presented.

A survey of 13 drilling contractors operation 193 drilling rigs in northern Canada and Alaska indicated that there is a wide range of experience and operating practices under extremely low temperature conditions. While there is very little precise information available, there have been a sizeable number of failures in portable masts while in the lowering or raising process in winter. Thus the exposure to low temperature failures focuses on mast lowering and raising operations. Based on reports, however, this operation has been accomplished successfully in temperatures as low as -50 degrees F. While the risk may be considerably greater because of the change in physical characteristics of steel at low temperatures, operators may carry on "normal" operations even at extremely low temperatures. This may be accomplished by a program of closely controlled inspection procedures and careful handling and operation. This should reduce damage and impact loading during raising and lowering operations. At the present, there seems to be no widely accepted or soundly supported basis for establishing a critical temperature for limiting the use of these oilfield structures. Experience in the operation of trucks and other heavy equipment exposed to impact forces indicates that -40 degrees F may be the threshold of the temperature range at which the risk of structural failure may increase rapidly. Precautionary measures should be more rigidly practiced at this point. The following recommended practices are included for reference:

* Make use of any practical, available means to warm sections of the mast, such as using high pressure steam to heat the points of attachment between the mast and its base; also timber bonfires, and the like.

If maintained to these tolerances the sags will indicate a pretension of 1000 pounds for crown to ground guywires and 500 pounds for tubing board guywires. this is based on the use of 5/8 inch, 6x19, or 6x37 class, regular lay, ips, IWRC wire rope, installed according to the rigging guidelines set forth in chart depicted in Figure 5-5

The drawing on the following page, Figure 5-4, (SAME AS FIGURE 4-4) is another illustration of the continuing evolution of Rig Stability System engineering and design. It represents the latest API thinking relative to planing and preparing a Rig Stability System.

CAUTION: SOLE EMPHASIS SHOULD NOT BE PLACED ON PULL TESTING OR ALTERNATIVES TO PULL TESTING AS THIS MEASURES ONLY ONE COMPONENT OF THE RIG STABILITY SYSTEM.

The rig contractor should be responsible for the following: a. Insuring that anchor capacities are verified and that anchor spacing and capacity is suitable for the mast guying pattern and anticipated loading.

b. Records of pull testing or records of other methods used to verify temporary anchor capacity should be retained by the rig contractor until the job is complete and the guy wires have been removed from the anchors. The records should indicate the capacity of each anchor, the date of verification, name and phone number of the party responsible for verification, and the soil condition at the time of verification.

OUT OF AN ABUNDANCE OF CAUTION IT IS EXTREMELY IMPORTANT TO POINT OUT THAT THE PREVENTION OF RIG UPSET IS DIRECTLY DEPENDENT ON THE TOTAL INTEGRITY OF THE RIG STABILIZATION SYSTEM. THE SYSTEM INCLUDES ALL OF ITS COMPONENTS AND IS ONLY AS SOUND AS ITS WEAKEST MEMBER.

Our research has concluded, that the latest State-of-the-Art in RIG STABILIZATION is to be found in the pending American Petroleum Institute, Recommended Practice for MAINTENANCE and USE of DRILLING and WELL SERVICING STRUCTURES.

8613371530291

8613371530291