workover rig blocks manufacturer

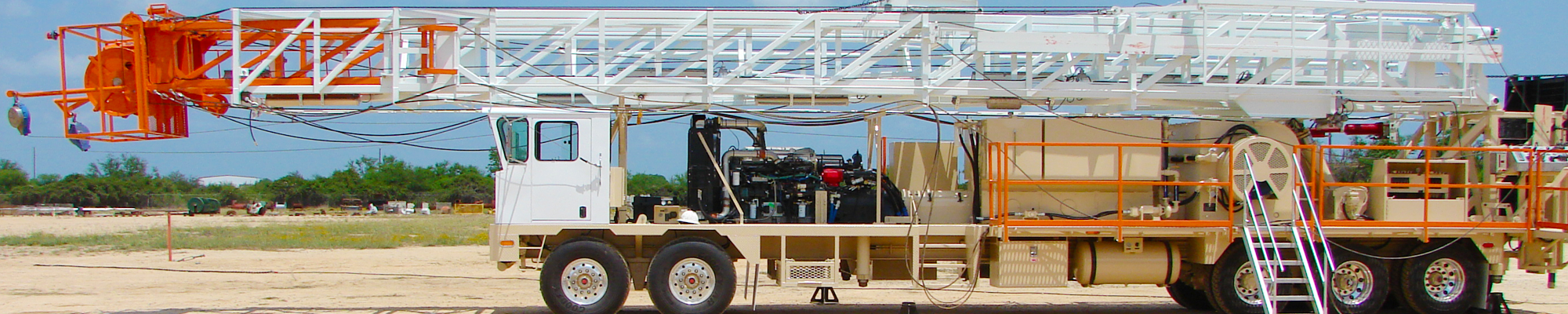

Manufacturer of standard & mobile rigs & carriers for oilfield applications. Includes well servicing from 14,000 ft. to 22,000 ft., workovers from 10,000 ft. to 16,000 ft. & drilling from 6000 ft. to 10,000 ft. Specifications include brakes range from 28 in. dia. x 8 in. wide to 42 in. dia. x 12 in. wide, barrels from 12 3/4 in. x 38 in. to 18 in. x 43 in., chains from 1 1/4 in. to 1 3/4 in., clutches of 24 in. with single & 2 plate air friction outboards, shafts of 5 in. dia. to 6 1/2 in. dia. & gross weights from 63,200 lbs. to 115,000 lbs. Also includes forged steel, demountable options, mufflers with spark arrestors, dry type air cleaners, transmissions with torque converters, water splash brake cooling & up to 6 axles.

Welcome to Pickett Oilfield’s traveling blocks & hooks web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used traveling blocks and traveling equipment to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including traveling blocks & hooks to choose from at competitive prices. Browse our inventory of traveling blocks and traveling equipment for sale at competitive rates.

Bishop Lifting specializes in supplying McKissick® Oilfield Blocks for Drilling, Oilfield Service and Rig Moving applications. The Traveling Blocks available include the RJ and RP style Drilling blocks with McKissick® Roll-Forged® sheaves with flame hardened grooves and an API profile. The Tubing Blocks available are the Series 70 and Series 80. The series 70 has a spring loaded hook that is better for heavy usage and larger depths. It"s also available with Rod Hook and Clevis and utilizes the new Split Nut Retention System. The McKissick® M-491 Tower Block, also called a Derrick Block or Man Rider Block, is available from 4 to 30 tons, and is suitable for hoisting personnel . The McKissick® Alloy High Capacity Blocks are the Rig Movers and Gin Pole operators choice of snatch blocks. Model 434 with hook, model 435 with shackle, and model 401 are available in wire rope sizes 1" to 1-1/4" in capacities from 25 to 60 tons.

Split Blocks are customized for service rig applications. TSM designs, manufactures and monograms split blocks as per API 8C and PSL-1 or 2 per client request. Our Split Blocks maximize mast headroom, which can allow a Top Drive to be installed in compact masts.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Bentec designs and manufactures a large range of Bentec Traveling Blocks to meet your specific drilling requirements. Sufficient weighting ensures fast free fall. Compact and streamlined design eliminates interference with mast or derrick components.

Inserting and pulling up pipe tubing from oil wells is a precise and challenging job that not every rig is up for. That’s why you need a mobile workover rig from Dragon to get it done right every time. Our workover rigs are state-of-the-art and ready to tackle even the harshest conditions. A workover rig is perfect for site preparation while a standard mobile oil rig can handle a variety of piping tasks. Need workover rig parts, or service on another mobile rig? Dragon has that covered with our parts selection, too. View all of our workover rigs and other drilling rigs today.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Cameron provides traveling blocks from 275- to 1,250-tonUS. Precise weighting of our traveling blocks ensures fast free-fall, while their streamlined, compact design eliminates interference with mast or derrick components. Their long service life is enhanced through quality fabrication and the advanced metallurgy of sheaves, beckets, and components. Cameron traveling blocks feature low-inertia sheaves for high performance and reliability.

American Block manufactures a wide range of traveling blocks to meet the diverse needs of oilfield drilling. Whether 200 tons or 1500 tons, traditional drilling or top drive, conventional style or split configuration, American Block can provide a traveling block solution for the drilling rig. In addition to our various standard blocks, customizable design options are available. All of our traveling equipment is designed and manufactured in accordance with API 8C, and third-party certification (e.g. ABS, DNV, CE) is available as an option.

Cameron provides traveling blocks from 275- to 1,250-tonUS. Precise weighting of our traveling blocks ensures fast free-fall, while their streamlined, compact design eliminates interference with mast or derrick components. Their long service life is enhanced through quality fabrication and the advanced metallurgy of sheaves, beckets, and components. Cameron traveling blocks feature low-inertia sheaves for high performance and reliability.

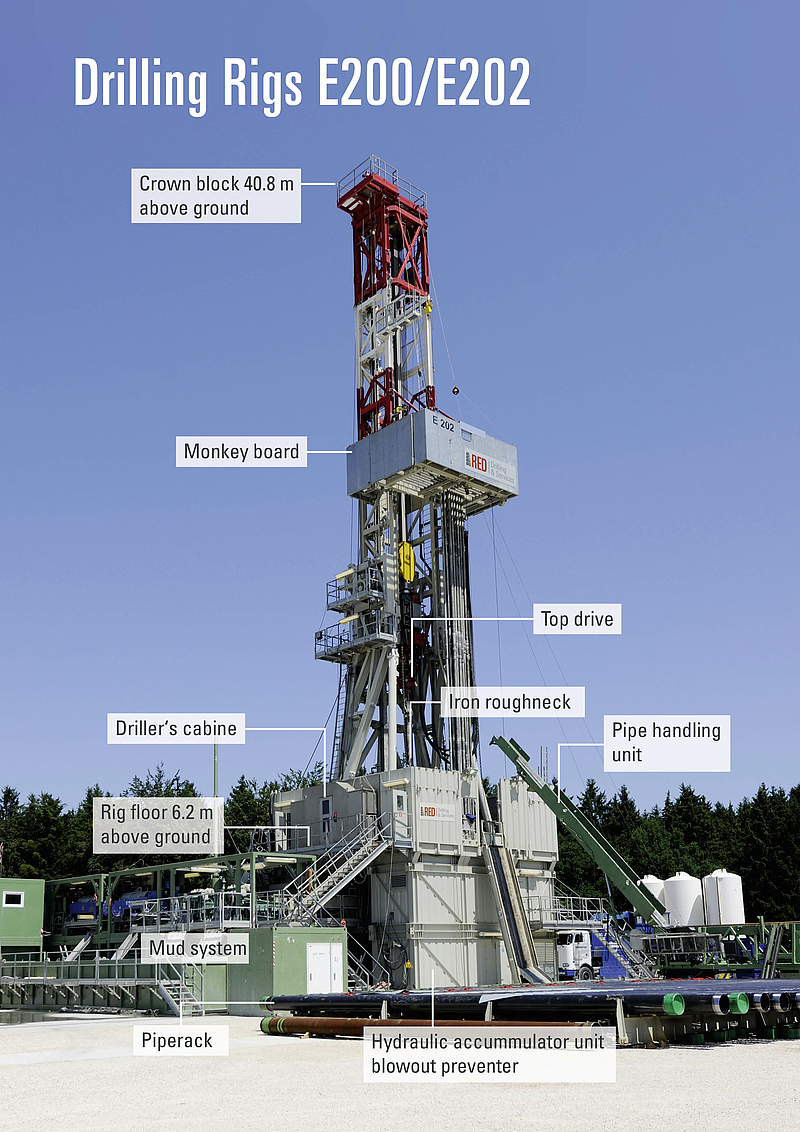

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

American Block manufactures a wide range of traveling blocks to meet the diverse needs of oilfield drilling. Whether 200 tons or 1500 tons, traditional drilling or top drive, conventional style or split configuration, American Block can provide a traveling block solution for the drilling rig. In addition to our various standard blocks, customizable design options are available. All of our traveling equipment is designed and manufactured in accordance with API 8C, and third-party certification (e.g. ABS, DNV, CE) is available as an option.

EVDANCO OGC SRLoffers a wide range of brake blocks such NON ASBESTOS OILFIELD BRAKE BLOCKS especially designed for all known drawworks brands as well as customized models that can be installed on drilling and workover rigs.

The blocks are manufactured with special fabrics of uniform density and friction surfaces that adapt precisely to the shape of brake drums. The blocks are manufactured with fiberglass yarns mixed with synthetic and natural fibers, according to specific technical requirements. The yarns contain copper or brass metallic inserts that ensure efficient dissipation of heat. The woven are impregnated with special resins, and processed appropriately to ensure continuing and stable friction under low and high temperatures. The sets of blocks include non-asbestos wiper blocks, retaining screws and sealing plugs.

Brake blocks are mainly used in oil industry services. They equip the brake bands of the drawworks, air clutches of the different transmissions of the drilling rigs and other wellhead equipment.

Brake blocks are mainly used in oil industry services. They equip the brake bands of the drawworks, air clutches of the different transmissions of the drilling rigs and other wellhead equipment.

Are molded blocks mounted at the dead end of the brake band. Provide a non-abrasive scouring and polishing action on the brake flange. Prevent lodging of metal particles in the other blocks and promote a better wear pattern.

8613371530291

8613371530291