workover rig blocks quotation

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Explore the various traveling block in drilling rigs products available for wholesale at Alibaba.com. Get a traveling block in drilling rigs for drilling water wells, water exploration holes, geological exploration, coal mines, and other kinds of mining. Some traveling block in drilling rigs options use caterpillar tread to move. Others use rubber tires, while others require a separate means of transport. Caterpillar tread propulsion can climb up to 25 degrees inclination. Some products in the range are capable of drilling over 200 meters, while others are only used for open-pit mining with depths of around 3 meters. Drilling can be done vertically downwards, horizontally, or in a slanting direction. Drilling speed depends on the power of the machine and the general hardness of the surface. The hole diameter can vary from 90mm to 200mm.

traveling block in drilling rigs options also include an air compressor, a mud pump, drilling rods of various sizes, connectors, and a drilling tower. Drilling is done using drill bits of various shapes, sizes, and compositions. You can choose between diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits. Each drill bit uses different drilling methods, including rotary, percussion, blast hole, and core drilling.

Smaller products have a lifting power of around 25 kilonewtons and weigh about 2,500kgs. They’re ideal for small-scale drillings such as farms and homes. Larger ones are faster with more power, making them ideal for commercial use. Browse through Alibaba.com and find a traveling block in drilling rigs that’s ideal for your work scope. Buy mine drilling rigs for your wholesale business at competitive prices. Chinese wholesalers provide you with customization options and great after-sales services.

Welcome to Pickett Oilfield’s traveling blocks & hooks web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used traveling blocks and traveling equipment to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including traveling blocks & hooks to choose from at competitive prices. Browse our inventory of traveling blocks and traveling equipment for sale at competitive rates.

PickettOilfield.com offers prospective buyers an extensive selection of quality new and used drilling rig equipment, including Blocks and Hooks to choose from at competitive prices. For more information or to request a quote, please contact us by phone at

Bishop Lifting specializes in supplying McKissick® Oilfield Blocks for Drilling, Oilfield Service and Rig Moving applications. The Traveling Blocks available include the RJ and RP style Drilling blocks with McKissick® Roll-Forged® sheaves with flame hardened grooves and an API profile. The Tubing Blocks available are the Series 70 and Series 80. The series 70 has a spring loaded hook that is better for heavy usage and larger depths. It"s also available with Rod Hook and Clevis and utilizes the new Split Nut Retention System. The McKissick® M-491 Tower Block, also called a Derrick Block or Man Rider Block, is available from 4 to 30 tons, and is suitable for hoisting personnel . The McKissick® Alloy High Capacity Blocks are the Rig Movers and Gin Pole operators choice of snatch blocks. Model 434 with hook, model 435 with shackle, and model 401 are available in wire rope sizes 1" to 1-1/4" in capacities from 25 to 60 tons.

Main Parts and Quotation for XJ550 Workover RigItem Descriptions Model Technical Specification Qty/UnitWorkover Rig XJ550RemarkI Main part The main unit is self-propelled structure,including: self-propelled carrier, powersystem, double engines, transmissionsystem consists of two hydraulic torqueconverters, angle gear, transfer case, doubledrum drawworks, three sets of clutches,rotary table, auxiliary brake, chain drivingdevice, mast and crown block assembly,double telescoping cylinders, hydraulic cat,double raising cylinders, double hydraulicwinches, hydraulic system, pneumaticsystem, operation system, crown saverdevice, electrical system, substructure andMud boat etc.Max. hook load: 1350kNTraveling system: 5x4Hook up speed: 0.2-1.3m/swireline diameter: Φ26mmmast height:33msubstructure height: 3.7mmove way: self-propelledmax. road speed: 45km/hoverall dimension: 19000x2910x3100mm1 Carrier Drive way 10 x 8Max. road speed 45km/hSlope gradient 30%Approach angle/departure angle: 33 o /18 oMax. ground clearance 311mmTurning radius 16.5mMax. width 3mIncluding: cab, axles, suspension, frame, subframe, four hydraulic jacks and steeringmechanism, steering hydraulic system,double fuel tanks, air bag, transmissionsystem, took kit, mud fender and safetyguardrail, electrical system and lightingsystem, back alarm device1 set1 set1.1 Frame CJ-01B Including crossbeam assembly, frontboarding, mud-guard, raising cylinderbracket and beam of hydraulic jack

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The 844 TD-HD Workover Rig by Franks has a 3/4″ Tubing Line, Air Clutches and is powered by a Detroit Diesel 6V71 Motor & Allison CLT 4460 transmission. The 844 TD-HD Workover Rig is in excellent working condition, has a current OK Tag and clean Title.

Performance proven main drum draw works assemblies are modular construction for versatile rig assembly. Designed to allow maximum parts interchangeability and easy add-on features to customize this for your specific operation.

The hoisting system on a drilling rig does the heavy lifting on the rig. It is used to raise, lower, and suspend the drill string and lift casing and tubing for installation into the well.

A schematic of the hoisting system is shown in Figure 9.03 for a kelly drive rig. In this figure, the derrick (or mast) provides the structural support for the hoist system. It must be capable of supporting the entire load on the system including the weight of the drill string (accounting for buoyancy effects) and any frictional forces.

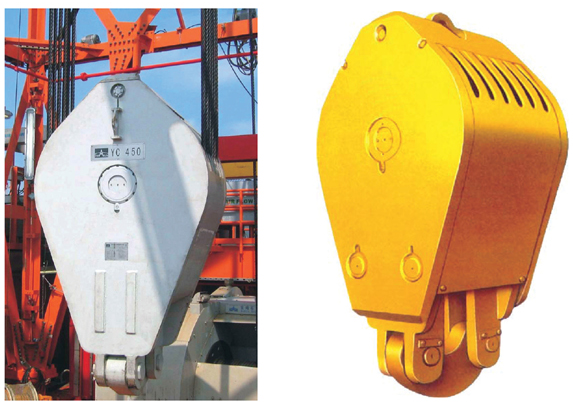

The crown block and the traveling block form a Block and Tackle System on the rig. The drill line can be strung as pairs of 2 through 12 lines (six pairs). The greater the number of lines (and pulleys) in the block and tackle system, the greater its lifting power but at the expense of slower upward and downward movement of the system.

The drawworks of the hoisting system is a winch that reels the drilling line in or out causing the traveling block to move up or down. The drawworks is the component of the hoisting system that consumes energy from the power system. The drum on the drawworks is grooved to accommodate a specific size drilling line. Figure 9.04 shows a photo of an actual drawworks used on a drilling rig .

Not shown on the schematic or the photo is the braking system on the drawworks. Modern rigs use both a mechanical brake and an electromagnetic brake. The braking system is an integral part of the drilling process because it is used to control the Weight-on-Bit (WOB) during drilling. The two most important drilling parameters within the Driller‘s control to maximize the Rate of Penetration (ROP) are the weight-on-bit and the rotational speed of the rotary system in Revolutions per Minute (RPM).

Working on a drilling rig is risky business by anyone’s standards. Safety must a matter of paramount concern in order to prevent injuries and accidents.

Unfortunately, accidents that result from failure to pay attention to safety protocols and procedures happen all too often. A good motto to keep in mind is that no job is so important or service so urgent that rig operations cannot be done with a “safety first” mindset.

Workers on drilling and workover rigs may sometimes take matters into their own hands, resulting in safety violations or, worse, injury. And while it is the rig operator’s responsibility to see that they are sufficiently trained and that the workplace is free from hazards, it is vital that every person on a rig site develop a keen sense of safety.

Grainger says that routine safety audits at rig sites are essential. Both the Occupational Safety and Health Administration (OSHA) and OGP provide fact sheets and a variety of tools for performing on-site safety audits.

Implement the use of wearable ID tags and routine shift check-in/check-out procedures. This let supervisors and emergency responders know the location of every worker on the rig at all times.

Oil and gas rig workers may require ready access to tool boxes equipped with equipment needed to take care of repairs and to perform routine maintenance. Depending on the worksite, these may include electrical parts, material handling aids, plumbing components, hand tools, power tools, and welding gear.

Emergency Preparedness OSHA requires emergency response plans for every drilling site, which can vary depending on the rig’s location and layout. Grainger says that an effective plan should always include the ready availability of appropriate emergency and rescue equipment, as well as a program for training and drilling of all supervisors and workers on emergency escape and rescue procedures.

Oilfield safety is no different than safety anywhere else. Common sense, good judgment, and the right equipment for the job help to ensure workers are protected from injury. But remember the motto: No job is so important or service so urgent that rig operations cannot be done with a “safety first” mindset.

Block Energy Plc, the exploration and production company focused on the Republic of Georgia, is pleased to announce execution of a non-binding Memorandum of Understanding ("MOU") with Georgia-based drilling contractor, JSC Norio Oil Company ("NOC"), for the provision of a drilling and a workover rig. Subject to a final agreement, these will be utilised on the 2018/2019 work programmes across Block"s three licence areas: Norio (100% working interest), Satskhenisi (90% working interest) and West Rustavi (75% working interest after earn-ins described below) which collectively have net proven oil reserves of 1.5 million barrels plus 61 million barrels of oil and c.473 billion cubic feet ("bcf") of gas classified as net unrisked 2C contingent resources.

Subject to a final binding agreement, NOC will provide an A50 workover rig that will be used to undertake a short three well workover programme at Satskhenisi before being moved to the nearby Norio licence where eight candidate wells have been selected for workover. Block is aiming for the eight Norio wells to be completed and on production by Q1 2019. It is anticipated that the rig will also be used at West Rustavi, where two wells will be prepared for side tracks and the re-testing of a legacy gas discovery in the Lower Eocene, a play being targeted on neighbouring licences by Schlumberger, the leading oil and gas services provider and operator. Under an existing agreement, the preparation of the two wells at West Rustavi will trigger an increase in the Company"s working interest in the West Rustavi licence to 50% from 25%.

In addition, it is planned that NOC"s ZJ40 drilling rig will drill two high impact horizontal side tracks in the West Rustavi permitduring Q4 2018 / Q1 2019. Targeting initial oil production of c. 600 barrels per day. The two side tracks will increase the Company"s working interest in the West Rustavi licence to 75% from 50%.

Paul Haywood, Director of Block Energy, said: "The MOU signals the start of exciting times for Block during which shareholders can expect high-impact news flow on work programmes commencing across our three licence areas in Georgia. Following a comprehensive tendering process, the principles for favourable terms for rig contracts have been negotiated which we expect, once finalised, will secure considerable cost savings.

"The Company is fully funded to complete the first of a three phase work programme focused on scaling up production to a gross 900 barrels of oil per day within 24 months and on testing legacy gas discoveries at West Rustavi, which have been assigned 600 bcf of gross, unrisked contingent resources. The MOU secures two suitable rigs for the Company for a period of 12 months, giving us the flexibility and security to execute and complete our first phase of work before immediately moving into phase two with the same rig and crew. Furthermore, the terms of the agreement reduce the risks related to rig availability and cost overruns associated with hiring on a daily rate basis. We look forward to providing further details of the final contracts along with updates as operations get underway."

Block Energy (BLOE.L) is an AIM quoted oil and gas company with a growing portfolio of production, development and exploration assets in the Republic of Georgia. Block holds a 100% Working Interest ("WI") in the producing Norio licence, a 90% WI in the producing Satskhenisi licence and a 25% WI in the West Rustavi licence with the right to farm-in to up to a 75% WI. Block"s three licences lie in the heart of the Schlumberger"s 100% held position in the Kura basin, which at its peak produced ~70,000 barrels of oil per day ("bopd") in Georgia and is estimated to hold over 7 billion barrels of proven reserves in Azerbaijan and North Caucasus (Russia).

Appraisal of West Rustavi is being conducted contemporaneously with the rehabilitation of the producing Norio (100% WI) and Satskhenisi fields (90% WI) which provide immediate production uplift on commencement of field operations in Q3. The near-term target is to raise production to 900 bopd from 15 bopd within 18 months via a low cost, low risk workover and sidetrack programme, and then to utilise the cash flow to drill horizontal wells and sidetracks to raise production to c.2,000 bopd. Oil production on the fields offers excellent netbacks, with the current cost of production of c.US$25 per barrel providing netbacks of c. US$30-35 per barrel.

8613371530291

8613371530291