workover rig components pdf quotation

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Download Workover & Drilling Rig Inspection Checklist As we mentioned in the Rig Audit Article, rig inspection is an important process that shall be done from time to time. Especially, after the rig moving to a new drilling location.

In order to solve low degree of work over automation, labor-intensive job dangerous, poor working environment issues, Shengji has developed a series of mechanical work over system, including workover automatic system, minor workover automatic system and snubbing operation equipment.

Oil well workover is a high-tech, high-risk work. The conventional oilfield workover rig has problems such complicated operating procedures and high labor intensity. Shengji, in cooperation with the Shengli Drilling Corporation, have designed an oilfield workover rig automation system.

The oilfield automatic workover rig has a high degree of automation adopting modular integration and advanced robot closed-loop control technology. It functions as self-diagnosis, leakage and short circuit protection and fault alarming, etc. It has remote monitoring capability.

The automatic workover rig greatly increases the automation of workover operations, reduces the number of operators, decreases workers’ labor intensity. The technology is advanced, safe and reliable.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

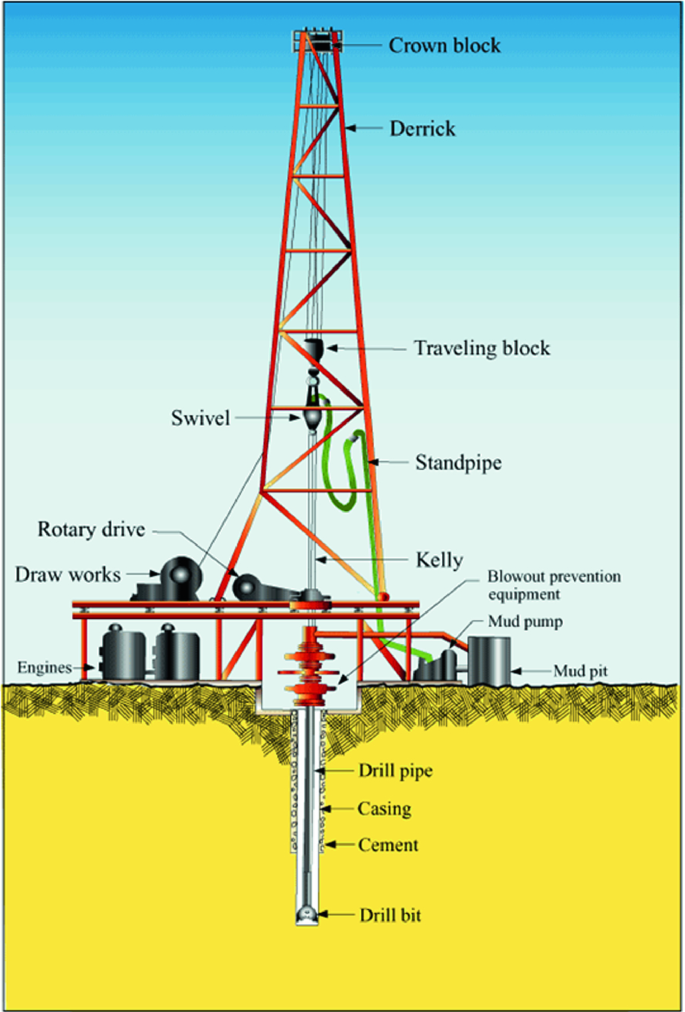

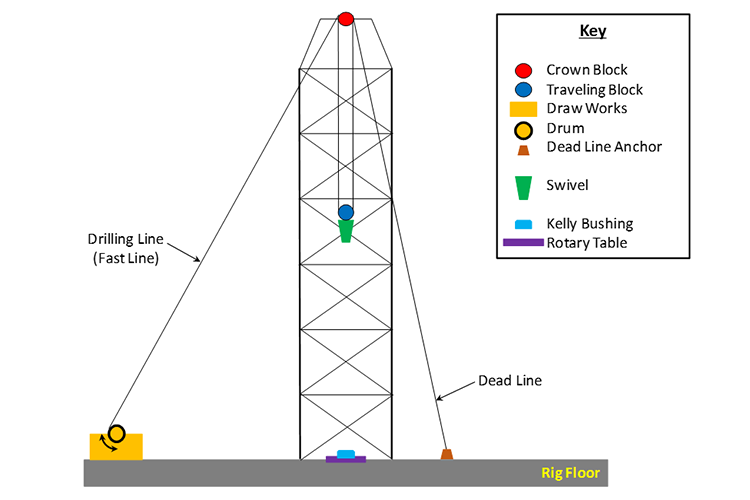

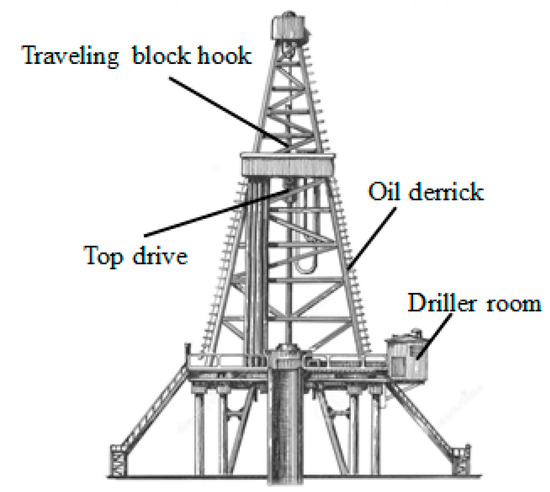

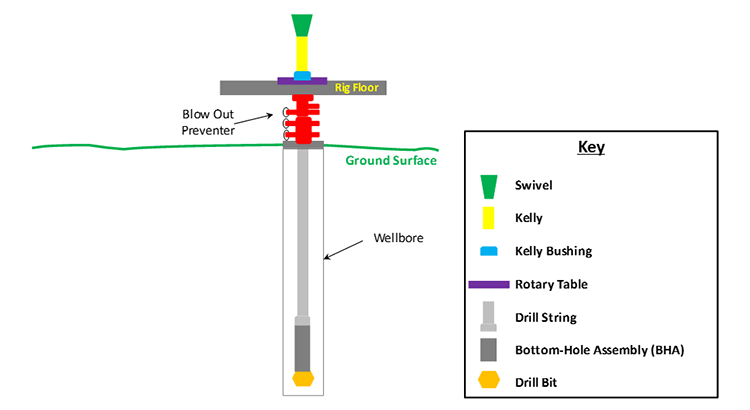

The power system on a drilling rig provides the power for the other main systems on the rig and other ancillary systems, such as electrical systems, pumps, etc. The system typically consists of a prime mover (the component of the power system that generates the raw power) and a means to transmit the raw power to the end-use components on the rig.

Historically, coal was used to generate the power for drilling rigs; however, modern drilling rigs use other sources of fuel. Typically, modern rigs are now run using an internal combustion engine with diesel or lease fuel. Diesel oil is a petroleum-based fuel that is a product of the distillation process. If the rig is running in a developed field, then the field may have a small on-site refinery that is used to distill the diesel fuel. If the rig is drilling an exploration, appraisal, or delineation well, then the fuel will need to be delivered from an external source and stored on-site.

Lease fuel is typically produced natural gas. As we have learned, natural gas is always produced along with crude oil. Again, if the rig is drilling wells in a developed field, then the field may use the natural gas or Natural Gas Liquids (NGL) to fuel the prime mover. This natural gas may be processed to remove NGLs if a gas plant is available on site; may need to burn these hydrocarbon liquids (possible sales product) if a gas plant is unavailable; or may burn the processed NGLs (butane).

In the mechanical transmission, power is generated with the prime mover and is transmitted to the end-use components by the application of chains and sprockets (similar to a bicycle), drive belts, drive shafts, etc. In a direct current (DC) electrical system, an internal combustion engine operates an electrical generator (in this case a DC generator) and the electrical energy is transmitted to the motors, electrical actuators, etc. Finally, in an alternating current (AC) electrical system, an internal combustion engine operates an electrical generator (in this case an AC generator) which is converted to DC with a silicon-controlled rectifier (SCR). AC-SCR power systems are the most widely used power systems on modern drilling rigs.

The document applies to rotary drilling rigs, well servicing rigs, and special services as they relate to operations on location. First published in 1981, significant revisions in this edition of Recommended Practice 54 include a new section on flowback operations which is key for safe well testing, revised requirements for facility and site process hazard assessment and mitigation, and introduction of formal risk assessments as well as expanded provisions for offshore operations.

8613371530291

8613371530291