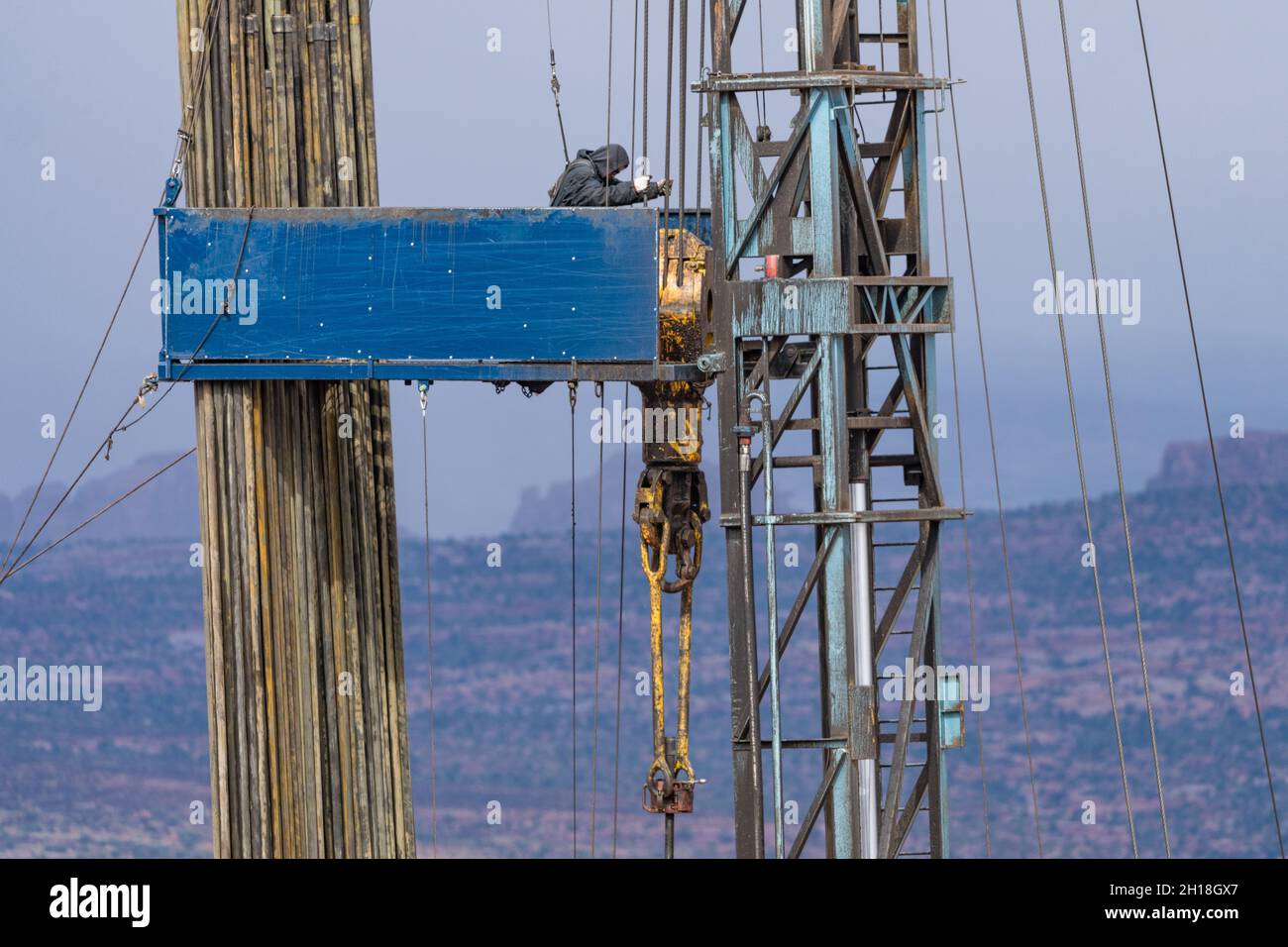

workover rig derrick hand price

The Floorhand performs the duties of general manual labor on the rig and supports and assists other members of the drilling crew during all rig operations.

Develops an understanding of all major rig components and the necessary servicing. Prior experience in oil field, heavy industry or construction is beneficial.

Assist in rig moves: help with rig-up / rig-down, nipple up and down blowout preventers, assist with general assembly and maintenance and help prepare new…

Assist in rig moves: help with rig-up / rig-down, nipple up and down blowout preventers, assist with general assembly and maintenance and help prepare new…

Must have reliable transportation to and from the rig. The job of the Floorhand is to safely and efficiently perform all manual labor tasks on the drilling…

Develops an understanding of all major rig components and the necessary servicing. Prior experience in oil field, heavy industry or construction is beneficial.

Cleans and services drilling subs and equipment before removing them from rig floor. Ensures all loads leaving the rig floor with the crane are rigged properly…

Develops an understanding of all major rig components and the necessary servicing. Prior experience in oil field, heavy industry, or construction is beneficial.

Develops an understanding of all major rig components and the necessary servicing. Prior experience in oil field, heavy industry or construction is beneficial.

Manages tools on the workover rig floor and assists in daily maintenance. May be responsible for working the floor or operating the rig when necessary.

Assist in rig moves: help with rig-up / rig-down, nipple up and down blowout preventers, assist with general assembly and maintenance and help prepare new…

The successful candidate will have an outstanding track record of success in workover rig experience in operating heavy equipment while ensuring communication…

*Floor Hands - *minimum experience required 6 months. *Derrick Hands - *minimum experience required 1 year. Job Requirements: *Job requirements include but are…

Reliable means of transportation to and from rig site. The Floorhand is responsible for safely and efficiently performing a variety of physically demanding…

Crew Member positions include Rig Trainee (no experience required), and Floor hand, Derrick hand, Relief Crew Chief, and Crew Chief, which are experience…

JOB SUMMARY: * Responsible for performing various rig operations and equipment maintenance in the course of drilling a well, preparing the rig floor before…

Maintains all safety belts and ropes in derrick and checks derrick pins, safety pins, electrical cords and lights, ladder and derrick cages, and all safety…

Floor hands and Derrick hands needed for rig out of Pratt, KS. Competitive wages and benefits, guaranteed 40 hours. Job Type: Full-time Pay: $20.00 - $27.00…

Assist in construction of steel derricks. Use of power tools and other hand tools. Assemble and disassemble casing and drillpipe sections using hand and power…

2 years minimum experience as a rig hand on a production rig working floors and derricks. Starting pay is $23.00 per hour with an increase to $26.00 per hours…

Trains and mentors floor hand on day to day operations. Must be able to successfully perform the duties of a floor hand. Assist in racking of rod of tubing.

Must be experienced and willing to work the derrick board. Derrick Hand / Assistant Driller / Motorman / Floor Hand, all rig positions available, must be…

Currently accepting applications for experienced Workover Rig crew members including floor hands, derrick hands and operators. Minimum of 1 year operating rig.

Operates tubing elevators for standing tubing in derrick. The primary responsibilities of a Derrick Hand is to work anywhere on the derrick of the workover rig…

If pump on location help assist derrick-hand with rigging up lines and staking them down. While using rod elevators ensure hand placement is proper, and latch…

Floorhands should be proficient in the use of hand tools, such as sledge hammers, large pipe wrenches, chain tongs and other hand tools used to maintain and…

Inspect all safety equipment before going up to and in the derrick prior to usage. Perform daily inspection and preventive maintenance on derrick structure…

2 years of solids control or derrick hand experience a plus. This position is responsible for the set up/tear down, general maintenance, and trouble-shooting of…

Key Energy Services-A dynamic and well respected company with a mission to be a leading global well intervention and production enhancement service company. We are the largest provider of onshore well service rigs in the United States and one of the leading onshore, rig-based well servicing contractors in the world.

Key Energy Services (Key) is an equal opportunity employer. Key does not discriminate against any applicant or employee based on race, color, religion, sex, sexual orientation, disability, national origin, age, genetic information, military status, status as a Vietnam-era or special disabled veteran, or any other basis protected by federal, state, or local laws.

Key Energy Services-A dynamic and well respected company with a mission to be a leading global well intervention and production enhancement service company. We are the largest provider of onshore well service rigs in theUnited Statesand one of the leading onshore, rig-based well servicing contractors in the world.

Key Energy Services (Key) is an equal opportunity employer. Key does not discriminate against any applicant or employee based on race, color, religion, sex, sexual orientation, disability, national origin, age, genetic information, military status, status as a Vietnam-era or special disabled veteran, or any other basis protected by federal, state, or local laws.

and Accountabilities Derrick Hands must use a harness and platform-climbing device to get to the proper position on the derrick when the drill string (lengths of pipe) or casing pipe is being raised from ...

The schedule for this role will be Monday - Friday, 7 am - 3:30 pm Work closely with the Driller and the Rotary Helpers (Floor Hands) to ensure that drilling rig operations are performed safely and efficiently ...

Work closely with the Driller and the Rotary Helpers (Floor Hands) to ensure that drilling rig operations are performed safely and efficiently Align and manipulate sections of pipe or drill stem from ...

WILSON WELL SERVICE RIG (Ref#3000Ta) 103’ x 248,000# derrick, Out of service since 2017, lot of rust, will start and run and/or drive down the road POR

Refurbished, 700 hp, Double drum 2042 drawwroks with Parmac 202 brake assist, (2) Caterpillar 3406 Engines, (2) rebuilt Allison 750 6 speed auto transmission with reverse. 112" x 300,000 # hook load capacity on 8 lines, clear height 97 feet, leg spread 7" 6-1/2", racking board, oil bath chain case, elevated rotary drive, all raising lines and guidelines. The Draw-works, hydro-mantic break, and crown assembly have been rebuilt. Heavy duty Draw works drive propeller shaft through right angle gear box, rotary drive propeller shaft, heavy duty reverse gear box and oil bath roller chain, and a self-locking handling winch. Mounted on triple front axle mechanical 6 axle carrier with 134,000# capacity designed to meet highway safety standards with necessary toughness for off road operations. Price: $265,000

Built 2012, 42 x 12 drawworks, Cat C15 (475 hp) engine, 112’ x 300,000# derrick, mounted on 5 axle carrier. Includes skid mounted Gardner Denver PAH mud pump with Detroit 8V92 engine (gear end is good, but needs fluid ends machined or replaced). Package Price: $270,000

Manufactured 2014, 72’ x 180,000# derrick on 4-line (250,000# on 6-line), mounted on 5 axle carrier, Detroit Series 60, Allison transmission, all hydraulic, 8000’ of 5/8” sandline, 100 ton McKissick casing blocks, 1” line 42” x 12” casing drum, 42” x 12” sand drum, disc assist on casing drum, 1500 hours, 3000 miles. Westco power tongs 1-1/2”, 2”, 2-7/8” and 5-1/2”, set of bails/links, tubing elevators 1-1/2” – 2”, rod hook, elevators, wrenches, swab tools, Martin Decker weight indicator, stored inside Price: $645,000

Derrick fell onto rig when being raised, derrick would need to be replaced or repaired. Built 1981, double drum, 42 x 12, 42 x 8, swab drum removed from jack shaft, 5-axle back in carrier, 250,000# derrick with double racking board and triple rod basket, Cat 3408, CLT 5860 transmission, Cooper right angle box, 4 hydraulic leveling jacks, air rod transfer in derrick, hydraulic winch, Kerr 6 cyd 10000 psi Mustang pump powered from jack shaft, Kerr 3-valve release 10,000 psi, tong carrier f/Foster, steel work platform, Parmac 22 SR hydromatic brake. Extra rebuilt 3408 Cat engine. Price as is: $112,500

Chinese built 2006, 8300 hours, 104’ x 250,000# derrick, rod basket and tubing board (18000’ tubing capacity), Detroit Series 60 diesel engine, 5680 Allison 5-speed transmission, sandline drum with 14,500’ 9/16” sandline (new January 2022), main drum with 1’ drill line on 6 lines with conventional brake pads and brake assist (new November 2021), brand new winch line (replaced May 2022), mounted on 6 axle carrier (2 steer, 2 drive and 2 tag), total weight 100,000 lbs., currently working Price: $270,000

Manufactured 1981, 400 CCC drawworks, single 22” Hydromatic, 96’ x 215,000# CCC derrick (level 4 inspected 2015), mounted on 5 axle carrier, Detroit 60 Series 14 liter engine, Allison 5860-2 drop box, 1 winch, work floor, McKissick 83 block, 72” links, BJ RS tubing tong with manual backup, pad type weight indicator, 2 7/8 – 2-3/8 100 ton, 14,000’ 9/16 sandline capacity, 875’ 1” drill line, Price: $395,000

Rebuilt 2010 to Level IV, Double drum drawworks, Detroit 6V53 diesel engine, Allison 5860 3-speed transmission, 60’ x 100,000# stiff mast derrick, 4 lines with 4’ well spacing, 35-ton McKissick block and hook (2) 17” sheaves 7/8” wire, 75-ton elevator bails with 25-ton elevator pickup adapter, working floor, stairs, handrails, lights, 20’ lubricator, 5000 winch with hook, tandem axle single steer drive carrier, located Canada Price: $120,000 USD

Manufactured 2008, 72’ x 150,000# derrick, Detroit Series 60 engine, mounted on 4 axle Crane Carrier, tooled out, Guiberson T60 air slips 100 ton casing blocks, Westco power tongs, currently working Price: $445,000

Manufactured 1981, mounted on 5 axle carrier, double triple service rig, 96’ x 250,000# derrick, Detroit Series 60 12.7 diesel engine, Allison transmission, 9/16” sandline, 1” drill line, hydraulic jacks, hydraulic catwalk, travelling block, tubing bard, rod basket and all necessary lines. Tooling not included. Price: $115,000

Rebuilt 2010, double/triple, 8V92 Detroit with Turbo charger and after cooler, trailer mounted, single drum drawworks, Allison transmission 588 Series, 102’ x 225,000# derrick, gooseneck 3 axle trailer

Manufactured 1983, double drum, 96’ x 180,000# derrick, mounted on 5 axle carrier with 92T engine, Allison transmission Price rig only: $300,000 Price with tooling:$340,000

WILSON 42 WELL SERVICE RIG(Ref#7562Ta) Manufactured 1975, 180,000# Pemco double/triple derrick, mounted on Wilson carrier with Detroit 8V71 engine, 4 hydraulic leveling jacks, ready to work Price rig only: $74,500 Price with tooling: $94,500

Manufactured 1983, 70" x 120,000# non telescoping stiff mast, double drum 26 x 8, Detroit 6V71 diesel engine, 740 Allison transmission with Spicer power divider, mounted on 4 axle carrier. Rig runs and truck drives, stacked for several years, good condition Price: $93,500 USD

110’ x 250,000# Cooper derrick, Detroit 60 Series engine, 6061 Allison transmission, 6 axle Pettibone carrier, 3 front and 3 rear axles, drop box converted to air control, tubing drum, sand drum, 24” Wichita clutches Price: $315,000

Manufactured 2009, 96" x 205,000# derrick, TI 260 drawworks, 48" sandrum brake, 9/16" sandline, 1" Lebus grooved tubing drum, 60" turbing drum brake size, 41,500# max single line pull Price: $425,000 PRICE REDUCED: $389,500

FRANKS 500 WORKOVER RIG(Ref#7615Tc) Built 1980, refurbished 2018, 102’ derrick, 150 ton blocks, 15,000’ sandline, new engine and transmission, ready to work Price: $430,000

FRANKS 400 WORKOVER RIG(Ref#7615Ta) Built 1979, refurbished 2017, 102’ x 215,000# derrick, 100 ton blocks, 15,000’ sandline, 4 lines Price: $390,000

Built 1981, refurbished in 2018, 102’ derrick, new drilling line, no sand line, 100 ton blocks, 2 winches, has not worked since refurbishment. Price: $390,000

FRANKS 300 SERVICE RIG(Ref#1169Ta) 4-legged derrick, Series 60 Detroit engine, 6850 Allison transmission, blocks, Foster tongs, mounted on 4 axle carrier, working condition Price: $37,500

Double drum Wilson Sr and Wilson JR drawworks, sandline capacity 10000" of 3/16", mounted on tandem axle, 1987 Freightliner tandem axle truck powered by Detroit diesel engine, 2 hydraulic leveling jacks, Detroit diesel on deck, 50" hydraulically raised mast, brand new hydraulic cylinder just replaced for lifting derrick, has pulled a minimum of 3000" wells, all new hydraulics PRICE: $137,500

WILSON MOGUEL 42 WELL SERVICE RIG(Ref#3177Tb) Two available, 96" x 280,000# mast, Detroit Series 60 engine, 5860 Allison transmission, mounted on 5 axle Wilson carrier, handling tools Price: $315,000

Double/Triple 96" x 225,000# derrick, 60 Series Detroit engine, mounted on 4 axle carrier, 750 Allison transmission, sandline, blocks Price: $72,500

Built 1980, 102" x 260,000# derrick, factory rebuilt Detroit 8V92T engine installed April 2010, inframe on motor 2015 derrick sandblasted and magnafluxed July 2006, new chain on main drum October 2017, brand new rear end and rear drive line and axels Sept 2016, new drill line and winch line November 2017.

Workover rig with 83’ telescoping derrick, 10’ crown extension, 200,000# lift capacity, 100,000# snubbing capacity. Catwalk with 42’ reach, forward and revere motion, hydraulic pipe slide, six portable pipe racks, powered by workover rig. 5000 ft/lb hydraulic rotary, 15k psi working pressure capability kelly hose, 300 ton mast with 5 x 5 heavy wall box tubing and 2 x 2 heavy wall cross sections, (2) mast raising cylinders, 9-1/8 x 25’ telescoping cylinders/crown sheaves with cable guides, (2) winch sheaves/snubbing sheaves, SRS fall protection, retractable flow tube design, non-swivel boom pole on curb side winch, (2) mast supports, 1” lifting cables, mounted on 5 axle Crane Carrier (3rd axle drop), with 375k Volvo Penta engine, 150 gal fuel capacity, hydraulic self-leveling components, 6 speed Allison transmission, 1:1 gear box, (2) 65 gpm pumps, (2) 30 gpm pumps, (1) 28 gpm Commercial shearing pump, 40 gal accumulator storage, single man cab, hydraulic leveling jacks Price on Request

Year 2006, double drum, 8V71 Detroit diesel engine, 5860 Allison automatic transmission, mounted on 5 axle Crane Carrier, 108’ x 225,000# derrick, 100 ton McKissick 3-sheave block, fully tooled with 6’ bailers, 58-93 tongs, 2-3/8 and 2-7/8 elevators, 3/4 and 7/8 rod elevators and wrenches, eight indicator, laydown floor Price: $162,500

Refurbished, Double/Triple, 96" x 215,000# derrick, Detroit 60 Series, mounted on 4 axle carrier, 750 Allison transmission, sandline, blocks Price: $102,500

Manufactured 1982, Tubing drum 42 x 12, sand drum 38 x 8, Detroit Series 60 diesel engine, 96’ x 200,000# derrick with set of tubing blocks, hydraulic and air hoses gone through, installed all new engine harness and electrical wiring to all lights, transmission. Rebuilt valve bank Price: $200,000

Manufactured 1960’s, double drum, single rig mast, 64’ x 250,000# (tubing and rod racks), 70 ton blocks, 2 lines, Detroit diesel 60 gpm @ 2000 psi, hydraulic system, air clutch. Rig was refurbished 2013/2014 at a cost of $130,000: repairs included used 65’ derrick installed, new 1” main line, repairs to air system, hydraulic system upgrade, leveling jacks, derrick ljghting, tires, 70 ton blocks installed. But the rig has been sitting since 2015 and now needs rebuilding. It doesn’t run. Price as is: $19,500

Manufactured 1980, completely refurbished 2004, 5 axle double drum well service unit, double 15 Parmac brake on main drum, 96" x 180,000# hydraulic raised mast, mast lighting, Detroit 60 Sereis engine, 5860 Allison 6 speed transmission, 4 hydraulic leveling jacks, dual manual outriggers, PD12 Braden utility winch, McKissick 100 ton tubing block 21-31 diving, 1000" of 1" tubing line, 13000" of 9/16" sandline Price: $225,000

CARDWELL KB200B SERVICE RIG(Ref#11674Ta) 72’ x 140,000# stiff mast, 40 x 10 double drum drawworks, 2 aux deck winches, tubing board, rod board, cat walks, railing, stairs, floor BOP controls and accumulator bottles, McKissick 75 ton tubing block and hook, mounted on 5 axle carrier, Detroit 8V71 diesel engine, Alliston CLBT4460 auto transmission PRICE: $127,500

Rig manufacture 1980, mounted on 1980 GMC Brigadier with Cat 3208 engine, includes elevators & misc tools, also includes 1996 1-ton Super Duty tool truck, tandem axle, Cat 3208 diesel, sitting 1-1/2 years Price: $92,500

95’ x 212,000# Ideco telescoping derrick, 42 x 10 double drum drawworks, 100 ton McKissick block and hook, hydromatic, tubing board, monkey board, catwalks, railings, stairs, lights, ladders, mounted on 4 axle carrier, Detroit 8V71 diesel engine, Alliston CLT 5860-DB automatic transmission Price:$137,500

104’ x 225,000# telescoping double derrick, 42 x 10 double drum drawworks, hydromatic, 100 ton McKissick block and hook, mounted on tandem steer/tandem drive carrier, Cat 3406T diesel engine, Allison CLBT-5860-2 automatic transmission Price:$137,500

1980, 475 hp, single drum (new), reworked, 96" x 205,000# hydraulically raised mast, 6 lines, crown block: 3 new sheaves blocks and bearings, racking board, guide wires, (2) hydraulic hoist, weight indicator, block, elevator links, fall safety device, work platform, mounted on 4 axle carrier with Detroit Series 60 diesel engine, Allison transmission, rig in excellent condition and has been well maintained, ready for use PRICE: $115,000

SKYTOP BREWSTER RR400(Ref#13190T) Mounted on 4 axle carrier, single drum drawworks, 8x7 disc assisted brakes, tubing board, Cat3406B engine, Allison 860DB transmission, 100 ton McKissick block, Foster 58-92R tongs, misc hand tools, approx 36" base beam for rig, ready to work Price: $110,000

Manufactured 1976, 50 Series Detroit engine, 4460 Allison auto transmission, 96" x 180,000# Skytop derrick, 100 ton McKissick blocks, 7000" of 9/16" sandline, BJ tubing tongs, Guiberson air slips, 2-3/8 and 2-7/8 elevators, rod wrench, rod elevators, weight indicator, lubricator pump, misc tools Price: $320,000

500 hp, manufactured 2007, Pemco 104" x 225,000# derrick, double triple, 100 ton McKissick blocks, BJ style tubing tongs, rod tongs, rod basket, 8"3" bales, 16,993 miles on truck, 4016 hours, all handling tools

Built 1966, Double drum 1058 drawworks, 8500’ sandline, blocks, 96’ x 150,000# derrick, mounted on 4 axle carrier, Detroit 6V92T replaced August 2019, PTO, power steering and alternator/generator needs modifications to work with new Turbo diesel engine

Refurbished 2017, 4 lines, 96’ x 205,000# mast, 8V71 Detroit engine, mounted on CCC, 75 ton McKissick blocks, tubing board, rod basket, work platform, rigged up and working in field Price: $295,000

Manufactured 1977, 72’ x 125,000# derrick, 8V71 Detroit engine (rebuilt), Allison 750 transmission, 6500’ of new 5/8” sand line, tubing line new, drum brakes new, new style McKissick blocks, working daily Price rig only: $157,500

Double drum drawworks with hydromatic brake, 10" brakes, 96" x 180,000# derrick, mounted on 4-axle PEMCO carrier with hydraulic support legs, 8V71 Detroit, 4460 Allison transmission, Spicer 784 split shaft gearbox, 250 hp right angle drive, 650" of 7/8" tubing line, 8000" of 9/16" swab line, 100 ton Sowa block, hydraulic winch, hydraulic weight indicator, 84" links, 2-3/8" and 2-7/8" tubing elevators, BJ tubing slips, Foster 5893R power tongs with lift in derrick, rod hook, rod stripper, rod elevators, wrenches, transfers, rod fishing tools, misc hand tools and connections Price: $140,000

Manufactured 1974, double drum drawworks, double triple 96" x 180,000# derrick with a hydromatic. The rig has working line with heavy traveling block and approx. 12,000" 9/16 sand line. Mounted on Skytop carrier with tandem steering and rear ends 4 axles W/ tag axle, 4 leveling jacks, powered by an 8V-71 with a Allison 4460 transmission, (note transmission was overhauled in early 2000"s) and the engine has a new head on right bank. The rig has two leveling jacks on the rear and two leveling jacks on the front which are located right behind the steering axels. Tooled out with hydraulic rod and hydraulic tubing tongs, air slips, rod and tubing elevators, hand tools and misc over items. PRICE REDUCED: $115,000

10 x 13 pole, double Drum, Franks 33” air over grease, brakes in good shape, 7/8” tubing line, tubing blocks, tong pressure adjustment, hi/low on tubing, air slips control, master kill on drawworks, Foster 36 with 8’ lift ram, air backup, swing around tong rack, mounted on 2001 Freightliner F80 truck, Cat C12 Series 3125, Fuller 9-speed transmission, PTO, winch for pole scope Tulsa 48, blocks raise pole, dual fuel tank, dual battery, 50 gal hyd tank, toolboxes, hydraulic outriggers, BJ rod tongs, ¾” and 7/8” heads, tools, swabs, extra tongs, orbits, drilling head Price: $242,500

Double drum (second drum is removed, rig is running as single drum), hyd pole and down riggers, mounted on 1990 Crane Carrier, 9 sp Eaton Fuller transmission, 100,000 miles, 8 x 10 telescoping poles, 3/4” cable, no tooling Price: $52,500

10 x 13” pole, single drum, mounted on 1980 Brigadier 9500 Series truck with 671 inline Detroit, drop box, travelling blocks, tubing lines, hyd jacks, no tooling, sitting since 2000 PRICE: $49,500

Manufactured 1960, Double drum, all air operated, 7/8" drill line, 9/16" sandline, 60" single pole 10 x 13, mounted on Franks 3 axle carrier, will handle 8000" of 2-3/8" tubing or 6000" of 2-7/8" tubing, tools include tongs and handling tools, good condition Price: $69,500

Cable Tool Drilling and Completion Rig, 60" double poles rated to 150,000#, 5000" drill capacity, 10,000" pull capacity, propane Waukesha 145 engine, 500 gal propane tank, trailer moutned with International 4300 truck, last drilled 2012, 2300" drill line on drum, 3500" on spool casing drum, heavy block sandline drum, cat heads each side, tooling, spare engine Price: $72,500

400’ of 7/8” block line, 9/16” sandline drum (no cable), 2000’ of ¾” drilling drum, 3 McKissick sheaves, air clutches and controls, mounted on 1961 Mack truck with 250 hp Cummins engine, older rig but runs good. Includes elevators, oil saver pump, no BJ tongs, currently working. Price: $87,500 - Pennsylvania

Triple drum, friction clutch, cathead (sandline holds 2400’ of 5/8” line), mounted on tandem axle Chevy truck with 427 gasoline engine, 8-5/8” x 45’ single pole, new tires, power steering, wireline unit, good usable rig for shallow oil/gas lease, drills, workover, swab capabilities, no tools Price: $112,500 - Oklahoma

Would you like to further your career in Oil & Gas as part of our team of professional workover rig crews? At Brigade Energy Services, we provide you with training, skills, and a career with a company that prides itself on Safety and developing its people. We’re looking for additional team members who want to be the best at what they do, who think just “good” is never good enough, who take pride in their work, and want to work with others who feel the same way.

Brigade Energy Services is one of the fastest growing and the largest privately held workover rig companies in the United States. We have competitive benefits, compensation packages, and growth opportunities. Visit us at www.brigadeenergy.com/careers

The Workover Rig Crew Member (Derricks and Floors) works as part of a team to ensure all daily operational activities are performed in accordance with our policies and procedures to ensure the safety of our people and service delivery to our customers. Safety is a core value for Brigade Energy Services and we are seeking like-minded team members who consider Safety as the number one priority. A successful Crew Member will perform assigned duties while striving for excellence. In return, we will provide opportunities to grow and advance, to become an expert at what you do, or progress to higher positions within the company.

Total compensation includes not only the wages you will receive in your paycheck, but also the additional benefits Brigade Energy Services provides to you. We have created an individualized Total Compensation Statement:

At Brigade Energy Services, we do not just accept differences — we celebrate them, we support them, and we thrive on it for the benefit of our employees, our products, and our community. Brigade is proud to be an equal opportunity workplace and is an affirmative action employer. All employment is decided based on qualifications, merit, and business need.

A Derrick hand handles the uppermost section of the working string as it is brought from or lowered into the wellbore. The Derrick hand is responsible for the safe and effective operation and working condition of the derrick, mud pumps, fluids, and related equipment. Takes directions from the Operator or Relief Operator.

Dragon manufactures a full line of 300 to 1,000 HP Cooper ™ Rigs at our state-of-the-art U.S. facility and our rig team is one of the most seasoned in the industry. Whether you need a used well servicing rig, a workover rig, a drilling rig, mud pumps and systems or parts and service, Dragon has you covered.

Our expansive inventory of parts and accessories includes mud systems, mud hoppers and mud guns, agitators, pipe racks, draw works, API 4F, 4th Edition certified masts, break blocks, McKissick tubing and drilling blocks and refurbished gear boxes for most brands of well servicing units. Our rig masts have a clearance height range of 71-124′ and capacities of 150,000 lbs too 500,000 lbs.

Like all Dragon equipment our used Cooper Workover Rigs are severed duty engineered. We also have hands-on experience building to severe, cold weather specs and in compliance with the state of California’s requirements. When you buy a Cooper™ Rig from Dragon you get a custom, easy to operate, safe rig at a competitive price. Whatever mobile rig solution you need, Dragon will build it, deliver it and back it with the highest level of service and support in the industry.

The following is a list of seasonal work gear worn by service rig workers. Savanna supplies rig employees with coveralls, hard hat, safety glasses, and hearing protection (ear plugs). Always have at least one set of extra clothes to change into if your current work wear gets contaminated.

Service rigs typically work from a base location, and crews work between 4 and 12 hour shifts each day. Service rig crews are generally made up of five (5) people: Rig Manager, Driller/Operator, Derrickhand, and two Floorhands.

Most days begin by meeting the Driller/Operator who drives the crew to the rig in a company vehicle or personal vehicle. Each member of the crew is responsible for getting themselves to the meeting point, so having a reliable vehicle is an asset. At the end of each shift, the crew returns to the meeting point and is dropped off.

Work in the oil and gas services industry is seasonal. Because of the weight of rigs and their equipment, and the remote location of wells, these locations are often only accessible when the ground conditions can tolerate heavy loads. Therefore, wells are typically drilled and serviced in the winter when the ground is frozen solid, or in the summer, when the ground has thawed and dried sufficiently. During the spring and fall, when the ground is in a transitional state, it is too soft to move equipment on and easily damaged. For this reason, provincial governments implement “road bans” prohibiting heavy loads from operating in certain areas. During this time, rig work is slower, and many rigs are shut down and their crews sent home. Be prepared to be off for anywhere from 6 to 12 weeks without pay during this time. However, rigs that are shut down are usually in need of maintenance, and there may be opportunities for employees who would like to help in this regard. Employees may be eligible for Employment Insurance benefits during seasonal shutdowns.

If you would like to work on a service rig, you should live in or near these areas. In some instances, rigs are required to operate in remote locations for extended periods of time. When this happens, rig crews either live in camps or in local hotels, and their room and board are paid for by Savanna.

Once you have completed your orientation, you will immediately receive any other necessary training. This involves Workplace Hazardous Materials Information System (WHMIS) and Transportation of Dangerous Goods (TDG), along with an in-depth General Safety Orientation. This training is mandatory and provided by Savanna at no cost to the employee. Job-related, hands on training is conducted in the field through the Enform Service Rig Competency Program.

While it is not mandatory to have this certification, each service rig crew is required to have two members who are certified in Standard First Aid with CPR level C. Therefore, obtaining a certification beforehand is a great way to improve your chances of being hired.

At Savanna, there is an excellent opportunity for good quality employees to quickly advance to more senior positions. If you would like to pursue a career as a Derrickhand or Driller, please speak to your Rig Manager or Human Resources. The service rig industry in Canada, through Enform, has adopted a competency assessment program to allow Drillers and Derrickhands to evaluate and promote Floorhands when they are ready. Savanna’s recruiters can provide you with more information if you would like to pursue a career in either one of these positions.

It’s really tough to explain to someone who has never seen a rig before. We drill holes, but it’s more than that. It ain’t for everybody, especially not the faint of heart. But I will say its possibly the funnest career out there. Knowing that the gas in your truck could be coming from a well that you drilled. Or the look on people’s face when you tell them what you do.

Basically, we’re hired by companies like Exxon/Mobil and Shell to drill holes in the ground to get to fossil fuels buried in the earths crust. There’s a thousand other details that go into making a 22,000 ft deep hole, though. But these details are for the driller to worry about. The heirarchy of a rig is the toolpusher at the top, he keeps the rig supplied with what we need to keep it and us running and makes final decisions if one can’t be made by the crew or driller.

Below him is the driller, he is kind of like a crew leader. He sits in a chair and runs the rig how the ompany man and directional drillers want him to. He’s just there so they have someone to blame if something happens. Then, my job, derrickhand, he monitors the pits, shakers and mud pumps. Makes sure they are functioning right and fixes them when they don’t. He also treats the mud (drilling fluid) with the chemicals the mud engineer tells him to. Then comes the motorhand. He is the toolpushers slave who does anything and everything the pusher or driller tells him to. He takes care of the paperwork, the generators, and he lines out the floorhands. Which is the next position, at the bottom of the totem pole. Floorhands do it all. They help the derrickhand and motorhand with anything and everything that needs done and alson keep the rig clean aand orderly while drilling. It is at times the dirtiest profession out there. If you’re afraid of a little mud, you definitely need to stay away from drilling, because you won’t last five minutes.

Well for starters, nowadays the typical work week is two weeks long. You work for two weeks, then you get two weeks off. I know it sounds too good to be true, but trust me. Spend 14 days on one 5 acre location with ten other dudes in the middle of no where, work on a rig 12 hours a day, lose a bunch of sleep at night and tell me if you don’t need 14 days away from it.

Anyways, you never know what to expect when you come back to work. The other side may have busted their butts and got stuff done and got the rig moved. Or they may have not. Now you’re stuck with another 1,000 ft to drill and stuck with a 3-4 day rig move. Coming to the rig on the first day or night, you should be able to map out what your hitch is going to be like. But you’ll never know until you get there.

I was working in a shop for a small contract company in Houston, Tx building rigs for the drilling company I work for now. I had a really good friend that worked for the drilling company as a safety rep, so he talked with all the pushers for every rig before it left the yard. I asked if there was any way I could get on a rig, and the first one going to North Dakota had an opening. Here I am now.

The one thing I love the most about my job is goin up in the Derrick when we trip pipe. Standing on the board 80 ft from the rig floor and about 130 ft from the ground, and no one around me, no bs, it’s clean, I can listen to my music up there. It’s just awesome compared to the floor. It’s dirty, oil base mud everywhere, driller yelling at you from the doghouse. It doesn’t really suck, but it sucks. Tripping pipe is when we pull all the pipe out of the hole, 94 ft sections at a time, change out a bit or a tool on the bottom, then put all the pipe back in the hole. The drill pipe is all standing up in the Derrick, and I’m the guy that puts it there and takes it out.

There’s really no way to explain it other than to show you or let you try it. If you’re on this site, that means you have Internet. Go to YouTube and look up tripping pipe on an oil rig. That’s the best way I know to explain it. Another thing, like I said earlier, is some of the reactions you get when you tell someone what you do for a living. A lot of men you meet are jealous, or curious about the industry. Everyone wants to know how you do it, what you do out there, how do you “make hole.” And women always love roughnecks. They’re always interested in what we do and a lot of other things. You’d be surprised at how much attention you’ll get at a party or a bar when someone mentions what you do for a living.

There’s only one thing I hate about my job. Okay, there’s a number of things, but the one I hate the most is the fact that I have to spend over half my life 1600 miles from my home. My family, my friends, my town. Other than that I can deal with anything that rig can throw at me. I don’t necessarily enjoy getting covered, and mean literally, dripping wet from head to toe with oil base mud, or getting choked out of the hopper house because a floor hand likes to dump sacks of chemicals in the hopper too fast, or dealing with pump problems or valve washouts or busted shaker screens. But it’s all part of the job. It’s what I signed up for and I knew it when I did. When everything’s running smoothly, everything’s clean and working right, it’s probably the most laid back easy going job out there. And I love every second of it. Wouldn’t trade it for the world. Unless a job at home with more money and more time off came up. But you’d be hard pressed to beat this job for money or time off.

As a derrickman in North Dakota I make $32 an hour. My rig does get some bonuses, and we get a few extra hours a week due to safety meetings. My W2 for last year says $104,782. I’m 22. This is definitely something you want to get into while you’re young.

In south Texas, floormen (the entry level position) make from $18-$22 and hour. Where as in North Dakota floormen make from $26-$31 an hour. And we get at least 84 hours a week. But it’s only for two weeks a month. Starting off can be anywhere from $50,000 a year to $80,000 a year. Also you get mud pay. If there is oil base mud in your pits for five minutes of that tour, you get an extra amount of money for that day. Usually about $25-$50, not much but it adds up. And let’s not forget bonuses. If you drill a well faster than predicted, or use less materials, or just do it safely, you get bonuses depending in who you’re drilling for. Some rigs get them, some rigs don’t. But bonuses range from a measly $50 Walmart gift card to a check for $2,000 out of no where. And the wages just go up from floormen. Where else can you work half the year and make almost six figures starting out? That’s right, no where. I told you it’s an awesome job.

Knowing that the gas that is heating yours and everyone else’s homes, the fuel in yours and everyone else’s trucks, it comes from what you do. Heck it could even come from a well that you drilled. Knowing that the world literally revolves around your job. Without oil and gas, there would be no economy, no industry, no production, no progress. Without the oilfield, the world would collapse. Plain and simple. The brotherhood of your crew, your rig, and the entire batch of oilfield trash in the oil patch. There’s nothing like it, you could be from east Texas and meet someone from Billings, Montana. Never seen them before. But if both of you work rigs, you’ll have instant common ground. Because they know what it’s like. They know what you deal with and vice versa.

There’s times when it’s challenging to figure something out, or to get something built, or to get something just to work. Sometimes it’s a challenge to keep yourself from hitting someone. Especially when that someone almost just got you and the entire rig burned to the ground. The entire job is challenging. To learn it, to know it, understand it, and to do it. It’s not easy. It takes a special breed of human to do what we do day in and day out. But it’s one of the funnest careers other than being a pro athlete that I can think of.

First off, I’d say good luck getting in. I know how hard it is to get hired. Second off, I’d say abandon all your fears. You can’t be afraid of anything on the rig. Respect everything, but do not fear it. Once you fear something, you’ll hesitate to do it. And if you hesitate, it could kill you or your coworkers. Don’t be afraid to get dirty. No matter what the task, no matter how minuscule, dirty, confusing, or or down right hard it is, be willing to do it. Volunteer to do it. If you see something that needs doing, don’t wait to be told. Take initiative, it’ll help. Don’t be afraid to take orders. And most of all, don’t let no one, I mean no one, walk all over you or push you around. It’ll be the death of you and your career.

That we all do meth and get drunk on the rig. While we’re on tour. And out here a work shift is called a tour, but it’s pronounced tower, I know it’s weird. But it’s just an oilfield thing. There’s a lot of stuff like that out here. Anyways, we don’t do meth, or get on drunk on tour. At least not on the rig I work on. Some rigs are still like that, but you don’t find it hardly ever anymore. And a lot of people think that we pump the oil out of the ground and send it to gas stations. All we do is drill a hole. That’s it. Other people come in and set up production equipment, pump jacks and tree valves and what not. The big horse head looking things that go up and down in corn fields ARE NOT CALLED OIL DERRICKS. Those are pump jacks.

8613371530291

8613371530291