workover rig diagram manufacturer

PRODUCT DESCRIPTION This is one of our best selling product. A kit of Catterpillar and Allison transmission provides steady and powerful output to enable the 250 rig can actually handle much heav...

Product name: 5000m truck mounted drilling rig/workover rig Advantages: 1.truck mounted drilling rigs manufacturer 2.Approved API&ISO certificate 3.Max Nominal drilling depth:5...

PRODUCT DESCRIPTION XJ450 (80t) workover rig is capable of workover depth up to 4,500m and service depth up to 5,500m. Equipped with rotary table, swivel and drilling tools, it can also perform a...

This workover rig is mainly used for drilling service in 800m-4000m(4-1/2 DP) depth oil, water well and coal gas well.(1) The design and manufacturing for the rig stick to this principle that is...

The slant-well workover rigs* This kind of workover rigs are designed and manufactured in accordance with API Spec Q14F7k8C and technical standards of RP500,GB3826.1GB3836.2 GB7258,SY5202 as we...

The drilling rig is mainly used for Workover service of 5500m(2 7/8" oil tubing) deep of oil and water well,drilling 1500m(4 1/2" DP) deep oil-water and coal seam gas well,also used for deep...

350HP workover rig 350HP workover rigXJ350 workover rig is mainly used for shallow well workover, oil testing, fishing and pump check operations. It is equipped with a lifting system and a rotary...

PRODUCT DESCRIPTION The XJ350 workover rig is our best designed and developed product. It perfectly couples Caterpillar enginer with allison transmission to provide a steady energy output and exc...

PRODUCT DESCRIPTION As the pioneer of research and manufacture on Live Well Workover Rig in China, Tonghua Petro Machinery just announced the brand new Live Well Workover Rig----5th Generation wi...

PRODUCT DESCRIPTIONAs one of the best designed and manufacturered products of our workover rig series along with 50 year history of workover rig manufacture history, XJ750 adopts a complete U.S standa...

PRODUCT DESCRIPTION The XJ350 workover rig is our best designed and developed product. It perfectly couples Caterpillar enginer with allison transmission to provide a steady energy output and...

PRODUCT DESCRIPTION XJ450 (80t) workover rig is capable of workover depth up to 4,500m and service depth up to 5,500m. Equipped with rotary table, swivel and drilling tools, it can also perf...

The slant-well workover rigs * This kind of workover rigs are designed and manufactured in accordance with API Spec Q14F7k8C and technical standards of RP500,GB3826.1GB3836.2 GB7258,SY5202 as w...

We provide workover rigs/completion rigs from well-known and respected manufacturers including Corsair, BW Hyduke, Cooper, Load Craft and Service King. Please see our inventory below:

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Founded in 1969, RG Petro-Machinery Group Co., Ltd. is the manufacturing base of Chinese major technical equipment and fast move petroleum drilling rigs. At present, it has 12 subsidiaries with 9 production and supporting branches. Its main products include 12 series of more than 200 varieties, such as truck-mounted drilling rigs, skid-mounted drilling rigs, trailer-mounted drilling rigs, workover rigs, oilwell logging equipment, and integrated automatic well service equipment.RG Group has established a complete scientific and technical research and development system. It has academician workstation, post-doctoral scientific research workstation, and the National Petroleum Truck-mounted Equipment Standardization Work Department. It is responsible for hosting in drafting the national petroleum and petrochemical industry truck-mounted equipment standards. It has a nationally recognized enterprise technology center and metrology inspection laboratory, and has strong machinery fabrication and system integration capabilities. The company has passed ISO9001 and API Q1 international quality system and been authorized to use API 4F, 7K, and 8C monograms since 1990s.RG provides the oil and gas drilling equipment and all-round services according to the demands of the customers globally, including drilling services, equipment maintenance services, engineering services, inspection services, and equipment leasing etc. RG Petro-Machinery Group Co., Ltd. makes the great efforts to provide the first class equipment and services for the oil and gas industry of China and the world.

In order to solve low degree of work over automation, labor-intensive job dangerous, poor working environment issues, Shengji has developed a series of mechanical work over system, including workover automatic system, minor workover automatic system and snubbing operation equipment.

Oil well workover is a high-tech, high-risk work. The conventional oilfield workover rig has problems such complicated operating procedures and high labor intensity. Shengji, in cooperation with the Shengli Drilling Corporation, have designed an oilfield workover rig automation system.

The oilfield automatic workover rig has a high degree of automation adopting modular integration and advanced robot closed-loop control technology. It functions as self-diagnosis, leakage and short circuit protection and fault alarming, etc. It has remote monitoring capability.

The automatic workover rig greatly increases the automation of workover operations, reduces the number of operators, decreases workers’ labor intensity. The technology is advanced, safe and reliable.

NESR’s fleet of rigs range from 200 HP to 1,500 HP and offer drilling capabilities for all type of wells with depths up to 4000m. Our fleet includes 750 HP truck mounted, fast moving rigs which are ideal for both light and heavy work over campaigns as both rigs are equipped with full edge mud system that can handle normal drilling activities.

We continuously update our modern fleet of land drilling rigs through investment and application of the latest technology. Our rigs are equipped with the most advanced equipment available and this combined with our experienced drilling team makes NESR the best choice for drilling and work over projects.

The automatic operation equipment for minor workover is mainly composed of a wellhead operation device, hydraulic elevator, pipe and rod transmission and arrangement device and electro-hydraulic control system.

The device adopts the structural form of dispersing the functional modules and integrated installation on the workover rig: with the hydraulic tong, manipulator and anti splash snap device set on the derrick of the workover rig, which can expand and rotate, and the safety slip is installed above the BOP.

The device only needs to install safety slips, which realizes rapid installation and migration and shortens the auxiliary working time. The device has the function of moving back and forth, left and right, which is convenient to align the wellhead. The height of the hydraulic tong is adjustable and can adapt to the wellhead with different heights. Hoisting equipment and special transport vehicles are not required for the installation and removal of the device.

The main electric control box can be installed on the operation vehicle or integrated into the modular wellhead operation device. The make-up torque of various oil pipes is set on the touch screen to realize automatic make-up and break-down. Equipped with video monitoring, process prompt, safety alarm, etc. The control system has a perfect action interlocking function to ensure the safety and reliability of the workover operation process. All of the electric cabinets, sensors, connectors meet the requirement of Explosion-proof on field.

The automatic workover rig is a new type of wellhead operation automation equipment developed for the lifting and lowering of oil pipes (sucker rods) in small oil and water well repair operations.

The automatic workover rig has made major breakthroughs in key technologies such as unmanned automatic operation at the wellhead, automatic pipe and rod transfer, electro-hydraulic servo control, and man-machine synchronization control. Various performance indicators have been verified by a large number of field tests.

At present, although some oilfield workover operations have adopted some automatic equipment, the unmanned operation of the wellhead has been realized, which has greatly reduced the labor intensity of workers, improved the operating environment, and improved the safety factor. But the tubing cannot swing with the pipe pusher when working in windy weather, the pipe pusher cannot accurately align the tubing with the coupling, which affects the reliability and stability of the automated operation. At the same time, there are many equipment movement mechanisms, which are distributed around the wellhead, resulting in manual intervention in the operation space, especially in the wellhead emergency rescue process, which will affect the efficiency of emergency rescue.

For the above disadvantages, Sanjack Company provides an automatic wellhead operation device for oilfield workover operations, which mainly realizes the accurate alignment of tubing couplings, improves the reliability and stability of automated operations, and secondly, through innovative design and reasonable layout of the components of the workover platform, the platform operation space is increased, which is convenient for manual operation and wellhead rescue operations.

The automatic wellhead operation device for automatic workover operation adopts the principle of electro-permanent magnet suction pipe, and design a set of mechanism that can swing freely under its own gravity to achieve accurate alignment of the tubing.

This automatic wellhead operation device improves the reliability and stability of automated operations. At the same time, through the innovative design and reasonable layout of the components of the workover platform, the structure is compact and simple, which increases the platform operation space and facilitates manual operation and wellhead rescue operations. Accurate movement positioning achieves precise and reliable workover.

(1) This device is based on the power and lifting conditions of the existing workover rigs. Through the hydraulic control transformation of elevators and hydraulic clamps, the development of automatic positioning manipulators and manipulators, and the selection of pneumatic chucks, the workover workers can be far away from the wellhead. The completion of the lifting and lowering of the tubing operation, the construction speed is artificially controllable and can reach the level of manual operation, which greatly reduces the labor intensity of the workers, and reduces the various injuries faced by the workers at the wellhead of the station, which is generally welcomed by the workers on the spot.

(4) After the two-person operation of the oil pipe is realized, the original wellhead personnel is trained as the driver, and the vehicle is operated in turn, which can further improve the work efficiency.

(5) After unmanned operation at the wellhead, the manipulator of the workover rig moves more. Therefore, simplifying operations and improving work efficiency through automation and intelligence is the next development direction of this device.

Our fit-for-purpose equipment is incredibly strong and designed to withstand the most challenging environments. Every rig can be configured to meet your needs for these applications:

Inserting and pulling up pipe tubing from oil wells is a precise and challenging job that not every rig is up for. That’s why you need a mobile workover rig from Dragon to get it done right every time. Our workover rigs are state-of-the-art and ready to tackle even the harshest conditions. A workover rig is perfect for site preparation while a standard mobile oil rig can handle a variety of piping tasks. Need workover rig parts, or service on another mobile rig? Dragon has that covered with our parts selection, too. View all of our workover rigs and other drilling rigs today.

The land drilling market worldwide is structured primarily as a rental market, not a sales market, where land drilling companies lease their rigs to E&P companies for an agreed period of time – weeks, months, or years – at a day-rate. The rigs are then used to drill wells and execute the E&P’s drilling programs.

Drilling opportunities are analysed and explored in order, leaving a series of dry holes, until a discovery is made. It is rare for an E&P company to actually own the rigs which they operate, but there are some exceptions such as Chesapeake, who will purchase their own fleet of rigs.

Investors require a minimum level of return for their investment dollars in drilling operations, and typically equate cost with risk. These turnkey drilling contracts may limit risk by guaranteeing a minimum number of wells that can be drilled with the rig. The contract will also outline how the rig can be used – including the pieces of equipment, when to change pieces, temperature and pressure tolerances and the weight of mud.

Nabors operates the world’s largest land drilling rig fleet, with around 500 rigs operating in over 25 countries – in almost every significant O&G basin on the planet. It also has the largest number of high-specification rigs (including new AC rigs and refurbished SCR rigs) and custom rigs, built to withstand challenging conditions such as extreme cold, desert and many complex shale plays.

Headquartered in Tulsa, Oklahoma, H&P is a global business with land operations across the US, as well as offshore operations in the Gulf of Mexico. It is engaged primarily in the drilling of O&G wells for E&P companies, and recognised for its innovative FlexRig technology.

Patterson-UTI operates land based drilling rigs, primarily in O&G producing regions of the continental US, and western Canada. The company also provides pressure pumping services to US E&P companies and specialist technology, notably pipe handling components, to drilling contractors globally.

Precision is an oilfield services company and Canada’s largest drilling rig contractor, with over 240 rigs in operation worldwide. The Company has two segments. The Contract Drilling Services segment operates its rigs in Canada, the United States and internationally. The Completion and Production Services segment provides completion and workover services and ancillary services to O&G E&P companies in Canada and the US.

Pioneer operates a modern fleet of more than 24 top performing drilling rigs throughout onshore O&G producing regions of the US and Colombia. The company also offers production services include well servicing, wireline, and coiled tubing services – supported by 100 well-servicing rigs, and more than 100 cased-hole, open-hole and offshore wireline units.

In Texas, generally considered to be the centre of US land drilling, RigData reports that there are currently 678 active rigs – split between Helmerich & Payne (160), Patterson-UTI (85), Nabors (64), Precision Drilling (39) and 77 other drillers (330).

Most new onshore rigs, both drilling and work over rigs, are built by OEMs in China. In the US, the larger vertically integrated land drillers have in-house manufacturing operations, so they will outsource some equipment construction, but assemble the new rigs at their own facilities. The leading provider of US newbuild rigs is National Oilwell Varco.

The secondary market, where existing rigs are sold, is largely auction dominated with mostly older rigs changing hands. As a rule, the big land drillers do not sell their newbuild rigs, as each has their own flagship designs.

• Hydraulic workover equipment is more portable than conventional equipment and can be set up and torn down easily. This aspect is important in offshore or other remote locations where transportation of heavy equipment is difficult.

• Hydraulic workover equipment is flexible. Lifting capacities can be made high and currently range to 340,000 pounds. It is possible to handle, pull, and run large OD downhole tools of moderate length under pressure. Rotary capabilities have been

Figure 15 shows a typical hydraulic workover rig on a land location. BOP rams are visible below the vertical hydraulic cylinders. Above the cylinders is a work platform on which is

At that point, the stationary slips are closed, holding the pipe in place. The travelling slips are released and lifted to their original position, then closed. When the travelling slips have

tubing work. This capability is the most recent extension of the hydraulic workover technique. As such, the scope of potential applicability is significantly broadened in both initial completion and workover activities.

The circulating system (pumps, tanks, lines, etc.) is the same as for other workovers with the exception of a one-way check valve installed in the bottom of the workstring or tubing.

The final part of this section deals with workover rig selection criteria. Typical workover operations are listed as keywords in the left-hand margin, and the different factors affecting

conventional rigs are preferred for a number of reasons. For drilling it is often necessary to use a high weight-on-bit in order to achieve reasonable penetration rates. This requires a

Concentric rigs are suitable for some light milling operations, however. In particular, they can be used to mill up very hard sand bridges that cannot be washed through. They are also

All three categories of rigs (conventional, concentric, and coiled tubing) can be used for squeeze cementing operations, although the first two types perform the vast majority of jobs

Concentric rigs can and do perform a large percentage of routine squeeze cementing operations, especially when an entire set of perforations are to be squeezed. For these applications a balanced-plug technique is used to spot the cement across the interval, then the workstring is pulled above the cement top and squeeze pressure is applied. An example of this procedure, covered in detail i “Remedial Cementing”, is shown in

cement is pumped down the workstring, through the channel, and back out above the packer. The cost savings over using a conventional rig can be significant.

of where a conventional rig would be used is where holes that can be sealed with cement develop in the production casing above the packer. There may be other times when

The kind of rig used for the recompletion depends on wellbore specifics. If the intended interval after the workover is above an existing retrievable packer then a

If the new completion interval is below the existing perforations, however, the option theoretically exists to recomplete using concentric techniques or a conventional rig.

The type of workover rig that is required for repair or replacement of downhole equipment depends on what downhole equipment is involved. If the equipment is suspended in the

For other repair/replacement operations, however, a conventional rig usually be required since retrieval of the entire completion string becomes necessary. Examples in this

often with the drilling rig. If performed at some later time in the well’s history, it is necessary to use a conventional workover rig to pull the tubing, run the screen and gravelpack packer, and re-run the completion.

The exception to this is the rare occasion when a gravel-pack is designed for a tubingless completion. In this case a concentric rig can be used to run the small diameter screen.

string approach are the cost of the rig and the chance of sticking the pipe in the hole if a leak develops while pumping the consolidation chemicals. In general, however, placement

Stimulation treatments are so varied that each of the general workover categories, bullhead, concentric, and conventional, can be the optimum solution. Each one of these is discussed

• Conventional – A conventional workover rig is primarily required when a well is to be fractured and the existing completion must first be pulled either because the tubing is

From a workover standpoint, low reservoir pressure presents a difficult situation. Stimulation is less effective than in a high-pressure reservoir because there is less pressure differential

to capitalize on the increased permeability. Perforating an additional interval is a temporary measure, at best, and may complicate future workovers. Installation of artificial lift

Water production problems can originate from the reservoir itself or from other sources such as casing leaks and primary cement failures. Water production is costly from both lifting and disposal standpoints. However, recovery from water-drive reservoirs requires a large influx of water into the reservoir, which may eventually necessitate producing considerable quantities of water from the reservoir before the economic limit for oil recovery is reached.

Gas production form an oil well result from a gas originally dissolved in the reservoir oil or from free gas that has segregated and become trapped above the oil as a gas cap. Free gas

In the dissolved-gas-drive reservoir, gas originally in the oil is liberated from solution as oil production begins and reservoir pressure declines. Further liberation and expansion of solution gas is requirement for primary oil recovery from a reservoir

gas production in this instance is usually not a well problem but a problem of the reservoir as a whole. Workovers are not generally successful at reducing the gas-oilratio for these wells.

When performing a workover to repair a mechanical failure, the engineer should study the well files to determine if other problems exist, which can be repaired at the same time.

A detailed cost survey will usually reveal that auxiliary rig tools and equipment cost approximately as much as the rental rate of the basic workover rig. Thus, as much attention should be given to the choice of auxiliary equipment as is given to the choice of workover technique and rig rate.

Contractors vary widely with respect to the tools and equipment furnished with the rig. An inventory of the equipment provided with a rig will make comparisons of hourly rig rates more meaningful. In addition, use of an inventory will ensure that all necessary equipment is on-hand and extra equipment is not ordered.

Some rigs include a swab line, which can reduce the cost of completion operations, if the rig is intentionally kept in place until the zone is evaluated. However, using a rig-provided swab line can be a disadvantage if using it means that the rig is

kept in place at workover-rig rates when it could be replaced by a lower-cost swabbing unit. In addition, keep in mind that swabbing is a specialized operation. The workover

cost of units rented from service companies. However, in some cases, the rig pumps may not have sufficient capacity and pressure rating to perform the necessaryoperations.

Workover rigs sometimes include tankage. The amount of tankage needed depends on the quantity of circulating and treating fluids needed for workover operations. The quantity of fluid which must be premixed and on-hand for well control

crews to operate for longer periods of time without fatigue. Proper utilization of this equipment can double the speed of tripping operations and thus save rig time.

In addition, company personnel at the rig site should be sure that the rig and service company personnel are aware of and observe the established safety rules. This can be facilitated by holding pre-job meetings to inform all on-site personnel of safety hazards, safety equipment location and use, and established safety rules.

Rigs are often chosen on the strength and capability of the equipment. In practice, personnel and supervision on a particular rig are often of equal importance to the equipment brought to the rig site. The number of men in the rig crew often dictates

Associated with this concept are the employment practices of a contractor during slack periods. Some contractors maintain key supervisors on a full-time basis but pay rig crews only when work is available. This can result in rig crews with low experience levels.

additional cost to the workover operation, enough back-up equipment should be on hand to plan for contingencies. When planning the workover, consider what could go wrong

– If the workover is postponed, what would the cost be? Would impending additional recovery programs render workover of this well more attractive in the future?

As discussed earlier in this Chapter (Subject 19.4), the choice of workover technique is sometimes limited by the capabilities and limitations of the workover rig units. For example, treatment operations, such as remedial cementing, matrix acidizing, and corrosion treatments, sometimes require that the treatment fluid selectively placed into a single zone or portion of a zone. While wireline and concentric techniques have some flexibility in this respect, use of a conventional workover rig allows use of the full casing ID and thus a wider range of downhole tools and packers can be used. On offshore locations, the compactness of wireline and concentric units is a premium. In addition, wireline units are the quickest and most efficient, thus reducing rig time, a major

Conventional rigs are slow and cumbersome; however, they are not as limited by factors such as operating depth, high bottom-hole temperatures and pressures, and severe I d restrictions. All of these factors must be considered before selecting a particular workover technique to perform the desired workover operation

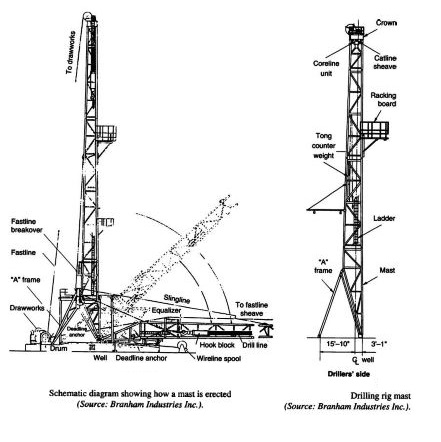

Drill floor (#21) is the area on the rig where the tools are located to make the connections of the drill pipe, bottom hole assembly, tools and bit. It is considered the main area where work is performed.

Drill pipe (#16) is a joint of hollow tubing used to connect the surface equipment to the bottom hole assembly (BHA) and acts as a conduit for the drilling fluid. In the diagram, these are stood in the derrick vertically, usually to save time while tripping pipe.

Setback (#17) is a part of the drill floor (#21) where the stands of drill pipe are stood upright. It is typically made of a metal frame structure with large wooden beams situated within it. The wood helps to protect the end of the drill pipe.

Stand (#16) is a section of 2 or 3 joints of drill pipe connected and stood upright in the derrick. When they are pulled out of the hole, instead of laying down each joint of drill pipe, 2 or 3 joints are left connected and stood in the derrick to save time.

8613371530291

8613371530291