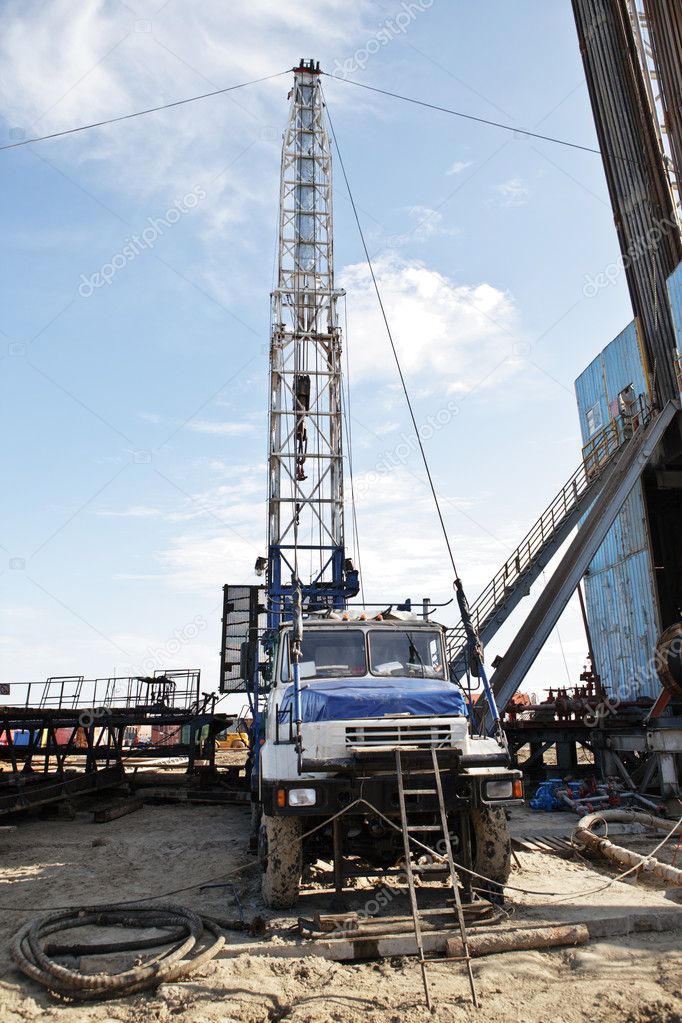

workover rig equipment free sample

Download Workover & Drilling Rig Inspection Checklist As we mentioned in the Rig Audit Article, rig inspection is an important process that shall be done from time to time. Especially, after the rig moving to a new drilling location.

When field operators are inspecting drilling equipment, the Work-Over Rig Field Inspection Check List of Rig Equipment app helps ensure that inspectors check all oilfield equipment carefully. The easy to use drilling rig equipment inspection app covers a wide variety of items, including the drill pipe, drill string, drilling fluid, and more.

Considering the number of Workover Rigs off contract and stacked it is now highly important that contractors have their equipment in ready to go on contract condition. Major oil companies and operating companies will require a history of good Rig Maintenance.

This Workover Rig Maintenance program consist of a complete maintenance schedule for all the equipment listed below. Any item listed on any of the check list worksheets can be changed and edited to suite any Workover Rig and any piece of equipment. It also covers Diesel Haulers and Water Haulers if you own your own trucks. Any item can be removed or changed to suite your Workover Rig and equipment.

To ensure our website performs well for all users, the SEC monitors the frequency of requests for SEC.gov content to ensure automated searches do not impact the ability of others to access SEC.gov content. We reserve the right to block IP addresses that submit excessive requests. Current guidelines limit users to a total of no more than 10 requests per second, regardless of the number of machines used to submit requests.

Drilling Operations. Drilling operations will be carried out using electrical rig for well. Drilling unit for drilling of oil and gas wells consists of a derrick at the top of which is mounted a crown block and a hoisting block with a hook. From the swivel is suspended a Kelly stem which passes through a square or hexagonal Kelly bush which fits into the rotary table. The rotary table receives the power to drive it from an electric motor. The electric motor rotates the rotary table, through which passes the Kelly bush, and the rotations are transmitted to the bit as the drilling progresses, the drill pipes in singles are added to continue the drilling process. At the end of the bit life, the drill pipes are pulled out in stands and stacked on the derrick platform. A stand normally has 3 single drill pipes. After changing the bit, the drill string is run back into the hole and further drilling is continued. This process continues till the target depth is reached. During the course of drilling, cuttings are generated due to crushing action of the bit. These cuttings are removed by flushing the well with duplex/triplex mud pumps. The mud from the pump discharge through the rotary hose connected to stationary part of the swivel, the drill string and bit nozzles. The mud coming out of the bit nozzles pushes the cuttings up hole and transports them to the surface through the annular space between the drill string and the hole. The mud not only carries away crushed rock from the bottom of the hole but it also cools the bit as it gets heated due to friction with formation while rotating. The mud also helps in balancing subsurface formation pressures and by forming a cake on the walls of the well also diminishes the possibility of crumbling or caving of the well bore. At the surface, the mud coming out from well along with the cuttings falls in a trough, passes through the solids control equipment"s i.e. shale shaker, de-sander/ de-silter and mud cleaner. These equipment"s remove the solids of different sizes, which get mixed with the mud during the course of drilling. The cleaned mudflows back to the suction tanks to be again pumped into the well. The drilling mud/fluid circulation is thus continuous cyclic operation. The most suitable clay for mud preparation is bentonite, which is capable of forming highly dispersed colloidal solutions. Various other chemicals are also used in mud preparation as per requirements dictated by the temperature/pressure conditions of the wells. The mud i...SaveCopy

About products and suppliers:Alibaba.com offers 465 workover rig equipment products. About 61% % of these are oilfield drilling rig, 7%% are mine drilling rig.

A wide variety of workover rig equipment options are available to you, You can also choose from diesel, electric and gasoline workover rig equipment,As well as from energy & mining, construction works , and manufacturing plant. and whether workover rig equipment is unavailable, 2 years, or 6 months.

planning,design and construction of main canal and structures including associated distribution system to provide irrigation facility to 41903 ha. area through piped irrigation network for upper high level canal of mahi bajaj sagar project,banswara

8613371530291

8613371530291