workover rig hand free sample

Here"s how cdl is used on rig hand resumes:Learned more of forklift operation as well as extensive CDL Driving experience.Skills UsedOperation of various equipment and tools.

Here"s how h2s is used on rig hand resumes:Worked & certified around H2S Accomplishments I was acknowledged multiple times in big safety meetings for showing my awareness of safety.

Here"s how heavy equipment is used on rig hand resumes:Remove and replace well heads, able to work safely around heavy equipment and flammables, operate machine shop tools safely.

Here"s how job safety analysis is used on rig hand resumes:Experience with safety meetings and Job Safety Analysis as per company standard and policies.

Here"s how safety meetings is used on rig hand resumes:Help co-workers repair rig, Participate in daily safety meetings to help avoid incidents, Help rig stay clean and keep drilling

Zippia allows you to choose from different easy-to-use Rig Hand templates, and provides you with expert advice. Using the templates, you can rest assured that the structure and format of your Rig Hand resume is top notch. Choose a template with the colors, fonts & text sizes that are appropriate for your industry.

Here"s how flow lines is used on rig hand resumes:Monitored issues with the well such as closed valves along the flow lines in order to prevent pressure buildup.

General maintenance is the regular check-up and repairs of machinery, buildings, and other mechanical equipment. General maintenance is performed by repair workers who are skilled to handle the day-to-day defects produced in the machinery. General maintenance aims to make sure the items remain in the best operational conditions. Usually, a set of planned activities are performed regularly by an expert to monitor the maintenance.

Here"s how general maintenance is used on rig hand resumes:Perform general maintenance of draw works, load and off-load pipe and assists in rig movement.

Here"s how swab is used on rig hand resumes:Help on Swab Rig/Fix Leaks/Hook up Wells/Roustabout/Read Meters/Keep Records of Wells/Walk Pipelines/Soap & Flow Wells/Maintain the Running of Four Compressors

Objective :Works under the direction of the Rig Operator/Driller. This individual is part of a crew that is responsible for the maintenance and day to day operation of the service rigs and/or the drilling rig.

Headline :Rig Hand is responsible for maintaining the rig in a safe and efficient manner. This includes ensuring the rig is properly maintained, repaired, and serviced by qualified staff. Ensure that all maintenance schedules are met and that all scheduled work is completed within acceptable time frames.

Objective :A Water Pipe Installer and as a Rig Hand in industries including Business Services, and Oil and Gas Extraction. Skills and experiences include machine operation, equipment operation, welding.

Headline :A Self-motivated, task oriented Prior military supervisor and shop foreman with working in the shop and field environment. A skilled candidate qualified and trained in the handling Hazardous-Materials including preparing, shipping.

Objective :Reliable Floor Hand with strong mechanical aptitude and a willingness to learn. Motivated to learn new trades and skills. Interested in growing a career and fostering leadership capabilities. A person who thrives in a dynamically changing environment while working as a team member and meeting all production deadlines. Self-motivated and can perform strenuous work in any weather condition.

Skills :Power And Hand Tools, Machine Servicing, Safety Procedures Knowledge, Works Well Independently, Strong Mechanical Aptitude, Effective At Multi-tasking

Description :Ran floors, picking up the pipe, picking up rods, pump change-outs, trip pipe, run tubing board, assist driller, hammer, setup pump, rigging up, rigging down.

Objective :Highly organized Floor Hand with strong interpersonal skills, high proficiency and cross-functional experience with excellent comprehension, training, mechanical and manufacturing skills, customer relation skills, organizational and process development skills. Dedicated team player that practices safe work performance on a daily basis while contributing to the professional growth within the organization. To obtain a challenging and rewarding position that allows me to utilize my acquired skills while allowing for professional growth and development.

Placed the 80-pound hand slips around the casing at the wellhead to prevent a string of casing from falling into the borehole during transport of casing sections.

Headline :Dedicated Floor Hand, Chain, And Motorman with 5+ years" experience with oilfield experience - willing to travel and relocate. Results of dedicated individual, proven records of accomplishments and consistent contributions that increased efficiency. A flexible team member who thrives in environments to prioritize and juggle multiple projects. A productive leader with the expertise to troubleshoot, initiate change and maintain a positive, safe, and productive environment.

Summary :Floor Hand with 15 years of experience in different warehouses and technical careers. Dependable and learns new skills quickly. Good with time management and getting things done as quickly as possible ensuring safety for everyone. Experience with forklifts, skid loaders, and backhoe. My objective is to obtain a long term position with a stable company that will allow me to gain tenure and grow within the company based on my work ethic and professional attributes that I bring forth to the company.

Headline :Floor Hand, with 6+ years of experience, seeking to obtain employment with an industry-leading company. Seeking an opportunity/position with a company that will allow me to fully utilize my leadership, communication, organizational, teamwork, and problem-solving skills with the opportunity to help improve efficiency and enhance profitability.

Objective :Floor Hand with keen attention to detail and an analytical mind, continually finding ways to improve the overall operations of the organization. Looking for a position as an active employee, involving responsibility and working with others as a team member to achieve advancement and growth for the company. Reliable, committed to top-quality works, Enthusiastic, dependable, and self-motivated.

Summary :A very dependable and hardworking Floor Hand, Chain, And Motorman with more than 14 years in the oilfield industry. Thrives in a fast-paced environment and picks up very quickly. Represents establishment with friendly and professional demeanor at all times. An employee who works effectively without supervision. Proficient in multitasking and maintaining a safe and efficient work area.

Objective :Experienced Floor Hand with over one plus years of oil field experience. Very familiar with several different types of drilling rigs and workover rigs. Also skilled at welding and other trades. Seeking a career where my diverse experience and training in management, leadership, and teamwork can help support the company"s vision.

Summary :Floor Hand experienced in most operations performed during completion and remedial work including drill outs with snubbing unit, drill outs with the hybrid tool and annular, TCP operations, remedial operations such as cleanouts, nitrogen kickoffs, cased hole fishing, cement, and gel squeeze jobs, and plug and abandon operations. Seeking a factory worker position with a reputable factory in order to utilize physical work capabilities as well as knowledge of basic factory operations.

Objective :Highly motivated Associate Floorhand seeking a full-time position to utilize my current skills and knowledge with the opportunity to learn and grow within the company. Responsible and motivated to handle tasks with accuracy and efficiency. Aspires to become a leading role in a company setting. Excellent communication and time management skills. Acquires new tasks quickly and proficient in growing key relationships.

This is a real resume for a Workover Rig Floor Hand in Christine, Texas with experience working for such companies as Virtex Operating Company, Inc, Americus Pipetesters. This is one of the hundreds of Workover Rig Floor Hand resumes available on our site for free. Use these resumes as templates to get help creating the best Workover Rig Floor Hand resume.

Foremost Well Service PUSHERS, OPERATORS, RELIEF OPERATORS, DERRICKHANDS & FLOORHANDS to work on workover rigs -24hr and daylight rotational work (14 days on…

2+ years previous oilfield and/or workover rig experience preferred. Work on floors or derricks on the rig as needed. May offer relocation package DOE.

The Crew Worker, under the direction of the Rig Operator, performs activities and operates hand and power tools to perform maintenance and repairs to oil or gas…

*Floor Hands - *minimum experience required 6 months. *Derrick Hands - *minimum experience required 1 year. Job Requirements: *Job requirements include but are…

Looking for experienced Floorhands for Workover Rigs in North Dakota. Full benefits, competitive pay with desirable schedule of TWO WEEKS ON / TWO WEEKS OFF.

Manages tools on the workover rig floor and assists in daily maintenance. Picks up/lays down pipe and latches tubing in elevators. This is a full-time position.

Workover rig company in Crosby, ND is accepting applications for floorhands and derrickhands. Immediate openings. Must be willing to work in all weather…

The successful candidate will have an outstanding track record of success in workover rig experience in operating heavy equipment while ensuring communication…

Crew Member positions include Rig Trainee (no experience required), and Floor hand, Derrick hand, Relief Crew Chief, and Crew Chief, which are experience…

As a rig hand, you will need to safely complete tasks and operations as the onsite supervisor instructs. You will be responsible for all aspects of maintaining…

Currently accepting applications for experienced Workover Rig crew members including floor hands, derrick hands and operators. Pay is based on experience.…

Derrick hands are part of a 3-5 Person workover rig crew that performs services on oil and gas wells. Performs all well-servicing tasks from an elevated…

Assist and trains as Derrickman or Pithand mixing mud, taking inventories of shale shaker screens, mud pump parts, on hand rig supplies, tank fluid levels and…

Previous experience as an Frac operator, coiled tubing, rig, oilfield, oil & gas, Oil and gas, energy, energy services, driving tractor trailers, well services,…

Previous experience as an Frac operator, coiled tubing, rig, oilfield, oil & gas, Oil and gas, energy, energy services, driving tractor trailers, well services,…

Transportation to and from various rig locations. Maintain the cleanliness of the rig. Use of power tools and other hand tools. 12-hour Shifts (Days or Nights).

The Crew Worker, under the direction of the Rig Operator, performs activities and operates hand and power tools to perform maintenance and repairs to oil or gas…

Ensuring rig is properly equipped and maintained. Our specialty is drilling and servicing large and deep diameter water wells for municipalities/cities, rig…

Complete rig in and rig out duties. Previous experience as an Frac operator, coiled tubing, rig, oilfield, oil & gas, Oil and gas, energy, energy services,…

The rig hand will operate rod wrenches, tongs, elevators, and associated equipment. Manages tools on the workover rig floor and assists in daily maintenance.

May be required to work floors or operate the rig when needed. Performs all well-servicing tasks from an elevated position up to 75 feet off the ground on the…

Reports safety hazards, accidents or maintenance issues to the rig supervisor. Operates rod wrenches, tongs, elevators and other associated rig tools and…

We are looking for candidates who have oilfield or rig experience. A valid driver"s license is a must. Should be able to work 12-12.5 hours shifts - 20 days on/…

Good manual dexterity (hand, hand with arm, two hands) and multi-limb coordination. Effectively and clearly communicates, as required, with mentor/crew pusher…

Complete rig in and rig out duties. Previous experience as an Frac operator, coiled tubing, rig, oilfield, oil & gas, Oil and gas, energy, energy services,…

Performing services on oil and gas wells as part of a crew of a well service rig. Assisting in rigging up and rigging down. Pay: $22.00 - $26.00 per hour.

Brigade Energy Services is hiring hardworking, career-minded people for all workover rig crew positions. We are currently looking for candidates for our Snyder,…

Willingness to install and demobilize temporary equipment for drilling rig power system. Of electrician role in an oil & gas field: 3 years (Required).

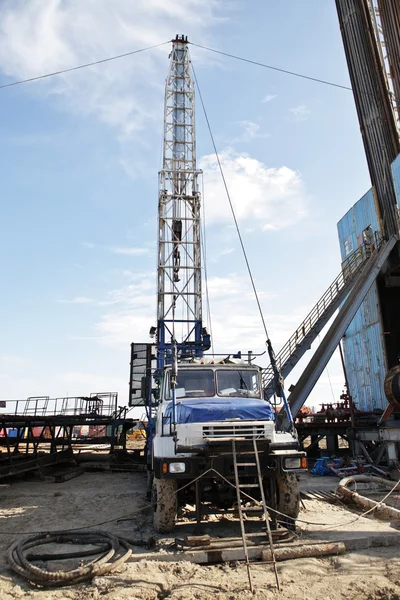

SUMMARY: A Workover Rig Floor Hand is responsible for performing services on oil wells utilizing a double, single, and Pole Rig. The duties of the floor hand include assisting in rigging up/down, pulling/laying rods, tubing, casing and other functions as specified by the rig operator.

Handle tubing, rods, casing and associated equipment such as rod strippers, polish rods, etc. The rig hand will operate rod wrenches, tongs, elevators, and associated equipment.

Must have one - two (1-2) years of experience within oil and gas workover rigs, drilling rigs, production facilities, pipeline labor or equivalent experience.

Perform physical activities that require considerable use of arms and legs and moving the whole body, such as climbing, lifting, balancing, walking, stooping, and handling of materials.

The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically, a workover refers to the expensive process of pulling and replacing completion or production hardware in order to extend the life of the well.

Workovers rank among the most complex, difficult and expensive types of wellwork. They are only performed if the completion of a well is terminally unsuitable for the job at hand. The production tubing may have become damaged due to operational factors like corrosion to the point where well integrity is threatened. Downhole components such as tubing, retrievable downhole safety valves, or electrical submersible pumps may have malfunctioned, needing replacement.

In other circumstances, the reason for a workover may not be that the completion itself is in a bad condition, but that changing reservoir conditions make the former completion unsuitable. For example, a high productivity well may have been completed with 5½" tubing to allow high flow rates (a narrower tubing would have unnecessarily choked the flow). Some years on, declining productivity means the reservoir can no longer support stable flow through this wide bore. This may lead to a workover to replace the 5½" tubing with 4½" tubing. The narrower bore makes for a more stable flow.

Before any workover, the well must first be killed. Since workovers are long planned in advance, there would be much time to plan the well kill and so the reverse circulation would be common. The intense nature of this operation often requires no less than the capabilities of a drilling rig.

The workover begins by killing the well then removing the wellhead and possibly the flow line, then installing a B.O.P commonly known as a blowout preventer, then lifting the tubing hanger from the casing head, thus beginning to pull the completion out of the well. The string will almost always be fixed in place by at least one production packer. If the packer is retrievable it can be released easily enough and pulled out with the completion string. If it is permanent, then it is common to cut the tubing just above it and pull out the upper portion of the string. If necessary, the packer and the tubing left in hole can be milled out, though more commonly, the new completion will make use of it by setting a new packer just above it and running new tubing down to the top of the old.

Style: Tripod Lamp Brighten up any room with this custom table lamp from Lamp-In-A-Box. Personalize the lamp shade with original artwork, photography, or bold graphics to create…

The following is a list of seasonal work gear worn by drilling rig workers. Savanna supplies rig employees with coveralls, hard hat, safety glasses & impact gloves (1 pair).

Drilling rig crews are generally made up of six (6) people: Rig Manager, Driller, Derrickhand, Motorhand, Floorhand, and Leasehand. Each crew works 12 hours shifts as the rig operates 24 hours per day, and each position is vital to the operation of the rig.

Work in the oil and gas services industry is seasonal. Because of the weight of rigs and their equipment, and the remote location of wells, these locations are often only accessible when the ground conditions can tolerate heavy loads. Therefore, wells are typically drilled and serviced in the winter when the ground is frozen solid, or in the summer, when the ground has thawed and dried sufficiently. During the spring and fall, when the ground is in a transitional state, it is too soft to move equipment on and easily damaged. For this reason, provincial governments implement “road bans” prohibiting heavy loads from operating in certain areas. During this time, rig work is slower, and many rigs are shut down and their crews sent home. Be prepared to be off for anywhere from 6 to 12 weeks without pay during this time. However, rigs that are shut down are usually in need of maintenance, and there may be opportunities for employees who would like to help in this regard. Employees may be eligible for Employment Insurance benefits during seasonal shutdowns.

To work on a drilling rig, you must be able to get to and from all of your work locations. As drilling often occurs in remote areas, having reliable transportation is considered mandatory for non-camp locations. Drilling rigs commonly operate 24 hours per day, 7 days per week with either three crews working 8 hour shifts or two crews working 12-hour shifts. Most often day crews and night crews will alternate weekly, so each crew has a chance to work during both the day and night. Most crews will work 14 days straight with 7 days off in-between. The typical living situation while working falls into three categories: Non-Camp, Full Camp and Texas Camp.

Non-Camp: When the rig site is near a town, non-camp conditions normally apply. Crews will stay in hotel rooms and receive a per day living allowance for food and accommodation. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and accommodation out of your own pocket.

Full-Camp: When a rig site is in a remote location, crews may stay in a full camp. In a full-camp all food and full accommodation is provided. Once at the camp, the crew travels to and from the rig in the crew truck. Almost all camp work is available in the winter only.

Texas Camp: These camps are typically located nearby the rig location. Crews are responsible for supplying their own bedding, cooking supplies, groceries and toiletries. While staying at a texas camp, a daily allowance is provided for food and toiletries. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and toiletries out of your own pocket.

Once you have completed your orientation, you will immediately receive any other necessary training. This involves Workplace Hazardous Materials Information System (WHMIS) and Transportation of Dangerous Goods (TDG), along with an in-depth General Safety Orientation. This training is mandatory and provided by Savanna at no cost to the employee. Job-related, hands on training is conducted in the field through Savanna’s Rig Mentoring Program.

While it is not mandatory to have this certification, each service rig crew is required to have two members who are certified in Standard First Aid with CPR level C. Therefore, obtaining a certification beforehand is a great way to improve your chances of being hired.

Power and hand tools can cause deadly accidents and injury if they are improperly maintained or utilized. This digital checklist helps inspectors ensure that power and hand tools used in the refinery meet safety requirements in order to protect the health and safety of employees.

This helpful job safety analysis tool can be used anywhere in the field and is easily accessible from any smartphone or tablet. Simply open the drilling rig power and hand tool safety checklist and you"ll be prompted to check oil and gas rig power and hand tools via the electronic hazard analysis tool. The checklist covers drill press operations, activity hazard analysis, machinery safety and the contact information for drilling contractors. Use the results of the risk assessment checklist to improve safety and health for those who work on drill rigs and to reduce accidents caused by machine tools used in the drilling and blasting process.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291