workover rig supervisor jobs free sample

Displayed here are Job Ads that match your query. SimplyHired may be compensated by these employers, helping keep SimplyHired free for jobseekers. SimplyHired ranks Job Ads based on a combination of employer bids and relevance, such as your search terms and other activity on SimplyHired. For more information, see the SimplyHired Privacy Policy.

Objective :A Rig Supervisor with 15 years of total oilfield experience. Looking for a position with a company that has a great reputation, a great work environment, and excellent pay with great benefits in their company.

Description :Responsible for managing all aspects of day to day operations, coordinating jobs, and making sure equipment and personnel were on the job sites.

Objective :Seeking a Rig Supervisor position with an outstanding career opportunity that will offer a rewarding work environment along with a winning team that will fully utilize management skills.

Summary :As a Rig Supervisor manage crew members, maintains productivity standards, and work closely with customers ensuring that quality products and services are being safely provided.

Headline :Diversified experience in the safety, management and workover, drilling rig operations. Particularly effective in determining customer needs and organizing and applying resources rapidly. Proven ability to solve difficult problems.

Description :Minimized the flat time by preparing for jobs in advance Supervised, reviewed, and followed up on the activities related to drilling, completion, and workovers.

Kept management informed of upcoming events and foreseeable issues Ensured all tools and equipment were at rig site for drilling of disposal well workover and complete two wells for injection and drill and complete a world-class well with the largest wellhead.

Coordinated logistics for both rig mobilization and the mobilization tools and equipment via hall road, ice road, airfreight, and helicopter, and barging.

Prepared daily reports including daily time operation cost problems consumption of materials and the progress of work at the well site for rig activity including time and cost.

Headline :To obtain a Rig Supervisor position with a company that will encourage growth in knowledge, skills, and abilities. Further, allowing me to utilize and improve my hands-on labor skills, positive attitude, and hardworking ability.

Summary :As a Rig Supervisor, responsible for managing crew members, maintaining productivity standards. Knowledge of all parts on a workover Rig, able to troubleshoot the mechanics of the rig and equipment on-site, etc,.

Objective :Rig Supervisor with 2+ years of experience in Performing rig components, work over rig, fall arrest system, harness, derrick, hoisting component inspections as required, etc,.

Directly supervised the rig operator and crew at all times ensuring maximum productivity, proper operation of all equipment, and adhere to all safety requirements.

Summary :Rig Supervisor with 15+ years experience in both vertical and horizontal drilling, and 3 years experience as a Rig Supervisor of seven rigs. Safety-conscious, goal-oriented leader with excellent troubleshooting skills, a strong work ethic, and a proven record of safety-first results.

Here"s how bop is used on rig supervisor resumes:Coordinated running and testing of casing, wellhead equipment, and BOP stack with Rig Superintendent.

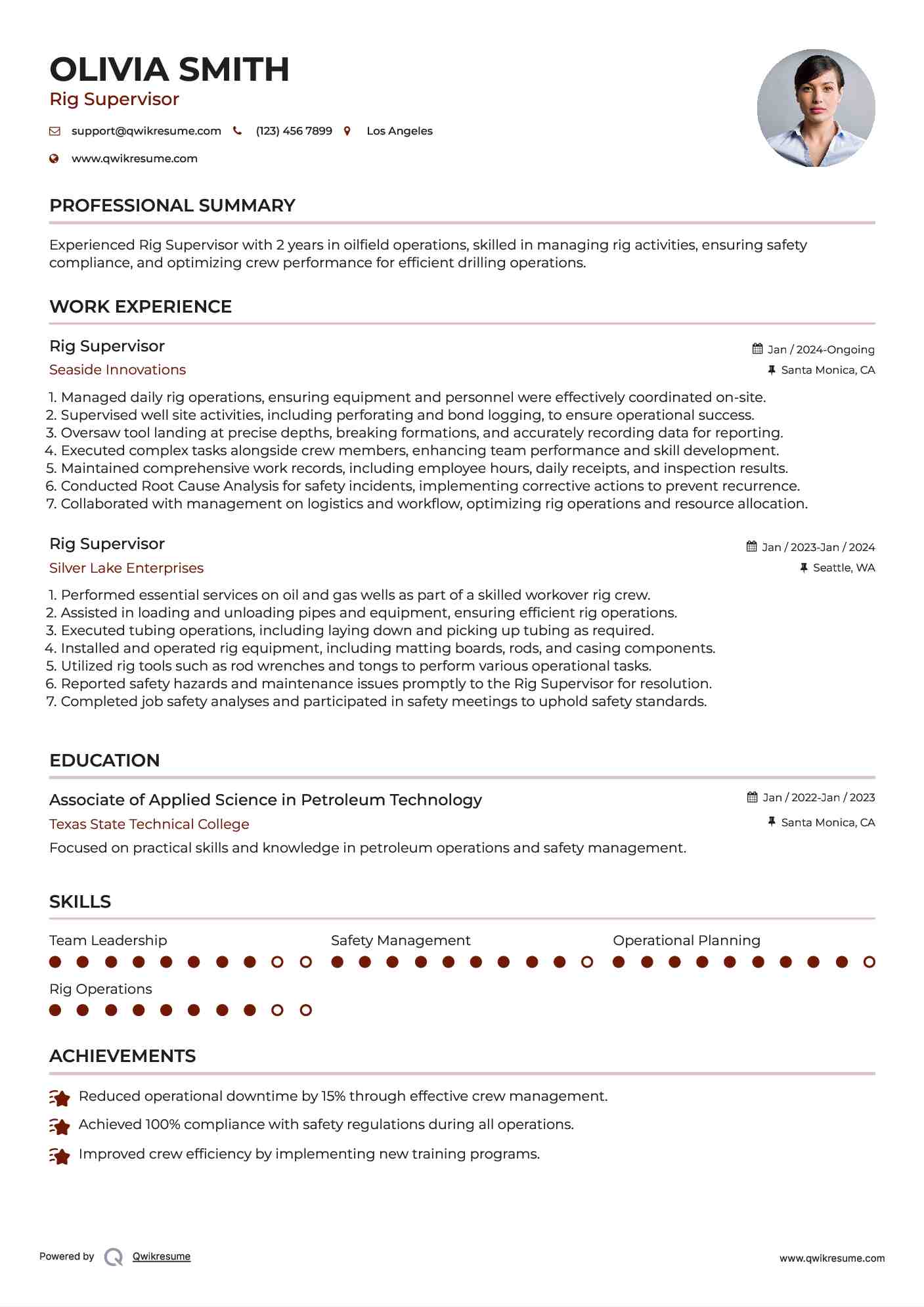

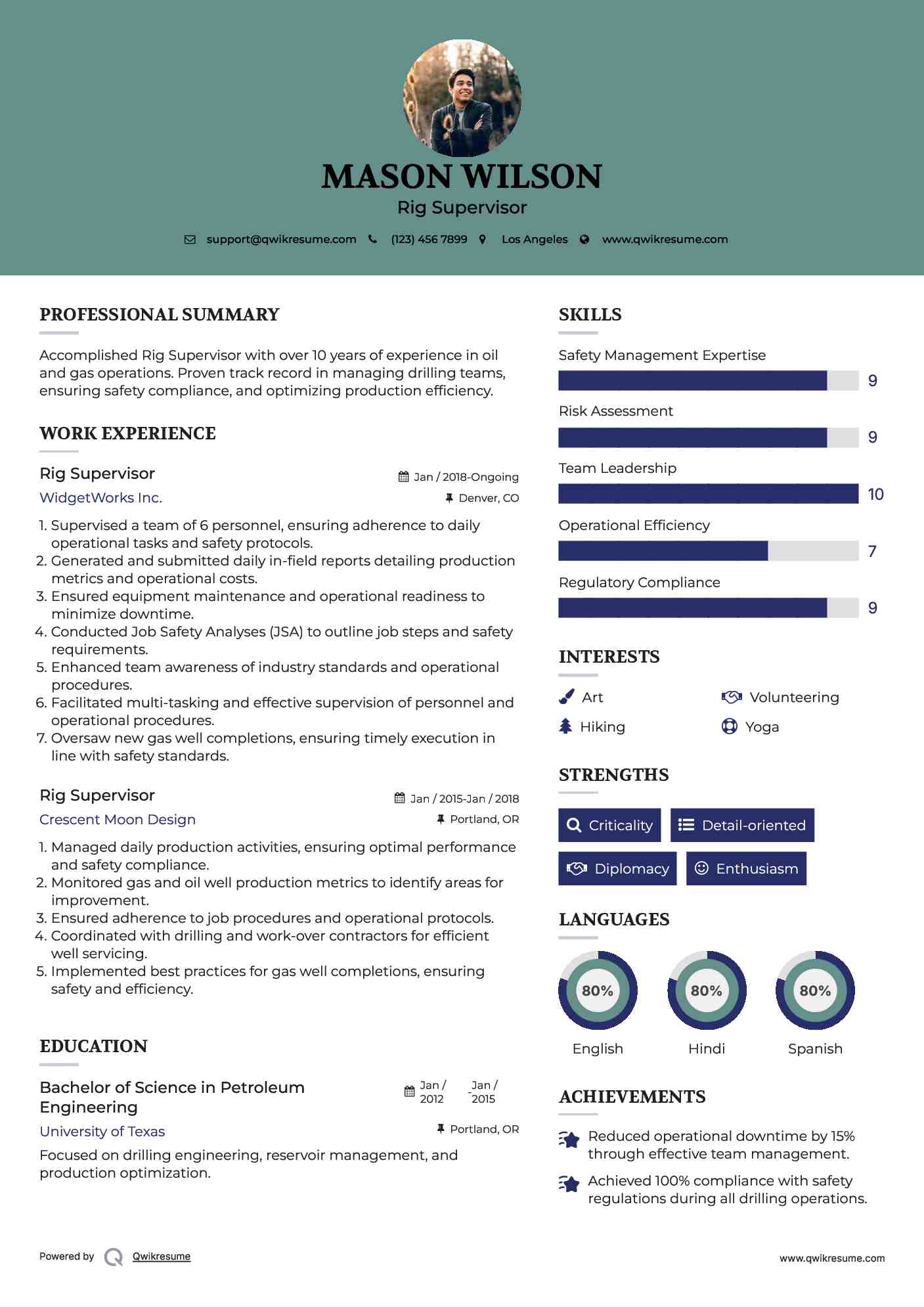

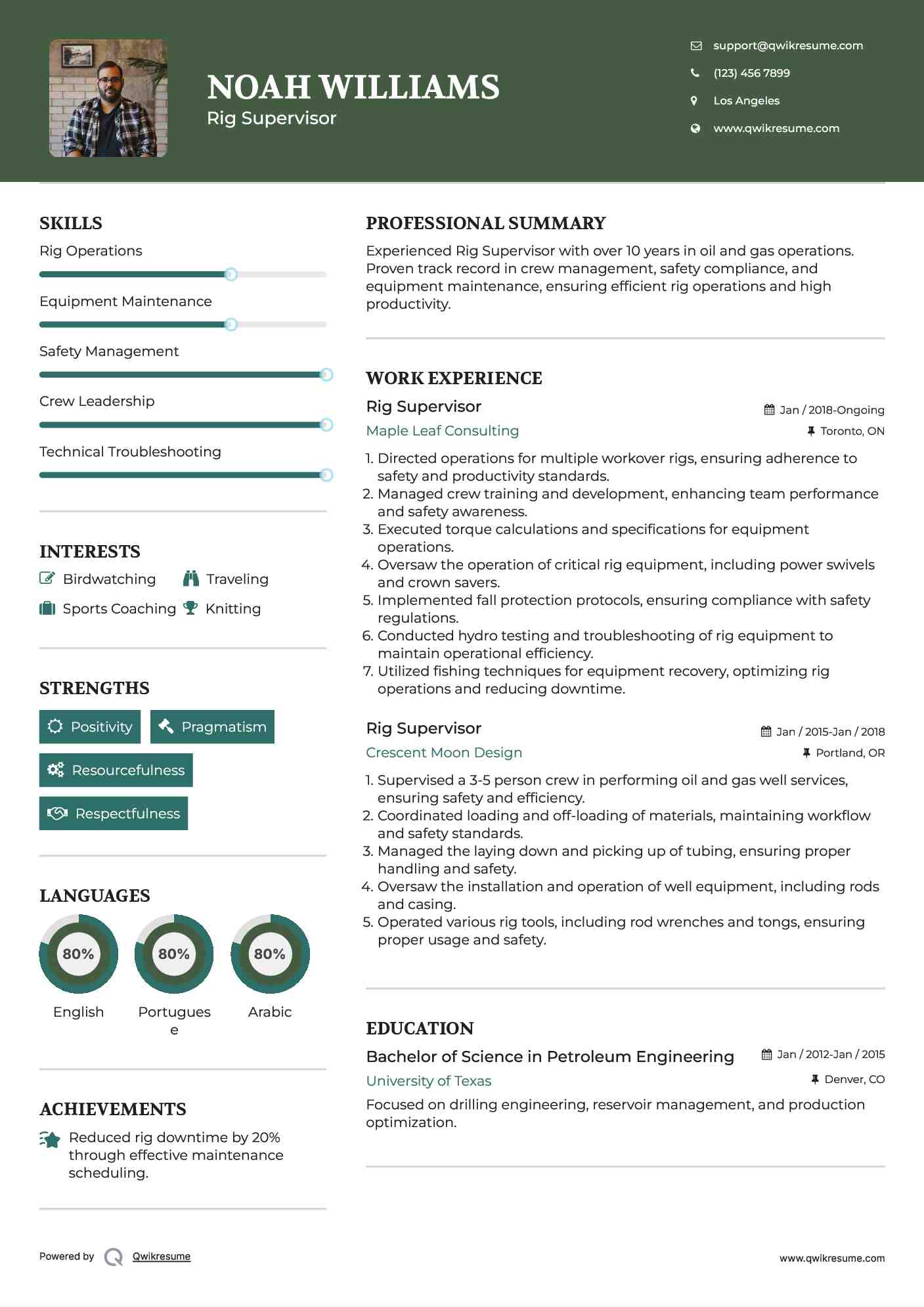

Zippia allows you to choose from different easy-to-use Rig Supervisor templates, and provides you with expert advice. Using the templates, you can rest assured that the structure and format of your Rig Supervisor resume is top notch. Choose a template with the colors, fonts & text sizes that are appropriate for your industry.

Here"s how on-site supervision is used on rig supervisor resumes:Provide on-site supervision for crew workers and rig activities, including well killing procedures for diatomite field.

Here"s how esp is used on rig supervisor resumes:Experience with artificial lift systems included Rod (Beam) pumps, ESP, hydraulic and gas lift systems.

Heavy equipment, also known as heavy machinery, refers to heavy-duty trucks that are specifically built to complete building works, most often earthwork activities or other major construction projects. Heavy machinery works by multiplying the amount of input force added to force exerted, allowing jobs that would otherwise take hundreds of workers and weeks of labor to be completed in a fraction of the time.

Here"s how heavy equipment is used on rig supervisor resumes:Controlled movement of heavy equipment through narrow openings and confined spaces using chains and poles.

Here"s how safety program is used on rig supervisor resumes:Worked under OSHA and Dow"s safety program and effectively maintained all work orders from supervisors.

Here"s how completion operations is used on rig supervisor resumes:Performed as a pulling unit operator by drilling new hole, re-entries, work/over and completion operations.

Responsible for the upkeep, maintenance, and any repairs necessary of assigned work over rigs, dog houses, utility trailers, and company vehicles assigned to crews.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The sample below is for a Oil Well Site Supervisor CV Resume Sample. This resume CV was written by a ResumeMyCareer professional CV resume writer, and demonstrates how a CV resume for an Executive Management CV Resume Sample should properly be created. Our Certified Professional CV Resume Writers can assist you in creating a professional document for the job or industry of your choice.

Experienced, knowledgeable, and well trained Oil Well Site Supervisor candidate with more than 16-years experience in international Air Drilling on well program operations. Extensive knowledge of drilling operations and services, and compliance with drilling programs in safe and efficient manner. Knowledge of equipment inspections, and capable of implementing contingency plans. Capable of managing inventory of consumable drilling supplies such as cement, barite, bits, and nozzles. Experience with Well Testing, Workover, Completion, Directional, Multi-lateral and HP/HT well construction operations.

Experienced operation of air drilling equipment on drilling rigs, performed cavitations of coal wells, and provided monthly maintenance on all related drilling equipment.

The following is a list of seasonal work gear worn by drilling rig workers. Savanna supplies rig employees with coveralls, hard hat, safety glasses & impact gloves (1 pair).

Drilling rig crews are generally made up of six (6) people: Rig Manager, Driller, Derrickhand, Motorhand, Floorhand, and Leasehand. Each crew works 12 hours shifts as the rig operates 24 hours per day, and each position is vital to the operation of the rig.

Work in the oil and gas services industry is seasonal. Because of the weight of rigs and their equipment, and the remote location of wells, these locations are often only accessible when the ground conditions can tolerate heavy loads. Therefore, wells are typically drilled and serviced in the winter when the ground is frozen solid, or in the summer, when the ground has thawed and dried sufficiently. During the spring and fall, when the ground is in a transitional state, it is too soft to move equipment on and easily damaged. For this reason, provincial governments implement “road bans” prohibiting heavy loads from operating in certain areas. During this time, rig work is slower, and many rigs are shut down and their crews sent home. Be prepared to be off for anywhere from 6 to 12 weeks without pay during this time. However, rigs that are shut down are usually in need of maintenance, and there may be opportunities for employees who would like to help in this regard. Employees may be eligible for Employment Insurance benefits during seasonal shutdowns.

To work on a drilling rig, you must be able to get to and from all of your work locations. As drilling often occurs in remote areas, having reliable transportation is considered mandatory for non-camp locations. Drilling rigs commonly operate 24 hours per day, 7 days per week with either three crews working 8 hour shifts or two crews working 12-hour shifts. Most often day crews and night crews will alternate weekly, so each crew has a chance to work during both the day and night. Most crews will work 14 days straight with 7 days off in-between. The typical living situation while working falls into three categories: Non-Camp, Full Camp and Texas Camp.

Non-Camp: When the rig site is near a town, non-camp conditions normally apply. Crews will stay in hotel rooms and receive a per day living allowance for food and accommodation. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and accommodation out of your own pocket.

Full-Camp: When a rig site is in a remote location, crews may stay in a full camp. In a full-camp all food and full accommodation is provided. Once at the camp, the crew travels to and from the rig in the crew truck. Almost all camp work is available in the winter only.

Texas Camp: These camps are typically located nearby the rig location. Crews are responsible for supplying their own bedding, cooking supplies, groceries and toiletries. While staying at a texas camp, a daily allowance is provided for food and toiletries. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and toiletries out of your own pocket.

Once you have completed your orientation, you will immediately receive any other necessary training. This involves Workplace Hazardous Materials Information System (WHMIS) and Transportation of Dangerous Goods (TDG), along with an in-depth General Safety Orientation. This training is mandatory and provided by Savanna at no cost to the employee. Job-related, hands on training is conducted in the field through Savanna’s Rig Mentoring Program.

While it is not mandatory to have this certification, each service rig crew is required to have two members who are certified in Standard First Aid with CPR level C. Therefore, obtaining a certification beforehand is a great way to improve your chances of being hired.

Including the right keywords will help you get past Applicant Tracking Systems (i.e. resume screeners) which may scan your resume for keywords to see if you"re a match for the job.

Go through the Drilling Supervisor posting you"re applying to, and identify hard skills the company is looking for. For example, skills like Well Control, Onshore Operations and Petroleum are possible skills. These are skills you should try to include on your resume.

Incorporate skills - like Drilling Engineering, Petroleum Engineering and Workover - into your work experience too. This shows hiring managers that you have practical experience with these tools, techniques and skills.

Specifically on Drilling Supervisor resumes, you should think about highlighting examples of where you supervised others. Recruiters want to see if you have experience supervising and providing oversight over teams of similar sizes.

Here are examples of proven resumes in related jobs and industries, approved by experienced hiring managers. Use them as inspiration when you"re writing your own resume. You can even download and edit the resume template in Google Docs.

It strikes the right balance between white space and content, and doesn"t waste space on unnecessary images and icons. Remember, recruiters aren"t looking at how creative you are when it comes to your template. Your content is core and should be the focus.

The first rule about including a resume summary is that it does not repeat accomplishments mentioned elsewhere on the resume. This resume stresses new software engineering and leadership skills right at the top of the resume, and includes an award too. If you include a summary, try to include a mix of both technical accomplishments (e.g. projects you developed or led), as well as career-related accomplishments (e.g. being promoted).

Use this Google Docs template if you"re a student, recent graduate, or a career changer. Right out of college, you may not have much experience in the field. To supplement that, use your experience in clubs and activities, volunteering, projects, and useful coursework to help highlight your knowledge on the subject.

The most common skills and keywords we found on Drilling Supervisor resumes and job postings were Drilling, Onshore Operations, Offshore Drilling, Oilfield, Petroleum, Completion, Energy Industry and Well Control.

SUMMARY: A Workover Rig Floor Hand is responsible for performing services on oil wells utilizing a double, single, and Pole Rig. The duties of the floor hand include assisting in rigging up/down, pulling/laying rods, tubing, casing and other functions as specified by the rig operator.

Handle tubing, rods, casing and associated equipment such as rod strippers, polish rods, etc. The rig hand will operate rod wrenches, tongs, elevators, and associated equipment.

Must have one - two (1-2) years of experience within oil and gas workover rigs, drilling rigs, production facilities, pipeline labor or equivalent experience.

? high elevations, trenches, or crawl spacesPossible travel during the work day between jobsites, although some out-of-area travel may be expected with seldom overnight travel.

Communicate and comprehend instructions/directions in accordance with safety requirements, which necessitate no language barriers exist between employees and supervisors.

To write an effective rig manager job description, begin by listing detailed duties, responsibilities and expectations. We have included rig manager job description templates that you can modify and use.

Our company is looking to fill the role of rig manager. If you are looking for an exciting place to work, please take a look at the list of qualifications below.

Must be proficient in well control, sustains the upkeep of rig equipment and suggests improvements, and maintains the paperwork (including morning reports, IADC daily log report)

Plans various rig activities such as repairs, daily maintenance, and preventative maintenance, major repairs to guarantee efficient drilling and minimize downtime of the rig

Ensures that crew members are properly trained and familiarized with standard operating procedures to include, but not limited to, proper care and maintenance of the rig and drill string, including lubrication of equipment and housekeeping

Our innovative and growing company is searching for experienced candidates for the position of rig manager. To join our growing team, please review the list of responsibilities and qualifications.

Responsibilities for rig managerEnsure that all required paperwork and approvals in connection with payment for ordered supplies of materials, equipment and services are carried out

At all times keep the Purchasing Manager, the management at the head office and the staff at the base office (if any) and on board the rigs well informed about the development of ordered supplies of materials, equipment and services

Maintain all required records and documentation at rig site and produce accurate and timely reports on all aspects of rig operations and personnel matters

Develop rig move plans and manage rig moves, taking personal responsibility for safely rigging-down & rigging-up of the drilling rig, camp and associated equipment

Take responsibility for all HR matters at rig site, including training and development of expatriate and national staff in the rig crews, particularly with regard to on the job training

Our growing company is hiring for a rig manager. If you are looking for an exciting place to work, please take a look at the list of qualifications below.

Our growing company is looking for a rig manager. We appreciate you taking the time to review the list of qualifications and to apply for the position. If you don’t fill all of the qualifications, you may still be considered depending on your level of experience.

Learn all aspects of the operation of the Dyno and Horizontal Drilling Machine (HDM) including the rig, HPU, controls, data acquisition, pump truck, test fixtures

Our company is hiring for a rig manager. Please review the list of responsibilities and qualifications. While this is our ideal list, we will consider candidates that do not necessarily have all of the qualifications, but have sufficient experience and talent.

Manage engineering design for all New Rig Construction, Refurbishing and Maintenance activities, including scope of work, drafting oversight and final drawing issuance

Are you trying to land a job on a drilling rig and start a career in the oil and gas industry? Like you - I started at the bottom and over a 15-year career progressed from an entry-level position to a project manager earning a six-figure income $$$,$$$. After this, I worked as a Recruiter and I am now an Executive CV / Resume Writer so have a very good understanding of the environment and what it takes to progress a career in the international oil and gas industry. This article will help you land an entry-level position like roustabout, operator, rigger or trainee graduate. It also contains a comprehensive guide of all the positions on a rig and descriptions of various types of rigs so that you can choose a career direction.

It is a realistic option for you to break into the industry, it just requires patience and for you to apply everywhere necessary but make sure your CV is looking its absolute best before you apply, if not, it’s a wasted exercise... You only have one chance at making the right first impression!

Jobs on the rigs will include cleaners, painters and roustabouts (both entry-level), riggers (slingers), floor hands, catering staff, crane operators, welders, electricians, mechanics, motormen, engineers, chief engineers, derrickman, assistant drillers, drillers, tool pushers, warehousemen, medics, (HSE) safety supervisors, ballast control men, dynamic position (DP) operators, barge operators, barge engineers, offshore installation managers (OIMs), rig managers and rig superintendents.

All these positions except entry-level will require some type of prior experience and specialist training unless you just get very, very lucky. Below is a guide for a more in-depth look at the permanent positions on a rig.

If you want to work overseas, understand that drilling contractors seldom if ever send lower echelon people overseas. An overseas crew usually have Expatriate Rig Managers, Tool pushers, Drillers, Assistant Drillers, Crane Operator, Barge Engineer, Electrician and Mechanic. Maybe even a few more, maybe a few less, it varies from company to company, rig to rig, job to job. All lower positions will be locally hired!

You are not going to see expatriate roustabouts, cleaners, painters, riggers or floor hands going overseas and working a 28/28 schedule because the country where the rig is working will use (nationals) for those jobs. Often local governments stipulate that a certain percentage of the crew needs to be national so expatriate positions are reduced.

You can also identify keywords for your CV / Resume by using Teal (It"s Free). Teal is the secret weapon that I"ve been happily using for the past couple of years to help my clients identify keywords for their CVs, Resumes and LinkedIn profiles - and believe me the tool is mind-blowing. Teal is a full-proof solution that easily stores jobs that you"re interested in, tracks your progress, including notes and also automatically highlights important keywords for every job you save. It"s like an online excel sheet on adrenalin and did I forget to mention, it"s free to use!

Laid out below are the basic jobs on an offshore drilling rig starting with the lowest level of the worker through to the Offshore Installation Manager (OIM) also including the support staff after the OIM.

Roustabout - The job of roustabout is about the easiest entry level job to get. It involves a lot of hard manual labor and long work hours. Roustabouts typically are involved on the main deck with painting and sandblasting, unloading pipe and other kinds of physical work. During breaks they also fill in for the roughnecks on the rig floor.

Roughneck - Higher up are the roughnecks also known as floor hands who do the jobs on the rig floor. The job of the roughnecks is to make connections in the drill pipe using pipe tongs or an automatic device known as an “iron roughneck”. Roughnecks “trip pipe” joints of drill pipe into and out of the hole when drill bits, etc, need to be changed.

Derrickman - Aligns and manipulates the sections of pipe or drill stem from a platform on the rig derrick during the removal and replacement of strings of pipe, or drill stem and drill bit. Assist in setting up, taking down and transporting drilling and service rigs. Supervises the roughnecks. This job entails working at height in the derrick usually at 170ft.

Crane Operators - Responsible for all crane operations on the rig and to and from the supply boats. Cranes are used to load supplies, such as casing, pipes and rig equipment, onto the oil rig. Crane operators also assist in general labour around the rig. Crane operators supervise the roustabouts and the crane operator assistant. This is a senior deck crew position.

Assistant Driller (AD)- Runs the work crew and takes information from the driller and gives it to their crew. While the assistant driller acts in a predominately supervisory role, they may also work alongside the roughnecks to run machinery. ADs train roughnecks to recognize abnormal well conditions in order to prevent leaks and rig blowouts.

Driller - A driller is a person in charge of the rig floor and of overseeing the drilling of an oil well. They directly control the rate of drilling and it is a skilled position that requires extensive knowledge of rock types and drilling procedures. Drillers must be highly knowledgeable and make real-time decisions in a calm and controlled manner.

Tool Pusher - On a land drilling rig the tool pusher may be the rig manager and responsible for all operations, but on drillships and offshore drilling rigs, tool pushers are in charge of the drilling department and report to the Offshore Installation Manager (OIM).

OIM (Offshore Installation Manager) - is the most senior manager of an offshore installation. If an emergency were to arise they control the situation and manage the response. He is responsible for all personnel and operations and reports to the Rig Manager who is onshore.

Rig Electrician - They are responsible for ensuring that all electrical systems on the rig are functioning properly. Duties include repairing, maintaining, installing and operating all electrical equipment on the rig. They need to be competent in the use of electricity in hazardous areas and communicate with the rig crew.

Motorman / Rig Mechanic - The primary job function is oil rig equipment maintenance. The motorman checks the rig motors and other mechanical equipment on the rig for proper functioning and takes all necessary steps including lubrication and regular maintenance to render equipment in a working condition.

Barge Engineer - The Barge engineer is in charge of control room operations, including anchor handling, rig stability and supply vessel operations. A barge engineer should have a good knowledge of Coast Guard operations and water safety. Most barge engineers have experience as master merchant in the Navy.

Radio Operator - Efficiently communicating vital information between land bases, rigs, boats and helicopters. Sets up, operates and maintains sensitive equipment to establish verbal, data and encoded interactions regarding emergency situations, weather conditions and important job directives.

HSE Supervisor - Monitor and manage a company"s health, safety and environmental program. HSE Supervisors will attend moring meetings with management to report on HSE statistics and also facilitate seeking safety meetings with all the crew (often on Sundays). The main responsibility is to ensure all work is performed in compliance with HSE standards and to implement HSE initiatives and projects.

The most commonly used rigs in the industry are Jack-ups, used to drill in shallow water, Semi-submersibles used to drill in deep water and land rigs which are moved on trailers and spotted on concrete bases on land, I will also mention fixed platforms which can have drilling facilities on board. The most expensive to run is the semi followed by the jack-up and finally the land rig. This is all down to the size, equipment differences and also the difficulty with logistics to and from the rig. Each rig will have similar drilling equipment on board but some will vary due to the nature of the rig.

These types of rigs come in a variety of sizes depending on the type of well you will be drilling. The rig breaks down into many parts so that it can be transported with trucks and trailers. First, a concrete base will be laid at the location of the well and a pit will also be dug next to the location for the cuttings from the well to be temporarily dumped into. These rigs can be assembled very quickly usually within 3-7 days and can be transported in as little as 12 truckloads.

These rigs are towed into location and then jack their 3 legs down until the legs reach the sea bed. Some larger rigs can have up to 5 legs. The rig will then raise itself out of the water to the deserved height. Jack-ups are good in water depths of up to 400ft (120m) and can be found most commonly in the North Sea because of the seas shallow nature. Once settled the Jack-up rig has a static base in which to drill from. Occasionally rocks has to be placed around the legs to keep the platform from sinking or tilting into the seabed.

Sit on pontoons and float high above the water. The ballast tanks can be adjusted to raise or lower the rig and they can be moved under their own power or towed into place. Once in place the rig will deploy its six anchors and they will be tensioned accordingly to move the rig over the drilling location. Semi-Submersible rigs can be used in water depths from 200ft – 10,000ft (60m – 3000m). The main difference with drilling from a Semi is that the rig is not static and is constantly moving with the swell, therefore the drill pipe moves up and down with the swell. The rig is fitted with heave compensators which keep the drill pipe firmly at the bottom whilst drilling. When the rig moves upwards the heave compensators push down the drill pipe and vice versa.

A drillship is a mobile offshore drilling rig where a mono-hull ship, catamaran, triple-hull ship, or barge is adapted or built for use as a platform. After reaching the well position, the drillship first gets into position with the mooring system or dynamic positioning (DP) system and then begins to drill a well. From the action of wind and waves, the drillship will encounter a heaving motion and sway on all sides, hence, it needs measures such as a drilling string heave compensation device and swing angle reduction device as well as dynamic positioning (DP) to guarantee displacement of drillship within the allowable limits, so as to properly drill a well.

Fixed drilling platforms offer stability but not mobility. Today they’re usually used to tap shallow, long term oil deposits. These platforms are permanently anchored directly to the seabed with the use of a steel structure known as a “jacket”. This rises from the seabed to support a surface deck that is above the ocean. The jacket provides the rig’s sturdy base and holds everything else out of the water, while the drilling modules and crew quarters are located on the surface deck. They can drill to depths of about 1,500 feet below the surface but are expensive to build, so they usually require a large oil discovery to justify their construction.

ENSCO, Dallas, TX, USA One of the leading offshore oil and gas drilling contractors in the world with a fleet of 56 offshore drilling rigs and 27 oilfield support vessels. Work Area: Gulf of Mexico, Australia, Asia, Latin America, the North Sea, the Middle East and West Africa. http://www.enscous.com/\

FEMCO, Far East Marine Company, Sakhalin Region, Russia - A regular participant of all oil and gas development projects in offshore Sakhalin who plans to extend the sphere of theor traditional fleet activities as well as mastering new opportunities. 1 rig working in the Far East, 3 in the Persian Gulf. http://www.femco.ru/

Helmerich and Payne, Inc, Metairie, LA, USA Owns and operates12 platform rigs and manages 4 offshore management contracts in the Gulf of Mexico and the West Coast Santa Barbara Channel. H&P"s diverse offshore fleet consists of deepwater tension leg platform (TLP) rigs, self-moving rigs and traditional self-contained platform rigs. Work Area: Gulf of Mexico, West Coast California. http://www.hpinc.com/

Mannai Offshore, Doha, Qatar Operates a fleet of vessels, jack-up accommodation rigs and early production facilities that provide a wide range of specialized services to the offshore oil and gas industry. Work Area: Offshore Qatar and surrounding areas. http://www.mannai.com/

Nabors Industries, Houston, TX, USA The largest land drilling contractor in the world. One of the largest well-servicing and workover contractors in the United States. A leading provider of offshore platform workover and drilling rigs. A provider of ancillary well site services such as oilfield management, engineering, transportation, construction, maintenance and well logging. Work Area: Gulf of Mexico, Latin America and the Middle East. http://www.nabors.com/

Odfjell Drilling, Bergen, Norway Owns and operates semi-submersible drilling rigs in the North Sea and is also a leading platform drilling contractor with operations on fixed and floating production platforms. http://www.odfjelldrilling.com/

Parker Drilling Company, Houston, TX, USA A global drilling company providing drilling rigs, labor management and rental tools to the energy industry. Parker"s primary business segment is drilling rigs with 33 in the United States Gulf of Mexico and 46 internationally. The company’s international rig fleet consists of barge rigs in the Caspian Sea and Nigeria and land rigs in 12 countries. Work Area: Gulf of Mexico, Eastern Europe and West Africa. http://www.parkerdrilling.com/

Prosafe ASA, Tananger, Norway World"s leading owner and operator of semi-submersible service rigs, the largest platform drilling contractor in Norway and a major owner and operator of floating production- and storage vessels outside the North Sea. http://www.prosafe.no/

Paterson UTI, INC., Houston, TX, USA The second-largest provider of onshore contract drilling services to exploration and production companies in North America. The company owns 324 land-based drilling rigs and is also engaged in drilling and completion fluid services and pressure pumping services. Work Area: Texas, New Mexico, Oklahoma, Louisiana, Mississippi, Utah and western Canada. http://www.corporate- ir.net/ireye/ir_site.zhtml?ticker=PTEN&script=2100&layo/

Petrolia Drilling ASA, Oslo Owns and charters drilling vessels for offshore, deepwater oil and gas exploration and development drilling. It intends to continue to expand its current rig fleet through a strategy of acquiring, refurbishing and selectively deploying offshore drilling rigs and drillships on fixed-rate, long-term contracts. http://www.petrolia.no/

Precision Drilling, Alberta, Canada Maintains a fleet of 240 plus land rigs working in Canada and other countries, making the company one of the largest land drilling contractors in the world. Operations include drilling, catering, well servicing and oilfield rentals. Work Area: Canada, Mexico, Columbia, Venezuela, Brazil, Argentina, the United Kingdom, the Netherlands, Germany, Egypt, the Middle East, China, India, Indonesia and Kazakhstan. http://www.precisiondrilling.com/

Pride International, Houston, TX, USA One of the world"s largest drilling contractors providing offshore and onshore drilling, workover and related services in more than 30 countries. Fleet of 328 rigs includes 2 ultra deep water drillships, 12 semi submersibles, 35 jackups, 5 tender assisted rigs, 3 barge rigs, 21 offshore platform rigs and 250 land based drilling and workover rigs. Work Area: Gulf of Mexico, West Africa, the Mediterranean, Latin America, the Middle East, Australia and Asia. http://www.mardril.com/

Prosafe SE, Stavanger, Norway Prosafe is the world ́s leading owner and operator of semi- submersible service rigs and a major owner and operator of floating production and storage vessels. http://www.prosafe.com/

Rowan Companies, Houston, TX, USA A provider of international and domestic contract drilling and aviation services. Rowan has a marine division which has designed or built over one third of all mobile offshore jack up drilling rigs, including 22 operated by the company. Work Area: Gulf of Mexico, East Coast of Canada http://www.rowancompanies.com/

An oil and gas commissioning supervisor is someone who works on an oil rig or at an offshore location overseeing well drilling. They also manage the installation of oil or gas pumps and the well’s connection to a distribution system. Their work can take them to oil fields around the world, on land or at sea, to ensure the safe, profitable completion of the process that brings petroleum products from the earth to consumers.

Oil and gas well commissioning supervisors can organize a project and bring it to completion. They understand how to bring vendors, equipment and procedures together in a safe, environmentally sound and profitable manner. A commissioning supervisor"s cv or resume should highlight problem-solving skills. For example, they should include examples of how they have overcome problems of time, supply, and personnel to manage the timely construction and operation of a well, including the distribution of the product from the well to their petroleum company.

The responsibilities of a commissioning supervisor begin before a company begins to drill an oil or gas well, working with petroleum company personnel and vendors, such as the chosen drilling company and other suppliers. Duties in an oil and gas supervisor job description include managing the construction of the drilling derrick, the preparation of the well for pumping, installation of the pump that moves the oil or gas out of the well and the connection of the well to a distribution system, whether a pipeline for real-time distribution to another location or an on-site collection system for later distribution.

Oil and gas commissioning supervisors follow environmental guidelines and company policies during the installation of oil or gas wells, participate in inspections, resolve complications related to a well’s installation, and directly supervise the contractors tasked with drilling the well and bringing the well into full operation. Commissioning supervisors ensure the safe installation of the well, that contractors and vendors keep to their schedules and meet assigned quality and production targets.

Commissioning supervisors learn their trade through a combination of education and experience. They usually have a degree in mechanical or petroleum engineering along with extensive experience in the oil field, including work in drilling, safety and project management. Indeed indicates that some companies such as Progeco NeXT in Texas look for commissioning supervisors with an electrical engineering degree.

The Bureau of Labor Statistics reported in 2021 that petroleum engineers, including commissioning supervisors, working in the oil and gas sector earned an average salary of $157,900 per year. Mechanical engineers employed by oil and gas companies averaged $131,280 per year. Electrical engineers earned on average $132,950 per year. Higher than average earnings correlated with years of experience in the field, supervisory authority and expertise in regulatory compliance.

8613371530291

8613371530291