workover rig tools factory

Manufacturer of standard & mobile rigs & carriers for oilfield applications. Includes well servicing from 14,000 ft. to 22,000 ft., workovers from 10,000 ft. to 16,000 ft. & drilling from 6000 ft. to 10,000 ft. Specifications include brakes range from 28 in. dia. x 8 in. wide to 42 in. dia. x 12 in. wide, barrels from 12 3/4 in. x 38 in. to 18 in. x 43 in., chains from 1 1/4 in. to 1 3/4 in., clutches of 24 in. with single & 2 plate air friction outboards, shafts of 5 in. dia. to 6 1/2 in. dia. & gross weights from 63,200 lbs. to 115,000 lbs. Also includes forged steel, demountable options, mufflers with spark arrestors, dry type air cleaners, transmissions with torque converters, water splash brake cooling & up to 6 axles.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Since 1999, Rig Tool Products has been serving the Drilling and Well Servicing community to meet the demand for products that exceed industry standards. Our many years of experience in manufacturing have given us the knowledge to meet these demands, allowing us to produce quality parts at affordable prices.

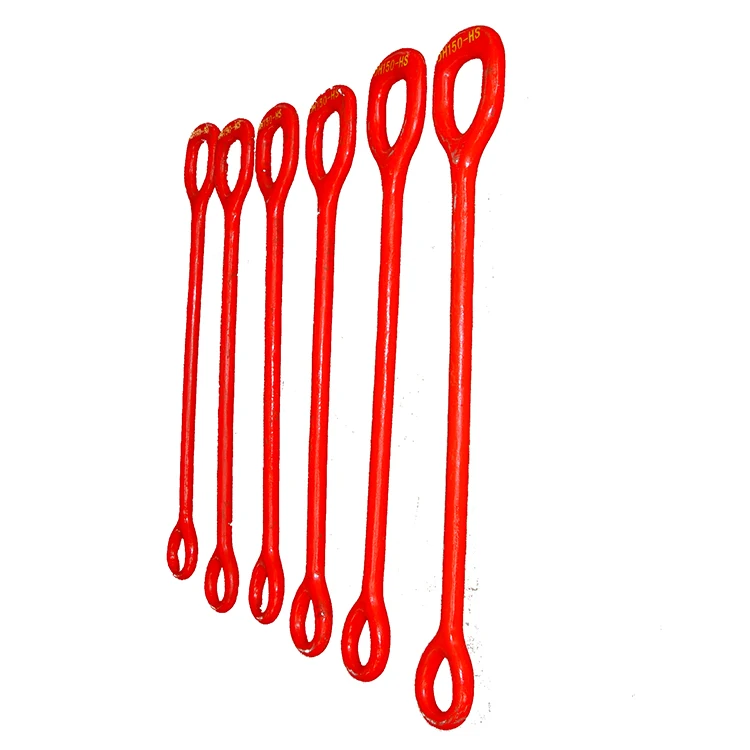

Rig Tool Products offers many consumable parts for name brand handling tools in today’s marketplace. Our specializations include tong dies, slip inserts, tubing spiders, manual slips, power tong parts, elevators, manual tong parts, rubber products, brake blocks, brake rims and brake bands. Through precise engineering, our goods have the ability to interchange with OEM tools such as Varco, Baash Ross, Woolley, Guiberson, Cavins, Foster, BJ, Oil Country and many more.

With multiple manufacturing facilities, we have allowed ourselves the opportunity to expand our product lines as well as increase our inventory, giving us the ability to meet your needs when you need it most. As Rig Tool Products continues to expand our global presence, our company and employees remain dedicated to the standard of service and parts we’ve come to be known for!

About products and suppliers:Alibaba.com offers 226 workover rig manufacturing products. About 49% % of these are oilfield drilling rig, 29%% are mine drilling rig.

A wide variety of workover rig manufacturing options are available to you, You can also choose from diesel, electric and gasoline workover rig manufacturing,As well as from energy & mining, construction works , and manufacturing plant. and whether workover rig manufacturing is unavailable, 2 years, or 6 months.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In order to solve low degree of work over automation, labor-intensive job dangerous, poor working environment issues, Shengji has developed a series of mechanical work over system, including workover automatic system, minor workover automatic system and snubbing operation equipment.

Oil well workover is a high-tech, high-risk work. The conventional oilfield workover rig has problems such complicated operating procedures and high labor intensity. Shengji, in cooperation with the Shengli Drilling Corporation, have designed an oilfield workover rig automation system.

The oilfield automatic workover rig has a high degree of automation adopting modular integration and advanced robot closed-loop control technology. It functions as self-diagnosis, leakage and short circuit protection and fault alarming, etc. It has remote monitoring capability.

The automatic workover rig greatly increases the automation of workover operations, reduces the number of operators, decreases workers’ labor intensity. The technology is advanced, safe and reliable.

If you are in need of a mast and subbase or drawworks to compliment your current equipment, we have some of the best designed and manufactured components in the industry. Our service rigs have many special features that are only available from MW Industries.Established in 2005, MW Industries is located in Kenmare, North Dakota, along the north central portion ofHighway 52. The manufacturing facility is staffed with 50+ highly skilled workers with manufacturing and production backgrounds. By combining field tested designs and superior workmanship we are confident that our equipment will help make your company more profitable.

The automatic operation equipment for minor workover is mainly composed of a wellhead operation device, hydraulic elevator, pipe and rod transmission and arrangement device and electro-hydraulic control system.

The device adopts the structural form of dispersing the functional modules and integrated installation on the workover rig: with the hydraulic tong, manipulator and anti splash snap device set on the derrick of the workover rig, which can expand and rotate, and the safety slip is installed above the BOP.

The device only needs to install safety slips, which realizes rapid installation and migration and shortens the auxiliary working time. The device has the function of moving back and forth, left and right, which is convenient to align the wellhead. The height of the hydraulic tong is adjustable and can adapt to the wellhead with different heights. Hoisting equipment and special transport vehicles are not required for the installation and removal of the device.

The main electric control box can be installed on the operation vehicle or integrated into the modular wellhead operation device. The make-up torque of various oil pipes is set on the touch screen to realize automatic make-up and break-down. Equipped with video monitoring, process prompt, safety alarm, etc. The control system has a perfect action interlocking function to ensure the safety and reliability of the workover operation process. All of the electric cabinets, sensors, connectors meet the requirement of Explosion-proof on field.

In order to solve low degree of work over automation, labor-intensive job dangerous, poor working environment issues, Shengji has developed a series of mechanical work over system, including workover automatic system, minor workover automatic system and snubbing operation equipment.

Oil well workover is a high-tech, high-risk work. The conventional oilfield workover rig has problems such complicated operating procedures and high labor intensity. Shengji, in cooperation with the Shengli Drilling Corporation, have designed an oilfield workover rig automation system.

The oilfield automatic workover rig has a high degree of automation adopting modular integration and advanced robot closed-loop control technology. It functions as self-diagnosis, leakage and short circuit protection and fault alarming, etc. It has remote monitoring capability.

The automatic workover rig greatly increases the automation of workover operations, reduces the number of operators, decreases workers’ labor intensity. The technology is advanced, safe and reliable.

Drill floor (#21) is the area on the rig where the tools are located to make the connections of the drill pipe, bottom hole assembly, tools and bit. It is considered the main area where work is performed.

Drill string (#25) is an assembled collection of drill pipe, heavy weight drill pipe, drill collars and any of a whole assortment of tools, connected and run into the wellbore to facilitate the drilling of a well. The collection is referred to singularly as the drill string.

Setback (#17) is a part of the drill floor (#21) where the stands of drill pipe are stood upright. It is typically made of a metal frame structure with large wooden beams situated within it. The wood helps to protect the end of the drill pipe.

Stand (#16) is a section of 2 or 3 joints of drill pipe connected and stood upright in the derrick. When they are pulled out of the hole, instead of laying down each joint of drill pipe, 2 or 3 joints are left connected and stood in the derrick to save time.

This is a family owned company operated by people with over 40 years in the oilfield equipment industry. We have over 100,000 square foot of warehouse and offer a wide selection of well service, work over, and drilling rig tools and parts to accommodate the industry"s many varied needs.

We can create complete rig tool packages, as well as provide equipment locating. We provide our customers with additional expertise to aid in choosing the best products for their application. Our team has skill, experience and knowledge in everything from operating the brake handle to operating oil and gas wells. We understand The tool and supply needs of the petroleum industry.

One of the most key pieces of oil drilling rig systems is the rig substructure. The first step in setting up a drill rig, setting up the rig substructure involves unloading equipment and moving it to the location where it will remain during drilling. From there, personnel must assemble, weld and level the various pieces of equipment. During this process, personnel can become injured due to a number of hazards that exist.

Are your personnel being as safe as they should be while setting up the drill rig substructure? To improve the safety of your oil drilling equipment, be sure to follow these three impossible-to-ignore tips:

First and foremost, all personnel must be properly trained in safety procedures and job hazards for setting up the rig substructure. Whether the training takes place during pre-job safety meetings or during JSA briefings, no one should be working on your drilling rig systems without undergoing safety training first.

When setting up the rig substructure, personnel should be wearing protective equipment like eye and face protection for welding, long-sleeved clothing and more. Welding, in particular, can be very dangerous work. Ensure that your workers never look directly into a welding flame.

SOFE"sdrilling engineering equipmentincludes drilling rig,workover rig, cementing equipment, drillbits, drilling tools, auxiliary rock breaking tools, etc.

Forthe drilling rigs, SOFE has the product technologies of truck-mounted drillingrig, automatic module drilling rig, fast moving drilling rig, arcticdrilling rig, helicopter drilling rig, desert drilling rig and hydraulicdrilling rig. With the technical features such as fast moving, fastinstallation, automatic control and the adaptability to complex environmentoperation, they are widely applied to oil & gas exploitation anddevelopment in plains, arctic regions, deserts, mountains and other regions.

Equipped with the advanced manufacturing, testing and inspection facilities, SOFE has an annual capacity of producing 3,000 sets of PDM and turbo drilling tools. The PDM tools with self-owned intellectual properties is leading the domestic market, and the various size ranges from φ95 to φ244.

8613371530291

8613371530291