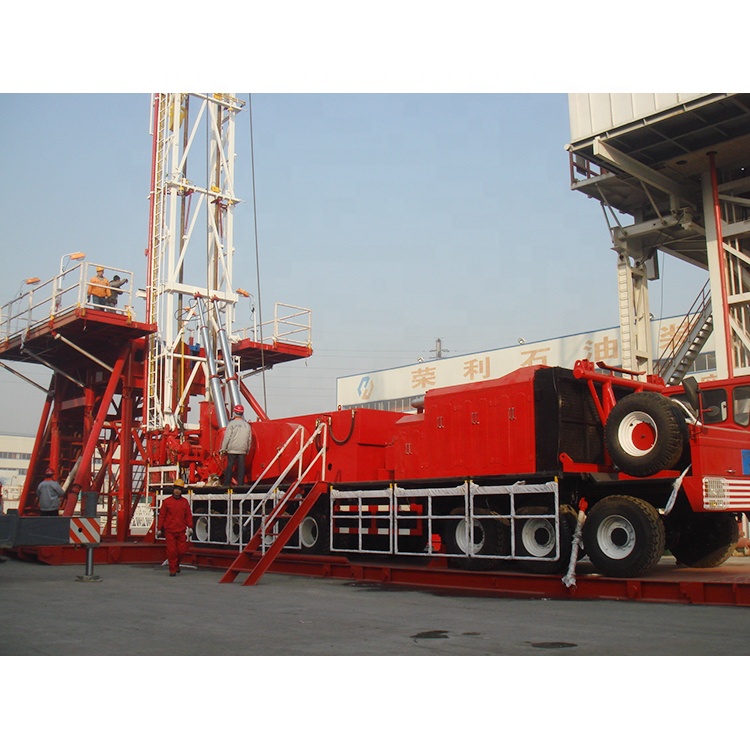

workover rig tools made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs.

Belonging to the same family, Sovonex™ service rigs comprise many of the technological advantages that result in smooth operation and make the life of our customers’ easier:

Wide selection: At our production facility in China we design and develop workover rigs for service depths ranging from 1,600 m to 8,500 m (5,250 ft-27,900 ft), and workover depths from 2,000 m to 9,000 m (6,600 ft-30,000 ft) for 2 7/8” DP.

Full API coverage: The different components of our well-servicing rigs are manufactured to the following API standards:Steel structures, such as the mast: API Spec 4F

Highly maneuverable : Sovonex™ mobile drilling rigs and self-propelled workover rigs possess excellent driving properties in the desert, mountain, and other impassable terrains.

Reduced NPT: The mast is erected hydraulically to reduce time for rig up and increase safety. Likewise, all rig components have been designed to allow for fast assembly and disassembly.

With every service rig, we send technical staff to our customer to provide first-hand technical support. The engineer responsible for the rig design is always part of the service crew.

Main Features Name: traveling hook Brand: KH Original: China Domestic famous fluid end, strong driving force, low fuel consumption, high economic benefits. Machine Parts Name: derrick platform Brand: KH Original: China Domestic famous, strong driving force, low fuel consumption, high economic benefits. After-Sales Service * Training how to instal the machine, training how to use the machine.

Beyond products cover but not limited to: oil drilling & workover rig, water well drilling rig, pile drilling rig, horizontal directional drilling rig, mud pump and spares, solid control system & equipment, and other different drilling materials. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. We can customize the product supply as per your on-site conditions, and we can offer overseas after-sale services with our strong technical support. Thanks to our professional services, quality products, fast delivery and competitive prices, we have built up a very good reputation among our customers. Our products had covered countries like USA, Venezuela, Argentina, India, Singapore, Kazakhstan, Azerbaijan, Egypt and Ethiopia.

With "Professional & Efficient, Customer Focus, Win-win Cooperation" as its business principle, Beyond believes we will become your trustable and reliable partner in China. We warmly welcome you to be our customers to establish good cooperation and create a bright future with us together. Choose Beyond, You will get beyond your expectations and we will not let you down.

The automatic operation equipment for minor workover is mainly composed of a wellhead operation device, hydraulic elevator, pipe and rod transmission and arrangement device and electro-hydraulic control system.

The device adopts the structural form of dispersing the functional modules and integrated installation on the workover rig: with the hydraulic tong, manipulator and anti splash snap device set on the derrick of the workover rig, which can expand and rotate, and the safety slip is installed above the BOP.

The device only needs to install safety slips, which realizes rapid installation and migration and shortens the auxiliary working time. The device has the function of moving back and forth, left and right, which is convenient to align the wellhead. The height of the hydraulic tong is adjustable and can adapt to the wellhead with different heights. Hoisting equipment and special transport vehicles are not required for the installation and removal of the device.

The main electric control box can be installed on the operation vehicle or integrated into the modular wellhead operation device. The make-up torque of various oil pipes is set on the touch screen to realize automatic make-up and break-down. Equipped with video monitoring, process prompt, safety alarm, etc. The control system has a perfect action interlocking function to ensure the safety and reliability of the workover operation process. All of the electric cabinets, sensors, connectors meet the requirement of Explosion-proof on field.

Sanjack has been committed to the research of automatic workover technology for many years and has a perfect automatic workover technology development, production, and manufacturing system.

In recent years, a whole set of automation technology has been formed in the automation and intelligent development of automatic workover equipment. Through the application of module design, servo drive, integrated control, electro-hydraulic compound drive and other technologies, the supporting products suitable for various types of workover equipment have been developed to meet the needs of oilfield workover equipment upgrading.

Drill floor automatic pipe arranging manipulator can replace workers to complete the placement of the column on the drill floor surface, and connect single joint, thread connection, etc., to achieve unmanned operation of the drill floor for major workover operations.

The original integrated structure of hydraulic tong and punching tong can meet the thread up and down of tubing/drill pipe at the same time. The tong head has a floating function, which can automatically compensate the center deviation between the pipe string and the jaw and reduce the damage when the tong teeth clamp the pipe body. The torque can be accurately controlled and set, and the make-up torque of pipe string meets the requirements of API. When in standby, it can rotate and give way as a whole to provide more active operation space for the drill floor. The tong head can be deflected to meet the make-up & break-down of the mouse hole string.

As a China top oil drilling rig solids control system manufacturer: GN Solids Control now list the top 10 oil drilling rig manufacturers for your reference.

equipment in China, is the earliest established, largest and most powerful oil drilling rig and production equipment developer and manufacturer under CNPC, the largest research and production base of land rigs and series mud pumps in the world, and also the largest and most powerful base for R&D and production of wire ropes for special purposes in China.

Lanzhou LS-National Oilwell Petroleum Engineering Co. Ltd. (LS-NOW for short) is a Sino-American Joint Venture established between Lanzhou Petrochemical Machinery Equipment and Engineering Group Corporation (LS Group) and National Oilwell International, Inc. (NOI). Scope of business: design, develop and manufacture complete land and offshore drilling rigs and workover rigs, and provide equipment package, components, fittings, parts and full services.

Main products: serial drilling rigs that are electrical or mechanical or electrical-mechanical compounded driven and suitable for different applications such as land, shallow, offshore and desert and meet the requirements of drilling and workover services. The drilling depth ranged from 1000 to 9000 meters.

Sichuan Honghua Petroleum Equipment Co., Ltd., established in 1997, is a subsidiary of Honghua Group which has been listed successfully in the Stock Exchange of Hong Kong. The company has been engaged in research, design, manufacturing and general assembly of oil drilling rig and equipments for oil exploration and development. Now it is the world’s second land drilling rig manufacturer, and China ‘s largest exporter of drilling rigs.

The company owns five subsidiaries totally in home and abroad, with 3600 employees. Company headquarter is located in Deyang City, Sichuan, a heavy-duty equipment base in China, which covers an area of about 1,000 mus, and with more than 2,200 employees, annual output of 150 drilling rigs and 600 mud pumps etc. Its production capacity is up to 8 billion RMB production scale.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electric rig, mechanical drilling rig, composite drive rig, trailer mounted rig and independent RT electric drive drilling rig, as well as their matched equipments, i.e. drilling pumps, traveling block system, solid control system, electric control system etc.

RG PETRO-MACHINERY (GROUP) CO. LTD is one of the largest manufacturers for petroleum drilling rig equipment in China. It is a stock company, reorganized from Nanyang petroleum machinery plant (former No.2 Petroleum Machinery Manufacturing Plant of National Petroleum Industrial Ministry of China). As a former national technical equipment production base, authorized by former national economic and commercial committee of China, RG PETRO-MACHINERY (GROUP) CO. LTD has become a company for national new product trial production of China, light-duty drilling rigs production base of SINOPEC and a high-tech enterprise in Henan Province.

RG PETRO-MACHINERY (GROUP) CO. LTD, with its technical center, information center and quality inspection center at provincial level, has possessed 16 production plants for forging, metal machining, heat treatment, steel-structure manufacturing, general assembly, painting and new product trial production, and 3 comprehensive testing sites for drilling rigs as well as 2 Sino-American joint ventures and 2 share-holding joint ventures.

SJ Petroleum Machinery Co. , one of petroleum drilling rig and production equipment backbone manufacturers and Manufacturing Base for National Key Equipment (Workover, Cementing and Fracturing Equipment) recognized by National Economy and Trade Commission, has provided lots of advanced equipment to domestic customers in lieu of expensive imported equipment, and played an important role in increasing profits of petroleum industry and decreasing domestic oilfield development cost.

Our company Shandong Kerui Holding Group is located in Shengli Oilfield the second largest oilfield in China. Our company arranges a wide range of businesses covering the scientific research and manufacture of the petroleum drilling equipment and oilfield engineering technical service. The main products manufactured and supplied include drilling equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China.

The main products manufactured and supplied include oil drilling rig equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China

(shanghai) petroleum equipment co., ltd. is established on august 2001. the 3h is the first rig manufacturer that introduces ship-building technology to the fabrication of petroleum equipment.

Drilling Rig: Highland Company Drilling Rig Plant has advanced key facilities and assembly workshops for manufacturing rigs and it has enough test sites for assembling 12 sets of large scale drilling rigs at the same time,5 series (ZJ20~ZJ70, including 18 types) of drilling rigs have been developed and manufactured. These developed and manufactured products consist of mechanical drive, DC driven, AC VF drive and Electromechnical drilling rigs, which can handle the well with depth of 1500- 7000m in most of the large oilfields both at home and overseas.

State-run and privately controlled Chinese rig makers, oil and gas services and engineering firms are showing up in the supply chain everywhere from the Middle East, the North Sea and North America to frontier areas like Mozambique.

Chinese yards, having come from nowhere in less than a decade, are building more jack-up rigs - the most common offshore rig used for shallow water drilling - than all the other yards in the world put together, data from industry consultants IHS Petrodata shows.

The rise of Chinese energy equipment manufacturers and services firms overseas, partly fuelled by the rapid expansion of state energy giants, is putting pressure on established companies including Singapore oil rig makers Keppel Corp and Sembcorp Marine, and land drilling giant National-Oilwell Varco Inc (NOV).

To stay ahead, both Keppel and Sembcorp are increasingly building more sophisticated equipment, an area where Chinese firms still lack expertise. <^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^ GRAPHIC-China"s offshore rig orders: link.reuters.com/cen38v ^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^ Leading the Chinese overseas expansion are state-controlled shipyards and units of state giants China National Petroleum Corp (CNPC), parent of PetroChina , Sinopec Group and China National Offshore Oil Corp (CNOOC).

Chinese companies won over half the global orders for jackup rigs last year, up from around a third between 2008 and 2012, data from IHS Petrodata showed.

In the area of land drilling equipment, a number of privately run companies have emerged as major overseas players. These include Honghua Group Ltd, the second-largest land rig manufacturer globally with 80 percent of revenue driven by overseas orders, and Hilong Holding Ltd, which started its overseas foray in 2005 and is now the world’s second-largest drill pipe maker after Houston-based NOV.

COSCO Corp, China State Shipbuilding Corp , China Shipbuilding Industry Corp, Yantai CIMC Raffles and Offshore Oil Engineering Corp can build a jack-up rig for $170-180 million, significantly lower than the $200-220 million price tag for the same rig built in Singapore.

Chinese manufacturers can also make land rigs, drilling pipes, bits, modules, pumps and valves at up to half the price of the same equipment made elsewhere. Prices are so competitive that the United States in 2012 slapped hefty anti-dumping duties on imports of Chinese seamless steel pipes, including pipes used for oil and gas drilling.

As relative newcomers, Chinese companies remain far behind in terms of making sophisticated tools like deepwater rigs and hydraulic fracturing, or fracking, equipment which is used to extract natural gas trapped in shale formations.

Baoji Oilfield Machinery Co., Ltd (BOMCO), as a leading one in researching,designing, manufacturing and assembling Oil Drilling Rig and equipments for oilexploration and development since 1970s. It belongs to CNPC. Complete sets of onshore and offshore drilling rig and relating equipments could be produced. It produced most drilling rigs in 2005 in the world.

Main products: drilling rigs including AC VFD, DC, diesel engine and gear,chain, hydraulic and belt drive, truck-mounted and trailer-mounted series,ranging from 1,000 meters to 12,000 meters in drilling depth; a series of API7K-compliant mud pumps ranging from F-500 to F-2200; CGDS-I, a near-bitgeosteering system for well drilling, consists of the CAIMS (China AdjustableInstrumented Motor System), WLRS (Wireless Receiver System), CGMWD (ChinaGeosteering MWD), and the CFDS (China Formation/Drilling Software System).CGDS-I has three major functions: logging/measurement, transmission andsteering.

Scope of business: design and manufacture complete land and offshore drillingrigs and oil service rigs, and provide relating equipment package, components,parts and full services.

Main products: oil drill rigs that are electrical or mechanical orelectrical-mechanical compounded driven and suitable for different applicationssuch as land, shallow, offshore and desert and meet the requirements of drilling and oilfield services. The drilling depth ranged from 1000 to 9000meters.

Sichuan Honghua Petroleum Equipment Co., Ltd., established in 1997, is asubsidiary of Honghua Group which has been listed successfully in the StockExchange of Hong Kong. The company has been engaged in research, design,manufacturing and general assembly of Oil Drilling Rig and equipments for oil exploration and development. Now it is the world’s second land drilling rigmanufacturer, and China’s largest exporter of drilling rigs.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electricrig, mechanical drilling rig, composite drive rig, trailer mounted rig andindependent RT electric drive drilling rig, as well as their matchedequipments, i.e. drilling pumps, traveling block system, solid control system,electric control system etc.

RG PETRO-MACHINERY (GROUP) CO. LTD is a stock company, reorganized from Nanyang petroleum machinery plant (former No.2 Petroleum MachineryManufacturing Plant of National Petroleum Industrial Ministry of China in1969). RG has possessed 16 production plants for forging, metal machining, heattreatment, steel-structure manufacturing, general assembly, painting and new product trial production, and 3 comprehensive testing sites for drilling rigsas well as 2 Sino-American joint ventures and 2 share-holding joint ventures.

RG could provide 12 series of products in 200 kinds, including skid-mounteddrilling rig, truck-mounted drilling rig, trailer-mounted drilling rig,workover rig, offshore drilling/workover equipment, solid control and mudcirculation equipment, oilwell logging equipment, petroleum special Vehicle,top drive drilling equipment, Hydraulic water drilling rig,mud pump,hoisting and rotaryDrilling equipment and related spare parts, etc.

It supply four major categories of products including drilling & workoverequipment, production equipment, offshore drilling & production equipmentand high pressure manifolds, 12 families and more than 200 types of products.

Its star products include pumping units, workover rigs, cementing units,fracturing packages, fracturing pump and high pressure fluid control products.

The main products include oil drilling rig equipment, Oil pumpingequipment, Special equipment for oilfield, Oilfield tubing system and auxiliarymachines and tools. Kerui manufactures various workover rigs and drilling rigswith drill depth from 3000m to 9000m.

The 3H(Shanghai) Petroleum Equipment Co., Ltd. , established in 2001, isthe first rig manufacturer that introduces ship-building technology to thefabrication of petroleum equipment.

main business activity covers the design and manufacture of the followingseries of: electrical, mechanical drilling rigs, and electro-mechanic rigs withthe drill depth from 2,000 meters to 9,000 meters; module offshore drilling andworkover platforms, module offshore drilling rig, polar drilling rigs, andtruck mounted rigs; electrical driving control and system, and; main rig componentsof crown blocks, traveling blocks, hook, mud pump, swivel, and etc.

The current product lines include workover & drilling rig series, oilfield environmental protection equipment series, oil recovery machinery seriesand water well & mineral drilling machinery series.

Shaanxi TEFICO Petroleum Mechanical And Electric New Technology Co., Ltd.(Tefico) located in Baoji, China biggest drilling rig manufacture center, andowning a strong technical expert team with nearly 30 years experience, has beendedicated to ensuring customers receive the highest quality land drilling rigsand drilling equipments for Oil, Gas , Geothermy, Shale Gas and Coal BedMethane since 2000.

TEFICO is provides complete land drilling rigs for sale and rental and majormechanical components, such as mast, substructure, crown block, rotary table,drawworks, travelling block, hook, mud pump, top drive. TEFICO is also aproject management company hence it can work as a subcontractor to join projector partner with clients in all relevant project.

This article is about the onshore oil rig. For offshore oil rig, see Oil platform. For drilling tunnels, see Tunnel boring machine. For handheld drilling tool, see Drill.

A drilling rig is an integrated system that drills wells, such as oil or water wells, in the earth"s subsurface. Drilling rigs can be massive structures housing equipment used to drill water wells, oil wells, or natural gas extraction wells, or they can be small enough to be moved manually by one person and such are called augers. Drilling rigs can sample subsurface mineral deposits, test rock, soil and groundwater physical properties, and also can be used to install sub-surface fabrications, such as underground utilities, instrumentation, tunnels or wells. Drilling rigs can be mobile equipment mounted on trucks, tracks or trailers, or more permanent land or marine-based structures (such as oil platforms, commonly called "offshore oil rigs" even if they don"t contain a drilling rig). The term "rig" therefore generally refers to the complex equipment that is used to penetrate the surface of the Earth"s crust.

Small to medium-sized drilling rigs are mobile, such as those used in mineral exploration drilling, blast-hole, water wells and environmental investigations. Larger rigs are capable of drilling through thousands of metres of the Earth"s crust, using large "mud pumps" to circulate drilling mud (slurry) through the drill bit and up the casing annulus, for cooling and removing the "cuttings" while a well is drilled. Hoists in the rig can lift hundreds of tons of pipe. Other equipment can force acid or sand into reservoirs to facilitate extraction of the oil or natural gas; and in remote locations there can be permanent living accommodation and catering for crews (which may be more than a hundred). Marine rigs may operate thousands of miles distant from the supply base with infrequent crew rotation or cycle.

Antique drilling rig now on display at Western History Museum in Lingle, Wyoming. It was used to drill many water wells in that area—many of those wells are still in use.

Until internal combustion engines were developed in the late 19th century, the main method for drilling rock was muscle power of man or animal. The technique of oil drilling through percussion or rotary drilling has its origins dating back to the ancient Chinese Han Dynasty in 100 BC, where percussion drilling was used to extract natural gas in the Sichuan province.Edwin Drake to drill Pennsylvania"s first oil well in 1859 using small steam engines to power the drilling process rather than by human muscle.Cable tool drilling was developed in ancient China and was used for drilling brine wells. The salt domes also held natural gas, which some wells produced and which was used for evaporation of the brine.

Oil and natural gas drilling rigs are used not only to identify geologic reservoirs, but also used to create holes that allow the extraction of oil or natural gas from those reservoirs. Primarily in onshore oil and gas fields once a well has been drilled, the drilling rig will be moved off of the well and a service rig (a smaller rig) that is purpose-built for completions will be moved on to the well to get the well on line.

Mining drilling rigs are used for two main purposes, exploration drilling which aims to identify the location and quality of a mineral, and production drilling, used in the production-cycle for mining. Drilling rigs used for rock blasting for surface mines vary in size dependent on the size of the hole desired, and is typically classified into smaller pre-split and larger production holes. Underground mining (hard rock) uses a variety of drill rigs dependent on the desired purpose, such as production, bolting, cabling, and tunnelling.

In early oil exploration, drilling rigs were semi-permanent in nature and the derricks were often built on site and left in place after the completion of the well. In more recent times drilling rigs are expensive custom-built machines that can be moved from well to well. Some light duty drilling rigs are like a mobile crane and are more usually used to drill water wells. Larger land rigs must be broken apart into sections and loads to move to a new place, a process which can often take weeks.

Small mobile drilling rigs are also used to drill or bore piles. Rigs can range from 100 short tons (91,000 kg) continuous flight auger (CFA) rigs to small air powered rigs used to drill holes in quarries, etc. These rigs use the same technology and equipment as the oil drilling rigs, just on a smaller scale.

An automated drill rig (ADR) is an automated full-sized walking land-based drill rig that drills long lateral sections in horizontal wells for the oil and gas industry.Athabasca oil sands. According to the "Oil Patch Daily News", "Each rig will generate 50,000 man-hours of work during the construction phase and upon completion, each operating rig will directly and indirectly employ more than 100 workers." Compared to conventional drilling rigs", Ensign, an international oilfield services contractor based in Calgary, Alberta, that makes ADRs claims that they are "safer to operate, have "enhanced controls intelligence," "reduced environmental footprint, quick mobility and advanced communications between field and office."steam assisted gravity drainage (SAGD) applications was mobilized by Deer Creek Energy Limited, a Calgary-based oilsands company.

Baars, D.L.; Watney, W.L.; Steeples, D.W.; Brostuen, E.A (1989). Petroleum; a primer for Kansas (Educational Series, no. 7 ed.). Kansas Geological Survey. p. 40. Archived from the original on 8 November 2020. Retrieved 18 April 2011. After the cementing of the casing has been completed, the drilling rig, equipment, and materials are removed from the drill site. A smaller rig, known as a workover rig or completion rig, is moved over the well bore. The smaller rig is used for the remaining completion operations.

"Ensign Launches Newest And Most Powerful Automated ADR 1500S Pad Drill Rigs In Montney Play", New Tech Magazine, Calgary, Alberta, 21 November 2014, archived from the original on 10 December 2014, retrieved 6 December 2014

Our company founded in the Yellow River delta (Shengli Oil Field, the second large oil field in China)--- Dongying City, Shandong Province. It engages into the designing, developing, testing, manufacturing, repairing, and drilling service. Its business covers drilling rig, workover rig, solids control equipment, drilling rig supporting and drilling strings and other equipments related with petroleum.

We have more than 20 years of professional rig manufacturing experience, the design team brings together dozens of outstanding experts, the key parts of the core drilling equipment for sale use the products from international well-known rig manufacturing companies, and cooperate with many scientific research institutions to provide technical support for the innovation of the drilling rig manufacturer"s products.

Enjoy the best returns on your investment with these supreme oil rig ranges at Alibaba.com. Their efficacy and reliability will prove that they’re worth their price tags. They will empower you to attain your mining and drilling goals and definitely surpass your expectations.

Are you looking for a wholesale oil rig? Look no further than Alibaba.com. Boilers are advantageous for several reasons. First of all, a oil rig is energy efficient. This is because water is a better thermal conductor. So it warms up faster and retains the heat for longer. This helps in cutting on energy expenses. Secondly, a boiler system heats evenly and comfortably. Lastly, boiler systems move heat from one thing to another, keeping it close to the room"s floor, where most people will feel it more easily.

Find parts you need to repair or maintain your machines. At Alibaba.com, you can shop for oil rig at affordable rates to tackle new obstacles and challenges. In the ever-changing industry, you can find what you need and speak to the supplier directly. Thanks to Alibaba’s collection of wholesale oil rig you also get to buy these parts at lower prices, which means you can explore new levels every day more comfortably. From bulldozers to dragline excavators, wheel tractor scrapers to shotcrete machines, any part you need for a heavy-duty mining machinery; you can find it at Alibaba.com.

Naturally, with such attractive conditions for human habitation, Sichuan has been occupied by humans since the early dawn of our existence. The countryside has been worked by the human hand for so long, that it is hard to spot a single wild area in the basin proper. Even steep hillsides are terraced for farming, and ancient family crypts hewn into rock cliff outcrops can be spotted frequently from the highway. The contrast between the luxury cars speeding along the modern 6-lane highways, and the ancient terraces, tombs and irrigation systems is startling, but one can easily imagine one long continuous evolution of human technology here, from thousands and thousands of years ago, to the present. Many of China’s ancient technical accomplishments came from this region, including sophisticated irrigation techniques, and what I am particularly interested in, their drilling technology.

At some point around 2,000 years ago the leap from hand and shovel dug wells to percussively drilled ones was made (figure 4). By the beginning of the 3rd century AD, wells were being drilled up to 140m deep. The drilling technique used can still be seen in China today, when rural farmers drill water wells. The drill bit is made of iron, the pipe bamboo. The rig is constructed from bamboo; one or more men stands on a wooden plank lever, much like a seesaw, and this lifts up the drill stem a metre or so. The pipe is allowed to drop, and the drill bit crashes down into the rock, pulverizing it. Inch by inch, month by month, the drilling slowly progresses. It has been speculated that percussive drilling was derived from the pounding of rice into rice flour. When I read of this technique in Salt, I imagined a fairly crude technology. I had no idea how sophisticated these drilling methods became, to the point where these people really had developed most of the tools and techniques one might see on a modern drilling rig, albeit on a smaller scale and without the benefits of modern machining methods.

The drilling method on its own is impressive, especially when considering that the rest of the world had nothing comparable in the earlier centuries. But even more impressive are all the techniques the Sichuan drillers developed to overcome common drilling problems – cave ins, lost tools, deviated wells, and so on (figures 5 & 6). A huge variety of tools and techniques evolved to handle well repair issues (figure 7). Many different drill bits were also developed, with different sizes, shapes and compositions, to deal with the different rock types encountered, and the many different drilling requirements. For example, opening the hole at the wellhead required a large heavy bit (3m long, 150-250 Kg) called the “Fish Tail” (figure 8); the “Silver Ingot” drilled the well bore rapidly, but roughly; the “Horseshoe” bit drilled slowly, but achieved round, smooth, high quality well bores. Hollow logs were used in the near surface as casing.

Figure 7. A variety of down hole tools on display at the Salt Museum. Upper left a re tools designed to repair the surface of the well bore wall, by scraping off salt build up, reestablishing the correct diameter, etc. Bottom and middle left are lost tool retrieval tools. The rest are drill bits and miscellaneous tools.

Figure 13. An ancient sketch originally fro m "The Annals of Salt Law of Sichuan Province". A "Kang Pen" drum is seen in the centre foreground, with gas pipes directly feeding the salt stoves on the right. At the top, brine from a remote well is being carried in buckets by men, who feed it into a bamboo pipeline that runs down to the stoves. One of the carriers is being paid at top left, and it appears that a blow out is depicted on a new well being drilled in the left foreground; maybe the men operating the drill rig have run away, as tragically happened at a Chongqing, Sichuan sour gas well, late 2003.

My brief visit to Sichuan left me intrigued, fascinated, and eager to learn more about China’s ancient technical accomplishments. I can highly recommend the region as a place to visit, not only for its interesting historical sites, but also for its natural beauty (most of Sichuan is mountainous and unpopulated, especially the west, with bamboo forests, and panda bears), its rich culture with many interesting ethnic minorities, its delicious food, great shopping, and its wonderful, friendly people. However, the highlight of my trip was the visit to the Salt Museum, and I hope I have passed on my enthusiasm for this topic to readers.

8613371530291

8613371530291