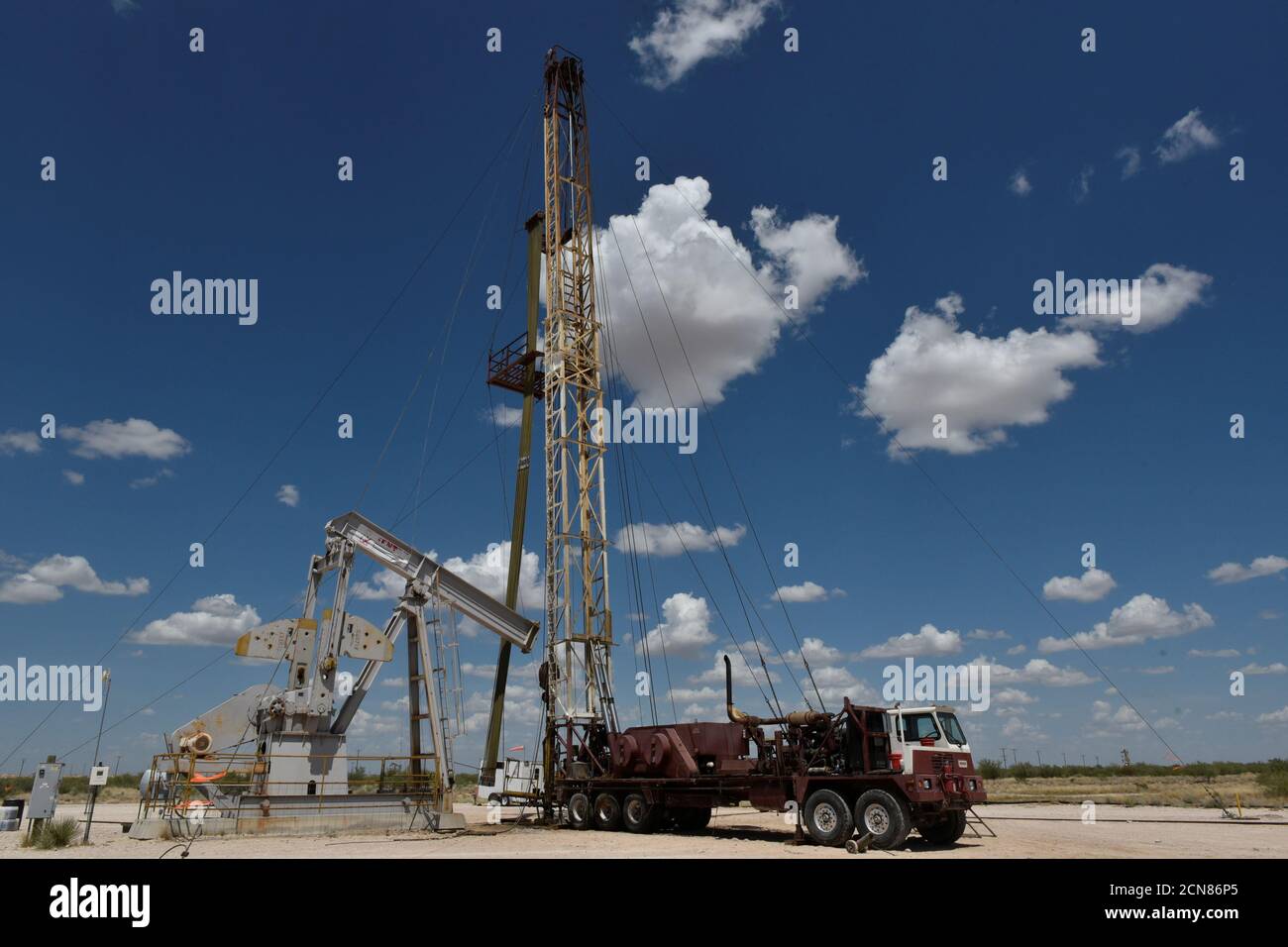

workover rig training in stock

After successfully completing the course and achieving a passing grade on the final exam you will receive a Falck certificate at the Supervisory level in Workover/Completions, Coiled Tubing, Snubbing, and Wireline. This certificate is recognized across the globe.

Explains the major differences and relative pros and cons of both oil based and water based drilling mud. Also, briefly explores synthetic oil based mud, cement slurry, and fluids used during the workover and completions process.

Uses the real-life example of a highway system to introduce valves and manifolds on a drilling rig. Walks through the definition, function, and importance of the pump, standpipe, and choke manifolds through vibrant animations. Introduces the adjustable choke and briefly goes into its importance in well control operations.

Defines the blowout and introduces the terrible consequences of an uncontrolled blowout on causing injury to personnel, loss of rig, and harm to the environment. Then, introduces the kick and examines how a kick is caused by pressure differentials and how a kick can turn into a blowout.

Explains the pressure felt on rig surface equipment and the consequences of exceeding the maximum surface pressure limits of well equipment. Creates an analogy to compare wellbore surface pressure with surface pressure felt on the cap of a shaken soda bottle.

Explains some of the most dangerous gases experienced during oil and gas operations, exploring the properties that make them dangerous to rig personnel. Explains the low density of gas and how it can lead to gas migration when mixed together with other liquids. Introduces Boyle’s Law and the concept of gas compressibility.

Introduces the lubricator as an important tool during many well servicing operations such as wireline, coiled tubing, and snubbing, that may be introduced onto a workover rig during workover operations.

Well Control School offers Instructor-Led training in the comfort of your facility. In-House training courses provide all the advantages of our Instructor-Led training, with simulation workshops and electronic testing, plus dedicated attention at your convenience.

Designed to meet the oil and gas industry"s need for an educated and prepared workforce, Lone Star College is now offering an Oil and Gas Drilling Floorhand Roustabout program. Classroom and lab training will provide entry-level knowledge and skills needed for workers in the drilling and exploration sector of the oil and gas industry. Upon successful completion of the Floorhand Roustabout program three nationally recognized certifications will be provided by the International Association of Drilling Contractors (IADC®).

Lone Star College is the first provider to offer the Floorhand Roustabout Fast-track career certificate that has been accredited by the International Association of Drilling Contractors (IADC), for the Knowledge, Skills and Abilities (KSA) competencies in relation to the Workforce Attraction & Development Initiative (WADI) Project. The WADI project was a world-wide effort to attract and provide the industry with greater number of screened, rig-ready new hire candidates. The collective courses in our Floorhand Roustabout Fast-track career certificate program have been approved to provide the training vital for entry level oil and gas personnel.

This course presents the basics of drilling and completion operations, plus post-completion enhancement (workovers). Participants will learn to visualize what is happening downhole, discover what can be accomplished, and learn how drilling and completion can alter reservoir performance. Learn to communicate with drilling and production personnel. No experience or prerequisites are required.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In partnership with NAIT, ADSC has developed a Drill Rig Operator Training Program. The below courses are available to take individually. Fees vary depending on the course.

Foundation Drill Rig Operator Level I (FDRO101)The Foundation Drill Rig Operator program provides you with the knowledge, skills, and abilities required to safely and successfully operate a foundation drilling rig for industrial, commercial, or residential projects. The first level consists of 6 courses. The first five courses are online and theoretical in nature. The sixth course is practical and on the job.

The Foundation Drill Rig Operator program provides you with the knowledge, skills, and abilities required to safely and successfully operate a foundation drilling rig for industrial, commercial, or residential projects. The second level consists of 5 courses. The first four courses are online and theoretical in nature. The final course is practical and on the job.

Take the worry and hassle out of your eyewash stations. Keep your eyewash station ANSI-compliant with Eagle Safety’s workover rig eyewash station inspection. Ensure that your eyewash station is properly cleaned and serviced with the knowledge and expertise of our dedicated service professionals.

Eagle Safety’s workover rig technician will ensure your SCBA’s are cleaned, inspected, and properly charged. SCBA units are inspected to ensure valves, regulators, harnesses, and face masks are all in good operating condition and are clean and ready for use at each workover rig location.

A significant advantage of our SCBA inspection and maintenance service is that our equipment is mobile. With our mobile recharging van, we can complete all recharge services on-site which mitigate the need to remove the SCBA’s from the workover rig location. This ensures complete respiratory protection during the inspection process in addition to not having to provide leave behind units. Our preventative maintenance (PM) program can ensure you are compliant and ready for any emergency.

Eagle Safety’s workover rig technician will ensure your portable H2S monitor is bump tested and working properly. The use of portable gas detection devices helps ensure a workplace free from recognized hazards by providing employees working in potentially harmful environments the means to monitor their air quality. Harmful environments may include those with high levels of toxic or combustible gases or oxygen-deficient or enriched air. Many of these conditions cannot be detected by smell or sight and therefore require instrumental monitoring to view their levels.

Eagle Safety’s workover rig technician will ensure your fixed H2S monitor is calibrated and working properly. Calibration is defined by OSHA bulletin SHIB 09-30-2013 as ‘an instrument’s measuring accuracy relative to a know concentration of gas. Direct reading portable gas monitors compare the sensor’s response to a know concentration of the test gas’. The bulletin stresses that direct-reading portable gas monitors that are properly calibrated can minimize the risk of injury, illness, or death from respiratory hazards such as oxygen deficiency or combustible or toxic gases.

In a crucial situation such as COVID-19 exposure, you need professionals who know how to properly sanitize, disinfect, and protect your workover rig location. Eagle Safety understands the delicate nature of managing a decontamination project when a work location is exposed and will work with you to make sure all aspects of your project are handled with the utmost professionalism.

If your workover rig location has a confirmed or suspected case of COVID-19 coronavirus, Eagle Safety has established protocols to provide the most effective sanitation available. In addition, we have a clear project communication plan to keep all stakeholders updated each step of the way. We understand that often the impact of exposure to a virus such as COVID-19 goes beyond the workover rig location itself and affects the morale of personnel, customers, residents, students, and even the general public. Having an effective decontamination plan completed by leading experts in the field of clean up and remediation is critical.

Welcome to the Drilling Rig Interactive created by the TOP Energy Training university consortium of The University of Texas at Austin, Penn State University and Colorado School of Mines. Together, we design and create online courses focusing on the fundamental technology, science, and engineering of oil and gas operations. Check out our entire catalog of online oil and gas training courses.

Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs.

Belonging to the same family, Sovonex™ service rigs comprise many of the technological advantages that result in smooth operation and make the life of our customers’ easier:

Wide selection: At our production facility in China we design and develop workover rigs for service depths ranging from 1,600 m to 8,500 m (5,250 ft-27,900 ft), and workover depths from 2,000 m to 9,000 m (6,600 ft-30,000 ft) for 2 7/8” DP.

Full API coverage: The different components of our well-servicing rigs are manufactured to the following API standards:Steel structures, such as the mast: API Spec 4F

Highly maneuverable : Sovonex™ mobile drilling rigs and self-propelled workover rigs possess excellent driving properties in the desert, mountain, and other impassable terrains.

Reduced NPT: The mast is erected hydraulically to reduce time for rig up and increase safety. Likewise, all rig components have been designed to allow for fast assembly and disassembly.

With every service rig, we send technical staff to our customer to provide first-hand technical support. The engineer responsible for the rig design is always part of the service crew.

Snubbing units have evolved into one of the most capable and efficient well servicing tools in the oil & gas industry. In the 1920"s, the need for a rig to work with pressures at surface drove the invention of the snubbing unit. The first snubbing unit was primarily designed to work in well control situations to "snub" drill pipe and or casing into, or out of, a well bore when conventional well killing methods could not be used. The first snubbing unit relied on the draw works of the companion rig to supply its" power. A series of sheaves, cables and counter weights were rigged up so that as the rig"s traveling blocks hoisted up, the snubbing unit would snub in the hole. Conversely, when the traveling blocks on the rig were lowered, the snubbing unit would snub out of the hole. As you can imagine, this required close communication with several different contractors in order to perform the work safely and efficiently.

Today"s snubbing units can be employed to provide a wide range of services. In essence, a snubbing unit is a hydraulic rig that can do everything a rig can do, plus it can perform under pressure in an under balanced live well state. This is especially critical to the operators in the Haynesville Shale, which is known for HPHT wells. With the use of the snubbing units" hydraulic rotary, the unit can be employed for fishing, milling, drilling, side tracking or any task needed to remove bridge plugs, cement or deepen wells.

The industry has become more aware of damages caused by heavy kill weight fluids and mud. This has helped make snubbing units more popular in a completion and workover role, versus its" traditional use as a well control response tool. With the advances in drilling technologies in the unconventional shale market, the benefits of snubbing units have become very apparent. These types of completions often have laterals extending out thousands of feet. With costly stimulations used to help extract the gas more efficiently, operators often times do not wish to turn around and load the well with heavy fluids to complete the well dead.

In conclusion, with the snubbing unit"s size, ability to handle pressure, rotary capabilities, rigidity of jointed tubing and minimal wall contact, snubbing units have become the chosen resource for these types of completions.

The land drilling market worldwide is structured primarily as a rental market, not a sales market, where land drilling companies lease their rigs to E&P companies for an agreed period of time – weeks, months, or years – at a day-rate. The rigs are then used to drill wells and execute the E&P’s drilling programs.

Drilling opportunities are analysed and explored in order, leaving a series of dry holes, until a discovery is made. It is rare for an E&P company to actually own the rigs which they operate, but there are some exceptions such as Chesapeake, who will purchase their own fleet of rigs.

Investors require a minimum level of return for their investment dollars in drilling operations, and typically equate cost with risk. These turnkey drilling contracts may limit risk by guaranteeing a minimum number of wells that can be drilled with the rig. The contract will also outline how the rig can be used – including the pieces of equipment, when to change pieces, temperature and pressure tolerances and the weight of mud.

Nabors operates the world’s largest land drilling rig fleet, with around 500 rigs operating in over 25 countries – in almost every significant O&G basin on the planet. It also has the largest number of high-specification rigs (including new AC rigs and refurbished SCR rigs) and custom rigs, built to withstand challenging conditions such as extreme cold, desert and many complex shale plays.

Headquartered in Tulsa, Oklahoma, H&P is a global business with land operations across the US, as well as offshore operations in the Gulf of Mexico. It is engaged primarily in the drilling of O&G wells for E&P companies, and recognised for its innovative FlexRig technology.

Patterson-UTI operates land based drilling rigs, primarily in O&G producing regions of the continental US, and western Canada. The company also provides pressure pumping services to US E&P companies and specialist technology, notably pipe handling components, to drilling contractors globally.

Precision is an oilfield services company and Canada’s largest drilling rig contractor, with over 240 rigs in operation worldwide. The Company has two segments. The Contract Drilling Services segment operates its rigs in Canada, the United States and internationally. The Completion and Production Services segment provides completion and workover services and ancillary services to O&G E&P companies in Canada and the US.

Pioneer operates a modern fleet of more than 24 top performing drilling rigs throughout onshore O&G producing regions of the US and Colombia. The company also offers production services include well servicing, wireline, and coiled tubing services – supported by 100 well-servicing rigs, and more than 100 cased-hole, open-hole and offshore wireline units.

In Texas, generally considered to be the centre of US land drilling, RigData reports that there are currently 678 active rigs – split between Helmerich & Payne (160), Patterson-UTI (85), Nabors (64), Precision Drilling (39) and 77 other drillers (330).

Most new onshore rigs, both drilling and work over rigs, are built by OEMs in China. In the US, the larger vertically integrated land drillers have in-house manufacturing operations, so they will outsource some equipment construction, but assemble the new rigs at their own facilities. The leading provider of US newbuild rigs is National Oilwell Varco.

The secondary market, where existing rigs are sold, is largely auction dominated with mostly older rigs changing hands. As a rule, the big land drillers do not sell their newbuild rigs, as each has their own flagship designs.

The following is a list of seasonal work gear worn by service rig workers. Savanna supplies rig employees with coveralls, hard hat, safety glasses, and hearing protection (ear plugs). Always have at least one set of extra clothes to change into if your current work wear gets contaminated.

Service rigs typically work from a base location, and crews work between 4 and 12 hour shifts each day. Service rig crews are generally made up of five (5) people: Rig Manager, Driller/Operator, Derrickhand, and two Floorhands.

Most days begin by meeting the Driller/Operator who drives the crew to the rig in a company vehicle or personal vehicle. Each member of the crew is responsible for getting themselves to the meeting point, so having a reliable vehicle is an asset. At the end of each shift, the crew returns to the meeting point and is dropped off.

Work in the oil and gas services industry is seasonal. Because of the weight of rigs and their equipment, and the remote location of wells, these locations are often only accessible when the ground conditions can tolerate heavy loads. Therefore, wells are typically drilled and serviced in the winter when the ground is frozen solid, or in the summer, when the ground has thawed and dried sufficiently. During the spring and fall, when the ground is in a transitional state, it is too soft to move equipment on and easily damaged. For this reason, provincial governments implement “road bans” prohibiting heavy loads from operating in certain areas. During this time, rig work is slower, and many rigs are shut down and their crews sent home. Be prepared to be off for anywhere from 6 to 12 weeks without pay during this time. However, rigs that are shut down are usually in need of maintenance, and there may be opportunities for employees who would like to help in this regard. Employees may be eligible for Employment Insurance benefits during seasonal shutdowns.

If you would like to work on a service rig, you should live in or near these areas. In some instances, rigs are required to operate in remote locations for extended periods of time. When this happens, rig crews either live in camps or in local hotels, and their room and board are paid for by Savanna.

Once you have completed your orientation, you will immediately receive any other necessary training. This involves Workplace Hazardous Materials Information System (WHMIS) and Transportation of Dangerous Goods (TDG), along with an in-depth General Safety Orientation. This training is mandatory and provided by Savanna at no cost to the employee. Job-related, hands on training is conducted in the field through the Enform Service Rig Competency Program.

While it is not mandatory to have this certification, each service rig crew is required to have two members who are certified in Standard First Aid with CPR level C. Therefore, obtaining a certification beforehand is a great way to improve your chances of being hired.

At Savanna, there is an excellent opportunity for good quality employees to quickly advance to more senior positions. If you would like to pursue a career as a Derrickhand or Driller, please speak to your Rig Manager or Human Resources. The service rig industry in Canada, through Enform, has adopted a competency assessment program to allow Drillers and Derrickhands to evaluate and promote Floorhands when they are ready. Savanna’s recruiters can provide you with more information if you would like to pursue a career in either one of these positions.

8613371530291

8613371530291