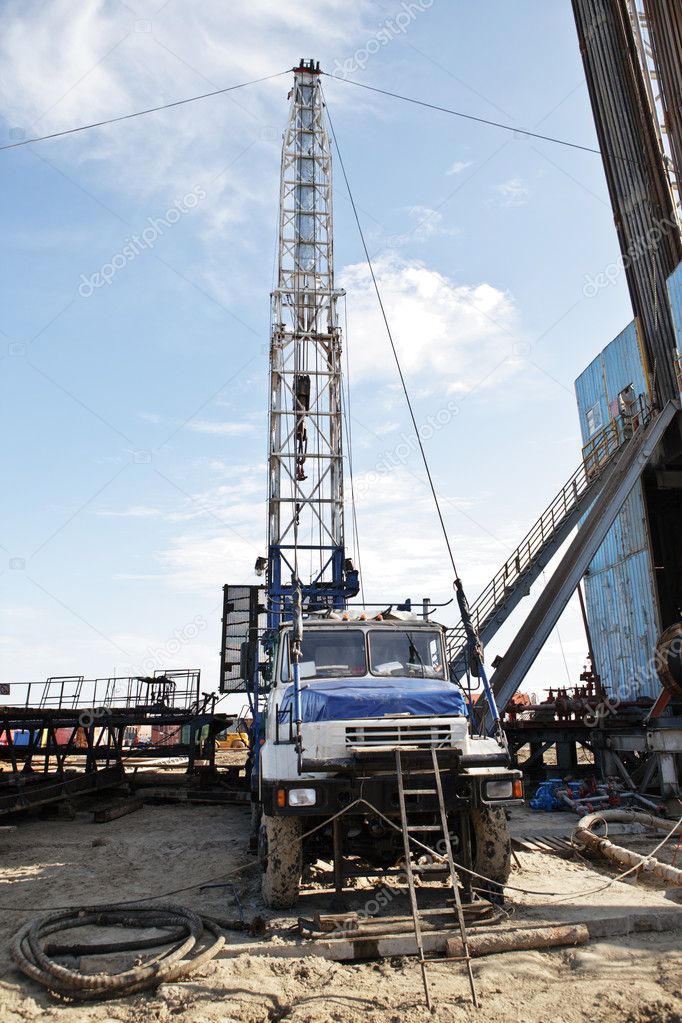

workover rig vs drilling rig in stock

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

We like to throw around “blog ideas” over here at Croft to help my fellow blog partner, Amy and I have a new fresh blog every week. We try to keep our readers up to date with both the new and the old. Someone threw out the idea of writing about a workover rig. Still being new to the industry, I snatched this topic up because I simply wanted to learn more about it myself! My main focus for this blog is simply discussing what is a workover rig and why it is important.

First off, maybe you know a workover rig by a different name. They can be called completion wells or pulling units. I just want to try to avoid any confusion! I am going to give Wikipedia’s definition first and then break it down to layman’s terms for those of you who don’t quite understand what the Wiki is trying to say (Like me). According to Wikipedia, “The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically though, it will refer to the expensive process of pulling and replacing a completion.” Let’s break down some of that Terminology…

Snubbing: This method is used in more demanding situations when wireline and coiled tubing does not offer the strength and durability needed. Snubbing runs the bottom hole assembly on a pipe string using a hydraulic workover rig.

So basically, the purpose of a workover rig is to replace a well with a fresh completion. This may have to happen due to the well deteriorating or the changing of reservoir conditions. This is performed if a well completion is unsuitable for the job at hand. An example of the well deteriorating is the equipment may have become damaged or corroded such as production tubing, safety valves, electrical pumps, etc. An example of the changing of reservoir conditions maybe if the flow of a well has decreased over time. If this happens, when the well was originally drilled, it was fit for tubing that was big enough for a higher flow of oil and gas. As the flow decreased, smaller tubing is now needed.

For a workover to take place, a well must be killed or in other words, stop the flow of oil or gas. This is an intense procedure for a workover to take place, so they are planned long in advance.

Inserting and pulling up pipe tubing from oil wells is a precise and challenging job that not every rig is up for. That’s why you need a mobile workover rig from Dragon to get it done right every time. Our workover rigs are state-of-the-art and ready to tackle even the harshest conditions. A workover rig is perfect for site preparation while a standard mobile oil rig can handle a variety of piping tasks. Need workover rig parts, or service on another mobile rig? Dragon has that covered with our parts selection, too. View all of our workover rigs and other drilling rigs today.

Rig means the vessel described in Recital (A) hereto and includes any share or interest therein and her engines, machinery, boats, tackle, outfit, spare gear, fuel, consumable or other stores, belongings and appurtenances whether on board or ashore and whether now owned or hereafter acquired (but excluding therefrom any leased equipment owned by third parties);

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A service rig is a mobile platform loaded with oil industry service equipment that can be driven long distances within the oil fields to service wells.

There are several specialized types of service rigs: the carrier, the pumptruck, the doghouse, a 5-ton equipment truck and several crew vehicles. The rigs usually travel in a convoy, because all of the component rigs are needed for proper oil well servicing. The crew use the equipment on the rigs to provide a variety of services, including completions, work-overs, abandonment"s, well maintenance, high-pressure and critical sour-well work and re-entry preparation.

The Rig, or Carrier, is a mobile truck with a derrick and a cab for one driver. The carrier can also be trailer-mounted, enabling it to be towed behind a prime mover. Traditionally, trailer-mounted service rigs are much larger and heavier, with greater capacities.

Each service rig has a manager called a Toolpush, who orders and monitors supplies, monitors and records the progress of each job and schedules the crew"s time. At times there is also a representative present from the oil company whose wells are being serviced.

Service rig crew"s are often under the supervision of a Consultant who is contracted through said oil company and reviews safety and job tasks with the crew, and organizes the process of moving from each well and ensuring the

Canadian drilling rigs meet some of the highest regulatory and safety standards in the world. It"s a dynamic and exciting community to build a career in.

Canada’s drilling fleet is always changing to incorporate new technology and meet market demand. Most noticeably, the Canadian drilling fleet is growing in numbers. The fleet has 40% more rigs than it did 15 years ago. Today, the rig fleet offers just over 600 rigs.

For the most part, a rig is a rig is a rig. For example, all rigs have a derrick (the mast-like structure that holds the pipe to be lowered into the well bore) a catwalk that holds the drill pipe, a rig floor where floorhands handle the drill pipe, a drawworks which is the machinery that hoists and lowers pipe and a blowout preventor that enables a driller to control well pressure.

But different size rigs are used depending on the drilling target formation. Oil formations tend to be deeper than gas formations. When investors are most interested in producing oil, large rigs are in high demand. When the market prefers gas production, small rigs are in demand. Western Canada has plenty of both gas and oil, and activity cycles back and forth between preferences of one over the other.

Drilling rigs come in three sizes: singles, doubles and triples. These categories refer to how many lengths of pipe can stand in the rig’s derrick. On a single, the derrick holds one length of pipe. A double holds two, and a triple holds three.

A tall derrick isn’t necessary to drill deeper. If more pipe is needed to drill deeper, a single section of pipe is hoisted to the rig floor and added to the drill string. But sometimes the entire drill string needs to be pulled out of the hole (to change the drill bit, for instance). A derrick that holds multiple lengths of pipe comes in handy and helps the crew to complete this evolution quickly.

The larger derrick is efficient to drill deep wells but isn’t necessary for shallow wells. Single rigs drill wells that are around 1 to 2 kilometres deep. These wells usually access gas basins. Single rigs and their crews change drilling locations often, sometimes every day or every other day.

Doubles and triples are larger rigs with bigger substructures and taller derricks. These rigs drill between 3 and 6 kilometres into the earth and might be at the same location for several months to complete deep drilling operations.

Singles, doubles and triples refer to conventional rig categories. Additional new categories of rigs have introduced different ways of handling pipe. For instance, some companies run coil-tubing rigs that stream tubing from a large reel instead of using drill pipe, or automated drilling rigs that are outfitted with a pipe-handling arm that raises the pipe into the derrick, eliminating the need for a derrickhand to work from the monkeyboard.

Through the 1990s, rig activity focused evenly on the two commodities. Then in 1998, there was a shift: gas wells began to make up the bulk of drilling activity. Through the early 2000s, rig activity increased year over year, but gas wells—which are shallower and can be drilled faster—far outstripped the increase in oil wells. Between 2001 and 2006, oil wells made up about 25% of rig activity, and gas wells 75%.

The drilling industry reacted to this demand by expanding the fleet. In 2007, the rig fleet grew faster than it ever it had before: 49 rigs were added. Most of these new rigs were the smaller ones best suited for gas drilling. Then in 2008, natural gas was on the market in abundance, and the stock market price of natural gas started to fall. Investors pulled back on gas drilling. In 2010, industry was back to an even split between gas wells and oil wells.

And then the turn-around happened: oil drilling overtook gas drilling in western Canada. In 2011, 61% of the wells drilled were seeking an oil formation, versus the 39% seeking gas. Today’s market continues to favour large rigs that can reach deep oil formations. There also is increased interest in accessing these formations at an angle: rig crews drill a well bore that curves toward a drilling target. Drilling rig contractors have been adding equipment in 2013. Unlike 2007"s fleet expansion, these rigs will be the larger, heavier rigs, primed for oil drilling.

The design of drilling rigs for the petroleum industry has remained basically unchanged for the last four decades. Today"s offshore rigs have evolved from the basic land rig concept towed offshore in the 1950"s. Factors such as deeper waters and harsher environments have increased demands for additional auxiliary equipment such as active crown mounted motion compensator, topdrive and comprehensive mechanised pipehandling equipment. Implementation additional equipment and new systems have followed an "add-on" philosophy which has resulted in concepts of monstrosity. Further development to meet today"s and future demands of versatility, such as integration of capabilities for snubbing and coiled tubing operations, will probably evolve to a stage where the "multi-functional" course could turn to the "multi-useless" curse.

A thorough review of the status, combined with the desire to be able to contribute with more optimal solutions, have lead Maritime Hydraulics to the development of the RamRig concept.

Main Objectives. Maritime Hydraulics launched the idea in 1987, whereafter a joint venture engineering study with British Petroleum Development Norway Ltd. was carried out in 1988 and 1989. The study evaluated all known rig concepts with emphasise on the aspects of hoisting and tubular handling efficiency. The main objectives of the development work were:Improve safety by reduced manning and improving working environments,

The study concluded the RamRig concept to be the most optimal of the alternatives considered. However, as it was found to be too bold and radical for its time, it was decided that the project was to be shelved. This was mainly due to the lack of field experience of important components like the control system and the large hydrostatic transmission required.

After about 5 years Saga Petroleum"s efficient exploration, "EfEx", study, re-vitalised the concept in 1994. The detailed design of a complete drilling rig for an application for deepwater exploration operations was completed by June 1995. In this study the RamRig was found to be an important enabler for developing more efficient total concepts.

RMC1JWE0–Cuadrilla Resources drilling equipment & workover derrick rig at Shale Gas well Drill Site, Presse Hall Farm, Singleton, Blackpool, Lancashire, UK

RMJTW1AW–Shale gas drilling in Blackpool, Lancashire, UK. 10th August, 2017. Caudrilla Fracking Rig under construction in Westby-with-Plumptons in the Fylde. Anti-fracking protesters said they were determined to delay the arrival of the main drilling rig at Cuadrilla’s shale gas site. More than 4,000 people have signed a petition in calling for the enforcement of planning conditions at Cuadrilla’s Preston New Road hydraulic fracturing shale gas site in Lancashire. Natural gas onshore drilling projects UK

Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs.

Belonging to the same family, Sovonex™ service rigs comprise many of the technological advantages that result in smooth operation and make the life of our customers’ easier:

Wide selection: At our production facility in China we design and develop workover rigs for service depths ranging from 1,600 m to 8,500 m (5,250 ft-27,900 ft), and workover depths from 2,000 m to 9,000 m (6,600 ft-30,000 ft) for 2 7/8” DP.

Full API coverage: The different components of our well-servicing rigs are manufactured to the following API standards:Steel structures, such as the mast: API Spec 4F

Highly maneuverable : Sovonex™ mobile drilling rigs and self-propelled workover rigs possess excellent driving properties in the desert, mountain, and other impassable terrains.

Reduced NPT: The mast is erected hydraulically to reduce time for rig up and increase safety. Likewise, all rig components have been designed to allow for fast assembly and disassembly.

With every service rig, we send technical staff to our customer to provide first-hand technical support. The engineer responsible for the rig design is always part of the service crew.

The land drilling market worldwide is structured primarily as a rental market, not a sales market, where land drilling companies lease their rigs to E&P companies for an agreed period of time – weeks, months, or years – at a day-rate. The rigs are then used to drill wells and execute the E&P’s drilling programs.

Drilling opportunities are analysed and explored in order, leaving a series of dry holes, until a discovery is made. It is rare for an E&P company to actually own the rigs which they operate, but there are some exceptions such as Chesapeake, who will purchase their own fleet of rigs.

Investors require a minimum level of return for their investment dollars in drilling operations, and typically equate cost with risk. These turnkey drilling contracts may limit risk by guaranteeing a minimum number of wells that can be drilled with the rig. The contract will also outline how the rig can be used – including the pieces of equipment, when to change pieces, temperature and pressure tolerances and the weight of mud.

The International Association of Drilling Contractors (IADC) lists 547 members in the category of Land Drilling Contractors. According to Statista, the key US land drilling contractors are: Nabors Industries Ltd, Helmerich & Payne Inc, Patterson-UTI Energy Inc, Precision Drilling Corporation and Pioneer Energy Services Corp.

Nabors operates the world’s largest land drilling rig fleet, with around 500 rigs operating in over 25 countries – in almost every significant O&G basin on the planet. It also has the largest number of high-specification rigs (including new AC rigs and refurbished SCR rigs) and custom rigs, built to withstand challenging conditions such as extreme cold, desert and many complex shale plays.

Headquartered in Tulsa, Oklahoma, H&P is a global business with land operations across the US, as well as offshore operations in the Gulf of Mexico. It is engaged primarily in the drilling of O&G wells for E&P companies, and recognised for its innovative FlexRig technology.

Patterson-UTI operates land based drilling rigs, primarily in O&G producing regions of the continental US, and western Canada. The company also provides pressure pumping services to US E&P companies and specialist technology, notably pipe handling components, to drilling contractors globally.

Precision is an oilfield services company and Canada’s largest drilling rig contractor, with over 240 rigs in operation worldwide. The Company has two segments. The Contract Drilling Services segment operates its rigs in Canada, the United States and internationally. The Completion and Production Services segment provides completion and workover services and ancillary services to O&G E&P companies in Canada and the US.

Pioneer operates a modern fleet of more than 24 top performing drilling rigs throughout onshore O&G producing regions of the US and Colombia. The company also offers production services include well servicing, wireline, and coiled tubing services – supported by 100 well-servicing rigs, and more than 100 cased-hole, open-hole and offshore wireline units.

Together these five companies dominate the US rental market. Other smaller but prominent contractors include: Parker Drilling, Unit Corp, Independence Contract Drilling, Seventy Seven Energy, Schramm and Ensign Drilling. Beyond these players, the market is highly fractured, with many “mom & pop” style drillers.

In Texas, generally considered to be the centre of US land drilling, RigData reports that there are currently 678 active rigs – split between Helmerich & Payne (160), Patterson-UTI (85), Nabors (64), Precision Drilling (39) and 77 other drillers (330).

Most new onshore rigs, both drilling and work over rigs, are built by OEMs in China. In the US, the larger vertically integrated land drillers have in-house manufacturing operations, so they will outsource some equipment construction, but assemble the new rigs at their own facilities. The leading provider of US newbuild rigs is National Oilwell Varco.

The secondary market, where existing rigs are sold, is largely auction dominated with mostly older rigs changing hands. As a rule, the big land drillers do not sell their newbuild rigs, as each has their own flagship designs.

8613371530291

8613371530291