workover rig work in stock

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Able to work closely with others in the confined area of the drilling rig and may live together in crew quarters. Six (6) months of stable work history.

Ability to Lift 50+ pounds and work outdoors in all weather conditions. For Casing Crew; at least two years of experience working the rig floor while running…

Able to work closely with others in the confined area of the drilling rig and may live together in crew quarters. High School Diploma or GED equivalent.

Ability to work effectively and communicate in a work environment that may be noisy. Maintain spatial orientation and awareness to safely move around work…

Interface with and facilitate the work of the Rig Crew during well work over and drilling operations. Identifying and evaluating the wells for malfunctions and…

Maintains a safe working environment and reasonably clean and tidy rig floor area by picking up and storing all tools in their respective storage areas after…

Adaptable/flexible -- enjoys doing work that requires frequent shifts in direction. We work for property management companies painting, cleaning, and repairing…

Verifying your legal right to work in the United States under the Immigration Reform and Control Act of 1986 (IRCA). 40 Hours Paid Sick Leave, minimum.

Job Requirements: *Job requirements include but are not limited to performing work rapidly and accurately, standing for long periods, frequent bending, stooping…

Participate in rig move (if moving locations) spot lines when rigging up or down, watch for over head hazards such as powerlines, help spot rig on headache rack…

Complete rig-up and rig-down of AFS. We provide opportunities to develop a skillset that equips the AFS Operator for oilfield work including equipment fueling…

Assists in drilling rig erection (rig up) and dismantling (rig down). Performs housekeeping around rig, keeping rig floor clean and clear of tools after each…

Prior land rig experience is preferred. Measures tubular goods using a rig tape. The position of Floorhand necessitates capacity to be able to perform very…

Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs.

Belonging to the same family, Sovonex™ service rigs comprise many of the technological advantages that result in smooth operation and make the life of our customers’ easier:

Wide selection: At our production facility in China we design and develop workover rigs for service depths ranging from 1,600 m to 8,500 m (5,250 ft-27,900 ft), and workover depths from 2,000 m to 9,000 m (6,600 ft-30,000 ft) for 2 7/8” DP.

Full API coverage: The different components of our well-servicing rigs are manufactured to the following API standards:Steel structures, such as the mast: API Spec 4F

Highly maneuverable : Sovonex™ mobile drilling rigs and self-propelled workover rigs possess excellent driving properties in the desert, mountain, and other impassable terrains.

Reduced NPT: The mast is erected hydraulically to reduce time for rig up and increase safety. Likewise, all rig components have been designed to allow for fast assembly and disassembly.

With every service rig, we send technical staff to our customer to provide first-hand technical support. The engineer responsible for the rig design is always part of the service crew.

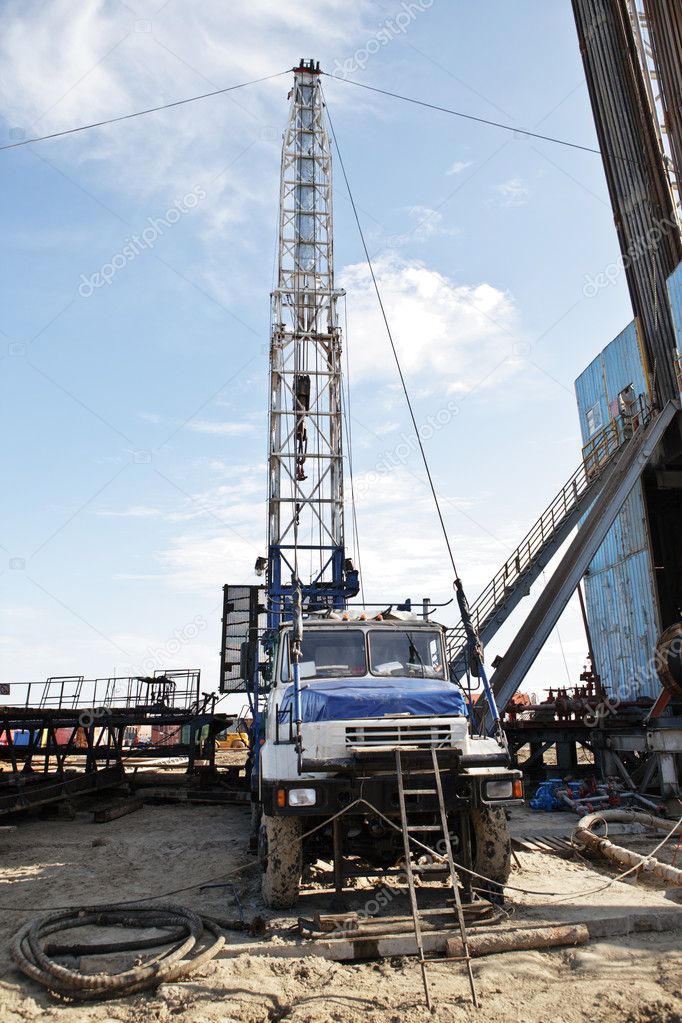

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

Take the worry and hassle out of your eyewash stations. Keep your eyewash station ANSI-compliant with Eagle Safety’s workover rig eyewash station inspection. Ensure that your eyewash station is properly cleaned and serviced with the knowledge and expertise of our dedicated service professionals.

Eagle Safety’s workover rig technician will ensure your SCBA’s are cleaned, inspected, and properly charged. SCBA units are inspected to ensure valves, regulators, harnesses, and face masks are all in good operating condition and are clean and ready for use at each workover rig location.

A significant advantage of our SCBA inspection and maintenance service is that our equipment is mobile. With our mobile recharging van, we can complete all recharge services on-site which mitigate the need to remove the SCBA’s from the workover rig location. This ensures complete respiratory protection during the inspection process in addition to not having to provide leave behind units. Our preventative maintenance (PM) program can ensure you are compliant and ready for any emergency.

Eagle Safety’s workover rig technician will ensure your portable H2S monitor is bump tested and working properly. The use of portable gas detection devices helps ensure a workplace free from recognized hazards by providing employees working in potentially harmful environments the means to monitor their air quality. Harmful environments may include those with high levels of toxic or combustible gases or oxygen-deficient or enriched air. Many of these conditions cannot be detected by smell or sight and therefore require instrumental monitoring to view their levels.

Eagle Safety’s workover rig technician will ensure your fixed H2S monitor is calibrated and working properly. Calibration is defined by OSHA bulletin SHIB 09-30-2013 as ‘an instrument’s measuring accuracy relative to a know concentration of gas. Direct reading portable gas monitors compare the sensor’s response to a know concentration of the test gas’. The bulletin stresses that direct-reading portable gas monitors that are properly calibrated can minimize the risk of injury, illness, or death from respiratory hazards such as oxygen deficiency or combustible or toxic gases.

In a crucial situation such as COVID-19 exposure, you need professionals who know how to properly sanitize, disinfect, and protect your workover rig location. Eagle Safety understands the delicate nature of managing a decontamination project when a work location is exposed and will work with you to make sure all aspects of your project are handled with the utmost professionalism.

If your workover rig location has a confirmed or suspected case of COVID-19 coronavirus, Eagle Safety has established protocols to provide the most effective sanitation available. In addition, we have a clear project communication plan to keep all stakeholders updated each step of the way. We understand that often the impact of exposure to a virus such as COVID-19 goes beyond the workover rig location itself and affects the morale of personnel, customers, residents, students, and even the general public. Having an effective decontamination plan completed by leading experts in the field of clean up and remediation is critical.

Although many companies thoroughly ‘clean’ the worksites, they rarely effectively disinfect them. Viruses and bacteria are thought to spread mainly from person-to-person. However, what is often overlooked is the possibility of contracting it through contact with a contaminated surface. When someone touches a surface or object contaminated with the pathogen that causes COVID-19 and then touches their own eyes, nose, or mouth, they may expose themselves to it. The virus can be detectable on surfaces like plastic and stainless steel for two to three days, making the spread even more likely. Therefore, virus prevention through disinfection is such a vital part of preparing your business to open its doors back up to the public.

RMJTW1AW–Shale gas drilling in Blackpool, Lancashire, UK. 10th August, 2017. Caudrilla Fracking Rig under construction in Westby-with-Plumptons in the Fylde. Anti-fracking protesters said they were determined to delay the arrival of the main drilling rig at Cuadrilla’s shale gas site. More than 4,000 people have signed a petition in calling for the enforcement of planning conditions at Cuadrilla’s Preston New Road hydraulic fracturing shale gas site in Lancashire. Natural gas onshore drilling projects UK

Workover rigs are specialized oil rigs utilized in the process of pulling and replacing production to extend the life of the well. They are also called completion rigs or pulling units. They are used in various operations such as handling rod & tubing work and other associated activities to improve the well output and perform plug & abandonment services. Moreover, oil & gas companies have shifted to workover operations to increase their oil & gas output from mature oilfields. Workover rigs are preferred in onshore and offshore applications. They provide high mobility, which allows companies to move them across oilfields. The stability in oil prices is expected to increase the demand for workover rigs due to increase in production activities across the globe. The rise in demand for oil and natural gas is expected to propel the growth of the workover rigs market over the forecast period.

Oil & gas industries are adversely affected due to the coronavirus outbreak. With decrease in oil prices, many companies are facing financial crisis, which is one of the major factors that reduce the demand for workover rigs over the forecast period. Similarly, the worldwide lockdown has suspended travel privileges, thereby decreasing the fuel consumption across the globe. The lockdown has disrupted the supply chain and forced many companies to shut down their power plants to prevent the spread of the virus. This has further reduced the demand for workover rigs across the globe.

The workover rigs market is expected to grow vigorously due to rise in demand for oil and natural gas. Rise in population and rapid urbanization have increased the demand for these fuels. Increase in demand for oil and natural gas is expected to make companies to enhance oil and gas production to meet the demand. Moreover, increase in oil & gas investments and government support for oil & gas E&P activities are anticipated to increase the requirement for intervention and completion services. Rise in well E&P activities, such as intervention and completion, is expected to boost the growth of the workover rigs market during the forecast period. However, uncertainty and fluctuations in crude oil prices are expected to reduce investments in E&P projects, which, in turn, may impact the workover rigs market over the forecast period.

Digitalization of workover rigs is one of the major trends observed. Automated workover rigs provide better safety and higher precision in operations as they use remotely operated robotic equipment. Integrated software system provides precise data to the operators for future decision making. This technological advancement in the workover rigs market is expected to boost the market growth over the forecast period.

Furthermore, huge investment from government and other private companies to drilling activities is also expected to propel the workover rigs market over the forecast period.

By region, the global workover rigs market is segmented into North America, Latin America, Western Europe & Eastern Europe, Asia-Pacific, and the Middle East & Africa. The Middle East & Africa is expected to become the market leader during the forecast period. High investments and increased current production activities contribute to the market growth in the region. North America is also expected to grow, owing to its increased shale field activities,

Key benefits of the report:This study presents the analytical depiction of the workover rigs market along with the current trends and future estimations to determine the imminent investment pockets.

Key Market Players Mesa Southern Well Servicing, Sun Well Service, Inc., Nordic Gulf, Drillmec Drilling Technologies, Automated Rig Technologies Ltd, Moncla Companies, San Antonio International, Eastern Well Services, MBI Energy Services, Superior Energy Services

Among Survey Participants:Rig Demand Down QTQ [See Question 1 on Statistical Review]. Seven of the eight respondents said that demand had dropped in 1Q15 vs 4Q14 and all but one blamed lower oil prices for the slowing. One respondent that had seen a slowdown in demand said it was because they had finished all of their completion work. The respondent who had not seen an effect on demand said that their work was steady, but they were hearing of others slowing down.Mid-Tier Well Service Manager: “We are seeing demand slow for rigs and prices are being reduced. Operators are asking for 20% reductions, some are asking for 30% and they may get it. The greater reductions will be from people who are local because they don"t have the overhead expense. The service won’t be as good. On average, operators may get 15% of that 30% they are seeking in reductions.”

Number of Rigs Sufficient [See Question 2 on Statistical Review]. Six of the eight respondents said that the workover rig inventory is excessive for the current demand, while two said that it is sufficient but tipping toward excessive.Mid-Tier Operator: “Operators here are basically focusing on the higher production wells and going to ignore the lower ones. We have heard companies are laying down workover rigs. One company is going from 17 to 13.”

Well Service Work Weighted Toward Standard Workovers and Routine Maintenance [See Question 3 on Statistical Review]. Among all respondents, standard workover work accounts for 34% on average, routine maintenance accounts for 34%, plug and abandonment (P&A) accounts for 16% and completion work accounts for 16%.Mid-Tier Well Service Manager: “Our work slowed because we finished our completion work so the client gave us some production work to keep us steady till we finish this fracking job.”

Hourly Rates Consistent Among HP Series [See Question 5 on Statistical Review]. Most workover rig horsepower falls within the range of the 500 series. The 500 HP hourly rates average $310 to $400/hour depending on what ancillary equipment is contracted. See Table II for Average Hourly Rates.

2015 Rates Under Pressure [See Question 8 on Statistical Review]. Five of the eight respondents said 2015 would see further reductions in demand and hourly rates and even labor rates if the price of oil did not rise. One respondent said that “iron would start laying down” if oil prices did not rise. One respondent said he expects that work demand would come back up after a couple of months as everyone adjusted.Manager for Mid-Tier Well Service Company: “As a company, we have backed off our growth budget for 2015 and our capex has been nixed. We implemented a 10% reduction in our rates. We are just going to lower rates not wages, because we can buy equipment and leave it sit, but if you do that with people, they starve.”

Hart Energy researchers completed interviews with nine industry participants in the workover/well service segment in areas of the Rocky Mountains outside of the Bakken Shale play. Participants included one oil and gas operator and seven managers with well service companies. Interviews were conducted during January 2015.

3. Looking at your slate of well service work - on a percentage basis - how much of it is workover vs. routine maintenance vs. plug & abandonment (P&A) vs. completion work?

8613371530291

8613371530291