Exploring the Manual Tong Q Type: A Guide to Understanding its Operation and Importance

In the vast world of industrial tools and machinery, the Manual Tong Q type stands as a reliable and efficient option for a wide range of applications. Its unique design and functionality have made it a sought-after tool in numerous industries, from construction to manufacturing. This article aims to provide a comprehensive guide to understanding the Manual Tong Q type, its operation, and the significance it holds in various fields.

I. Introduction to the Manual Tong Q Type

The Manual Tong Q type is a hand-operated tool that is used for various lifting, clamping, and tightening tasks. Its name, Tong Q, is derived from its distinctive features and capabilities. This tool is characterized by its sturdy construction, precision engineering, and user-friendly design. Its versatility allows it to be used in a wide range of environments and applications.

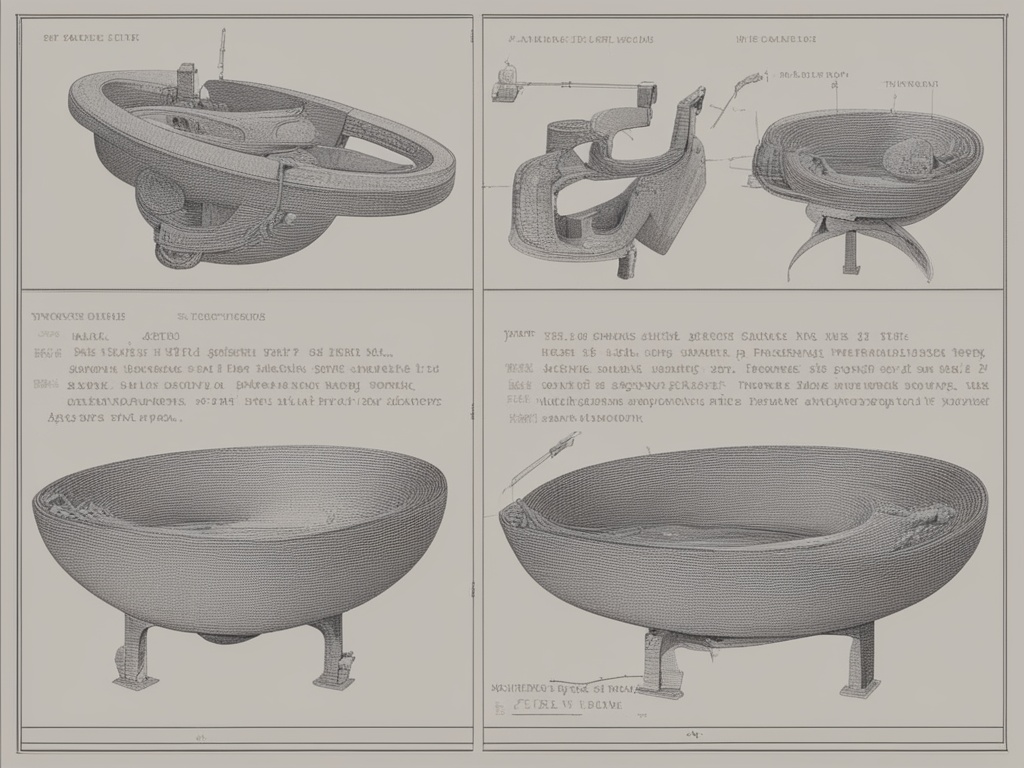

II. Design and Components of the Manual Tong Q Type

The Manual Tong Q type boasts a robust design that ensures durability and longevity. Its key components include a robust frame, a precision-engineered jaw mechanism, and a user-friendly handle. The frame is made from high-strength materials, such as steel, that can withstand heavy loads and repeated use. The jaw mechanism is designed to provide precise clamping and lifting capabilities, while the handle is ergonomically designed for maximum comfort and ease of use.

III. Operation of the Manual Tong Q Type

Operating the Manual Tong Q type is a straightforward process. To use it, simply grasp the handle firmly and squeeze it to open the jaws. Once the jaws are open, position them around the object to be lifted or clamped. Release the handle, and the jaws will close, securely grasping the object. To release the object, simply squeeze the handle again to open the jaws.

IV. Applications of the Manual Tong Q Type

The versatility of the Manual Tong Q type makes it suitable for a wide range of applications. In the construction industry, it is commonly used for lifting and moving building materials, such as bricks, tiles, and wooden beams. In manufacturing, it is utilized for clamping workpieces during machining or assembly processes. The tool is also useful in automotive repair, where it can be used to remove or install components such as nuts, bolts, and bearings.

V. Advantages of the Manual Tong Q Type

There are numerous advantages that make the Manual Tong Q type a valuable addition to any toolbox. Firstly, its sturdy construction and precision engineering ensure reliability and durability, even in demanding environments. Secondly, its user-friendly design and ergonomic handle make it easy to operate, reducing the risk of fatigue or injury. Additionally, the tool's versatility allows it to be used in various applications, making it a cost-effective investment.

VI. Safety Considerations when Using the Manual Tong Q Type

While the Manual Tong Q type is a safe and reliable tool, it is important to follow certain safety practices when using it. Always ensure that the tool is in good working order and inspected regularly for any signs of wear or damage. Avoid overloading the tool by using it for tasks that exceed its rated capacity. Additionally, ensure that the jaws are properly aligned when clamping or lifting objects to prevent slippage or accidental release.

VII. Conclusion

The Manual Tong Q type is a valuable tool that offers numerous benefits for a wide range of applications. Its sturdy design, precision engineering, and user-friendly features make it a reliable and efficient option for lifting, clamping, and tightening tasks. By understanding its operation and advantages, as well as adhering to safety practices, users can maximize the tool's potential and ensure its longevity. The Manual Tong Q type is a testament to the importance of precision engineering and user-oriented design in creating tools that meet the demands of modern industries.

8613371530291

8613371530291