The Importance and Benefits of Drill Pipe Protectors: A Comprehensive Guide

Introduction (100 words)

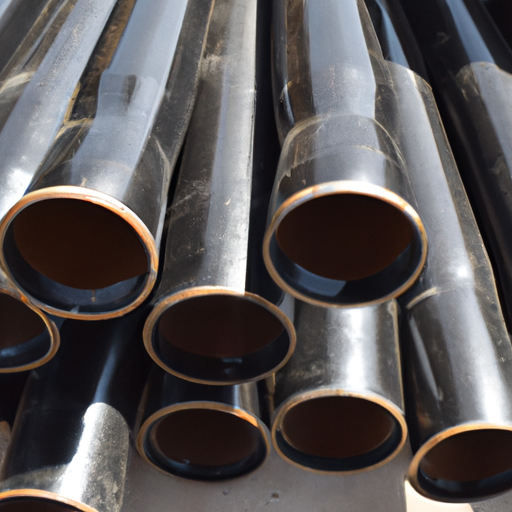

Drill pipe protectors play a crucial role in the oil and gas industry, safeguarding drill pipes and ensuring their longevity. This article aims to provide a comprehensive guide on the importance, benefits, and types of drill pipe protectors available in the market. As a vital component of drilling operations, drill pipe protectors not only enhance safety but also save time and money by preventing damage and extending the lifespan of the pipes. Read on to discover why investing in quality drill pipe protectors is essential for any drilling project.

1. The Significance of Drill Pipe Protectors (200 words)

Drill pipe protectors are designed to shield drill pipes from various external hazards during transportation, storage, and drilling operations. These protectors prevent damage caused by impact, corrosion, vibration, and other environmental factors that can compromise the integrity of the pipes. The main purpose of drill pipe protectors is to maintain the pipe's structural integrity, ensuring safe and efficient drilling operations.

2. Benefits of Drill Pipe Protectors (300 words)

2.1 Enhanced Safety: Drill pipe protectors reduce the risk of accidents and injuries by preventing pipe damage. By using protectors, potential hazards such as pipe thread damage, cross-threading, and pipe-to-pipe contact are minimized, ensuring a safer working environment for operators.

2.2 Increased Lifespan: Drill pipe protectors shield the pipe threads and body, reducing wear and tear during handling, storage, and transportation. By preventing damage, protectors significantly extend the lifespan of the drill pipes, leading to cost savings by reducing the need for frequent replacements.

2.3 Improved Efficiency: With drill pipe protectors in place, the risk of costly delays due to damaged pipes is greatly reduced. By enhancing the overall integrity of the pipes, protectors contribute to uninterrupted drilling operations, resulting in improved efficiency and productivity.

2.4 Corrosion Prevention: Drill pipe protectors act as a barrier against moisture, dust, and other elements that can cause corrosion. The protective coatings and materials used in these protectors help to preserve the pipe's surface, preventing rust and corrosion and prolonging its useful life.

3. Types of Drill Pipe Protectors (300 words)

3.1 Plastic Protectors: Plastic drill pipe protectors are lightweight, cost-effective, and provide excellent protection against impact, corrosion, and thread damage. They are easy to install and remove and are available in various sizes to fit different pipe dimensions.

3.2 Steel Protectors: Steel drill pipe protectors offer superior durability and protection, making them ideal for harsh drilling environments. They are resistant to impact, UV radiation, and extreme temperatures. Steel protectors are reusable and provide long-term protection for the drill pipes.

3.3 Composite Protectors: Composite drill pipe protectors combine the benefits of both plastic and steel protectors. These protectors are lightweight, yet provide excellent impact resistance and corrosion prevention. They are suitable for various drilling conditions and offer cost-effective protection for drill pipes.

4. Choosing the Right Drill Pipe Protectors (200 words)

When selecting drill pipe protectors, several factors should be considered, including the type of drilling operation, pipe dimensions, and environmental conditions. It is crucial to choose protectors that fit the pipe precisely, ensuring a secure fit and providing optimal protection. Consulting with industry experts and suppliers can help in determining the most suitable protectors for specific drilling requirements.

Conclusion (100 words)

Drill pipe protectors are integral to the success and safety of drilling operations. By safeguarding drill pipes from damage, these protectors extend their lifespan, enhance operational efficiency, and save costs. Whether using plastic, steel, or composite protectors, investing in high-quality drill pipe protectors ensures the longevity and reliability of the pipes, leading to improved drilling performance. As the oil and gas industry continues to evolve, the importance of drill pipe protectors in safeguarding valuable drilling assets cannot be overstated.

8613371530291

8613371530291