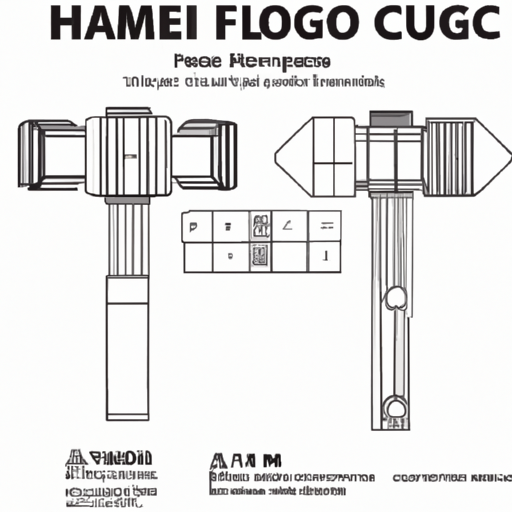

FMC Weco Fig 1003, 400, 602, and 1502 Female Hammer Union: A Comprehensive Guide for Oilfield Applications

Introduction

In the oil and gas industry, precision and reliability are crucial when it comes to connecting pipes and ensuring a secure flow of fluids. Hammer unions play a vital role in this process, providing a dependable connection between pipes and equipment. Among the various hammer unions available, the FMC Weco Fig 1003, 400, 602, and 1502 Female Hammer Unions have gained significant popularity due to their exceptional performance and durability. In this article, we will delve into the details and features of these hammer unions, discussing their applications, benefits, and why they are considered the preferred choice in the industry.

1. Understanding Hammer Unions

Hammer unions are designed to withstand high pressure and harsh conditions commonly encountered in oilfield operations. They consist of three main components: a male sub, a female sub, and a nut. These components interlock to provide a secure, leak-proof connection between pipes and equipment. The FMC Weco Fig 1003, 400, 602, and 1502 Female Hammer Unions are among the most reliable and trusted options available.

2. FMC Weco Fig 1003 Female Hammer Union

The FMC Weco Fig 1003 Female Hammer Union is a threaded and welded union ideal for low-pressure applications. It is designed with a working pressure of 1,000 psi and features a resilient lip-type seal, providing a tight and leak-free connection. The Fig 1003 union is commonly used in applications such as water lines, oilfield suction hoses, and low-pressure fluid transfer lines.

3. FMC Weco Fig 400 Female Hammer Union

The FMC Weco Fig 400 Female Hammer Union is a threaded union suitable for a wide range of applications. It is rated for a working pressure of 4,000 psi and can handle various fluids, including water, oil, and gas. The Fig 400 union is widely used in manifold and treating iron applications, as well as cementing, fracturing, and well testing operations.

4. FMC Weco Fig 602 Female Hammer Union

The FMC Weco Fig 602 Female Hammer Union is a compact and robust union designed for high-pressure applications. With a working pressure of 6,000 psi, it is commonly used in choke and kill lines, cementing, acidizing, and well servicing operations. The Fig 602 union is preferred for its reliable sealing capabilities and compact size, making it suitable for tight spaces and offshore applications.

5. FMC Weco Fig 1502 Female Hammer Union

The FMC Weco Fig 1502 Female Hammer Union is one of the most widely used unions in the oil and gas industry. It is specifically designed for extremely high-pressure applications, with a working pressure of 15,000 psi. The Fig 1502 union is commonly used in fracturing, cementing, and well testing operations, where the reliable connection is critical. It is known for its robust construction and excellent sealing capabilities, ensuring a secure and leak-free connection even under extreme conditions.

6. Key Features and Benefits

The FMC Weco Fig 1003, 400, 602, and 1502 Female Hammer Unions offer several key features and benefits that make them the preferred choice in the industry:

- High-quality materials: These hammer unions are constructed from durable materials, such as carbon steel, which ensures their longevity and ability to withstand harsh operating conditions.

- Reliable sealing: The resilient lip-type seal used in these unions provides a tight and leak-free connection, minimizing the risk of fluid loss and ensuring safe operations.

- Easy installation: The threaded design of the FMC Weco Fig 1003, 400, 602, and 1502 Female Hammer Unions allows for easy installation and disassembly, saving time and reducing downtime.

- Versatility: These unions are suitable for a wide range of applications, from low-pressure to high-pressure operations, making them highly versatile and adaptable to different oilfield requirements.

- Industry compliance: The FMC Weco hammer unions comply with industry standards and certifications, ensuring their reliability and adherence to safety regulations.

7. Maintenance and Safety Considerations

To ensure the longevity and optimal performance of FMC Weco Fig 1003, 400, 602, and 1502 Female Hammer Unions, regular maintenance and safety precautions should be followed. This includes:

- Regular inspection: Inspect the unions for signs of wear, damage, or corrosion. Replace any damaged or worn-out components promptly.

- Lubrication: Apply a suitable lubricant to the threads and sealing surfaces to minimize friction and ensure ease of installation.

- Proper torque: Follow the manufacturer's recommended torque values to avoid over-tightening or under-tightening, which can compromise the integrity of the connection.

- Safety precautions: Always follow proper safety procedures when working with hammer unions, including wearing appropriate personal protective equipment (PPE) and adhering to industry regulations.

Conclusion

In the oil and gas industry, reliable connections are essential for the safe and efficient flow of fluids. The FMC Weco Fig 1003, 400, 602, and 1502 Female Hammer Unions have proven to be dependable options that meet the stringent demands of the industry. With their robust construction, excellent sealing capabilities, and versatility, these hammer unions have become the go-to choice for various oilfield applications. By choosing FMC Weco hammer unions, operators can ensure the integrity of their connections, minimize downtime, and enhance overall operational efficiency in the oil and gas field.

8613371530291

8613371530291