Ensuring Efficient Drilling Operations with Drill Collar Slips and Power Tong Inserts

Introduction (150 words)

Drilling operations in the oil and gas industry require high precision and safety measures to ensure efficient performance. Two critical components that play a vital role in this process are drill collar slips and power tong inserts. These tools are indispensable for maintaining a secure grip on the drill collar during various drilling operations, preventing slippage or accidents that could lead to downtime or potential hazards. In this article, we will delve into the functions and importance of drill collar slips and power tong inserts, highlighting their role in enhancing drilling efficiency and safety.

I. Understanding Drill Collar Slips (300 words)

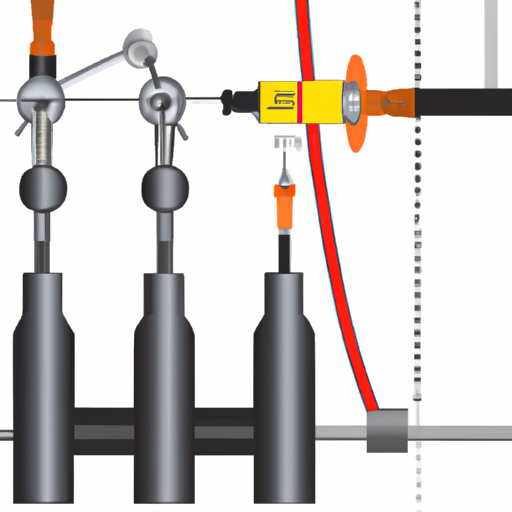

Drill collar slips are an essential part of the drilling process, primarily used to hold the drill collar in place. These slips are designed to grip the collar securely to prevent it from rotating or sliding down the drill string during drilling operations. The slips are made of high-grade alloy steel and are available in various sizes to accommodate different collar diameters.

1. Function and Types of Drill Collar Slips

Drill collar slips are typically used in conjunction with a spider or slip bowl assembly. They provide three-point grip support to the drill collar, ensuring stability and preventing any axial or radial movement. There are different types of drill collar slips available, including the Type B, Type X, and Type T slips, each designed for specific collar sizes and applications.

2. Benefits of Drill Collar Slips

a. Enhanced Safety: Drill collar slips ensure that the drill collar remains securely in place, reducing the risk of accidents caused by slippage or unexpected movement during drilling operations.

b. Improved Efficiency: By maintaining a stable grip on the drill collar, slips enable efficient drilling operations, preventing unnecessary downtime and optimizing the overall drilling process.

II. Power Tong Inserts (350 words)

Power tongs are widely used in the oil and gas industry to make up or break out drill pipe connections. These hydraulic or pneumatic tools are equipped with power tong inserts, which are crucial for achieving a secure and efficient grip on the drill pipe. Power tong inserts are available in various designs, materials, and sizes, tailored to different pipe specifications and conditions.

1. Role and Types of Power Tong Inserts

Power tong inserts are designed to provide a reliable grip on the drill pipe, ensuring accurate and controlled make-up or break-out operations. These inserts are typically made of high-quality alloy steel and feature specialized patterns or teeth to enhance gripping capabilities. Some common types of power tong inserts include the open jaw, closed jaw, and casing tong inserts.

2. Advantages of Power Tong Inserts

a. Efficient Operations: Power tong inserts enable faster and more efficient make-up or break-out of drill pipe connections, reducing downtime and increasing overall drilling productivity.

b. Reduced Manual Labor: With power tong inserts, the need for manual labor during pipe connection operations is minimized, leading to improved safety and reduced physical strain on workers.

c. Versatility: Power tong inserts are available in a wide range of sizes and designs, catering to various drill pipe specifications and conditions, ensuring versatility across different drilling applications.

III. Best Practices and Safety Considerations (200 words)

To ensure optimal performance and safety when using drill collar slips and power tong inserts, it is essential to follow best practices and adhere to safety guidelines.

1. Regular Inspection: Regularly inspect drill collar slips and power tong inserts for signs of wear, damage, or deformation. Replace any worn-out or damaged parts promptly to maintain optimal performance and prevent accidents.

2. Proper Lubrication: Apply high-quality lubricants to the slips and inserts to reduce friction and enhance gripping capabilities. Lubrication also helps prevent excessive wear and prolongs the lifespan of these tools.

3. Operator Training: Ensure that operators are well-trained in the correct usage of drill collar slips and power tong inserts. Proper handling and operating procedures are essential to prevent accidents and maintain drilling efficiency.

Conclusion (100 words)

Drill collar slips and power tong inserts are critical components in the oil and gas industry, ensuring secure gripping and efficient make-up or break-out operations during drilling. By utilizing these tools effectively and following best practices, drilling operations can be carried out with enhanced safety, reduced downtime, and improved overall efficiency. Regular inspection, proper lubrication, and operator training are vital for maximizing the lifespan and performance of drill collar slips and power tong inserts, ultimately contributing to successful drilling operations.

8613371530291

8613371530291