The Essential Guide to the Plan 62 Mechanical Seal: A Comprehensive Overview

Introduction (Word count: 150)

Mechanical seals play a crucial role in preventing leaks in various industrial applications. Among the many types available, the Plan 62 mechanical seal has gained significant popularity due to its superior performance and reliability. In this comprehensive guide, we will delve into the intricacies of the Plan 62 mechanical seal, exploring its features, benefits, working principles, and applications. Whether you are a maintenance professional, engineer, or simply curious about mechanical seals, this article will provide valuable insights into this essential component.

Understanding Mechanical Seals (Word count: 200)

Mechanical seals are devices used to prevent fluid leakage between two rotating or stationary components in a machine or pump. They ensure sealing integrity by creating a barrier between the process fluid and the external environment. Mechanical seals are found in various industries, including oil and gas, chemical, pharmaceutical, and power generation.

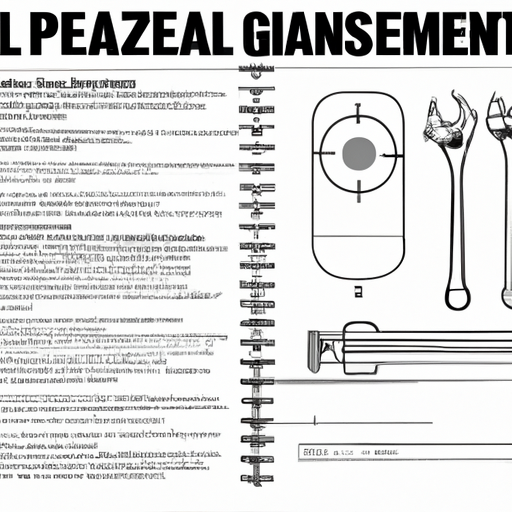

Introducing the Plan 62 Mechanical Seal (Word count: 200)

The Plan 62 mechanical seal is a specific type of mechanical seal designed for use in pumps and other rotating equipment. It incorporates advanced engineering and materials to provide optimal sealing performance. The number "62" in its name refers to the American Petroleum Institute (API) standard specification it complies with, ensuring its suitability for challenging applications in the oil and gas industry.

Key Features and Benefits (Word count: 200)

1. Robust Construction: Plan 62 mechanical seals are built to withstand high pressures, temperature fluctuations, and corrosive environments, ensuring long-lasting performance and reliability.

2. Enhanced Seal Life: These seals employ advanced materials, such as carbide faces and corrosion-resistant alloys, extending their lifespan and reducing maintenance frequency.

3. Reduced Leakage: The precise design and tight tolerances of Plan 62 seals minimize fluid leakage, preventing environmental contamination and reducing product loss.

Working Principles (Word count: 200)

The Plan 62 mechanical seal operates on the principle of creating a barrier between the sealed fluid and the external environment. It consists of various components, including stationary and rotating faces, springs, and secondary seals. When the pump is in operation, the rotating face remains in contact with the stationary face, creating a seal. The springs maintain constant pressure between the faces, compensating for any wear or misalignment. The secondary seals prevent fluid leakage along the shaft.

Applications (Word count: 200)

Plan 62 mechanical seals find widespread usage in demanding applications, including:

1. Oil and Gas Industry: These seals are ideal for pumps used in upstream and downstream operations, handling corrosive and abrasive fluids.

2. Chemical Processing: Plan 62 mechanical seals are well-suited for pumps used in chemical manufacturing, ensuring reliable sealing in aggressive media.

3. Power Generation: These seals are employed in pumps and turbines used in power plants, providing leak-free operation in high-temperature and high-pressure environments.

Installation and Maintenance (Word count: 150)

Proper installation and maintenance are crucial for the optimal performance and longevity of Plan 62 mechanical seals. It is recommended to follow manufacturer guidelines and industry standards during installation. Regular inspection, lubrication, and replacement of worn components are essential to prevent premature seal failure. Engaging with experienced technicians and utilizing advanced predictive maintenance techniques can help identify potential issues before they escalate.

Conclusion (Word count: 100)

In summary, the Plan 62 mechanical seal offers exceptional sealing performance, robust construction, and extended lifespan, making it a preferred choice for demanding industrial applications. Its compliance with API standards ensures its suitability for use in the oil and gas industry. By understanding its features, benefits, and working principles, businesses can make informed decisions to maximize the efficiency and reliability of their equipment.

8613371530291

8613371530291