oilgear hydraulic pump parts brands

Repairing and supplying remanufactured and new Oilgear hydraulics – Oilgear hydraulics pumps, Oilgear hydraulics valves, and Oilgear hydraulics motors. Search our online catalog or contact us and let us know how we can help you.

We can supply what you need or repair what you have. Before purchasing, there may be a good chance that your current hydraulic pump, motor, valve or cylinder can be repaired. Oilgear hydraulics pump repairs, including motors, valves & cylinders comes with our two year warranty.

When purchasing, consider Oilgear hydraulics remanufactured or after market hydraulic units. Best of all they can get you back up and running for less than the cost of a new hydraulic unit. We will give you a free quote so you can compare costs for a new, repaired or reman Oilgear unit.

Founded in 1921 in Milwaukee, Wisconsin, Oilgear hydraulics started manufacturing hydraulic presses for Bucyrus-Erie mining operations. Oilgear was a success from the outset, never suffering a loss, weathering periodic downturns in the economy, including the Great Depression of the 1930s. They gradually expanded product lines from single hydraulic presses to fluid meters, motors, valves for a growing range of industries including lumber, automotive, food, petroleum and chemical. As one of the first companies in the world to use microprocessors with hydraulics in the early 1980s, they began research and development to build complete computer-control systems. They now offer several pumps categories including variable displacement, high-pressure check valve, transfer barrier and injection and catalyst pumps; motion compensation, shot, prefill and exhaust, valves such as screw-in cartridge, subsea and high-pressure valves; accumulators; electronics as amplifier and controller cards.

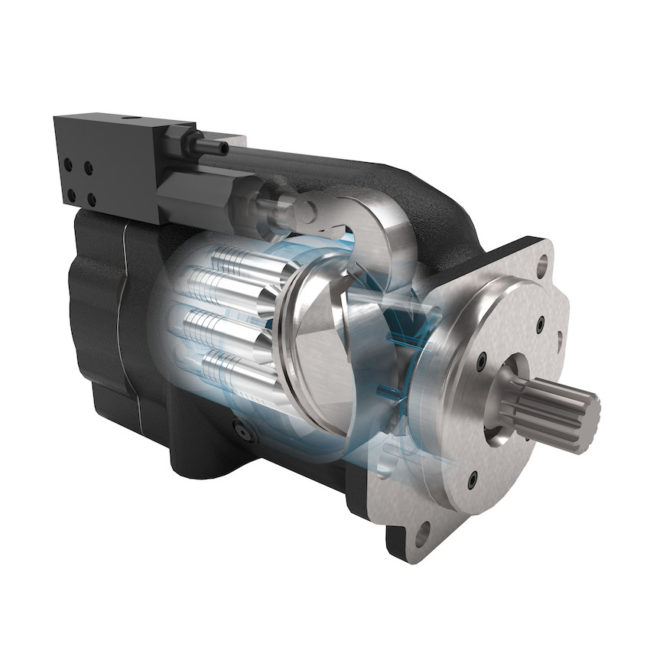

The most distinguishing component of Oilgear pumps is their patented “hard-on-hard” technology for rotating group in cylinder barrel. Proprietary Oilgear pump offers a greater resistance to contaminants, higher operating pressures as well as the ability to work with low viscosity fluids. Most competitors’ axial-piston pumps rely on load-carrying and mechanical bearings to support the shaft and rotating group. Oilgear pumps utilizes proprietary hydro-dynamic bearing which has no moving parts to wear out which allows for an infinite bearing life. Because there is no concern about contaminating a mechanical bearing, Oilgear pumps can run on a wide variety of tough fluids. Their proprietary hydro-dynamic bearing allows for a sealed front shaft bearing. Advantages include:The most distinguishing component of Oilgear pumps is their patented “hard-on-hard” technology for rotating group in cylinder barrel. Proprietary Oilgear pump offers a greater resistance to contaminants, higher operating pressures as well as the ability to work with low viscosity fluids. Most competitors’ axial-piston pumps rely on load-carrying and mechanical bearings to support the shaft and rotating group. Oilgear pumps utilizes proprietary hydro-dynamic bearing which has no moving parts to wear out which allows for an infinite bearing life. Because there is no concern about contaminating a mechanical bearing, Oilgear pumps can run on a wide variety of tough fluids. Their proprietary hydro-dynamic bearing allows for a sealed front shaft bearing. Advantages include:

Variable Displacement pumps convert mechanical energy to hydraulic (fluid) energy. Some pumps are reversible, acting as a hydraulic motor and convert fluid energy into mechanical energy. They provide high horsepower precision control and high pressure in a compact package.

This series of open loop, axial piston offers high pressure and superior performance in a compact design. They provide an almost instantaneous response to system commands through a high-response four-way pilot-operated control. These pumps feature Oilgear’s advanced “hard-on-hard” technology that provides longer operational life and allows for operation with any kind fluids. The PVG series have five models. Some have maximum continuous pressure up to 400 bar / 5800 psi, up to a speed of 2000 – 3000 rpm.

Also open-loop, axial-piston hydraulic pumps offer advanced engineering. It is computer-optimized with multiple controls available. PVM pumps deliver high performance in a compact design. These pumps feature Oilgear’s advanced “hard-on-hard” technology that provides a higher degree of contamination resistance and increases the pump’s lifecycle. The PVM series has twelve models with a peak pressure 293.1 bar / 4250 psi. Some models have a speed above 3000 rpm.

Designed for power and speed, axial-piston hydraulic pumps by Oilgear deliver the punch required for large, heavy-duty systems. The PVV pump line delivers up to 560 horsepower. Pumps are computer-optimized for maximum performance and compact in design with reduced noise levels and improved high-response controls. PVV series offer four models. Some have maximum continuous pressure up to 450 bar / 6500 psi, with top speed of 2000 rpm.

The cartridge valve concept is the modern approach to hydraulics. It is utilized in more installations as hydraulic engineers aware of its excellent performance, design flexibility and substantial savings. There are different valve varieties, sizes and types of valves with extensive size and pressure. Oilgear valves allow for as much fluid as needed, can flow to each function with no concern of high pressure drops, from 1 gpm to more than 300 gpm, with the pressure up to 5000 psi. The Oilgear screw-in cartridge valve line is one of the most complete in the industry. There are hundreds of exclusive specifications available from the 60 original conducts. Components are heat treated and honed as required. Steel-on-steel form construction guarantees high performance, utilizing all regular petroleum and synthetic or “high water content fluids”, or HWCF. Most importantly they are field serviceable with standard tools.

At Oilgear, we make historically good pumps, valves and engineering systems. But mostly, we make your problems go away. As your technology advisor and provider for mission-critical jobs, we take on the toughest challenges in the industrial, subsea and mobile industries. We’re your one-stop problem-solver; nonstop when it comes to looking at your issues with fresh eyes. Even helping you prepare for scenarios you haven’t imagined yet.

At Oilgear, our top priority is always the health and safety of our customers and team. Please read our message regarding the COVID-19 (Coronavirus) outbreak here.

Whether we have your unit in stock or not, repair is always an option. In fact, it may be your BEST option for obsolete and hard to find hydraulic pumps and motors. Letting us repair your unit can also be drastically cheaper than replacing it, especially if parts are hard to come by.

Do you need Oilgear hydraulic pump repair, rebuild, or replacement? We specialize in Oilgear pump repair and rebuilds. If you need a free estimate for any Oilgear pump, get in touch with us today to find out how much it will cost for repairs.

We provide fast, reliable hydraulic pump repair service on all Oilgear models. We are guarantee all repair work will be done with genuine OEM parts, so you know that you aren’t getting gray market or counterfeit parts.

Our team of skilled technicians will give your pump the attention it needs, and put it through our detailed inspection and repair process. Once the pump has been reassembled, we’ll test it thoroughly with our state-of-the-art-test equipment.

When you get your pump back, it will meet or exceed factory specs. Once you work with us, we think that you will keep coming back to us for all of your Oilgear hydraulic repair needs, including Oilgear hydraulic motors.

If you don’t see your model number listed below, don’t hesitate to call or contact us. We service just about every model of pump that is available from Oilgear and other manufacturers.

Oilgear Variable Displacement Pumps are some of the most reliable on the hydraulic market. They offer a wide range of displacement ranges, pressure ratings, speed ratings, and types of mounting configurations to meet your needs.

Choose your displacement ranges, pressure ratings, speed ratings, and types of mounting configurations. Oilgear’s pumps are designed to last longer and consume less energy.

When you are on the job and under a deadline and equipment fails, you need fast, reliable repair. We can send in our field technicians to get your Oilgear pump back up and running as soon as possible. Our reliable, experienced team can perform diagnostic services and minor repairs for equipment and machinery used in many industries. Our team can travel throughout the United States and many international locations, including North America and South America.

If repairs cannot be made on-site to your Oilgear pump, you can ship it to our facility. If you’re close enough, you can drop it off. We know how important it is to get your hydraulic systems back up and running. So you can trust us to get your pump repaired and back to you as fast as possible, and working properly.

Oilgear Products and systems are designed to operate with environmentally friendly fluids in mind. Oilgear makes both fixed and variable displacement pumps. Designed to last and be very efficient, Oilgear pumps last longer than many of their competitors. Featuring a long line of hydraulic accessories to meet the needs of consumers, Oilgear offers a comprehensive line of valves and integrated manifolds. Oilgear also offers Hydraulic power units and electronics.

Don’t see your Oilgear hydraulic pump model number? Not a problem. Call 800-800-6971 or send us an email. Chances are we’ve worked on it before and have parts for it, even if it’s not listed on our website.

These oilgear hydraulic pump parts are manufactured and assembled using sturdy and robust materials. Accordingly, they’re highly durable and give you long lifespans. With their innovative designs and advanced technologies, these oilgear hydraulic pump parts improve the efficacy of hydraulic machines by fitting in perfectly and with minimal resistance. Their quality is exemplary and warrants you the best outputs. As a measure to maintain top-rated oilgear hydraulic pump parts, only certified sellers and credible distributors are enlisted on the site, after having fulfilled all regulatory requirements.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes oilgear hydraulic pump parts wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

Alibaba.com has been an excellent wholesale supplier of oilgear hydraulic pump parts for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of oil gear hyd pump, you can find the product you want from the vast collection at Alibaba.com.therther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibaba.com has it.

We Can Supply Various Of HydraulicPump,Hydraulic Motor,Charge pump,Hydraulic Valve,Hydraulic reducer,Hydraulic swing motor,Hydraulic Travel Motor,Gear Pump ,Seal Kit , Gear Parts ,Hydraulic spare partsEct.

Hydraulic Rebuilt Parts OilGear PVG32 / PVG065 / PVG075 / PVG100 / PVG120 PRODUCT DESCRIPTION: Quick Detail:Place of Origin: ChinaModel No:PVG065 / PVG075 / PVG100 / PVG130 Oilgear PVG065 / PVG075 / PVG100 / PVG130 Piston Pump parts:You can get sorts of reliable piston pump parts like cylinder block, piston, valve plate, Retaining Plate,ball guide, shaft, swash plate for piston pumps or motors. All of these parts are highly interchangeablewith genuine products for pump repairing. Applications:excavator hydraulic system piston pump ,travel Motor,swing motor.construction machineryconcrete mixer carsUSE FOR : Heavy duty machine..such as Excavators / driller / tower machine Description:Here you can find different series of replacement hydraulic piston pumps (motors) parts for after market.If you have any need about hydraulic pump parts,motor parts, please feel free to contact us, we wouldlike to provide you all what we are manufacturing with the highest quality and the best service.We doing most of famous brands such as :Komatsu:PC200-6/PC200-7/HPV95/PC300-6/PC300-7/KMF40/KMF90/KMF160/KPV90/PC600-7 Travel MotorsHPV35/HPV55/HPV90/HPV160/HPV75/HPV95/HPV132/HPV140/HPV165(PC60-7/PC220-6/PC220-7/PC200-6/PC200-7 PC300-6/PC300-7 PC360-7 PC400-7) PC30UU/PC35MR/PC45/PC50/PC55/PC30-7/PC75UU/PC78US-6/PC40-8/PC2000-8 Main Pumps.PC45-8/PC75UU/PC40-7/PC50 /PC60-7/PC200-7/PC220-7/PC220-8/ PC300-7 PC300-8/PC400-7 Swing Motors

A10VD43 spare parts for hydraulic pump maintenance companies is very important, to help them repair the pump , and then used same with new pump,will waste much money , And all this spare parts with top quality and 100% replacement with Uchida original. Whatsapp:+8618031121586 http://heavyequipmentmaintain.com #hydraulic #hydraulicpump #hydraulicservice #hydraulicrepair #pistonpump #hydraulicsysterm #rexroth #sauer #pumprepair #vickers #vanepump #gearpump #tractorparts #tractorspareparts

Parker is a global manufacturer of hydraulic pumps, transmissions, gear pumps and motors, engineering superior products for a wide variety of applications. Delivering unsurpassed quality and performance, Parker’s extensive line of hydraulic pumps and motors helps you select the right product for your hydraulic application. Achieve easier, safer, and more efficient operation. The Pump & Motor Division assures consistent quality, technical innovation, and premier customer service.

Hydraulic Component Services can rebuild and supply many different varieties of pumps including hydraulic pumps, pneumatic pumps, gear pumps, vacuum pumps, piston pumps, centrifugal pumps, air over oil pumps, and bane pumps.

We provide service for all Vickers, Cessna, Hydreco, Commercial, Dynapower, Sundstrand, Char Lynn, Ross, Eaton, Continental, Webster, Hydura, Tyrone, H.P.M., Parker Hannifin, Gresen, Dynex, Racine, Denison, Oilgear, and Rexroth hydraulic pumps and motors. Mazak and Mori Seki are two of the many CNC machine manufacturers for whom we rebuild the components.

For complete service on all sizes and types of hydraulic and pneumatic rams and cylinders contact Hydraulic Component Services. We can provide you with the exact service you need.

At Hydraulic Component Services we specialize in rebuilding any hydraulic and machine tool index motors. Quality machine tool indexing motors, whether a positioning motor or a hydromechanical revolution positioner, can be brought back to their original high efficiency and reliability quickly, at a fraction of the price and much faster than taking delivery of a new indexing motor.

As Hydrotechnic Construction Machinery Antalya Hydraulic pump service and test center, we have been providing services and spare parts abroad as Iraq Turkmenistan Azerbaijan, Georgia, Kazakhstan, Kyrgyzstan as well as Turkey with our hydraulic system experience since 2004.

Don"t see your brand here? Don"t worry! With decades of experience keeping all kinds of hydraulic pumps and motors running at maximum efficiency and productivity, Nova Hydraulics can troubleshoot, diagnose, and service most brands. We"ll restore your hydraulic pump or motor to its own unique factory specifications with the industry"s fastest turnaround time. Contact our hydraulics experts to discuss your specific needs.

8613371530291

8613371530291